文章编号:1004-0609(2015)02-0351-09

铝/钢异种合金激光-电弧复合焊接接头的界面性能及抗拉强度

梅述文1,成群林1,姜 勇1,胡佩佩1,孙锡建1,高 明2

(1. 上海航天精密机械研究所,上海 201600;

2. 华中科技大学 武汉光电国家实验室,武汉 430074)

摘 要:以铝硅共晶合金Al-12Si为填充材料,采用光纤激光-冷金属过度(CMT)复合焊接技术制备铝/钢异种金属优质对接接头。通过SEM、EDS和XRD分析,结果表明:不锈钢和熔合区界面存在明显的金属间化合物(IMCs)层。从接头上部到下部,IMCs界面层逐渐增厚,并由锯齿状变成板块状。IMCs层通常表现为两层结构,分别为靠近钢基体侧的θ-Fe4(Al,Si)13层和靠近焊缝侧的τ5-Al8(Fe,Cr)2Si层组成。当激光偏移量为0.4 mm时,热输入的优化范围为80~110 J/mm。在此范围内,IMCs界面层厚度范围为3~8.5 μm,接头抗拉强度大于130 MPa,达到铝母材的80%以上。

关键词:铝合金;不锈钢;金属间化合物;激光-电弧复合焊接;异种连接

中图分类号:TG457.1 文献标志码:A

Interfacial properties and tensile strength of laser arc hybrid welded dissimilar Al/steel joint

MEI Shu-wen1, CHENG Qun-lin1, JIANG Yong1, HU Pei-pei1, SUN Xi-jian1, GAO Ming2

(1. Shanghai Spaceflight Precision Machinery Institute, Shanghai 201600, China;

2. Wuhan National laboratory for Optoelectronics, Huazhong University of Science and Technology, Wuhan 430074, China)

Abstract: Dissimilar metals of Al alloy to stainless steel was conducted by fiber laser-cold metal transfer (CMT) hybrid welding technique using Al-12Si filler wire. By the analyses of SEM, EDS and XRD, the results show that a IMCs layer is found at the interface between stainless steel and fusion zone. From top to bottom of the joint, the thickness of IMCs layer increases gradually and the shape changes from serrated to plate-like. The IMCs layer is usually composed of two layers, the θ-Fe4(Al,Si)13 layer near to stainless steel and the τ5-Al8(Fe,Cr)2Si layer near to fusion zone. When the offset is 0.4 mm, the optimal range of heat input is 80-110 J/mm. Within this range, the thickness of IMCs layer is 3-8.5 μm, and the tensile strength of the joint is greater than 130 MPa, which is more than 80% of the tensile strength of aluminum base material.

Key words: aluminum alloy; stainless steel; intermetallic compounds; laser-arc hybrid welding; dissimilar joining

近年来,国家大力倡导节能环保,节能减排成为汽车工业发展的主要研究课题。减少汽车自身质量是降低燃油消耗及减少尾气排放的最有效措施之一,实现这一目标主要有两种方法:一是优化汽车框架结构;二是在车身制造中采用轻质合金。铝合金及其加工材料由于具有一系列优良特性,如密度小、比强度和比刚度高、弹性好、抗冲击性能良好、耐腐蚀、耐磨、易表面着色、良好的加工成型性以及高的回收再生性等,因此,铝合金材料是汽车轻量化最理想的材料之一[1-2]。大量的汽车碰撞实验表明:全铝化的汽车在发生正面及侧面撞击时,安全系数远低于钢结构车身。为了解决这个问题,设计者期望在应用铝合金的同时采用钢质车身框架,以此来提高汽车的安全性能,由此提出了铝合金和钢材料的异种连接问题。由于铝和钢之间的固溶度低,两者物理性能差异大,连接过程中会生成大量脆性金属间化合物(IMCs),严重降低接头力学性能,限制了铝-钢异种材料结构件的应用[3-4]。因此,开发一种适宜的焊接方法来实现铝-钢异种金属的高效率、高质量连接是当前汽车工业连接技术关注的焦点。

