文章编号:1004-0609(2015)-05-1142-11

Ca添加及变形条件对Mg-Zn合金组织与织构的影响

丁汉林,王天一,徐成志,李殿凯

(安徽工业大学 材料科学与工程学院,马鞍山 243002)

摘 要:利用背散射电子衍射技术分析了Z1(Mg-1.0Zn(质量分数,%))和ZX115(Mg-1.0Zn-1.5Ca(质量分数,%))镁合金热压缩变形后的显微组织、织构特征及再结晶晶粒的Schmid因子。结果表明:Ca的添加可以有效地细化动态再结晶晶粒,固溶至基体的Ca降低镁晶格轴比值,而未完全固溶的富Ca相在变形过程中破碎成粒子后促进了再结晶形核,这些因素均有利于弱化合金形变织构。随着变形温度的升高或应变速率的降低,织构强度随之增加。再结晶晶粒的Schmid因子对变形温度的变化较对应变速率的变化更为敏感。

关键词:镁合金;热压缩;织构;动态再结晶;Schmid因子

中图分类号:TG146.21 文献标志码:A

Effects of Ca addition and deformation conditions on microstructure and texture of Mg-Zn alloy

DING Han-lin, WANG Tian-yi, XU Cheng-zhi, LI Dian-kai

(School of Materials Science and Engineering, Anhui University of Technology, Ma’anshan 243002, China)

Abstract: The microstructure, texture characteristics and Schmid factor of recrystallized grains of hot compressed Z1 (Mg-1.0Zn (mass fraction, %)) and ZX115 (Mg-1.0Zn-1.5Ca (mass fraction, %)) alloys were investigated by electron back-scattered diffraction. The results show that Ca addition contributes to the grain refinement due to the occurrence of dynamic recrystallization during the hot compression. Ca element is solution-treated into magnesium matrix, resulting in a relatively lower c/a axial ratio of crystal lattice than pure magnesium, and those undissovled Ca-rich phases are fractured to particles and then stimulate the recrystallization nucleation. Both of them promote the weakening of texture. The intensity of texture usually increases with increasing the temperature or decreasing the strain rate. The deformation temperature tends to have a stronger effect on the Schmid factor of recrystallized grains than strain rate.

Key words: magnesium alloy; hot compression; texture; dynamic recrystallization; Schmid factor

镁合金是目前可工业化应用的最轻的金属结构材料[1],在汽车、电子、医疗、航空等领域的应用日趋广泛[2-4]。相对而言,铸造镁合金的应用及其产品更为成熟,但变形镁合金具备了更加优越的综合力学性能,与之相关的研究、开发和应用也是越来越多。由于其密排六方结构 (HCP)的晶体学特征,镁及其合金室温时可启动的滑移系较少,较差的室温塑性变形能力严重制约了变形镁合金的广泛应用。此外,镁合金在塑性变形过程中往往会形成强烈的形变织构,导致镁合金材料各向异性显著,不仅影响了镁合金的力学性能,还大大降低了镁合金的二次成型性能。

如何弱化织构和提高镁合金的塑性成形能力是学术界研究的热点和难点,目前最常使用的方法有添加合金元素、改善加工工艺等。现阶段国内外对合金化弱化织构的研究主要集中在通过添加稀土元素开发出具有优异成型性能的镁稀土合金,如MISHRA等[5]向纯镁中添加0.2%(质量分数)的稀土元素Ce后使挤压态合金的织构得到明显弱化和偏转,织构强度的极大值从2.3降到1.5。但稀土元素的价格较为昂贵,限制了镁稀土合金的应用范围。研究表明,虽然Ca元素与稀土元素的物理特性差别很大,但镁合金中添加少量的Ca元素对镁合金轧板织构的影响却可表现出与稀土元素相似的情况[6]。值得关注的是,Ca较稀土价格便宜很多,对镁合金产品的开发与应用具有更好的推广性。HRADILOV 等[7]对Mg-4Zn和Mg-4Zn-0.4Ca镁合金进行了力学性能测试,发现无论固溶态还是等径角挤压态,Ca的添加对合金力学性能的提升均十分有利。本文作者以ZX115 (Mg-1.0Zn-1.5Ca(质量分数,%))镁合金和Z1(Mg-1.0Zn(质量分数,%))镁合金为研究对象,分析合金元素Ca、变形条件及动态再结晶对镁合金热压缩组织和织构的影响规律,并探讨了Ca元素影响镁合金动态再结晶及织构的原因。

