文章编号:1004-0609(2010)S1-s0685-05

冷却速度对VST55531钛合金的显微组织和力学性能的影响

付艳艳,惠松骁,叶文君,米绪军,于 洋

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:研究不同冷却速度(水冷、空冷和炉冷)对VST55531合金的显微组织和拉伸性能的影响。结果表明:合金分别经820 ℃和900 ℃固溶处理及580 ℃时效后,其强度随冷却速度的减小而逐渐降低,塑性逐渐升高。合金在900 ℃固溶的组织为粗大b晶粒的魏氏组织,其固溶水冷和空冷及时效后获得的强度最高,达到1 400 MPa。合金经820 ℃固溶及时效后,获得双态组织,且塑性较好;经820 ℃,1 h固溶空冷和580 ℃,4 h时效的合金,具有较高的强度和较好的塑性匹配。

关键词:VST55531钛合金;冷却速度;强度;塑性

中图分类号:TG146.4 文献标志码:A

Effects of cooling rate on microstructure and properties of VST55531 alloy

FU Yan-yan, HUI Song-xiao, YE Wen-jun, MI Xu-jun, YU Yang

(State Key Laboratory for Fabrication Processing of Nonferrous Metals, General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The microstructures and tensile properties of VST55531 alloys with different cooling rates were studied,including water cooling, air cooling and furnace cooling. The results show that when the cooling rate gets slower, the strength decreases while the plasticity increases. When the alloy is solution treated at 900 ℃ and then aged, the main microstructure is Widmanstatten with coarse β grain and the strength can reach 1 400 MPa with water cooling and air cooling methods. When the alloy is solution treated at 820 ℃ and then aged, the microstructure is bi-modal with good plasticity. The alloy has better balance of strength and plasticity under aging treatment of 820 ℃, 1 h solution (air cooling) and 580 ℃, 4 h.

Key words: VST55531 titanium alloy; cooling rate; strength; plasticity

钛合金因具有比强度高、耐腐蚀性强等优点,近年来已被广泛应用于航空、航天领域,迅速发展成为具有强大生命力的新型关键结构材料,具有非常重要的应用价值和广阔的应用前景[1]。在航空航天工业中,钛合金是飞机和发动机的主要结构材料之一。钛合金在飞机上使用可以减轻质量,提高结构效率,降低飞行成本,因此,钛合金在飞机的某些部位逐渐替代了钢、铝合金和镍基超合金,成为航空工业大型结构件的理想材料[2]。目前,传统的高强高韧钛合金主要有美国研制的近b型钛合金Ti-1023和俄罗斯研制的BT22[3-5]等。随着航空航天业的迅速发展,新型的高强高韧钛合金也在迅速得到开发和应用,新型高强高韧钛合金有美国研制的Timetal555[6-7]和俄罗斯与法国空客联合开发的VST55531合金。VST55531钛合金是一种新型b型钛合金,其名义成分为Ti-5Al-5Mo- 5V-3Cr-1Zr[8-9]。据报道,这种新型钛合金具有良好的断裂韧性和高强度匹配特性,比较适用于机翼和发动机挂架之间连接装置的制造,现已应用在A380空客 飞机上。为了进一步了解VST55531合金的性能特点,满足我国航空业的需求,本文作者主要研究冷却速度对该合金的显微组织和力学性能的影响。

1 实验

实验材料经2次真空自耗电弧炉熔炼制成50 kg铸锭。铸锭经β锻造开坯,在(α+β)两相区锻造成d36 mm×67 mm棒材。合金实际化学成分见表1,接近合金的名义成分。金相法测得本合金的β转变温度为 850 ℃。

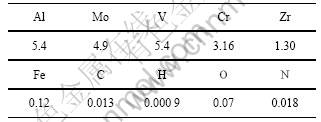

表1 实验材料的成分

Table 1 Chemical composition of alloy (mass fraction, %)

合金分别在 910 ℃和820 ℃固溶处理,冷却方式分别为炉冷、空冷和水冷,时效温度为580 ℃,时效时间为4 h。合金热处理后按标准制备金相试样,在金相显微镜上进行观察和照相。力学性能试样均采用直径为5 mm、标距为25 mm 的标准试样。拉伸实验在ZNSTRON200 LZC型材料拉伸试验机上进行。对经过不同方案热处理试样的显微组织和断口形貌,分别在Axiovert 200 MAT型Zeiss光学显微镜和JSM-840扫描电镜进行观察。