与传统的电弧焊相比,激光-电弧复合焊接具有焊接速度快、接头质量好的优点,在提高铝-钢异种金属接头性能上已经取得了一定成绩[5-6]。Fronius公司发明了一种新的MIG焊技术—冷金属过度技术(CMT),该技术具有焊丝回抽机构和反馈机构,可以显著提高焊接速度,减少热输入,提高工艺稳定性[7-8],部分学者采用CMT方法对铝和镀锌钢进行焊接可以获得成形美观、性能良好的搭接接头[9-10]。将其引入激光-电弧复合焊接形成新的激光-CMT复合焊接,能够获得比传统激光-MIG复合焊接更快的焊接速度、更高的工艺稳定性、更高的能量可控精度,从而更加适用于铝-钢异种金属间的焊接。因此,本文作者研究6061铝合金-304不锈钢异种金属的光纤激光-CMT复合焊接,重点研究了接头形貌特征、组织结构、力学性能以及断裂行为。

1 实验

实验设备采用YLR-6000光纤激光器、KUKA公司的KR60HA机器人、Fronius公司的TPS4000-CMT多功能脉冲焊机以及自主开发的激光-电弧复合焊接接头。实验原料为2 mm厚6061-F铝合金(AA6061)和2 mm厚304不锈钢(SS 304),具体成分如表1所列。不锈钢和铝合金试样的横截面尺寸均为100 mm×50 mm,不锈钢板开有30°的斜坡口(如图1所示)。焊接前用钢刷清除铝合金和不锈钢工件表面的氧化膜,然后再用丙酮擦洗清除油污。实验焊丝采用直径为1.2 mm的Al-12Si共晶焊丝,材料成分如表1所列。实验中使用的氩气浓度大于99.9%。

由于铝合金与不锈钢间的润湿性差,直接焊接难以成形,为了提高铝基钎料在不锈钢表面的润湿性,选用Nocolok钎剂预置于不锈钢焊缝表面[9]。该钎剂的主要成分为AlF3-KF共晶,无腐蚀型,具有使用简单方便且润湿效果好的特点,将该钎剂在钢母材坡口处均匀涂刷约20~30 μm厚的涂层。

实验采用激光在前,电弧在后,即激光引导的方式进行复合焊接。其中,激光采用零离焦,激光与焊丝尖端之间的距离(DLA)为3 mm,焊炬倾角为55°,焊丝干伸长量为10~12 mm,保护气体为由焊枪喷嘴吹出的氩气,流量为20~30 L/min。为了防止焊接过程中的激光反射对传输光纤造成的损害,激光束采用倾斜10°的方式入射。在焊接过程中,采用中间开有沟槽的紫铜板置于试样底部,使焊缝背部强制成型。另外,如图1(a)所示,在焊接过程中,激光束在工件表面的入射位置和铝母材边缘存在一定的间距,在此定义为激光偏移量(d)。

焊接完成后,通过线切割取出试样,经过标准的金相制备工艺制作成金相试样。然后,使用Keller腐蚀剂(1%~3% HF+2%~6% HNO3+91%~97% H2O,体积分数)腐蚀2~4 s。采用金相显微镜和扫描电子显微镜(SEM)对焊接接头各区域的组织进行观察,同时通过该设备内置的能谱仪(EDS)分析焊缝和界面层微区成分;采用X射线衍射仪对界面层进行XRD分析。