等[7]对Mg-4Zn和Mg-4Zn-0.4Ca镁合金进行了力学性能测试,发现无论固溶态还是等径角挤压态,Ca的添加对合金力学性能的提升均十分有利。本文作者以ZX115 (Mg-1.0Zn-1.5Ca(质量分数,%))镁合金和Z1(Mg-1.0Zn(质量分数,%))镁合金为研究对象,分析合金元素Ca、变形条件及动态再结晶对镁合金热压缩组织和织构的影响规律,并探讨了Ca元素影响镁合金动态再结晶及织构的原因。

1 实验

本研究中所用材料Z1(Mg-1.0Zn(质量分数,%))和ZX115(Mg-1.0Zn-1.5Ca(质量分数,%))镁合金是采用纯Mg、纯Zn和纯Ca配制熔炼而成。熔炼和铸造过程均在CO2(2 L/min)+SF6(11.25 mL/min)混合气氛保护下进行。将合金铸锭放入热处理炉中进行均匀化处理 (430 ℃、3 h) 后取出水淬,机加工为d10 mm×15 mm的圆柱形试样进行单轴热压缩实验。热压缩实验在Gleeble-3500热模拟机上进行,圆柱试样装夹后以5 ℃/s的速度加热至设计实验温度,保温60 s后按照设定的应变速率进行压缩,实验温度分别为400 ℃和450 ℃,应变速率分别为0.01 s-1、0.1 s-1和1.0 s-1,不同变形条件下的试样均压缩至应变量0.7后快速气冷至室温以保留高温变形组织。

金相试样经粗磨、精磨、精抛至镜面,经苦味酸溶液(苦味酸5 g、醋酸13 mL、酒精70 mL、蒸馏水12 mL)腐蚀、吹干后在Leica DM4000M LED型金相显微镜上进行组织观察,观察面选择应变量较大的试样中心区域。EBSD观察用试样经自动研磨后,先后经0.3 μm Al2O3悬浊液粗抛10 min、0.04 μm硅溶胶悬浊液精抛40 min,采用FEI NanoSEM 430高分辨场发射扫描电镜及HKL Channel 5进行EBSD分析。XRD实验在Bruker D8 Advance上进行,从均匀化处理后的铸锭上切取20 mm×20 mm×10 mm试样经研磨和抛光后使用。

2 结果与讨论

2.1 铸态和均质态组织分析

图1所示为Z1和ZX115两种合金铸态及均匀化处理后的显微组织。由图1(a)和(c)可以看出,两种合金的铸态组织均呈典型的枝晶状特征,且主要由α-Mg基体和连续或者零散分布的第二相所组成,其中Z1合金中的第二相为MgZn相,而ZX115合金中的第二相则为Mg2Ca或Ca2Mg6Zn3相[7-8]。值得注意的是,ZX115合金的树枝晶(尤其是二次枝晶)较Z1合金的明显细小,意味着Ca元素添加可以细化Mg-Zn合金的铸态组织[7]。

经均匀化处理后(见图1(b)和(d)),两种合金的枝晶状特征均消失,原始晶界清晰可见,平均晶粒尺寸大小相当,均在200 μm左右。但均匀化处理对合金中第二相的影响却有所不同,其中,Z1合金中的MgZn相完全固溶至基体中,晶粒大小及分布较为均匀,而ZX115合金中的第二相仍有部分未能固溶至基体,呈不连续状分布于晶界或晶粒内部。

