Structural considerations in friction welding of hybrid Al2O3-reinforced aluminum composites

In-Duck PARK1, Choon-Tae LEE2, Hyun-Soo KIM3, Woo-Jin CHOI4, Myung-Chang KANG4

1. Busan Metropolitan City Hall, Fundamental Industries Division, 2001 Jungang-ro, Yeonje-gu,

Busan 611-735, Korea;

2. Department of Automotive & Mechanical Engineering, Silla University, San 1-1, Gwaebop-Dong,

Sasang-Gu, Busan 617-736, Korea;

3. Research & Development Center, Sam-Ho precision, 1256-1 Daejeo2-dong, Gangseo-gu,

Busan 618-807, Korea;

4. National Core Research Center for Hybrid Materials Solution, Pusan National University,

Busan 609-735, Korea

Received 21 April 2010; accepted 10 September 2010

Abstract: Comparative studies on the relationship between the welding parameters and joining efficiency in the friction welding of hybrid Al2O3-reinforced aluminum composites were conducted. Metal matrix composites (MMCs) with 37% (volume fraction) aluminum particle were joined by friction welding. The results show that the effects of the rotation speed on the reduction rate of particle size are greater than those of the upset pressure, and the area of the MMC weld zone decreases as the joining efficiency increases, while it is considered that the joining efficiency does not increase as the reduction rate of particle size decreases. During the macro-examination of the bonding interface, a gray discolored region was observed on the bonding interface, and the center of the region was dark gray. After the micro-examination of the bonding interface, base metal made some second particulate formed by condensed alumina particulate but discoloration part distributed minute alumina particulate without second particulate. Consequently, it was also observed that rotational speed of 3 000 r/min and upset pressure of 63.6 MPa showed a very good joint.

Key words: friction welding; hybrid aluminum composite; bonding interface; joining efficiency; metal matrix composite

1 Introduction

Metal matrix composites (MMCs) offer several advantages: they have high strength in spite of having a low density, and they have high wear resistance, a large coefficient of thermal conductivity, a small coefficient of thermal expansion, and can be strengthened by plastic working. However, in order to use MMCs in vehicles and structures, an additional processing technology for welding MMCs together is required[1-3] There are still many problems on the joining of discontinuously reinforced aluminum matrix composite materials by the generally used fusion welding processes, such as: (1) in the melting state, the liquid welding pool of composite had a great viscosity with poor wettability, and it is difficult for composite itself to mix with the filler materials. (2) When the molten welding pool was cooled down, the reinforcement phases were rejected by the solidification front, and the normal solidification processes of the welding pool had been broken down, and this would lead to microsegregation or inhomogeneous distribution of the reinforced phases. In the case of friction welding with MMCs, which involves the formation of the solid bond, this problem does not occur, and the strength of the part welded is comparable to that of the base metal under specific conditions. Therefore, solid bonding is considered to be a useful method in the case of MMCs[4-5]. In this study, the relationship between the joining efficiency and reduction rate of particle size by friction welding was investigated, with an Al2O3-reinforced composite comprising 37% aluminum particle.

2 Experimental

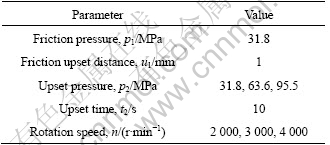

In this study, MMCs made from aluminum produced by Lanxide Inc., USA, and a composite for use in a pressureless metal infiltration process (PRIMEX; provided by Pacific Cement Inc.) were employed[6]. The A3004 aluminum alloy was used for strengthening. The average grain size of aluminum particles in the alloy is 2–5 μm, and the aluminum content is 37%. The chemical compositions of the A3004 aluminum alloy used as the base metal are listed in Table 1. The tensile strength is comparatively high (255 MPa), and the elongation is as low as 0.7%. A test piece for friction welding was used. The test piece had a processing length of 75 mm and was produced by electric discharge processing. The friction welding conditions are listed in Table 2. The friction pressure p1, friction upset length u1, and upset time t2 are held. p2 is the upset pressure and n is the rotation number. The upset pressure is three times the friction pressure, and the rotation speeds are 2 000, 3 000, and 4 000 r/min.