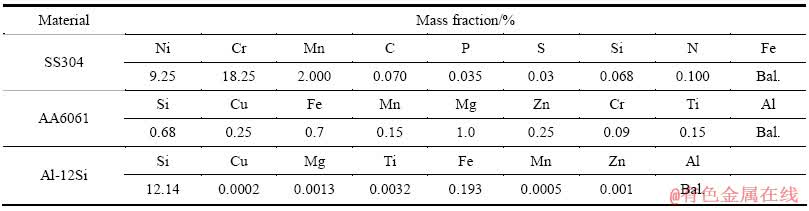

表1 实验原料和焊丝的化学成分

Table 1 Chemical composition of raw materials and filler wire

图1 焊接装置示意图

Fig. 1 Schematic diagrams of welding set

2 结果与分析

2.1 铝/钢异种金属接头连接特性及熔合区显微组织

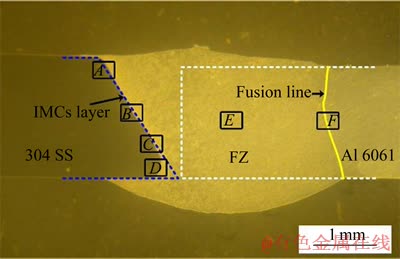

图2所示为在激光偏移量为0.4 mm、焊接速度为2 m/min、激光功率为2 kW、送丝速度为5.4 m/min的条件下获得的典型接头的截面形貌,左侧虚线表示不锈钢(304SS)在焊前的位置,右侧虚线表示铝合金母材(6061 Al)在焊前的位置。通过焊前和焊后界面的对比可知:在激光和电弧的热作用下,低熔点铝母材充分熔化并与熔化的Al-12Si焊丝混合后形成焊缝熔合区(FZ),具有典型的熔化焊接特征;相对而言,不锈钢母材除了根部尖角位置外,没有出现明显的熔化现象,界面形貌在宏观上仍然保持焊前特征,在微观上表现为液态焊缝金属和不锈钢母材在界面处通过化学反应形成紧密连接,具有典型的钎焊连接特征。脆性合金化合物的存在,焊缝金属和不锈钢母材之间的金属间化合物界面层是铝钢异种金属连接接头的薄弱环节,也是整个接头中需要关注和研究的重点[11-12]。

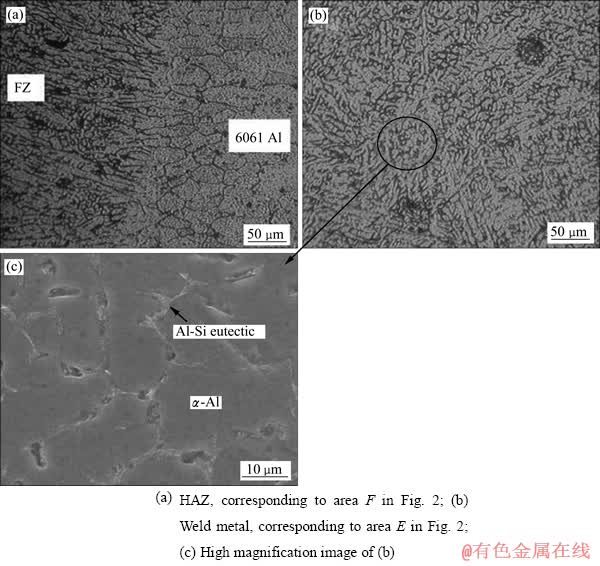

铝钢异种接头熔焊区域与传统熔焊接头一样包含有焊缝区、热影响区及铝母材。图3所示为熔焊区域焊缝金属和热影响区(HAZ)的显微组织,可以发现热影响区相对于母材晶粒明显粗化;焊缝金属则表现为树枝晶。其次,在焊缝金属晶粒晶界处有明显的析出相,通过EDS分析发现该析出相的成分为59.87Al-40.13Si(摩尔分数,%)。根据Al-Si二元相图可以确定该析出相为Al-Si共晶。

