文章编号:1004-0609(2011)06-1244-08

Al-Cu-Mg-Ag耐热铝合金的热稳定性

刘晓艳1,潘清林1, 2,陆智伦1,曹素芳1,何运斌1,李文斌1

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:采用力学拉伸性能测试和透射电镜微观组织观察,分析欠时效态和峰时效态Al-Cu-Mg-Ag合金的热稳定性,并研究热暴露温度和时间对合金组织与力学性能的影响。结果表明:在150 ℃下,欠时效态合金的稳定性能明显优于峰时效态合金的;峰时效态合金的抗拉强度随着热暴露时间的延长逐渐减小,合金中的强化相Ω相和少量的θ′相逐渐发生粗化;欠时效态合金的抗拉强度随热暴露时间的延长先增大后减小,合金组织中的析出相数量先增多后减少,并发生粗化;热暴露20 h后,欠时效态合金的抗拉强度达到峰值524 MPa,比峰时效态合金的强度高19 MPa;此时,合金组织中的Ω相呈弥散分布,并且出现大量细小的θ′相;欠时效态合金在150 ℃下热暴露1 000 h后,其抗拉强度减小为434 MPa,仍能达到峰时效态合金的86%;当热暴露温度升高至200 ℃时,随热暴露时间的延长,欠时效态合金的抗拉强度减小,伸长率增大;热暴露1 000 h后,其抗拉强度降低到307 MPa;在250和300 ℃下热暴露时,欠时效态合金的抗拉强度随时间的延长急剧减小,组织中的强化相数量明显减少,并逐步演变成粗大的平衡相θ相。

关键词:Al-Cu-Mg-Ag合金;热暴露;欠时效;力学性能;显微组织

中图分类号:TG 146.21 文献标志码:A

Thermal stability of Al-Cu-Mg-Ag heat-resistant alloy

LIU Xiao-yan1, PAN Qing-lin1, 2, LU Zhi-lun1, CAO Su-fang1, HE Yun-bin1, LI Wen-bin1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. The Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: The thermal stability of Al-Cu-Mg-Ag alloys under-aged and peak-aged was analyzed by tensile test and transmission electron microscopy (TEM). And the effects of thermal exposure temperature and holding time on the microstructure and mechanical properties of Al-Cu-Mg-Ag alloy were also studied. The results show that the thermal stability of the under-aged Al-Cu-Mg-Ag alloy is superior to that of the peak-aged alloy when exposed at 150 ℃. The tensile strength of the peak-aged alloy decreases with prolonging the holding time. And the strengthening phases Ω and little θ′ are coarsened gradually. The tensile strength of the under-aged alloy increases and then decreases with prolonging the time. And the number of the precipitations increases and then decreases with the slowly coarsening of the precipitations. The tensile strength of Al-Cu-Mg-Ag alloy reaches the peak value of 524 MPa after exposed for 20 h, which is 19 MPa larger than that of the peak-aged alloy. Meanwhile the precipitations Ω distribute dispersively and a large amount of fine θ′ phase is observed. The tensile strength of the under-aged alloy is 434 MPa after exposed at 150 ℃ for 1 000 h, which is 86% of that of the peak-aged alloy. When exposed at 200 ℃, the tensile strength decreases and the prolongation increases with prolonging the exposure time. The tensile strength decreases to 307 MPa after exposed for 1 000 h. The tensile strength decreases dramatically with prolonging the holding time. And the number of the strengthening phases decreases obviously and grows to equilibrium phase θ.

Key words: Al-Cu-Mg-Ag alloy; exposure; under-aging; mechanical properties; microstructure

2×××系耐热铝合金如2219和2618由于具有较高的强度和良好的耐热性能,被广泛用于航空航天领 域。随着航空航天技术的发展,对铝合金材料工作温度的要求也越来越高。近年来,为了提高Al-Cu-Mg系合金的使用温度,研究者发现,向高铜镁比Al-Cu-Mg合金中添加Ag后可改变合金的时效序列,析出一种均匀细小弥散的耐热强化相—Ω相,此相可在200 ℃以下长期存在而不发生聚集长大[1-2]。因此,Al-Cu-Mg-Ag新型合金有望满足超音速飞机的经济性要求及耐热性能要求,是超音速飞机备选材料的一个极有希望的发展方向。