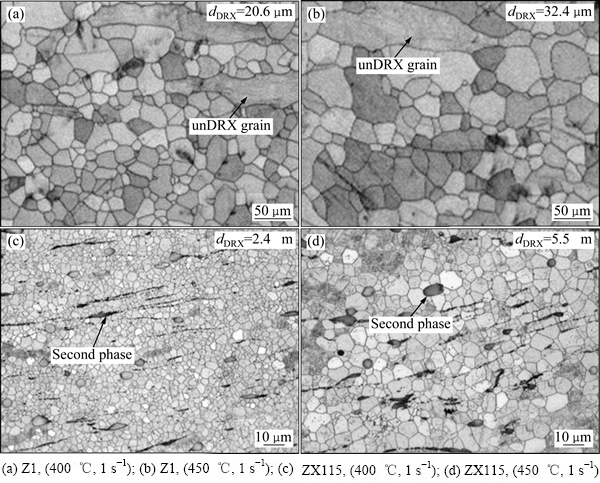

2.2 热压缩组织分析

Z1与ZX115合金经高温压缩后的显微组织如图2所示。与均质态合金相比,由于热压缩过程中动态再结晶过程的发生,两种合金的晶粒细化效果均十分明显,其中,Z1合金压缩后平均晶粒尺寸为20~30 μm,ZX115合金的平均晶粒尺寸则从200 μm细化至10 μm以下,尤其是在400 ℃下压缩的ZX115合金晶粒尺寸仅为2.4 μm。此外,随着变形温度的升高,两种合金的再结晶晶粒尺寸均明显增加,这主要是由再结晶晶粒形核后在较高温度下的生长速率较快所引起的。

所不同的是,ZX115合金中未完全固溶的第二相在压缩过程中被破碎,呈现出垂直于压缩方向的流线状分布(见图2(c)和(d)),而Z1合金中并未发现明显的第二相粒子。前期研究表明[8],ZX115合金中破碎的尺寸较大的第二相粒子在变形过程中可阻碍位错运动,从而促进动态再结晶形核。同时,在变形过程中,动态析出的细小的析出相还可限制再结晶晶粒的生长,亦可达到细化晶粒的效果。因此,与Z1合金相比,ZX115合金热压缩后的再结晶平均晶粒尺寸较小且分布更为均匀。此外,在所选取的显微组织观察区域内,ZX115合金的动态再结晶进行的较为充分,而Z1合金中依然有少量再结晶不完全的大尺寸晶粒存在(见图2(a)和(b))。

图1 Z1和ZX115合金铸态和均匀化处理后(430 ℃、3 h)显微组织

Fig. 1 Microstructures of Z1 and ZX115 magnesium alloys

图2 Z1和ZX115合金热压缩显微组织

Fig. 2 Microstructures of Z1 and ZX115 magnesium alloy after hot compression

2.3 织构分析

2.3.1 再结晶晶粒对合金织构的影响

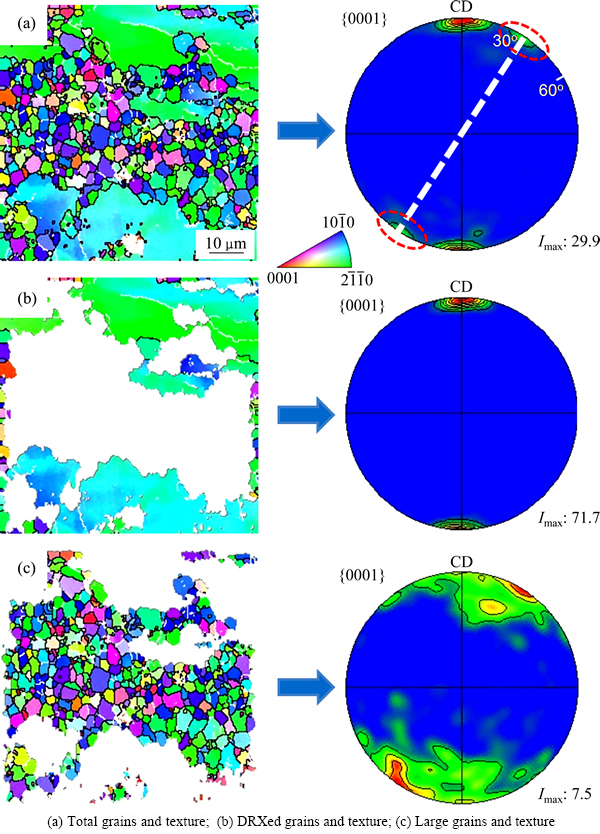

鉴于Z1合金动态再结晶并不完全,且同时为了考察动态再结晶晶粒对织构特征的影响,ZX115合金的EBSD测试区域稍稍偏离了试样中心区域,以获得细小的再结晶晶粒和再结晶不完全的大尺寸晶粒共存的显微组织。

图3所示为ZX115合金在温度400 ℃、应变速率1 s-1条件下热压缩后的取向成像图及对应的(0001)基面极图,晶粒取向成像图中的不同颜色表征了不同的晶粒取向,如图中反极图所示。一般来说,铸态合金经均匀化处理后,其晶粒取向随机,并没有明显的织构特征。但从图3(a)中的(0001)面极图可以清楚地看出,ZX115合金经热压缩后产生了强烈的织构特征,基面的法线方向(c轴方向)基本平行于外加载荷方向,最大极密度(Imax)为29.9。值得注意的是,基面极图中同时还存在着另一种织构组分,其基面法线偏离外加载荷方向约30°(虚线区域所标识)。