图2 铝/钢激光-CMT复合焊接接头截面SEM像

Fig. 2 Cross-section SEM image of aluminum/steel laser- CMT hybrid welding joint

2.2 铝/钢异种金属接头IMCs界面层显微组织

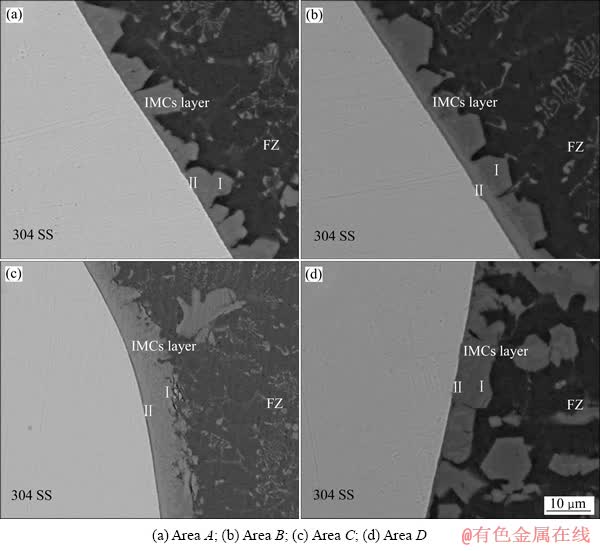

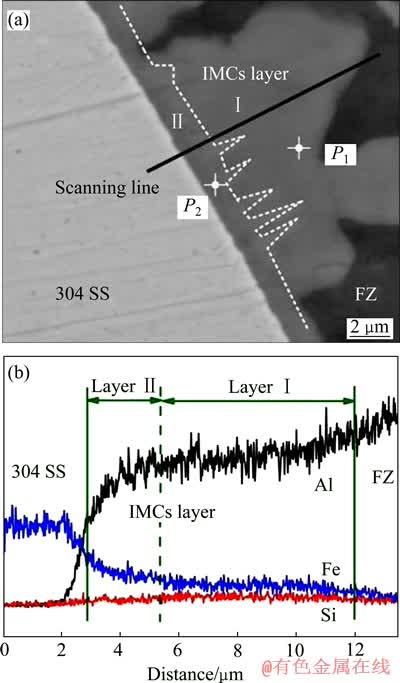

由于在接头根部不锈钢母材有少量熔化,为了便于说明,将界面层分为如图2中的A、B、C和D 4个区域进行讨论。图4所示为典型接头对应上述区域的IMCs界面层显微组织。从图4可以看出:从接头表面到根部,IMCs界面层在厚度和形状上存在不均匀性,界面层从上至下逐渐增厚,厚度变化范围为4~10 μm,而且形状由锯齿状变成板块状。在靠近界面层的焊缝金属内有大量网状金属间化合物和少量细碎的块状金属间化合物存在。另一个重要发现是界面层包含有两层金属间化合物。为了表述的方便,将靠近焊缝金属一侧金属间化合物层定义为Ⅰ层,靠近不锈钢母材一侧的金属间化合物层定义为Ⅱ层。

如图4(a)所示,接头最上部的A区域界面层呈锯齿状,平均厚度约为4 μm;Ⅱ层很薄,约为0.5 μm,呈细小针状向Ⅰ层内生长。如图4(b)所示,接头中上部的B区域的界面层形状仍然为锯齿状,平均厚度约为6 μm,而且Ⅱ层厚度开始增加。如图4(c)所示,接头中下部的C区域的界面层形状开始由锯齿状变成了板块状,而且界面层厚度达到最大,约为10 μm,Ⅱ层的厚度约有4 μm。此时,局部位置有裂纹出现。如图4(d)所示,接头根部的D区域的界面层呈大板块状,平均厚度约为6 μm,界面层附近的焊缝金属内散落着大量的大块状金属间化合物。上述界面层微观特征与文献[13-14]有关铝合金-不锈钢TIG熔钎焊研究中的界面层特征完全不同,在文献[4, 12]中,接头界面层上部由两层组成,平均厚度约为9 μm,但是下部则由一层构成,厚度约为4 μm。显然,这一差异和热源特性密切相关。