航空工业对材料往往有一定的使用温度要求。飞机在飞行过程中,机体与空气摩擦会引起飞机蒙皮温度上升。因此,作为航空用铝合金材料,在高温下Al-Cu-Mg-Ag合金的组织和性能随时间的变化关系显得尤为重要。热暴露实验可以模拟飞行使用条件,测定合金的组织与性能随温度和时间的变化,可以为该合金的工业应用提供可靠依据。

时效制度对合金的性能有很大影响[3-4]。LUMLEY等[5-6]在研究Al-Cu-Mg-Ag合金的高温蠕变性能时发现,欠时效态合金具有良好的高温抗蠕变性能,其蠕变速率远远低于峰时效态合金的。本文作者通过Al-Cu-Mg-Ag合金的力学性能测试和微观组织观察,探讨时效制度对该合金热稳定性的影响,并对Al-Cu-Mg-Ag合金在150~300 ℃下经不同时间热暴露后的组织与力学性能进行研究。

1 实验

实验所采用原材料为工业纯铝、纯镁和纯银以及A1-Cu、A1-Mn和A1-Zr中间合金。采用铸锭冶金方法制备了Al-5.3Cu-0.8Mg-0.5Ag-0.3Mn-0.15Zr(质量分数,%)合金铸锭。铸锭于500 ℃均匀化处理24 h后进行铣面,然后在460 ℃下保温2 h后将铸锭热轧至6 mm,再冷轧至3 mm。沿轧制方向截取拉伸试样。试样在515 ℃下固溶处理1.5 h,水淬之后进行时效处理,然后在150~300 ℃下进行热暴露。热暴露实验是在箱式干燥炉中完成的。

合金的室温力学性能测试在CSS-44100电子万能材料实验机上进行,拉伸速率为1×10-3 s-1。在401MVDTM显微维氏硬度计上进行硬度测试,每个试样测5个值,取平均值。TEM组织观察在TECNAI G2 20电镜上进行,加速电压为200 kV。透射电镜样品经机械预减薄后双喷穿孔而成,电解液为硝酸与甲醇的混合液(体积比为1:3),温度在-20 ℃以下。

2 实验结果

2.1 时效制度对Al-Cu-Mg-Ag合金热暴露性能的 影响

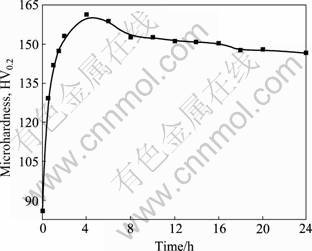

图1所示为Al-Cu-Mg-Ag合金在185 ℃的时效硬化曲线。从图1可以看出,该合金表现出显著的时效硬化特性。时效过程分为欠时效、峰时效和过时效3个阶段。时效初期,硬度随时间的延长迅速升高,4 h后合金硬度到达峰值。继续延长时效时间,合金硬度缓慢下降,但一直保持较高水平。

图1 Al-Cu-Mg-Ag合金在185 ℃下的时效硬化曲线

Fig.1 Aging hardening curve for Al-Cu-Mg-Ag alloy at 185 ℃

图2所示为Al-Cu-Mg-Ag合金经欠时效(185 ℃、2 h)和峰时效(185 ℃、4 h)处理后在150 ℃下热暴露不同时间后的拉伸性能。从图2可以看出,欠时效态合金的抗拉强度为480 MPa,低于峰时效态合金的抗拉强度505 MPa。随着热暴露时间的延长,欠时效合金抗拉强度先增大后减小,在时效20 h后达到峰值,为524 MPa。继续延长热暴露时间,抗拉强度又有所减小。热暴露100 h后抗拉强度降低为474 MPa。欠时效态合金的伸长率则随着热暴露时间的延长先减小,后增大。随着热暴露时间的延长,峰时效态合金抗拉强度逐渐减小,伸长率逐渐增大。热暴露100 h后,其抗拉强度降低为445 MPa,伸长率为12.9%。