根据取向成像图中的晶粒尺寸,将图3(a)中的测试范围分为再结晶不完全区和再结晶区两个区域,如图3(b)和(c)所示。对比分析两个区域的(0001)面极图可以发现,再结晶不完全的大尺寸晶粒的基面法线方向几乎全部平行于加载方向,最大极密度达71.7,而动态再结晶晶粒的基面法线并不完全平行于外加载荷方向,而是围绕压缩方向发生了不同程度的偏转,且漫散程度较大,织构的峰值位置也发生了近30°的偏转,最大极密度仅为7.5。

图3 ZX115镁合金热压缩后的取向成像图和(0001)面极图(400 ℃, 1 s-1)

Fig. 3 EBSD maps and (0001) pole figures of ZX115 alloy after hot compressed at 400 ℃ and 1 s-1

综合以上分析可以看出,ZX115合金压缩后之所以会得到如此强烈的基面织构,主要是因为在试样内存在着一些再结晶不完全的变形晶粒,且它们所占的面积比例较大。在外力作用下,这部分晶粒的晶格c轴逐渐从随机的取向转动至与外力平行的方向上,进而形成强烈的基面织构。相比之下,新生的动态再结晶晶核取向比较随机,能够有效弱化合金织构并降低织构强度,但再结晶晶粒在形核之后的长大过程中同样会在外加载荷的作用下发生转动,并有逐渐形成织构的倾向[9],因而图3(c)中动态再结晶晶粒也表现出一定的织构特征。

2.3.2 Ca添加对镁合金织构的影响

图4所示为EBSD分析的Z1合金热压缩变形后试样的晶粒取向分布图。由图4可以看出,Z1合金中也有少量再结晶不完全的大尺寸晶粒存在。同样按照图3的分析方法,考察Z1合金中动态再结晶晶粒的基面织构,如图中极图所示。通过与图3(c)对比可以发现,Z1合金的再结晶晶粒呈现出较强的基面织构特征,虽然再结晶晶粒的基面法线相对外加载荷方向也有所偏离,但其偏离程度远小于相同变形条件下ZX115合金的,且其织构强度明显高于ZX115合金的,最大极密度达15.9。显然,与Z1合金相比,ZX115合金中由于少量Ca元素的添加而促进了再结晶晶粒织构强度的弱化,也在一定程度上改变了织构类型。

2.3.3 变形温度对镁合金织构的影响

实际的热加工过程中,塑性变形和动态再结晶这两个过程所占的主导作用并不是一成不变的,而是受变形温度、应变速率等因素的影响,进而影响到形变织构的强度和类型[10]。图5所示为ZX115合金在不同温度下经应变速率1 s-1压缩至稳态时的动态再结晶晶粒的(0001)基面极图。为了更好地观察基面法线方向的偏转程度,将考察区域内各晶粒取向投影到与压缩方向垂直的圆柱体试样底面进行分析。显然,图5(a)较图3(c)更为清晰地展示了400 ℃下压缩时再结晶晶粒基面法线方向围绕压缩方向的偏转程度。

从图5(b)中可以看出,当变形温度升高至450 ℃时,(0001)基面织构呈双峰现象,表现出了与镁稀土合金轧板相类似的典型织构特征[11]。与图5(a)对比分析表明,450 ℃压缩时,ZX115合金晶粒的基面法线方向虽然也发生了明显偏转,但其漫散程度却相对较弱,织构强度则相对较高,最大极密度为15.0。可见,变形温度对镁合金织构的组分、类型和强度均产生了一定的影响。

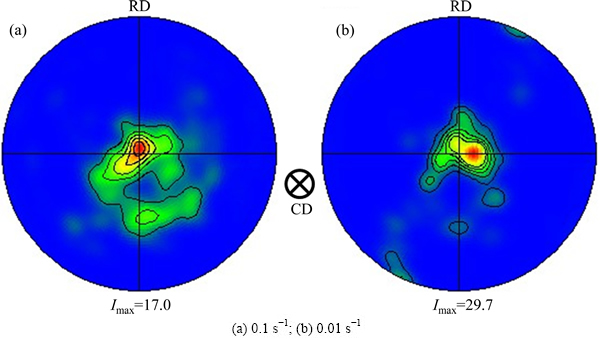

2.3.4 应变速率对镁合金织构的影响

图6所示为400 ℃时经不同应变速率压缩后ZX115合金再结晶晶粒的(0001)基面取向极图。由图6可知,较低的应变速率下压缩时,动态再结晶晶粒也形成一定的织构特征,且基面法线方向也有不同程度的偏转。与图5(a)对比分析可以看出,随着应变速率的降低,织构的漫散现象逐渐减弱,大部分晶粒的c轴更倾向平行于压缩方向,进而导致织构强度明显增加。

