Friction stir welding of 2219-T6 aluminum alloy

来源期刊:中国有色金属学报(英文版)2005年第z2期

论文作者:陈迎春 刘会杰 冯吉才

文章页码:75 - 78

Key words:aluminum alloy; friction stir welding; microstructure; mechanical property; fracture location

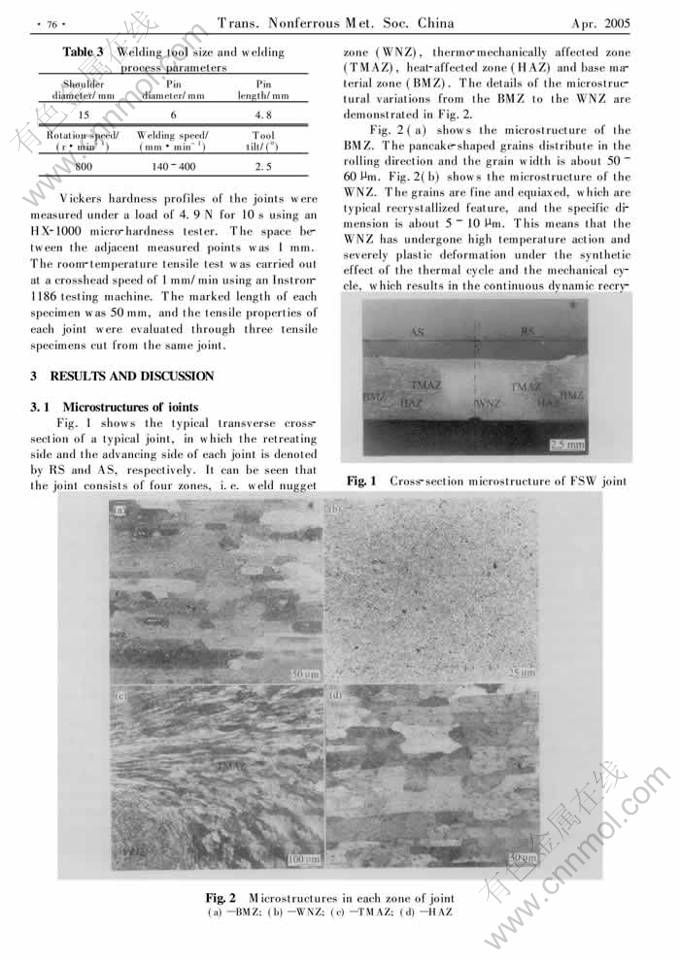

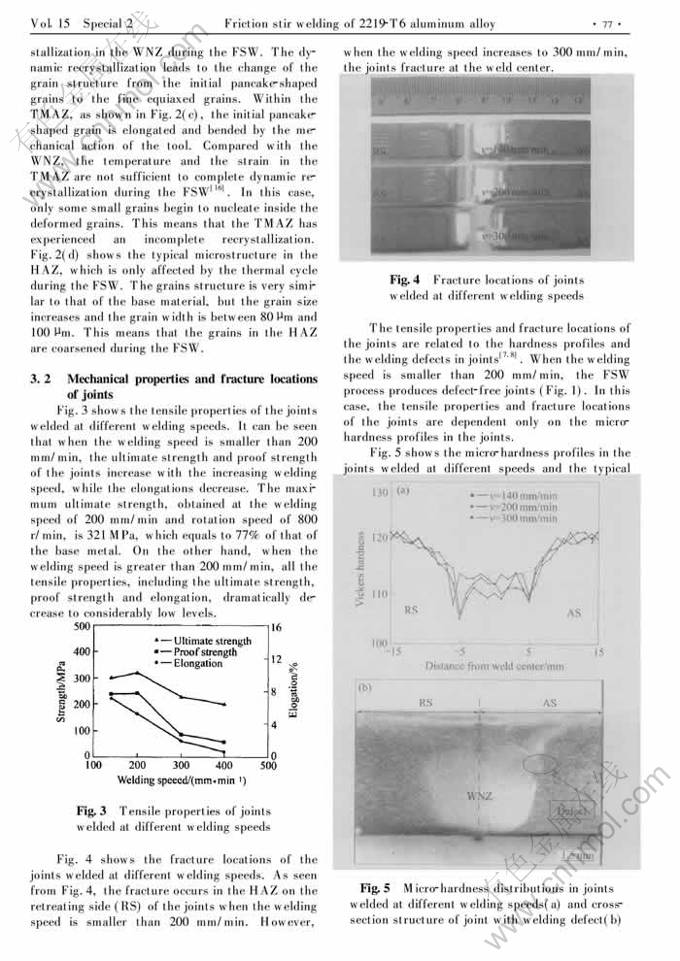

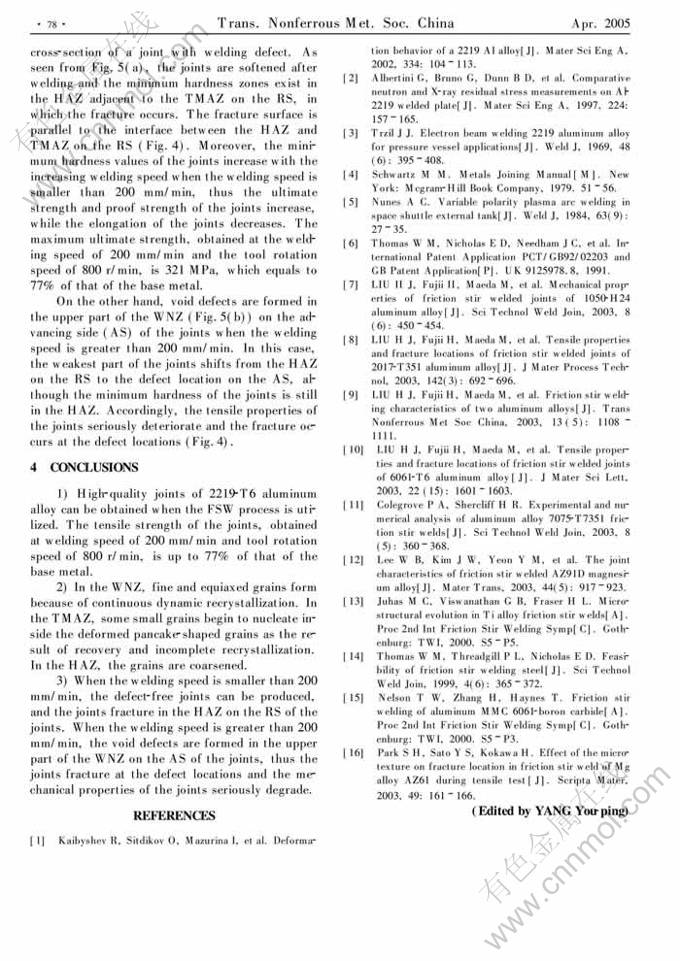

Abstract: 2219-T6 aluminum alloy was friction stir welded to investigate the microstructures and mechanical properties of the joints. Microstructural analyses show that fine and equiaxed grains form in the weld nugget zone (WNZ) because of continuous dynamic recrystallization. In the thermo-mechanically affected zone (TMAZ), some small grains begin to nucleate inside the deformed pancake-shaped grains as the result of recovery and incomplete recrystallization. In the heat-affected zone (HAZ), the grains are coarsened. Tensile tests show that the tensile strength of the joints increases with the increasing welding speed when the welding speed is smaller than 200 mm/min. The maximum tensile strength is equivalent to 77% of that of the base metal and the fracture occurs in the HAZ on the retreating side. However, when the welding speed is greater than 200mm/min, the mechanical properties of the joints seriously degrade because the void defects are formed in the WNZ on the advancing side and the joints fracture at the defect locations.