文章编号:1004-0609(2009)12-2067-07

Mg-8Gd-3Y-0.6Zr合金热压缩过程的动态再结晶

张新明1,周 楠1,李 理1, 2,唐昌平1,邓运来1

(1. 中南大学 材料科学与工程学院 长沙 410083;

2. 湖南工学院 机械工程系 衡阳 421002)

摘 要:研究Mg-8Gd-3Y-0.6Zr合金热压缩过程的动态再结晶规律。对该合金在变形温度为623~773 K、应变速率为0.01~1 s-1条件下进行单向压缩实验,用金相显微镜、场发射扫描电子显微镜及织构测试仪对压缩后的合金组织与晶体取向进行分析。结果表明:曲线的峰值应力、稳态流动应力均随Zener-Hollomon (Z)参数的增加而增加;变形温度的升高以及应变速率的提高均能减弱{0001}基面织构,强化 柱面织构;动态再结晶晶粒尺寸随Z参数的增加而减小。根据实验结果,该合金在热轧时ln(Z)宜控制在28~32之间,变形温度在723~773 K之间。

柱面织构;动态再结晶晶粒尺寸随Z参数的增加而减小。根据实验结果,该合金在热轧时ln(Z)宜控制在28~32之间,变形温度在723~773 K之间。

关键词:镁合金;热压缩;动态再结晶;Zener-Hollomon参数;织构

中图分类号:TG146.2 文献标识码: A

Dynamic recrystallization of Mg-8Gd-3Y-0.6Zr alloy during hot-compression

ZHANG Xin-ming1, ZHOU Nan1, LI Li1, 2, TANG Chang-ping1, DENG Yun-lai1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Department of Mechanical Engineering, Hunan Institute of Technology, Hengyang 421002, China)

Abstract: The regularity of dynamic recrystallization in Mg-8Gd-3Y-0.6Zr alloy during hot-compression was investigated. For this purpose, the uniaxial compression was conducted at different deformation temperatures (from 623 K to 773 K) and various strain rates (from 0.01 s-1 to 1 s-1). The microstructure and macrotexture after compression were studied by optical microscope (OM), scanning electron microscopy (SEM) and X-ray texture measurement. The results show that the peak stress and the steady-state flow stress become higher with increasing Zener-Hollomon parameter (Z); Increasing deformation temperature or strain rate can weaken the {0001} basal texture and strengthen the  prismatic texture; the grain size of dynamic recrystallization becomes smaller with increasing Z parameter. Therefore, ln(Z) ranging in 28-32 and the deformation temperature ranging in 723-773 K are proposed for hot-rolling of Mg-8Gd-3Y-0.6Zr alloy.

prismatic texture; the grain size of dynamic recrystallization becomes smaller with increasing Z parameter. Therefore, ln(Z) ranging in 28-32 and the deformation temperature ranging in 723-773 K are proposed for hot-rolling of Mg-8Gd-3Y-0.6Zr alloy.

Key words: magnesium alloy; hot-compression; dynamic recrystallization; Zener-Hollomon parameter; macrotexture

镁合金在航空航天领域有着广阔的应用前景[1],但是一般镁合金的高温力学性能低,因此,开发高强耐热镁合金越来越受到人们的重视。研究表明,添加Gd、Y等稀土元素的Mg-Gd-Y-Zr系合金具有优良的耐热性能以及高温力学性能,是一种新型高强耐热镁合金,其性能明显高于目前应用广泛的WE54、ZM6等耐热镁合金[2-4]。

镁合金制品多是通过压铸成形[5],然而镁合金 经过如挤压、轧制等热变形加工后力学性能会更加优异[6-7]。国内外对镁合金室温以及高温变形及动态再结晶行为的研究发现,镁合金由于层错能较低,易于发生动态再结晶。GALIYEV等[8]报道了镁合金中较为典型的连续动态再结晶,即随着变形量的增加,亚晶界的取向差逐渐增加,亚晶逐渐转变为大角度晶界的新晶粒。YANG等[9]发现了镁合金变形过程中的扭折带对新晶粒形核的促进作用。SIDIKOV等[10]提出孪生再结晶机制。国内外对高性能Mg-Gd-Y系合金也有类似研究[11-12]。张新明等[13]研究了Mg-Gd-Y-Zr合金高温压缩变形过程中的真应力─真应变关系曲线,计算了形变表观激活能及应力指数,但是未确定Zener-Hollomon参数(Z参数)与动态再结晶的关系。本文作者通过对Mg-8Gd-3Y-0.6Zr合金进行不同温度不同应变速率的热压缩实验,研究热压缩变形参数对合金动态再结晶行为的影响,以及变形参数对合金织构的影响,探讨Z参数与动态再结晶的关系,为优化稀土镁合金的热塑性加工工艺提供参考依据。