一般而言,高速变形时,因位错来不及抵消而导致位错缠结,进而提高动态再结晶形核率,这些新生成的没有明显择优取向的动态再结晶晶粒可以大幅度弱化织构,因而应变速率1 s-1下合金的织构强度相对较低。此外,应变速率将影响变形过程中试样的温度变化,特别是当变形温度较低时,增大应变速率可以显著提高试样温度[12],产生类似于高温变形的效果,进而影响织构类型和强度的多样性变化。当然,应变速率的变化对形变过程中的晶粒转动、滑移、晶内和晶界扩散、动态再结晶等速度控制过程均会产生较大影响,进而导致塑性变形模式和织构的变化[13]。

图4 Z1合金热压缩(400 ℃, 1 s-1)试样的取向成像图及再结晶晶粒的(0001)基面织构

Fig. 4 EBSD maps of Z1 alloy after hot compressed at 400 ℃ and 1 s-1 (a) and (0001) pole figures of DRX grains (b)

图5 ZX115合金在不同温度下经应变速率1 s-1热压缩亚稳态时的动态再结晶晶粒的(0001)基面取向极图

Fig. 5 (0001) pole figures of recrystallized grains in ZX115 alloy after hot compressed to stable states at different temperatures and 1 s-1

图6 400 ℃时经不同应变速率压缩后ZX115合金再结晶晶粒的 (0001)晶面取向极图

Fig. 6 (0001) pole figures of ZX115 alloy after hot compressed at different temperatures

对图5和6进行分析可以推断,高温高速的变形工艺有助于改善ZX115合金的织构类型,而低温高速工艺有利于弱化织构强度。

2.4 Schmid因子分析

上述分析表明,ZX 115合金经热压缩后形成了强烈的形变织构。形变织构使得合金表现出显著的力学性能各向异性,对材料的延展性、二次成形性等方面产生诸多不利影响。本研究中根据EBSD测试结果,借助Schmid因子探讨Ca添加及不同变形条件对Mg-Zn合金织构及二次成形性的影响。计算中,设定力轴方向平行于压缩方向,分别考察各晶粒{0001}< >基面滑移的Schmid因子。

>基面滑移的Schmid因子。

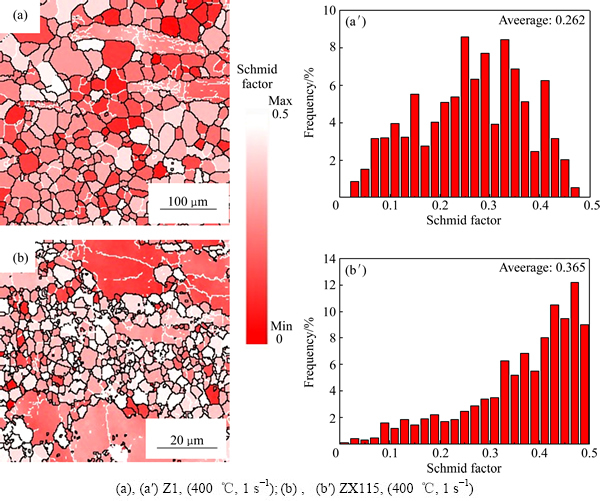

2.4.1 Ca元素对镁合金Schmid因子的影响

图7所示为相同变形条件下热压缩后Z1和ZX115合金再结晶晶粒的Schmid因子及其分布图。在Schmid因子成像图中,红色(深色)表征Schmid因子趋于0的晶粒,白色表征Schmid因子趋于最大值0.5的晶粒,由深色到白色晶粒的Schmid因子逐渐增大。通过对比可以清楚地发现,不含Ca的Z1合金经过热压缩后,红色区域较多,而ZX115合金中则白色区域相对更多。从Schmid因子分布图中也可以看出,Z1合金的Schmid因子多数分布在0.1~0.4之间,大于0.35的晶粒所占的比例约为26.4%,Schmid因子平均值为0.262。而ZX115合金中Schmid因子大于0.35的晶粒所占比例达到66.6%,Schmid因子平均值为0.365。Schmid因子越大,可开动的基面滑移越多,合金的塑性变形能力越强,因此,可以说Ca元素的添加很大程度上减弱了镁合金压缩后的各向异性,这不仅有利于提高合金的塑性,还有利于改善材料的二次加工成形性能。