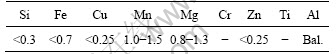

Table 1 Chemical composition of A3004 Al alloy (mass fraction, %)

Table 2 Friction welding conditions

Joining was completed while upset pressure was exerted along with rotation. The tensile test was performed with a balanced part length of 20 mm and diameter of 14 mm, in accordance with JIS Z 2201. The tensile strength of each test piece is measured, and the joining efficiency is evaluated in order to compare the tensile strengths of the MMC-based metal. Microstructures were observed by SEM in order to examine the relationship between the joining efficiency and microstructure. The conditions in the first test were as follows: n=2 000, 3 000, and 4 000 r/min; p1=31.8 MPa; u1=1 mm; p2=63.6 MPa; and t2=10 s. This test was performed in order to examine the relationships among rotation speed, joining efficiency, and microstructure. The conditions in the second test in this study were as follows: p2=31.8, 63.6, and 95.5 MPa; p1=31.8 MPa; u1=1 mm; t2=10 s; and n=3 000 r/min. The second test was performed to examine the relationships among upset pressure, joining efficiency and microstructure.

3 Results and discussion

The results of SEM microstructural observation and tensile test are obtained. Fig.1 shows the reduction rate of particle size as function of rotational speed and upset pressure in the friction welding test. A shown in Fig.1(a), the reduction rate of particle size steeply increases with increasing rotational speed as mentioned in Ref.[7]. Previous works[8] have shown that there are three main regions apparent in the interface zone of all the friction welded joints involving metal contacts: the fully plastic deformed zone around the welding line, partial deformed zone and the unaffected zone. Thus, the rotational speed influences the decrease rate of the particle size.

Fig.1 Characteristics of reduction rate of particle size according to welding parameters in friction welding test (p1=31.8 MPa, u1=1 mm, p2=63.6 MPa, t2=10 s): (a) Relationship between reduction rate of particle size and rotational speed; (b) Relationship between reduction rate of particle size and upset pressure

Fig.1(b) shows the relationship between the reduction rate of particle size and the upset pressure. As upset pressure increases, the reduction rate of particle size gradually increases. Consequently, a comparison of Figs.1(a) and (b) reveals that the effects of the rotation speed on the reduction rate of particle size are greater than that of the upset pressure.

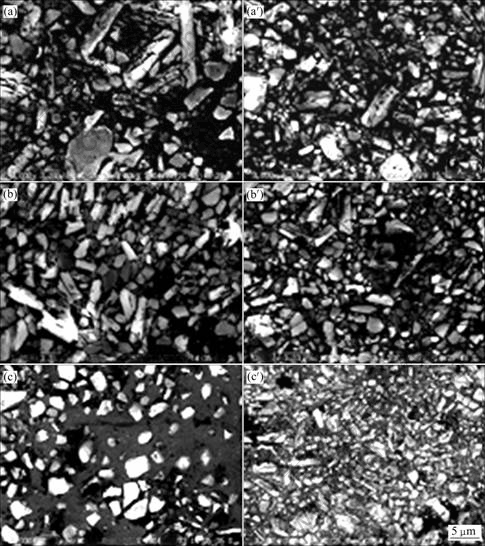

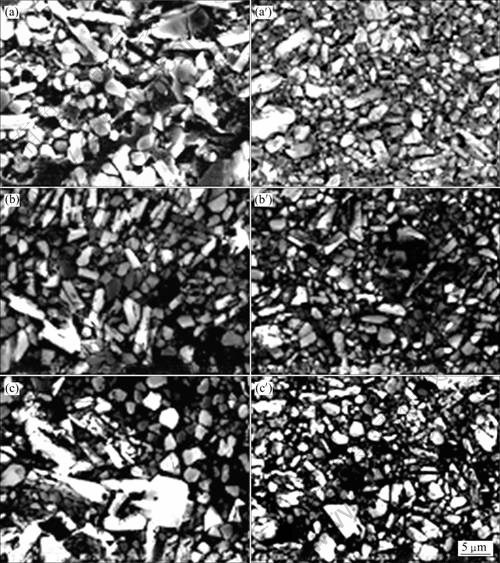

Figs.2 and 3 show the SEM images of the base metal about the microstructure of weld zone. The images correspond to conditions with different rotation speeds, and those in Fig.3 correspond to conditions with different upset pressures. During the macro-examination of the bonding interface, a gray discolored region was observed on the bonding interface, and the center of the region was dark gray. After the micro-examination of the bonding interface, base metal made some second particulate formed by condensed alumina particulate but discoloration part distributed minute alumina particulate without second particulate. The effect of the increase in the rotational speed and upset pressure on the microstructure, which formed at the interface during and after friction welding process, can be observed at a high rotational speed of 4 000 r/min and upset pressure of 95.5 MPa.