1 实验

实验所用材料为Mg-Gd-Y-Zr合金铸锭,具体成分如表1所列。熔炼是在自制的带有抽真空、氩气保护和水冷装置的不锈钢坩锅中进行,Gd、Y、Zr分别以Mg-Gd、Mg-Y、Mg-Zr中间合金的形式加入,通过电阻炉加热和插搅使中间合金均匀化。熔炼温度保持在1 123 K左右,充分熔化后加Mg-Zr中间合金,加精炼溶剂搅拌后,保温15 min,分别在金属模和薄壁不锈钢管中浇注。

表1 试验合金的名义成分

Table 1 Nominal composition of experimental alloy(mass fraction, %)

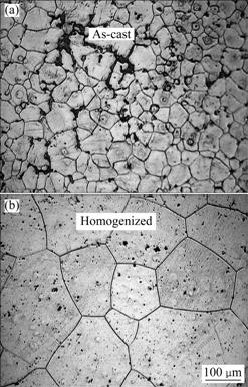

铸锭经(793 K, 24 h)均匀化处理后用线切割机切成尺寸为10 mm×10 mm×15 mm的压缩试样。铸态及均匀化后的组织如图1所示。铸锭均匀化处理后,非平衡结晶相已经完全消失,但是晶粒有所长大。

热压缩在Gleeble-1500试验机上进行,试样在压缩前两端涂含石墨的固体润滑剂以尽量减少压缩时试样两端的摩擦力。压缩变形的温度范围在623~773 K之间。试样在1 min内升到指定的温度,保温3 min,应变速率在0.01~1 s-1之间,最大压缩变形量为80%。试样压缩后立即水淬,以保留高温变形组织。试验数

图1 合金的铸态以及均匀化组织

Fig.1 Optical microstructures of cast ingot and homogenized sample: (a) As-cast ingot; (b) Homogenized sample

据由计算机自动采集,压缩后的样品沿垂直于压缩的方向切开制成金相试样,用10%的酒石酸溶液进行腐蚀,在XJP-6A金相显微镜以及Sirion200场发射扫描电子显微镜下观察组织形貌,采用Bruker D8 Discover X射线衍射仪测试压缩面中部的宏观织构,压缩方向(CD)垂直于测试面。

2 结果及分析

2.1 合金压缩的真应力─真应变曲线

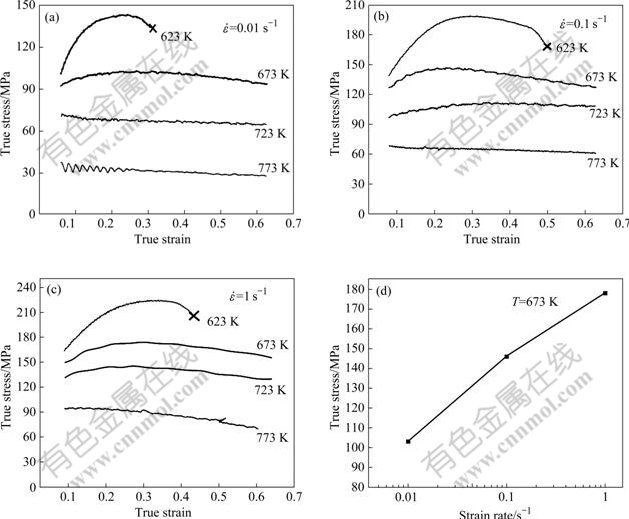

图2所示为实验合金压缩后的真应力─真应变曲线。由图2可知,试样在623 K压缩时发生了与压缩方向成45?角的剪切破裂,这说明加工硬化在合金的塑性变形中起了主导作用;随着温度的上升,加工硬化现象减弱,真应力─真应变曲线可明显分为3个阶段:在变形的初期,应力随着应变的增加而急剧升高;继续压缩变形,动态回复逐渐增强,此阶段的真应力-真应变曲线呈抛物线状;当应变增大到一定程度时,变形进入了稳态流变阶段,即动态回复和加工硬化达到了动态平衡。当温度达到一定值时,流变应力达到峰值后随即上下波动,产生锯齿形状,随后进入稳流变状态,产生了典型的动态再结晶型曲线。峰值应力是由位错累积产生的硬化和动态再结晶产生的软化叠加的结果。当流变应力达到极大值后,动态再结晶加快,于是流变应力开始下降。