图7 Z1和ZX115合金的Schmid因子成像及分布图

Fig. 7 Schmid factor imaging ((a), (b)) and their distributions ((a′), (b′)) for Z1 and ZX115 alloy

2.4.2 变形条件对Schmid因子的影响

图8所示为不同变形条件下热压缩后ZX115合金再结晶晶粒的Schmid因子及其分布图。结合图7(b)和8(a)及分析变形温度对Schmid因子的影响可以发现,当合金经450 ℃压缩后,各晶粒的Schmid因子趋向于分布在0.35~0.5之间,这部分晶粒所占的比例高达84.4%;Schmid因子平均值为0.409,明显高于400 ℃时的Schmid因子平均值为0.365。而较大的Schmid因子平均值意味着经高温压缩后的试样中,多数晶粒的基面滑移更易于开动,从而利于材料的二次成形,这与其织构弱化所产生的结果基本一致。

结合图7(b)以及图8(b)和(c)分析应变速率对Schmid因子的影响可以发现,应变速率为1、0.1、0.01 s-1时,压缩试样中各晶粒的Schmid因子平均值分别为0.365、0.344、0.336,其中Schmid因子大于0.35的晶粒所占比例分别为66.6%、56.2%、47.2%。也就是说,虽然应变速率对再结晶晶粒的Schmid因子平均值的影响并不明显,但应变速率较高时压缩试样中基面滑移易于开动的晶粒分数却有所增加。

综合以上分析可以得出,变形温度的变化对压缩试样中再结晶晶粒的Schmid因子的影响明显大于应变速率的影响,且高温高速压缩后再结晶晶粒的Schmid因子较大,易于基面滑移的开动。

2.5 Ca添加弱化镁合金织构的探讨

通过以上分析,可以发现Ca元素加入到镁合金中,不仅促进了动态再结晶的发生,还使合金的织构得到了明显弱化、变形后合金的Schmid因子增大。究其原因,可以从以下两个方面进行分析。

图8 ZX115镁合金的Schmid因子成像及分布图

Fig. 8 Schmid factor imaging and the distribution map of ZX115 magnesium alloy

1) 合金元素Ca的加入可能改变了纯镁的晶格结构。稀土元素对镁合金晶格结构的改变已得到证实,COTTAM等[14]发现,稀土元素的添加会使镁合金c/a比值降低,使锥面滑移开启所需的临界分切应力(CRSS)减小。AGNEW等[15]认为,通过添加Y或Li元素可以改变各种塑性变形机制的平衡,从而改变板材的织构演变。为了确定Ca元素添加对合金晶格参数的影响,本文作者研究采用XRD对均质态ZX115合金的晶格常数进行测定,测试所得的合金中α-Mg基体的衍射图如图9所示。将结果导入Celref软件中进行分析,计算出合金的晶格常数如表1所列。与纯镁晶粒常数进行对比可以看出,ZX115合金的c/a轴比值稍小于纯Mg的轴比值,这说明Ca添加可引起Mg晶格对称性的适当增强,进而使得棱柱面和锥面滑移更容易被激活,从而改变了塑性变形模式以及各种变形模式在总变形中的作用和贡献,最终改变晶体取向。

图9 ZX115均质态合金晶体结构的XRD谱

Fig. 9 XRD pattern of crystal structure of homogenized ZX115 alloy

表1 镁合金的晶格常数及轴比值

Table 1 Lattice parameters and axial ratio of magnesium alloys

2) 富含Ca的第二相粒子促进了变形过程中的动态再结晶。对于稀土合金元素对镁合金再结晶的影响已有较多报道,BALL等[16]提出第二相粒子诱导形核是WE54挤压镁合金弱化织构的主要机制,MACKENZIE等[17]也证实了粒子诱导形核的再结晶行为导致了WE43镁合金挤压织构的弱化,此外,HANTZSCHE等[18]发现稀土镁合金中固溶元素的偏聚或析出相会阻碍再结晶晶粒的生长,也会使其变形过程中的织构得以弱化。