比较图2(a)和(b)可以看出:虽然欠时效态合金的强度低于峰时效态合金,但仍能达到峰时效合金的95%;欠时效合金在热暴露后其抗拉强度明显高于峰时效合金的;热暴露20 h后欠时效态合金的抗拉强度达到峰值524 MPa,比未经热暴露的峰时效态合金的高19 MPa;在经过100 h的热暴露后,欠时效合金的抗拉强度比相同状态下峰时效合金的抗拉强度高6.5%。因此,在研究Al-Cu-Mg-Ag合金的高温热暴露时,将欠时效合金作为研究重点。

图2 Al-Cu-Mg-Ag合金在150℃下热暴露不同时间后的拉伸性能

Fig.2 Tensile properties of Al-Cu-Mg-Ag alloy exposed at 150 ℃ for different times: (a) Under-aged; (b) Peak-aged

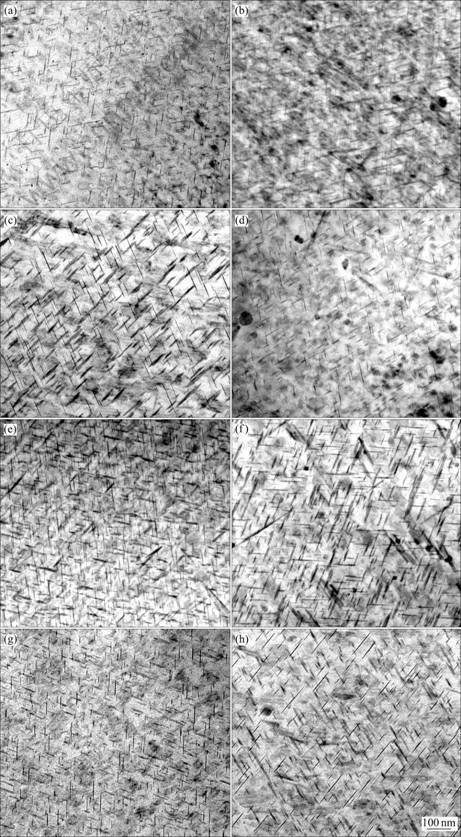

图3所示为Al-Cu-Mg-Ag合金在150 ℃下热暴露不同时间后的TEM像。从图3可以看出:Al-Cu-Mg-Ag合金的主要强化相是Ω相和θ′相;在欠时效状态下,合金中析出大量细小的Ω相和少量的θ′相;而峰时效合金中析出大量弥散分布的Ω相;在150 ℃下热暴露10 h后,欠时效合金中的析出相明显增多,热暴露20 h后Ω相呈弥散分布,并且合金中出现许多细小的θ′相;随着热暴露时间的进一步延长,析出相略有长大;与欠时效合金相比,峰时效合金中析出相随着热暴露时间的延长逐渐发生粗化和长大,并且Ω相和θ′相的粗化速率明显大于欠时效态合金的。

2.2 欠时效Al-Cu-Mg-Ag合金高温热暴露性能

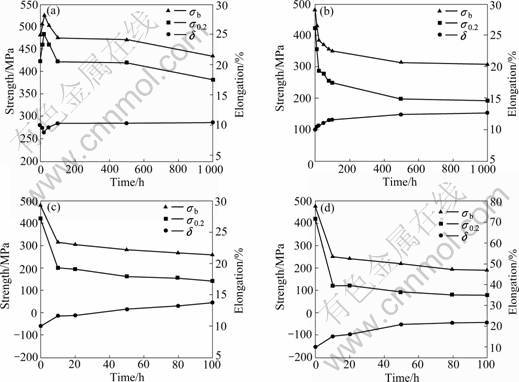

图4所示为Al-Cu-Mg-Ag合金在高温下热暴露不同时间后的力学性能曲线。从图4可以看出:在150 ℃下,Al-Cu-Mg-Ag合金的抗拉强度随着热暴露时间的延长先增大,后减小(见图4(a));在热暴露1 000 h后,抗拉强度为434 MPa,仍能达到该合金在峰时效的抗拉强度的86%。这说明经欠时效处理的Al-Cu-Mg-Ag合金在150 ℃下具有良好的热稳定性。在200 ℃下,随着热暴露时间的延长,合金的抗拉强度减小,伸长率增大(见图4(b))。在热暴露1 000 h后,其抗拉强度降低到307 MPa,为峰时效态合金的60%。合金在250℃和300℃下热暴露时,其抗拉强度随着时间的延长急剧减小(见图4(c)和(d))。在100 h后分别降低至258 MPa和191 MPa,仅为峰时效态合金的51%和38%。