2 结果与讨论

2.1 冷却速度对合金组织的影响

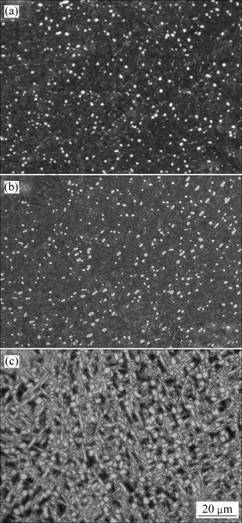

图1所示为VST55531合金经(α+β)相区820 ℃加热后不同冷却速度冷却后的显微组织的变化规律。从图1可以看出:合金在(α+β)相区固溶时,合金中的初生α相以球状形貌长大;水冷时,由于冷却速度很快,合金中的β相发生淬火转变生成淬火α?,α?由于处于高能态不稳定状态,而在随后的时效中,以针状形态出现;空冷时,合金组织主要为球状初生α相和β相;合金在炉冷时,其组织为初生α相和转变β相,呈“网篮状”形貌。由于炉冷的冷却速度较小,合金中的初生α相可以拥有较高的能量而长大,因此,相邻的α相不断长大、靠拢,形成互相交错的条状α相组织,合金中的残余β相则存在于条状α相之间。

图1 VST55531合金在820 ℃固溶后不同冷却条件下的显微组织

Fig.1 Microstructures of VST55531 alloys after solution treated at 820 ℃ with different cooling rates and aged at 580 ℃ for 4 h: (a) 820 ℃, 1 h, WQ; (b) 820 ℃, 1 h, AC; (c) 820 ℃, 1 h, FC

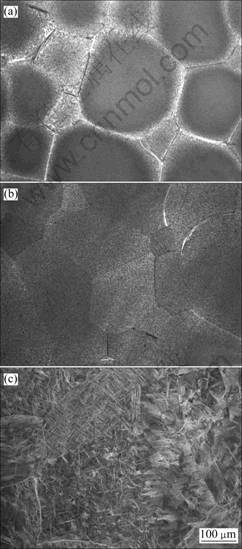

图2所示为VST55531钛合金经β相区900 ℃加热后不同冷却速度冷却后的显微组织的变化规律。从图2可以看出:合金在900 ℃固溶时生成了粗大的β晶粒(100~200 μm),在β晶界上分布清晰的晶界α相。水冷时由于冷却速度快,合金部分β相发生相变切变,首先在β晶界上形成过饱和固溶体α?。在随后的580 ℃时效时,β晶粒内部析出大量均匀的次生α相。空冷时,由于冷却速度较快,可以使得合金在固溶时生成的部分β晶粒保留到室温。合金在该温度炉冷时,β晶粒的晶界和晶粒内分别析出初生α相。由于炉冷的冷却速度较小,β晶界上的晶界α相较宽,而初生α相沿着一定的惯习面析出,呈现较为细长且互相平行的针状形貌,其α束域较粗大。

图2 VST55531合金在900 ℃固溶后不同冷却条件下的显微组织

Fig.2 Microstructures of VST55531 alloys after solution treated at 900 ℃ with different cooling rates and aged at 580 ℃ for 4 h: (a) 900 ℃, 1 h, WQ; (b) 900 ℃, 1 h, AC; (c) 900 ℃, 1 h, FC

2.2 冷却速度对合金性能的影响

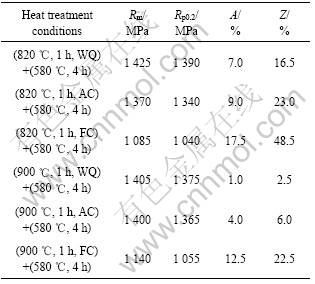

不同冷却速度对合金力学性能影响结果见表2所列。从表2可以看出:随着冷却速度的降低,合金的强度呈逐渐降低趋势,塑性则相反。合金经炉冷后,强度仅在1 100 MPa左右,而合金经水冷和空冷后的抗拉强度较炉冷提高分别约为300 MPa和400 MPa。经900 ℃固溶水冷和空冷的合金,强度都达到1 400 MPa,而且相差幅度不大,但合金塑性很差,尤其是水冷试样的A和Z仅为1.0%和2.5%,发生了明显的脆断现象。经850 ℃固溶空冷的合金强度在1 300 MPa以上,而A和Z分别为9.0%和23.0%,具有良好的强塑性匹配。

表2 VST55551合金经热处理后的力学性能

Table 2 Properties of VST55531 alloys after different heat treatments

合金在820 ℃固溶时具有较大的强度和较强的塑性匹配,产生这种现象的原因是因为合金在两相区固溶时会生成一定量的球状初生α相,使得合金中β相的α稳定元素减少,稳定了β相。合金在水冷时,这些β相就可以保留到室温,在随后的时效中析出高度弥散的次生α相,提高了合金的强度。合金在空冷时,只有部分β相保留到室温,在冷却过程中,α相沿初生α相颗粒边界析出,使初生α颗粒粗化,亚稳β相析出次生α相的含量比水冷的低,这就是空冷时合金的强度低于水冷时的强度,但塑性却高于水冷时的塑性的原因。合金炉冷时,初生α相更为粗大,导致合金的强度最低,而塑性最高。