图2 试验合金在不同条件下压缩的真应力─应变曲线与673 K压缩时真应力─应变速率曲线

Fig.2 True stress─strain curves of investigated alloy under different conditions and peak stress─strain rate curve at 673 K:

(a)  =0.01 s-1; (b)

=0.01 s-1; (b)  =0.1 s-1; (c)

=0.1 s-1; (c)  =1 s-1; (d) Peak stress─

=1 s-1; (d) Peak stress─ curve at 673 K

curve at 673 K

如图2(d)所示,在温度相同(673 K)的情况下,峰值应力随着应变速率的增大而增大。这是由于当应变速率增大时,发生单位应变所需的时间缩短,能发生运动的位错数量增加;然而应变速率越高,材料进行动态回复以及动态再结晶的时间也就相应越短,软化时间不充分,于是峰值应力便随之增大。

2.2 组织观察与织构分析

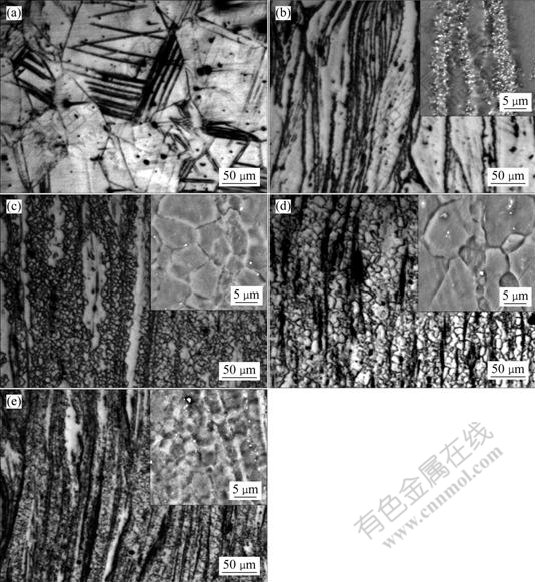

图3所示为试样在不同条件压缩后的微观组织。图3(b)~(e)右上角所示为对应的扫描组织。如图3(a)所示,试样在623 K、0.01 s-1条件下压缩时发生了与压缩方向成45?角的剪切破裂;由于试样在形变量不大时即发生破裂,因此并未发现晶粒被拉长的现象,但在组织中发现有大量的孪晶。如图3(b)所示,试样在673 K压缩时组织中并未发现动态再结晶晶粒,而是观察到被拉长的形变纤维组织。试样在723 和773 K压缩时均发生了明显的动态再结晶。如图3(c)所示,当温度为723 K时,再结晶并不完全,仍可见被拉长的原始晶粒,再结晶晶粒包围在原始晶粒的周围,但此时再结晶晶粒直径较小。如图3(d)所示,随着变形温度的升高,变形后的晶粒尺寸变得基本均匀,再结晶晶粒尺寸长大,形成完全再结晶组织。

图3(c)和(e)所示为试样在相同温度下压缩的微观组织。如图3(c)所示,当应变速率为0.01 s-1时,再结晶晶粒大多在晶界处生成,在金相组织中可以观察到许多细小的等轴晶粒组成晶带包围在大晶粒周围。如图3(e) 所示,随着应变速率的增加,细晶区的面积逐渐增大,只有少数区域能观察到被拉长的原始晶粒,从扫描组织可以看出,大多数晶粒都被细小的等轴晶所取代。在该应变速率下压缩后的微观组织与应变速率低压缩后的微观组织相比,晶粒分布更加均匀。