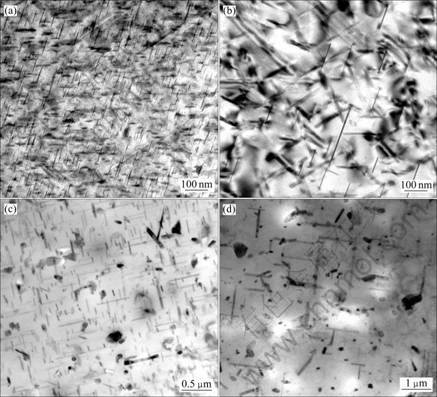

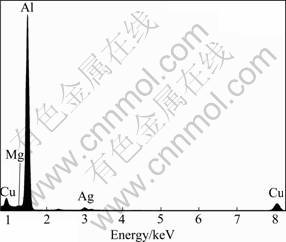

图5所示为Al-Cu-Mg-Ag合金在不同温度下热暴露100 h后的TEM像。从图5可以看出,与未经热暴露的合金相比,在150 ℃下热暴露100 h后,合金中析出的Ω相略有长大,θ′相数量明显增多(见图5(a))。当温度升高至200 ℃时,析出相尺寸明显变大,且析出相数量大幅度减少(见图5(b))。在250 ℃下热暴露100 h后,合金中析出相的尺寸进一步增大,并且出现了少量的平衡相θ相(见图5(c))。仔细观察可以看到,合金中有黑色的块状相形成。经能谱分析可知,该相富含Cu、Mg和Ag(见图6)。魏修宇等[7]在研究ML377合金的高温热暴露时也发现这种块状相,但相的组成还不确定。温度升高至300 ℃时,合金中析出大量的平衡相θ相,且块状相也发生长大(见图5(d))。

3 分析与讨论

3.1 时效制度对Al-Cu-Mg-Ag合金性能的影响

从图2中可知,与峰时效态Al-Cu-Mg-Ag合金相比,欠时效态合金在150 ℃下具有良好的热稳定性能。

LUMLEY等[5]在研究Al-Cu-Mg-Ag合金的抗蠕变性能时发现,欠时效态合金的抗蠕变性能明显优于峰时效态合金的。经峰时效(185 ℃、10 h)处理的合金,在150 ℃、300 MPa下的蠕变速率为1.12×10-9 s-1,而欠时效态(185 ℃、2 h)合金在此条件下的蠕变速率为3.5×10-10 s-1,仅为峰时效态合金的蠕变速率的31%。这在很大程度上提高了Al-Cu-Mg-Ag合金的抗蠕变性能。TEM结果表明,峰时效合金在150 ℃、300 MPa下蠕变100 h后,Ω相平均尺寸从56 nm增大到85 nm,500 h后增大到113 nm;但θ′相发生了回溶现象,随着蠕变时间的延长,θ′相的数量和平均相尺寸均逐渐减小。欠时效状态下,Ω相和θ′相均发生粗化,但是Ω相的粗化速率远远低于峰时效态合金的。经欠时效处理的合金,蠕变100 h后,Ω相平均尺寸从53 nm增大到61 nm,500 h后增大到69 nm,并且在合金组织中发现了θ′相的二次析出。因此,欠时效态合金的抗蠕变性能远远优于峰时效态合金的。根据这一现象,CSIRO公司发明了T6I6(Interrupted T6)热处理技术,并申请了专利[8]。该技术适用于2×××系、6×××系、7×××和8×××等大量可热处理的合金。通过T6I6处理,合金的抗拉强度和屈服强度比T6态合金的提高5%~30%,合金的断裂韧性和疲劳性能也得到改善,且对合金的塑性影响不大。

图3 Al-Cu-Mg-Ag合金在150 ℃下热暴露不同时间后的TEM像

Fig.3 TEM images of Al-Cu-Mg-Ag alloy exposed at 150 ℃ for different times: 0 h(a), 10 h(c), 20 h(e) and 50 h(g) for under-aged alloy; 0 h(b), 10 h(d), 20 h(f) and 50 h(h) for peak-aged alloy