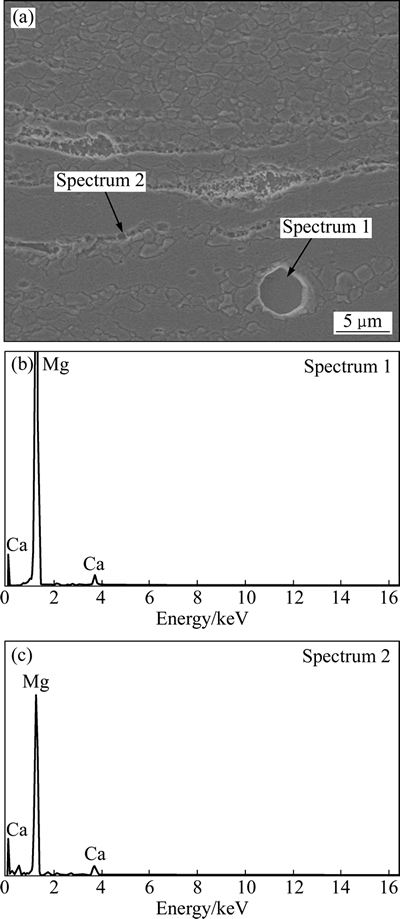

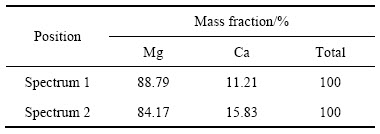

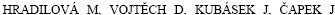

从图2(c)和(d)中可以观察到,部分第二相呈颗粒状或流线状分布在晶界处和晶粒内部,这种第二相也同样存在于其他变形条件试样的显微组织中。对颗粒相进行EDS能谱分析,结果如图10和表2所示,排除颗粒相脱落等原因对元素含量的干扰,可以证实这两种第二相均为富含Ca的Mg-Ca二元相。变形过程中,这些第二相粒子可有效阻碍位错运动,提高其附近的位错密度,为动态再结晶提供了更多的形核质点。而再结晶形成的新晶粒并没有明显的择优取向,使得变形织构明显弱化。且第二相粒子的大量存在亦可起到钉扎晶界的作用,它们阻碍了再结晶晶粒的进一步长大,这也会弱化镁合金的形变织构。

以上两方面因素虽然可以解释Ca添加弱化镁合金织构这一现象,但并不十分充分。如Ca添加虽然改变了镁晶格轴比值,但其与纯镁的差值并不大,是否足以导致柱面和锥面滑移的开动并不明确。此外,虽然少量添加的Y或RE元素可以有效地弱化镁合金织构[10],但其显微组织中并没有太多第二相粒子存在。因此,对于Ca添加影响镁合金织构变化的原因可能很多,或许是多种因素共同作用的结果,其具体原因仍需进一步分析与研究。

图10 热压缩后的ZX115合金SEM像及EDS谱

Fig. 10 SEM image (a) and EDS spectra ((b), (c)) of ZX115 alloy after hot compression

表2 热压缩后的ZX115合金EDS能谱分析结果

Table 2 EDS results of ZX115 magnesium alloy after hot compression

3 结论

1) 相同的热变形条件下,ZX115合金的动态再结晶晶粒尺寸明显小于Z1合金的,且分布均匀。由于动态再结晶晶核并不具有明显的取向性,因而,动态再结晶行为可较大程度上弱化镁合金织构。

2) Ca元素添加后,固溶至基体的Ca可使镁晶格的轴比值降低、晶格对称性增强,有利于柱面和锥面滑移系的开动,从而起到改善织构的作用;ZX115合金均匀化处理时,未完全固溶的富Ca相粒子可以有效促进再结晶形核,进一步促进了织构弱化。

3) ZX115合金经450oC压缩后形成了与镁稀土合金相类似的双峰特征的形变织构,随变形温度的升高或应变速率的降低,织构强度增加。

4) Ca添加使得热压缩后ZX115合金中再结晶晶粒基面滑移的Schmid因子较高,有利于其二次成形性的改善。随变形温度的升高或应变速率的降低,再结晶晶粒Schmid因子减小,变形温度的变化对压缩试样中再结晶晶粒的Schmid因子的影响明显大于应变速率的影响。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium alloy[M]. Beijing: Chemical Industry Press, 2004.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[3] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[4] 高云凯, 林 典, 余海燕, 邵力行. 镁合金在座椅骨架轻量化设计中的应用[J]. 同济大学学报(自然科学版), 2009, 37(7): 938-942.