图3 铝/钢激光-CMT复合焊接头热影响区(HAZ)和焊缝区的SEM像

Fig. 3 SEM images of laser-CMT hybrid welded Al/304SS joints in different areas

图4 图2中不同区域IMCs界面层的SEM像

Fig. 4 SEM images of IMCs layers of different areas in Fig. 2

在铝钢激光电弧复合焊过程中,激光主要作用熔池底部,电弧则对熔池上部区域影响明显[15]。由于激光的高能密度特性,激光束位置处的铝合金母材会瞬间汽化形成一个深宽比很大的“小孔”,激光可以穿过小孔直射到接头根部。这样开有V形坡口的不锈钢的底部尖角正处于激光束作用范围内,从而该位置的不锈钢母材会因为激光束的直接照射而熔化。熔化后的不锈钢材料会跟随液态熔池内的对流进入焊缝金属,并和焊缝金属反应在界面层前沿形成如图4(d)所示的块状金属间化合物。在其他区域,因为不锈钢母材没有熔化,只是通过与液态焊缝金属发生界面反应。相对来说,由于不锈钢坡口的缘故,接头下部距离高温激光小孔更近,从而获得更高的界面温度,具有更强烈的界面反应,形成较厚的IMCs层。相应的,接头上部和中上部距离高温激光小孔较远,另一方面,CMT焊热输入对熔池上部影响较小,此时界面主要通过熔池对流换热的方式获得热量,导致界面温度相对较低,从而形成较薄的IMCs层。另外,接头中上部的IMCs层因为界面温度较低,局部先达到生长条件的位置会有优先生长,导致界面层各位置的生长速度不一致,从而形成锯齿状形貌;接头下部和根部的IMCs层则因为界面温度更高,界面各个区域都能得到充分的反应,生长速度更加接近,从而形成块状界面层。

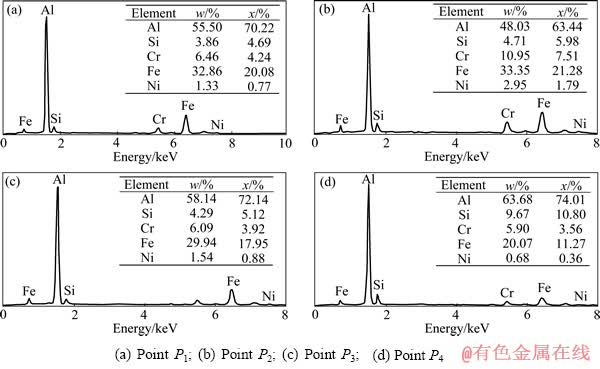

2.3 界面层合金化合物成分

图5所示为IMCs层的高倍SEM像和EDS线扫描谱。从图5可以发现,从不锈钢母材到焊缝金属,Al含量逐渐增加,Fe含量逐渐减少,Si在界面层的含量明显高于不锈钢母材。其次,Ⅰ层和Ⅱ层中的Al、Fe、Si的含量明显不一致,表明这是两种不同类型的金属间化合物。