图4 Al-Cu-Mg-Ag合金经欠时效处理后在150~300 ℃热暴露不同时间后的拉伸性能

Fig.4 Tensile properties of Al-Cu-Mg-Ag alloy exposed at 150-300 ℃ for different times: (a) 150 ℃; (b) 200 ℃; (c) 250 ℃; (d) 300 ℃

图5 欠时效态Al-Cu-Mg-Ag合金在不同温度下热暴露100 h后的TEM像

Fig.5 TEM images of under-aged Al-Cu-Mg-Ag alloy exposed for 100 h at different temperatures: (a) 150 ℃; (b) 200 ℃; (c) 250 ℃; (d) 300 ℃

图6 图5(c)中块状相的DEAX谱

Fig.6 EDAX pattern of massive phase in Fig.5(c)

T6I6热处理是指在合金时效过程中,中断时效,在低温(25~65 ℃)下停留一段时间后再进行时效。而本文作者在研究Al-Cu-Mg-Ag合金高温热暴露性能时,在欠时效时将试样从干燥炉中取出,在室温停留1~2 h后,再放入干燥炉中进行热暴露。其实质也是断续时效。实验结果表明,欠时效合金在室温停留一段时间后,再进行热暴露,其抗拉强度大幅度提高。在150 ℃下热暴露,其抗拉强度在20 h后达到峰值,为524 MPa。与峰时效态合金相比,抗拉强度提高19 MPa,而伸长率略有降低(见图1)。微观组织表明,欠时效态合金在热暴露初期(10~20 h),合金组织中的Ω相和θ′相数量均增多(见图3(c)和(e))。这是由于在欠时效态合金中存在一部分未析出的溶质原子,在随后的热暴露过程中发生了二次析出。与峰时效态合金相比,组织中出现了大量细小的θ′相。因此,欠时效态合金的热稳定性能优于峰时效态合金的。这为后续研究Al-Cu-Mg-Ag合金的T6I6热处理提供了依据。

3.2 Al-Cu-Mg-Ag合金高温热暴露性能

早在1966年,VIETZ和POLMEAR[9]研究发现,在高铜镁比Al-Cu-Mg三元合金中添加微量Ag能够改变合金的析出序列。Ag的添加能够提高合金的时效硬化速率,使合金中的主要析出相由θ′相和S′相分别变成Ω相和θ′相。Ω相是一种沿{111}α析出并与基体半共格的片状相。其与θ′相具有相同的化学成分 ——Al2Cu。

肖代红[10]发现,Al-Cu-Mn-Ag-Zr合金在185 ℃下时效720 min后,在TEM与SAED观察中均未发现Ω相的存在。这说明Ag并不是Ω相形成的必要条 件。而陈志国[11]在研究Al-4Cu-0.3Mg-0.2Sc合金时发现,合金在180 ℃时效132 h后,SAED中在1/3{111}α、2/3g{111}α处出现了属于Ω相的衍射斑。这说明Mg的存在是Ω相形成的必要条件,而Ag的作用是促进并加速新相Ω相的形成。在时效初期,Ag原子可以作为Mg原子的陷阱,促进Mg-Ag共聚原子团的大量形成。Mg原子半径大于Al原子半径,Cu原子半径小于Al原子半径,而Ag原子与Al原子半径相当。因此,Mg-Ag共聚原子团为Ω相提供了大量有利的形核位置,最终使Al-Cu-Mg-Ag系合金的析出相主要由细小弥散的Ω相组成。RINGER等[12]认为,Ag有效地套住Mg原子并形成Mg-Ag共簇,降低合金中Cu原子在Al中的扩散系数,促进Ω相的析出,从而延缓强化θ′相的粗化,使得Ω相与θ′相的竞争析出中占优势[13-14]。这说明Mg的存在是Ω相形成的必要条件,而Ag并不是Ω相形成的必要条件,Ag的加入能够促进Ω相的析出。