图3 试样在不同条件下压缩后的微观组织

Fig.3 Microstructures of samples compressed under different conditions: (a) 623 K, 0.01 s-1; (b) 673 K, 0.01 s-1; (c) 723 K, 0.01 s-1; (d) 773 K, 0.01 s-1; (e) 723 K, 1 s-1

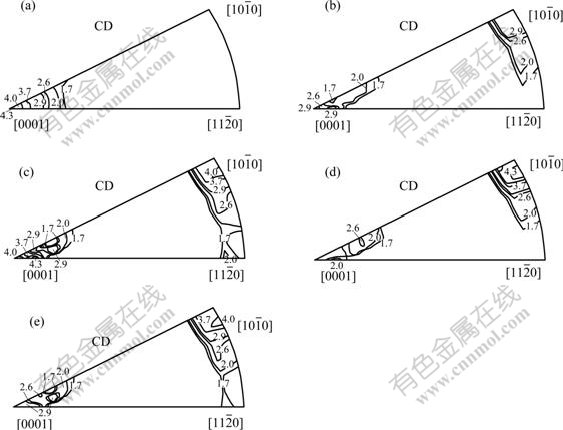

图4所示为压缩后样品的反极图。图4(a)所示为在623 K、0.01 s-1条件下压缩后得到的反极图。从图4(a)可见,材料在变形后出现了{0001}基面织构。当变形温度上升为673 K时,基面织构减弱,并出现了{10 0}柱面织构(见图4(b))。图4(c)所示为在723 K、0.01 s-1条件下压缩后得到的反极图。由图4(c)可见,由于该温度下材料发生了明显的动态再结晶,材料在该条件下压缩后基面织构与柱面织构均有所增强。当温度上升为773 K时,基面织构明显减弱,柱面织构增强(见图4(d))。图4(e)所示为在723 K、1 s-1条件下压缩后得到的反极图。由图4(e))可见,与图4(c)所示相比,基面织构也明显减弱。由此可见,随着温度和变形速率的增加,基面织构均有所减弱,柱面织构增强,且温度对压缩后上述织构的影响更为明显。

0}柱面织构(见图4(b))。图4(c)所示为在723 K、0.01 s-1条件下压缩后得到的反极图。由图4(c)可见,由于该温度下材料发生了明显的动态再结晶,材料在该条件下压缩后基面织构与柱面织构均有所增强。当温度上升为773 K时,基面织构明显减弱,柱面织构增强(见图4(d))。图4(e)所示为在723 K、1 s-1条件下压缩后得到的反极图。由图4(e))可见,与图4(c)所示相比,基面织构也明显减弱。由此可见,随着温度和变形速率的增加,基面织构均有所减弱,柱面织构增强,且温度对压缩后上述织构的影响更为明显。

3 分析与讨论

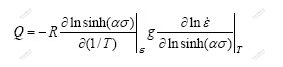

Z参数(Zener-Hollomon参数)表征了材料热变形过程中温度与应变速率对变形和微观组织的综合影响效果。WATANBE等[14]的研究表明,随着Z参数的增加,Mg-Al-Zn合金再结晶平均晶粒尺寸d减小,并且lnZ与lnd呈线性关系。Z参数与温度以及应变速率的关系可以表达为[15]

图4 试验合金在不同条件压缩后的织构演变

Fig.4 Texture evolution of investigated alloy compressed under different conditions: (a) 623 K, 0.01 s-1; (b) 673 K, 0.01 s-1; (c) 723 K, 0.01 s-1; (d) 773 K, 0.01 s-1; (e) 723 K, 1 s-1

形的绝对温度, 为应变速率。大量实验研究证明,Z与σ遵循下述关系[15]:

为应变速率。大量实验研究证明,Z与σ遵循下述关系[15]:

(2)

(2)

式中:α为常数。根据ln ─lnσ和ln

─lnσ和ln ─σ的线性拟合分别得到的斜率n′ 和β,通过α=β/n′ 得到常数α。将式(1)与式(2)联立并两边求对数得到:

─σ的线性拟合分别得到的斜率n′ 和β,通过α=β/n′ 得到常数α。将式(1)与式(2)联立并两边求对数得到:

(3)

(3)