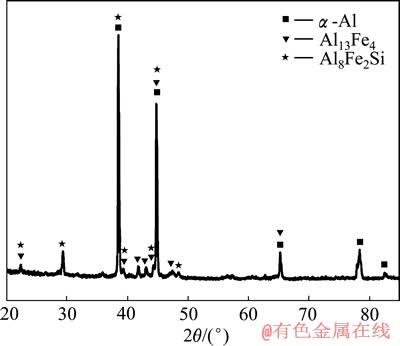

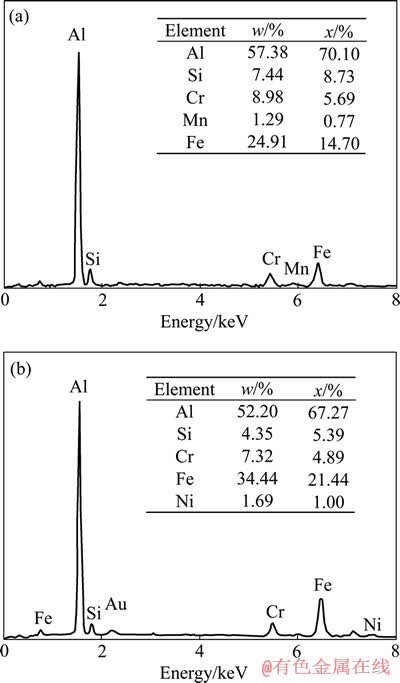

IMCs界面层的微区XRD结果如图6所示,从图6可知:IMCs界面层由Al13Fe4和Al8Fe2Si两种金属间化合物组成。图7所示为图5中位于I层的P1 点和位于Ⅱ层的P2点的EDS分析结果。由于IMCs界面层在形成的过程中,Si原子可以替代Al13Fe4晶格中的Al原子位置并固溶于其中,而Cr原子也可以替代Al8Fe2Si晶格中的Fe原子位置并固溶于其中,从而在计算IMCs中各原子的摩尔分数时,Al与Si原子的摩尔分数可以相加一起计算,同理Fe与Cr原子的摩尔分数也一起计算。通过计算得到Ⅰ层中各元素的摩尔比为x(Al):x(Fe,Cr):x(Si)=8.03:2.33:1,Ⅱ层中各元素的摩尔比为x(Al,Si):x(Fe)=13.6:4。这两个比例分别和XRD分析结果中的Al8Fe2Si相和Al13Fe4相的摩尔比有很好的对应关系。因此,Ⅰ层的金属间化合物可以确定为Al8Fe2Si相,Ⅱ层的金属间化合物可以确定为Al13Fe4相。需要指出的是,由于Cr原子替代Al8Fe2Si相晶格中的Fe原子位置并固溶于其中,此时Ⅰ层的金属间化合物的应该为Al8(Fe,Cr)2Si,同理Ⅱ层的金属间化合物应该为(Al,Si)13Fe4。另外,Al8(Fe,Cr)2Si在Al-Fe-Si三元相图中通常用τ5相表示,而(Al,Si)13Fe4在Al-Fe二元相图中通常用θ相表示[16]。

图5 接头界面层的SEM像及EDS线扫描能谱

Fig. 5 SEM image of IMCs layer(a) and corresponding line scanning EDS spectrum(b)

图6 接头界面层的XRD谱

Fig. 6 XRD pattern of IMCs layer

图7 接头界面层图5中P1点和P2点的EDS能谱

Fig. 7 EDS spectra of points P1(a) and P2(b) in IMCs layers in Fig. 5

2.4 铝钢异种接头的抗拉强度与断裂行为

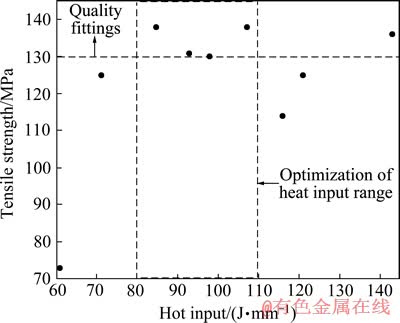

图8所示为激光偏移量为0.4 mm时不同的焊接热输入对应的铝钢异种接头的强度。通过对实验数据的统计分析,规定接头抗拉强度不低于130 MPa时为优质接头,此时接头抗拉强度达到铝母材的80%(铝母材抗拉强度为170 MPa)。这样优质接头对应的热输入优化范围为80~110 J/mm,此时对应的界面层厚度范围约为3~8.5 μm。

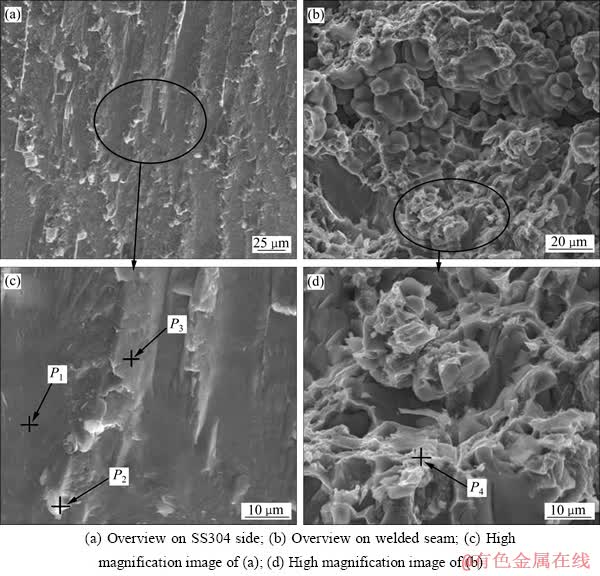

在拉伸实验中发现所有接头均断裂在界面位置。图9(a)所示为拉伸试样在界面位置的宏观断裂形貌。如图9(b)~(c)所示,通过对断口位置的高倍SEM像分析发现,在不锈钢母材一侧以及熔合区焊缝一侧都能够发现金属间化合物,说明在拉伸测试中,裂纹起源于IMCs界面层,并由此扩展造成整个接头的断裂。