由于Ω相的存在,Al-Cu-Mg-Ag系合金具有较好的热稳定性[14-15]。REICH等[16]利用三维原子探针(3DAP)检测了Al-1.9Cu-0.3Mg-0.2Ag合金中Ω相的形成过程。时效初期(15 s),Ag和Mg形成共簇,随后,Cu原子与Mg和Ag共簇结合,并沿着{111}α面生长。随着时效时间的延长,共簇中Cu原子含量逐渐增大,而Ag原子和Mg原子含量逐渐降低,并且逐渐向α/Ω的界面偏聚,最终形成稳定相Ω,此时Cu原子含量达到33%,与θ相的化学成分相同(Al2Cu)。他们认为,Ω相是由Ag和Mg共簇逐步演变形成的。因此,在时效过程中,Ω相的粗化与长大必然伴随着Cu、Mg、Ag重新分配。肖代红[10]研究认为,Ω相的增厚也可通过台阶机制解释,在析出相的宽面上形成台阶后,Mg、Ag 扩散到Ω/α之间的界面上,与垂直惯习面方向的空位应变场发生相互作用,使得片状相的增厚速度降低。Ω相的伸长必然伴随着Cu、Mg、Ag的长程扩散。伸长过程中,Mg、Ag可稳定新形成的(001)Ω//(111)α界面。由于Cu 或Mg、Ag的供应有限,使得Ω相的伸长速度减慢。因此,Al-Cu-Mg-Ag合金具有良好的热稳定性。

在本实验中,当热暴露温度为150 ℃时,由于温度较低,Cu、Mg、Ag原子扩散速度较慢,Ω相的粗化速率较低。随着热暴露时间的延长,Ω相的平均尺寸变化不大。在热暴露进行1 000 h后,Ω相仍能保持较小的尺寸。当热暴露温度为200 ℃时,原子的扩散速率增大,Ω相的粗化速率增大;当热暴露温度升高到250、300 ℃时,溶质原子的扩散速率急剧增大,Cu、Mg、Ag原子易于通过长程扩散聚集在台阶上,促使台阶沿着棱边迁移方向加速,导致Ω相发生粗化,与基体的共格性降低,最终转变成θ相,从而降低了合金的强度。

4 结论

1) 欠时效态Al-Cu-Mg-Ag合金在150℃下的热稳定性能明显优于峰时效态合金的。峰时效态合金的抗拉强度随着热暴露时间的延长逐渐减小;欠时效态合金的抗拉强度随着热暴露时间的延长先增大后减小。在热暴露20 h后欠时效态合金的抗拉强度达到峰值524 MPa,比峰时效态合金的强度高19 MPa。欠时效态合金在150 ℃下热暴露1 000 h后,其抗拉强度降低为434 MPa,但仍能达到峰时效态合金的86%。

2) 欠时效态合金在200 ℃下进行热暴露时,随着热暴露时间的延长,合金的抗拉强度减小,伸长率增大。在热暴露1 000 h后,其抗拉强度降低到307 MPa。在250和300 ℃下热暴露时,合金的抗拉强度随着时间的延长急剧减小,在100 h后合金抗拉强度分别减小至258 MPa和191 MPa。

3) 欠时效态Al-Cu-Mg-Ag合金组织中主要强化相是Ω相和少量的θ′相。在150 ℃下热暴露时,随着时间的延长,合金组织中的强化相逐渐增多,当热暴露时间达到20 h时,合金组织中的强化相呈弥散分布,并出现大量细小的θ′相。进一步延长热暴露时间,强化相尺寸略有增大。在200 ℃下热暴露时,合金组织中的强化相尺寸随时间的延长逐渐增大。当热暴露温度提高至250和300 ℃时,组织中的强化相数量明显减小,并逐步演变成粗大的平衡相θ相。

REFERENCES

[1] CHANG C H, LEE S L, LIN J C, YEH M S, JENG R R. Effect of Ag content and heat treatment on the stress corrosion cracking of Al-4.6Cu-0.3Mg alloy[J]. Materials Chemistry and Physics, 2005, 91(2/3): 454-462.

[2] XIAO D H, WANG J N, DING D Y, CHEN S P. Effect of Cu content on the mechanical properties of an Al-Cu-Mg-Ag alloy[J]. Journal of Alloys and Compounds,2002, 343(1/2): 77-81.