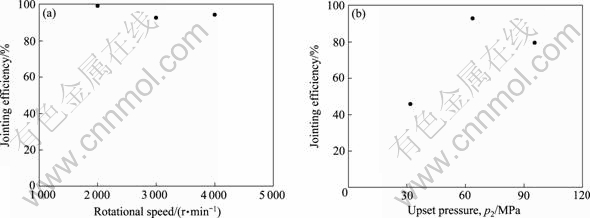

Fig.4(a) shows the changes of the joining efficiency as function of rotational speeds. It can be seen that the joining efficiency was not influenced with the increase of rotational speeds. Whereas the joining efficiency during friction welding with MMCs showed very good joint. From this result, it is believed that the joining efficiency does not increase as the reduction rate of particle size decreases. Fig.4(b) shows the change of joining efficiency according to upset pressure. As the upset pressure increased, the joining efficiency steeply increased, and reached a maximum value of about 92.7% at a upset pressure of 92.7 MPa, and then dropped again with further increase of upset pressure. Beyond the maximum point, the heat produced brings about meltings that decrease the welding strength[9].

Fig.2 SEM images of matrix (a, b, c) and welding zone (a′, b′, c′) with different rotation speeds (p1=31.8 MPa, u1=1 mm, p2= 63.6 MPa, t2=10 s): (a), (a′) n=2 000 r/min; (b), (b′) n=3 000 r/min; (c), (c′) n=4 000 r/min

Fig.3 SEM images of matrix (a, b, c) and welding zone (a′, b′, c′) with different upset pressures (p1=31.8 MPa, u1=1 mm, n=3 000 r/min, t2=10 s): (a), (a′) p2=31.8 MPa; (b), (b′) p2=63.6 MPa; (c), (c′) p2=95.5 MPa

Fig.4 Characteristics of joining efficiency according to welding parameters in the friction welding test (p1=31.8 MPa, u1=1 mm, p2=63.6 MPa, t2=10 s): (a) Relationship between joining efficiency and rotational speed; (b) Relationship between joining efficiency and upset pressure

Consequently, the area of the MMC weld zone decreased as the joining efficiency increased, while it is considered that the joining efficiency does not increase as the reduction rate of particle size decreases.

4 Conclusions

1) The reduction rate of particle size and joining efficiency according to welding parameters were evaluated in the hybrid Al2O3-reinforced aluminum composites with MMCs. The effects of the rotation speed on the reduction rate of particle size are greater than that of the upset pressure. The area of the MMC weld zone decreases as the joining efficiency increases, while it is consider that the joining efficiency does not increase as the reduction rate of particle size decreases.

2) After micro-examination of the bonding interface, the base metal made some second particulate formed by condensed alumina particulate, however, discoloration part distributed minute alumina particulate without second particulate.

Acknowledgements

The first (In-Duck PARK) and the second (Prof. Choon-Tae LEE) authors contributed equally to this work.

References

[1] Kobayashi F. Welding of metal matrix composite [J]. Material, 1995, 9: 1099-1106.

[2] Katou T. Friction welding of 5052 aluminum alloy and Al2O3/6061 aluminum alloy composite materials [J]. Friction Welding, 1996, 3: 104-109.

[3] Katou T. Bonding interface of aluminum alloy friction welding joint and aluminum alloy composite materials [J]. Light Metal Welding, 1995, 10: 429-434.

[4] LEI Yu-cheng, ZHANG Zhen, NIE Jia-jun, CHEN Xi-zhang. Effect of Ti-Al on microstructure and mechanical properties of plasma arc in-situ welded joint of SiCp/Al MMCs [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 809-810.

[5] LEI Yu-cheng, YUAN Wei-jin, CHEN Xi-zhang, ZHU Fei, CHENG Xiao-nong. In-situ weld-alloying plasma arc welding of SiCp/Al MMC [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 313-314.

[6] Maruyama M. Light weight rotor of ceramics reinforced aluminum composite materials [J]. NIKKEI Mechanical, 2001, 561: 60-61.

[7] OZDEMIR N. Investigation of the mechanical properties of friction-welded joints between AISI 304L, AISI Steel as a function rotational speed [J]. Materials Letters, 2005, 59: 2504-2509.

[8] OZDEMIR N, SARSILMAZ F, HASCALIK A. Effect of rotational speed on the interface properties of friction-welded AISI 304L to 4340 steel [J]. Materials & Design, 2007, 28: 301-307.

[9] SAHIN M, EROL AKATA H, GULMEZ T. Characterization of mechanical properties in AISI 1040 parts welded by friction welding [J]. Materials Characterization, 2007, 58: 1033-1038.

(Edited by LONG Huai-zhong)

Foundation item: Project (2010-0008-277) partly supported by the National Core Research Center Program through the National Research Foundation of Korea funded by the Ministry of Education, Science and Technology

Corresponding author: Myung-Chang KANG; Tel: +82-51-5102361; E-mail: kangmc@pusan.ac.kr