图8 铝钢异种接头焊接热输入和接头抗拉强度的关系

Fig. 8 Relationship between hot input and tensile strength of Al/steel joint

图9 铝钢异种接头拉伸试样的断口形貌

Fig. 9 Fracture morphologies of tensile specimens of Al/steel joint

图10所示为铝钢异种金属复合焊接接头的断面形貌,图11所示为图10中断面上不同点的成分分析结果。在不锈钢母材一侧的断面形貌为“河流花样”,是典型的解理断裂,其断面成分分析结果显示其主要成分为θ-Fe4(Al,Si)13相。在熔合区焊缝金属一侧的断面形貌为“冰糖状”,断裂晶粒棱角清晰且局部存在裂纹,是典型的沿晶断裂形貌,其断面成分分析结果显示其中含有较多破碎的τ5-Al8(Fe,Cr)2Si相。SONG等[15]指出,尽管τ5相和θ相均是脆性相,但τ5相具有更高的抗裂性。因此,在拉伸测试中,θ相会因为较差的抗裂性而首先形成裂纹,随着裂纹的聚集繁殖沿整个界面层扩张,导致接头断裂。

图10 铝钢异种接头断面的SEM像

Fig. 10 SEM images of fracture surfaces of Al/steel joint

图11 图10中铝钢异种接头断面不同点的EDS能谱

Fig. 11 EDS spectra of different points in Fig. 10 of fracture surfaces of Al/steel joint

3 结论

1) 光纤激光-CMT复合焊可以实现铝/钢异种金属高效连接,接头存在明显的IMCs界面层,该界面层的厚度和形状存在不均匀性。从上至下,界面层逐渐增厚,厚度范围为4~10 μm,形状则由锯齿状变成板块状。

2) 接头界面层是由靠近不锈钢母材一侧的θ-Fe4(Al,Si)13相和靠近熔合区焊缝金属一侧的τ5-Al8(Fe,Cr)2Si相组成。

3) 铝钢异种金属激光-CMT复合焊接工艺热输入的优化范围为80~110 J/mm,在该热输入范围内的IMCs界面层平均厚度为3~8.5 μm,接头抗拉强度大于130 MPa,达到铝母材抗拉强度的80%以上。

4) 在拉伸过程中,界面层中的θ相会因为较差的抗裂性而首先形成裂纹,随着裂纹沿整个界面层扩张,导致接头断裂。

REFERENCES

[1] FRIDLYANDER N, SISTER V G, GRUSHKO O E. Aluminum alloys promising materials in the automotive industry[J]. Metal science and heat treatment, 2002, 44(9): 365-370.

[2] HARAGA K. Strength properties of aluminum/aluminum and aluminum/steel joints for light weighting of automotive body[J]. Weld World, 2002, 44: 7-23.

[3] 陈树海, 马 柯, 黄继华, 夏 军, 张 华, 赵兴科. 钢/铝异种金属双熔池TIG熔钎焊接头的显微组织与力学性能 [J]. 中国有色金属学报, 2011, 21(12): 3076-3081.

CHEN Shu-hai, MA Ke, HUANG Ji-hua, XIA Jun, ZHANG Hua, ZHAO Xing-Ke. Microstructure and mechanical property of joint by TIG welding-brazing with dual weld pools for steel/aluminum dissimilar metals[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3076-3081.

[4] 宋建岭, 林三宝, 杨春利, 马广超. 铝合金/不锈钢预涂层钨极氩弧熔钎焊接头的特性[J]. 中国有色金属学报, 2009, 19(7): 1209-1215.

SONG Jian-ling, LIN San-bao, YANG Chun-li, MA Guang-chao. Characteristics of precoating TIG welding-brazing joint of aluminum alloy to stainless steel[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1209-1215.