[3] 刘延斌, 刘志义, 李云涛, 邓才智. 时效对2524铝合金热稳定性的影响[J]. 材料研究学报, 2007, 21(6): 585-588.

LIU Yan-bin, LIU Zhi-yi, LI Yun-tao, DENG Cai-zhi. Effect of aging proeess on thermal stability of 2524 aluminum alloy[J]. Chinese Journal of Materials Research, 2007, 21(6): 585-588.

[4] KERMANIDIS A T, ZERVAKI A D, HAIDEMENOPOULOS G N, PANTELAKIS SP G. Effects of temper condition and corrosion on the fatigue performance of a laser-welded Al-Cu-Mg-Ag (2139) alloy[J]. Materials & Design, 2010, 31(1): 42-49.

[5] LUMLEY R N, MORTON A J, POLMEAR I J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing[J]. Acta Materialia, 2002, 50(14): 3597-3608.

[6] LUMLEY R N, POLMEAR I J. The effect of long term creep exposure on the microstructure and properties of an underaged Al-Cu-Mg-Ag alloy[J]. Scripta Materialia, 2004, 50(9): 1227-1231.

[7] 魏修宇, 郑子樵, 陈小珍, 李世晨. ML377铝锂合金热稳定性研究[J]. 材料热处理学报, 2008, 29(1): 71-74.

WEI Xiu-yu, ZHENG Zi-qiao, CHEN Xiao-zhen, LI Shi-chen. Study on heat resistant properties of aluminum-lithium alloy ML377[J]. Trasactions of Materials and Heat Treatmen, 2008, 29(1): 71-74.

[8] LUMLEY R N, POLMEAR I J, MORTON A J. Heat treatment of age-hardenable aluminum alloys: US7025839B2[P]. 2006.

[9] VIETZ J T, POLMEAR I J. The influence of small additions of silver on the ageing of aluminium alloys observations Al-Cu-Mg alloys[J]. Journal of the Institute of Metals, 1966, 94(12): 410-419.

[10] 肖代红. 微合金化对Al-Cu-Mg基耐热铝合金的显微组织和力学性能的影响[D]. 上海: 上海交通大学, 2004.

XIAO Dai-hong. An inverstigation of the microalloying effects on the microstructure and mechanical properties of Al-Cu-Mg based heat-resistant aluminum alloys[D]. Shanghai: Shanghai Jiao Tong University, 2004.

[11] 陈志国. 微合金化铝合金的微观组织演变与性能研究[D]. 长沙: 中南大学, 2004.

CHEN Zhi-guo. Microstructure evolution and properties in microalloed aluminium alloys[D]. Changsha: Central South University, 2004.

[12] RINGER S P, HONO K, POLMEAR I J, SAKURAI T. Nucleation of precipitates in aged Al-Cu-Mg-(Ag) alloys with high Cu:Mg ratios[J]. Acta Materialia, 1996, 44(5): 1883-1898.

[13] CHANGA C H, LEEB S L, LINB J C, YEH M S, JENG R R. Effect of Ag content and heat treatment on the stress corrosion cracking of Al-4.6Cu-0.3Mg alloy[J]. Materials Chemistry and Physics, 2005, 91: 454-462.

[14] LIU X Y, PAN Q L, LU C G, HE Y B, LI W B, LIANG W J. Microstructure and mechanical properties of Al-Cu-Mg-Mn-Zr alloy with trace amounts of Ag[J]. Mater Sci Eng A, 2009, 525(1/2): 128-132.

[15] XIA Qing-kun, LIU Zhi-yi, LI Yun-tao. Microstructure and properties of Al-Cu-Mg-Ag alloy exposed at 200 °C with and without stress[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(4): 789-794.

[16] REICH L, MURAYAMA M, HONO K. Evolution of Ω phase in an Al-Cu-Mg-Ag alloy—A three-dimension atom probe study[J]. National Research Institute for Metals, 1998, 46(17): 6053-6062.

(编辑 龙怀中)

基金项目:国防科工委军品配套研制项目(JPPT-115-2-948);中南大学优秀博士学位论文扶植基金资助项目(2008yb012)

收稿日期:2010-06-22;修订日期:2010-08-03

通信作者:潘清林,教授,博士;电话:0731-8830933,E-mail: pql@mail.csu.edu.cn