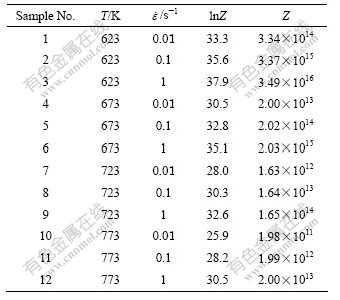

式中:第一项代表ln[sinh(ασ)]与1/T的斜率n,第二项表示ln 与ln[sinh(ασ)]的斜率P,由此再根据真应力─真应变曲线得到的数据计算出Q=196.4 kJ/mol。计算出每个变形条件下的Z参数值,则每个样品的形变参数与对应的Z参数值如表2所列。

与ln[sinh(ασ)]的斜率P,由此再根据真应力─真应变曲线得到的数据计算出Q=196.4 kJ/mol。计算出每个变形条件下的Z参数值,则每个样品的形变参数与对应的Z参数值如表2所列。

在本实验条件下,通过一元线性回归得到:

lnd=-0.149lnZ+6.138 (4)

其相关系数为0.986。lnd与lnZ的关系如图5所示。

由表2和图5可以看出,当温度为623 K时,在本实验条件下lnZ均大于33.3。此时,材料的变形机制主要为基面滑移与孪生协调变形。当变形温度大于723 K时,lnZ均小于32.6。此时材料发生了明显的动态再结晶,孪晶消失。晶粒尺寸均满足图5所示的线性关系。镁合金高温塑性变形时,基面与非基面滑移同时起动,动态再结晶通常从晶界开始。在高温变形条件下,晶界的强度比晶内的低;晶界在外加应力作用下发生滑动变形,变形受阻时晶界附近的位错密度增加。当位错密度达到一定的临界值时,再结晶晶粒

表2 变形参数与对应的Z参数值

Table 2 Deformation parameters and corresponding Z parameter

图5 lnd与lnZ的关系

Fig.5 Relationship between lnd and lnZ

首先在此区域形核并长大,包围了基体晶粒。图3(b)所示为样品在673 K、0.01 s-1下压缩后的变形组织,此时的lnZ=30.5,但是在金相组织中并未发现再结晶晶粒。这是因为在该温度下压缩时,在晶界处有大量细小析出相(图3(b)扫描组织),这些粒子阻碍了(亚)晶界的迁移。

因此,在确定热轧参数时,必须考虑Z参数对合金动态再结晶的影响,将lnZ控制在28~32之间。实验合金的实际变形温度应大于673 K,在723~773 K之间为佳,但考虑到镁合金热容小,应适当提高加热温度并注意保温。

4 结论

1) 通过对真应力─真应变曲线进行分析,Mg-8Gd-3Y-0.6Zr合金在623~773 K温度范围内,曲线的峰值应力、稳态应力均随变形速率的增加以及变形温度的降低,即Z参数的增加而增加。

2) 当变形温度高于673 K时,动态再结晶晶粒所占的比例随变形温度升高而增大;随着应变速率的增加,动态再结晶晶粒细化;变形温度的升高以及变形速率的提高均减弱了{0001}基面织构,加强了{10 0}柱面织构。

0}柱面织构。

3) Mg-8Gd-3Y-0.6Zr合金的变形表观激活能为196.4 kJ/mol,其动态再结晶晶粒尺寸随Z参数的增加而减小。晶粒尺寸lnd与lnZ的关系满足:lnd=-0.149lnZ+6.138,其相关系数为0.986。

4) Mg-8Gd-3Y-0.6Zr合金在热轧时宜控制lnZ在28~32之间,变形温度在723~773 K之间。

REFERENCES

[1] 肖 阳. 高强耐热Mg-Gd-Y-X合金的力学行为与耐热机理研究[D]. 长沙: 中南大学, 2008: 1-12.

XIAO Yang. Study on mechanical behavior and heat-resistant mechanism of high-strength and heat-resistant Mg-Gd-Y-X alloy[D]. Changsha: Central South University, 2008: 1-12.

[2] 肖 阳, 张新明, 陈健美. Mg-15Gd-0.6Zr合金的组织与力学性能[J]. 中国有色金属学报, 2006, 16 (11): 1888-1894.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei. Microstructures and mechanical properties of Mg-15Gd-0.6Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16 (11): 1888-1894.

[3] LIU X B, CHEN R S, HAN E H. Effects of ageing treatment on microstructures and properties of Mg-Gd-Y-Zr alloys with and without Zn additions[J]. Journal of alloy and compounds, 2008, 465: 232-238.