GAO Yun-kai, LIN Dian, YU Hai-yan, SHAO Li-xing. Application of magnesium alloy to seat back rest for weight reduction[J]. Journal of Tongji University (Natural Science), 2009, 37(7): 938-942.

[5] MISHRA R K, GUPTA A K, RAO P R, SACHDEV A K, KUMAR A M, LUO A A. Influence of cerium on the texture and ductility of magnesium extrusions[J]. Scripta Materialia, 2008, 59(5): 562-565.

[6] STANFORD N. The effect of calcium on the texture, microstructure and mechanical properties of extruded Mg-Mn-Ca alloys[J]. Materials Science and Engineering A, 2010, 528(1): 314-322.

[7]  , VLACH M. Structural and mechanical characteristics of Mg-4Zn and Mg-4Zn-0.4Ca alloys after different thermal and mechanical processing routes[J]. Materials Science and Engineering A, 2013, 586: 284-291.

, VLACH M. Structural and mechanical characteristics of Mg-4Zn and Mg-4Zn-0.4Ca alloys after different thermal and mechanical processing routes[J]. Materials Science and Engineering A, 2013, 586: 284-291.

[8] 王天一, 丁汉林, 刘育峰, 魏 峰, 张义伟, 程广萍. Mg-1.0Zn-1.5Ca合金热压缩过程的动态再结晶行为研究[J]. 中国有色金属学报. 2014, 24(10): 2474-2481.

WANG Tian-yi, DING Han-lin , LIU Yu-feng, WEI Feng, ZHANG Yi-wei, CHENG Guang-ping. Study on dynamic recrystallization of Mg-1.0Zn-1.5Ca alloy during hot compression[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2474-2481.

[9] LIU Li-wei, LIU Chun-ming, ZHAO Jun, ZENG Wen-bing, WANG Zhong-chang. Modification of grain refinement and texture in AZ31 Mg alloy by a new plastic deformation method[J]. Journal of Alloys and Compounds, 2015, 628: 130-134.

[10] 俞汉清, 陈金德. 金属塑性成形原理[M]. 北京: 机械工业出版社, 1998.

YU Han-qing, CHEN Jin-de. Principles of metal plastic forming[M]. Beijing: China Machine Press, 1998.

[11] 陈振华, 夏伟军, 程永奇, 傅定发. 镁合金织构与各向异性[J]. 中国有色金属学报, 2005, 15(1): 1-11.

CHEN Zhen-hua, XIA Wei-jun, CHEN Yong-qi, FU Ding-fa. Texture and anisotropy in magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(1): 1-11.

[12] BOHLEN J, N RNBERG M R, SENN J, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets[J]. Acta Materia, 2007, 55: 2101-2112.

RNBERG M R, SENN J, LETZIG D, AGNEW S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets[J]. Acta Materia, 2007, 55: 2101-2112.

[13] DING Han-lin, HIRAI K, HOMMA T, KAMADO S. Numerical simulation for microstructure evolution in AM50 Mg alloy during hot rolling[J]. Computational Materials Science, 2009, 47(4): 919-925.

[14] COTTAM R, ROBSON J, LORIMER G, DAVIS B. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development[J]. Materials Science and Engineering A, 2008, 485(1): 375-382.

[15] AGNEW S R, YOO M H, TOME C N. Application of texture simulation to understanding mechanical behavior of Mg and solid solution alloys containing Li or Y[J]. Acta Materialia, 2001, 49(20): 4277-4289.

[16] BALL E A, PRANGNELL P B. Tensile-compressive yield asymmetries in high strength wrought magnesium alloys[J]. Scripta Metallurgica et Materialia, 1994, 31(2): 111-116.

[17] MACKENZIE L W F, DAVIS B, HUMPHREYS F J, LORIMER G W. The deformation, recrystallisation and texture of three magnesium alloy extrusions[J]. Materials Science and Technology, 2007, 23(10): 1173-1180.

[18] HANTZSCHE K, BOHLEN J, WENDT J, KAINER K U, YI S B, LETZIG D. Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets[J]. Scripta Materialia, 2010, 63(7): 725-730.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51204003);安徽高校省级自然科学研究重点项目(KJ2011A051);教育部留学回国人员科研启动基金资助项目;人社部留学人员科技活动项目择优资助项目

收稿日期:2014-05-25;修订日期:2015-12-29

通信作者:丁汉林,副教授,博士;电话:0555-2311570;E-mail:hanlinding@yahoo.com