[5] 雷 震, 秦国梁, 林尚扬. 基于激光-MIG复合热源的5A02铝合金/镀锌钢熔钎焊[J]. 机械工程学报, 2009, 45(3): 94-98.

LEI Zhen, QIN Guo-liang, LIN Shang-yang. Fusion brazing joining for dissimilar between 5A02 aluminium alloy and Zn coated steel based on laser MIG hybrid welding[J]. Journal of Mechanical Engineering, 2009, 45(3): 94-98.

[6] SIERRA G, PEYRE P, BEAUME F D. Steel to aluminium brazing welding by laser process with Al-12Si filler wire[J]. Science and Technology of Welding and Joining, 2008, 13(5): 430-437.

[7] FENG J C, ZHANG H T, HE P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding[J]. Mater Des, 2009, 30: 1850-1852.

[8] PYZALLA A R, BORBELY A, DEGISCHER H P. Study of microstructure and residual stresses in dissimilar Al/steels produced by cold metal transfer[J]. Mater Sci Forum, 2008, 347: 571-572.

[9] 石常亮, 何 鹏, 冯吉才, 张洪涛. 铝/镀锌钢板CMT熔钎焊截面区组织与接头性能[J]. 焊接学报, 2006, 27(12): 61-64.

SHI Chang-liang, HE Peng, Feng Ji-cai, ZHANG Hong-tao. Interface microstructure and mechanical property of CMT welding-brazed joint between aluminum and galvanized steels[J]. Transactions of the China Welding Institution, 2006, 27(12): 61-64.

[10] 余 钢, 曹 睿, 陈剑虹. 铝/镀锌钢薄板CMT异种金属熔钎焊接头组织与力学性能[J]. 中国机械工程, 2012, 21(23): 2625-2629.

YU Gang, CAO Rui, CHEN Jian-hong. Microstructure and Mechanical Properties of CMT Welding-brazing joint for dissimilar materials between aluminum and galvanized steels[J]. China Mechanical Engineering, 2012, 21(23): 2625-2629.

[11] MEI Shu-wen, GAO Ming, YAN Jun, ZHANG Cheng, LI Gen, ZENG Xiao-yan. Interface properties and thermodynamic analysis of laser arc hybrid welded Al/steel joint[J]. Science and Technology of Welding and Joining, 2013, 19(4): 293-300.

[12] GAO Ming, MEI Shu-wen, LI Xiang-you, ZENG Xiao-yan. Characterization and formation mechanism of laser welded Mg and Al alloys using Ti interlayer[J]. Scr Mater, 2012, 67: 193-196.

[13] 陈树海, 李俐群, 陈彦宾. 铝/钛异种合金激光熔钎焊接头界面特性[J]. 中国有色金属学报, 2008, 18(6): 991-996.

CHEN Shu-hai, LI Li-qun, CHEN Yan-bin. Interface characteristic and property of Ti/Al dissimilar alloys joint with laser welding-brazing[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(6): 991-996.

[14] SONG Jian-ling, LIN San-bao, YANG Chun-li. Microstructure analysis of interface layer with tungsten inert gas welding-brazing joint of aluminum alloy/stainless steel[J]. Acta Metal Sinca, 2009, 45: 1211-1216.

[15] GAO Ming, MEI Shu-wen, WANG Zhe-ming, LI Xiang-you. Process and joint characterization of laser-MIG hybrid welding[J]. Mater Process Technol, 2012, 212: 1338-1346.

[16] MAITRA T, GUPTA S P. Intermetallic compound formation in Fe-Al-Si ternary system: PartⅡ[J]. Mater Charact, 2013, 49: 293-311.

[17] SONG Jian-ling, LIN San-bao, YANG Chun-li. Effects of Si additions no intermetallic compound layer of aluminum-steel TIG welding-brazing joint[J]. Alloys Comp, 2009, 488: 217-222.

(编辑 王 超)

基金项目:国家工信部04专项资助项目(2013ZX04001101)

收稿日期:2014-04-02;修订日期:2014-11-20

通信作者:梅述文,工程师;电话:021-37842747;E-mail: shuwenmei1@163.com