2.3 拉伸断口形貌分析

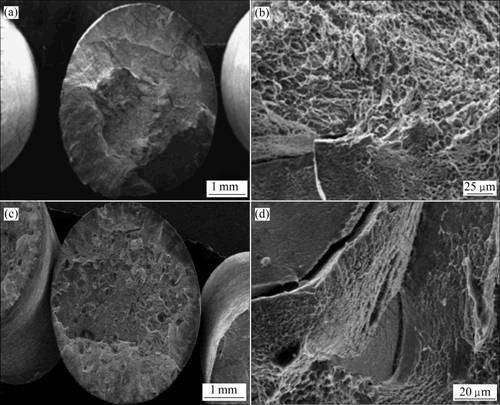

合金在820 ℃和900 ℃固溶空冷及时效处理后的拉伸断口见图3。

图3 VST55531合金热处理后的拉伸断口SEM形貌

Fig.3 SEM images of tensile fracture graphs for VST55531 alloys after heat treatment: (a), (b) (820 ℃, 1 h, AC)+(580 ℃, 4 h, AC); (c), (d) (900 ℃, 1 h, AC)+(580 ℃, 4 h, AC)

从宏观断口观察可知:在820 ℃固溶空冷及时效处理拉伸的断口,其芯部断口形貌表现为以韧性断裂的韧窝开裂和局部地方形成的准解理断裂的混合型断裂,表明此时合金的塑性较好(见图3(a)和(b))。合金在900 ℃固溶后,得到的是魏氏体组织,拉伸试样都无明显的缩颈,断口粗糙,在空冷条件下得到的试样其断口有较大的解理平面存在(见图3(c))。合金空冷后的拉伸断口则以穿晶断裂为主,伴有部分沿晶断裂,并出现了明显的解理平台,β晶粒的晶界上则出现了裂纹(见图3(d))。

3 结论

1) 合金分别在820 ℃和900 ℃固溶处理及580 ℃时效后,其强度随冷却速度的减小而逐渐降低,塑性逐渐升高。

2) 合金经820 ℃固溶时,获得双态组织,且塑性较好;经β相区900 ℃固溶时,获得含有粗大β晶粒(100~200 μm)的魏氏组织,经空冷和水冷及580 ℃时效后,强度可达1 400 MPa,但塑性较差。

3) 合金经820 ℃,1 h固溶空冷和580 ℃,4 h时效,具有较大的强度和较好的塑性匹配。

REFERENCES

[1] 李文平. 钛合金的应用及发展前景[J]. 轻金属, 2002(5): 53-55.

LI Wen-ping. Development and application of titanium alloys[J]. Light Metals, 2002(5): 53-55.

[2] 莱因斯 C, 皮特尔斯M. 钛与钛合金[M]. 北京: 化学工业出版社, 2005: 33.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. Beijing: Chemical Industry Press, 2005: 33.

[3] BOYER R R. Design properties of a high-strength titanium alloy, Ti-10V-2Fe-3Al[J]. Journal of Metals, 1980(3): 61-65.

[4] KUHLMAN G W. Acloa titanium alloy Ti-10V-2Fe-3Al forgings data sheets[C]//EYLON D, BOYER R R, KOSS D A. Beta Titanium Alloys in the 1990’s. Warrendale: TMS, 1993: 61-71.

[5] 韩 栋, 张鹏省, 毛小南, 卢亚锋, 奚正平, 杨建朝. BT22钛合金及其大型锻件的研究进展[J]. 材料导报, 2010, 24: 46-50.

HAN Dong, ZHANG Peng-sheng, MAO Xiao-nan, LU Ya-feng, XI Zheng-ping, YANG Jian-chao. Research progress of BT22 titanium alloy and its large forgings[J]. Materials Review, 2010, 24: 46-50.

[6] FANNING J C, BOYER R R. Properties of TIMETAL 555—A new near-beta titanium alloy for airframe components[C]// L?TJERING G, ALBRECHT J. Ti-2003 Science and Technology. Hamburg: DGM, 2003: 2643-2650.

[7] HARPER M, WILLIAMS R, VISWANATHAN G B, TILEY J, BANERJEE T, EVANS D J, FRASER H L. The effect of heat treatment on the microstructure of Ti-5Al-5Mo-5V-3Cr- 1Fe(Ti-555)[C]//L?TJERING G, ALBRECHT J. Ti-2003 Science and Technology. Hamburg: DGM, 2003: 1559-1566.

[8] DURET N. Titanium for damage tolerance applications on A380[C]//L?TJERING G, ALBRECHT J. Ti-2003 Science and Technology. Hamburg: DGM, 2003: 2667-2671.

[9] JérómePora. A380结构的先进材料和技术——未来发展的技术平台[J]. 航空维修与工程, 2003(6): 50-52.

JérómePora. Advanced materials and technology for A380 structure[J]. Aviation Maintenance & Engineering, 2003(6): 50-52.

(编辑 陈灿华)

通信作者:付艳艳;电话:010-82241162;E-mail: fuyanyan@grinm.com