[4] 肖 阳, 张新明, 蒋 浩, 陈部湘. Gd和Y偏析对Mg-9Gd-4Y-0.6Zr和Mg-7Gd-4Y-0.6Zr合金组织性能的影响[J]. 中南大学学报: 自然科学版, 2007, 38(1): 24-29.

XIAO Yang, ZHANG Xin-ming, JIANG Hao, CHEN Bu-xiang. Influence of Gd and Y elements segregation on microstructure and properties of Mg-9Gd-4Y-0.6Zr and Mg-7Gd-4Y-0.6Zr alloys[J]. Journal of Central South University of Technology: Science and Technology, 2007, 38(1): 24-29.

[5] 王栓强. 镁合金压铸技术进展[J]. 铸造技术, 2008, 9: 1292-1294.

WANG Suan-qiang. Progress in die-casting technology of magnesium alloy[J]. Foundry Technology, 2008, 9: 1292-1294.

[6] XIONG Chuang-xian, ZHANG Xin-ming, DENG Yun-lai. Effects of cryogenic treatment on mechanical properties of extruded Mg-Gd-Y-Zr(Mn) alloys[J]. Journal of Central South University of Technology, 2007(3): 305-309.

[7] PEREZ-PRADO M T, DEL VALLE J A, CONTRERAS J M, RUANO O A. Microstructural evolution during large strain hot rolling of an AM60 Mg alloy[J]. Scripta Materialia, 2004, 50: 661-665.

[8] GALIYEV A, KAIBYSHEV R, SAKAI T. Continuous dynamic recrystallization in magnesium alloy[J]. Materials Science Forum, 2003, 419/422: 509-514.

[9] YANG Xu-yue, MIURA H, SAKAI T. Dynamic evolution of new grains in magnesium alloy during hot deformation[J]. Materials Transactions, 2003, 44: 197-203.

[10] SIDIKOV O, KAIBYSHEV R, SAKAI T. Dynamic recrystallization based on twinning in coarse-grained Mg[J]. Materials Science Forum, 2003, 419/422: 521-526.

[11] YANG Z, GUO Y C, LI J P, HE F, XIA F, LIANG M X. Plastic deformation and dynamic recrystallization behaviors of Mg-5Gd-4Y-0.5Zn-0.5Zr alloy[J]. Mater Sci Eng A, 2008, 485: 487-491.

[12] 马志新, 张家振, 李德富, 张 奎. Mg-Gd-Y-Zr合金热压缩流变应力的研究[J]. 热加工工艺, 2007, 36(22): 26-29.

MA Zhi-xin, ZHANG Jia-zhen, LI De-fu, ZHANG Kui. Study on flow stress of Mg-Gd-Y-Zr magnesium alloy during hot-compression[J]. Hot Working Technology, 2007, 36(22): 26-29.

[13] 张新明, 陈健美, 邓运来, 肖 阳, 蒋 浩. Mg-Gd-Y-Zr耐热镁合金的压缩变形行为[J]. 中国有色金属学报, 2005, 12(15): 1925-1932.

ZHANG Xin-ming, CHEN Jian-mei, DENG Yun-lai, XIAO Yang, JIANG Hao. Deformation behavior of Mg-Gd-Y-Zr heat-resistant magnesium alloy during hot-compression[J]. The Chinese Journal of Nonferrous Metals, 2005, 12(15): 1925-1932.

[14] WATANABE H, TSUTSUI H, MUKAI I, ISHIKAWA K, OKANDA Y, KOHZU M, HIGASHI K. Grain size control of commercial wrought Mg-Al-Zn alloys utilizing dynamic recrystallization[J]. Materials Transactions, 2001, 42: 1200-1205.

[15] POIRIER J P. 晶体的高温塑性变形[M]. 大连: 大连理工大学出版社, 1988: 42.

POIRIER J P. The Plastic deformation of crystals at high temperature[M]. Dalian: Dalian University of Science and Technology Press, 1988: 42-43.

基金项目:国家重点基础研究发展计划资助项目(5233001E);国家高技术研究发展计划资助项目(2005AA741062)

收稿日期:2008-12-29;修订日期:2009-07-10

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail: xmzhang@mail.csu.edu.cn

(编辑 何学锋)