文章编号:1004-0609(2013)S1-s0629-04

冷却速率对TC4合金圆盘形变量、显微组织和力学性能的影响

李培跃,张斌斌,李 梁,李兆峰,陈 斌,李士凯

(中国船舶重工集团公司 第七二五研究所,洛阳 471039)

摘 要:利用金相显微镜、力学性能测试、插片法等手段,系统研究了不同冷却速率(水冷、PAG冷和风冷)对TC4合金圆盘形变量、显微组织和力学性能的影响。结果表明:从水冷、风冷到PAG冷,随着冷却速率的降低,圆盘变形程度逐渐减小,室温拉伸强度从水冷、PAG冷到风冷逐渐降低,塑性逐渐升高。PAG溶液作为钛合金的新型淬火介质,可有效降低TC4合金薄壁件的淬火形变量,提高合金的综合性能。

关键词:钛合金;冷却速率;形变;显微组织;拉伸性能

中图分类号:TG 146.4 文献标志码:A

Effect of cooling rate on distortion, microstructure and mechanical properties of TC4 alloy plate

LI Pei-yue, ZHANG Bin-bin, LI Liang, LI Zhao-feng, CHEN Bin, LI Shi-kai

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: The effect of cooling rate after solution treatment on the distortion, microstructure and mechanical properties of TC4 alloy disk was systemically investigated by means of optical microscopy(OM),mechanical properties and distortion measurements. Cooling modes include water quenching, air quenching and PAG quenching. The results show that the distortion decreases from water cooled disk, wind cooled to PAG cooled disk. The tensile strength decreases while the plasticity increases from water cooled disk, PAG cooled to wind cooled disk. The PAG quench bath, which can reduce the quenching distortion effectively, is suitable for titanium alloys. The PAG quench bath can be widely used in titanium alloys.

Key words: titanium alloy; cooling rate; distortion; microstructure; tensile strength

TC4钛合金(Ti-6 Al-4V)是20世纪50年代发展起来的一种中等强度的两相钛合金[1],它含有6%的α稳定元素Al和4%的β稳定元素V。TC4钛合金是应用最为广泛的钛合金之一,我国通常在航空航天和军事工业上用于制造飞机的受力结构件、锻件、钣金件,以及用超塑成型生产整体结构件等[2]。国内外学者针对TC4合金锻造工艺、超塑性成型、焊接、组织等开展了广泛研究[3-4]。

在对强度要求较高的场合,TC4合金常需进行固溶-时效处理,但薄壁件在固溶过程中的变形难于控制,目前,该领域的研究较少。在此,本文作者采用不同冷却介质对TC4合金圆盘构件进行淬火处理,考察冷却速率对合金板材形变量、显微组织和力学性能的影响,旨在为可热处理强化合金的淬火工艺提供试验基础。

1 实验

试验采用TC4锻棒切取的d 300 mm×12 mm盘形件,合金相变点为995 ℃。将圆盘表面涂抹防氧化涂料后,放入马弗炉中进行固溶处理,固溶制度为940 ℃、1 h,随后立即采用不同的冷却介质进行淬火,淬火转移时间少于5 s,淬火介质包括室温水、25 ℃的15%PAG淬火液和风机吹风,其中风机选用JF750型风扇,转速为1 400 r/min。淬火时选用两台风扇分别对着圆盘两面吹风强制冷却,圆盘距离风扇扇叶表面约600 mm。淬火后的试样放入马弗炉中进行540 ℃,4 h的时效热处理。采用插片法测量热处理后圆盘的最大翘曲形变量;在圆盘1/2半径处取15 mm×15 mm试样,将该试样沿圆盘厚度方向切开,采用OLYMPUS GX71金相显微镜观察剖开面合金的低倍、高倍组织,侵蚀剂选用氢氟酸(5 mL)+硝酸(20 mL)+水(75 mL);于圆盘1/2半径沿径向取力学性能试样,采用SINTECH20/G拉伸试验机测定合金的力学性能。

2 结果与讨论

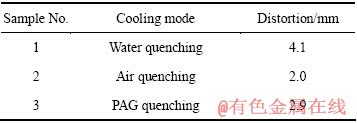

2.1 淬火形变量测定

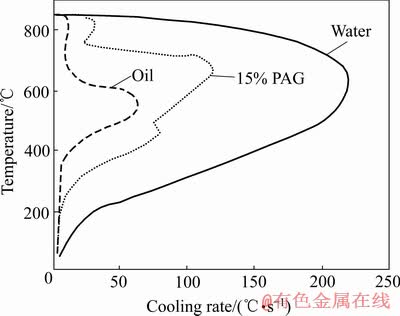

不同淬火冷却方式对圆盘翘曲形变量的影响如表1所示。从表1可以看出,采用15%PAG淬火圆盘的变形程度最小,仅为2.0 mm,而水冷试样变形达到了4.1 mm。由此可见,PAG溶液是一种有效控制合金构件淬火变形的介质。PAG溶液作为淬火变形控制的新型淬火介质在钢铁广泛应用,在铝合金领域也有一定应用[5]。图1所示为不同冷却介质的冷却速率[6]。从图1中可以看出,15%PAG溶液冷却速率处于室温水冷却和淬火油之间。在高于700 ℃时,PAG溶液的冷却速率随着温度的降低而逐渐升高,在约700 ℃时,达到峰值,约120 ℃/s;当温度低于700 ℃时,PAG的淬火冷却速率随着温度的降低逐渐降低,500 ℃时达到约75 ℃/s。相比之下,水在各个温度段的冷却速率都相对较大。PAG的冷却速率特性使得钛合金在淬火时,通过控制浓度和温度,可以使合金在淬火敏感区间段具有较高的冷却速率,保证合金具有较好的固溶效果[7]。低温段合金的冷却速率变小,减小了合金的低温冷却阶段的淬火应力,减小了合金圆盘的形变量。

表1 不同淬火冷却方式时圆盘翘曲形变量

Table 1 Quenching distortion of TC4 alloy with different cooling mode

图1 不同冷却介质的冷却速率[6]

Fig. 1 Cooling rates of different cooling media[6]

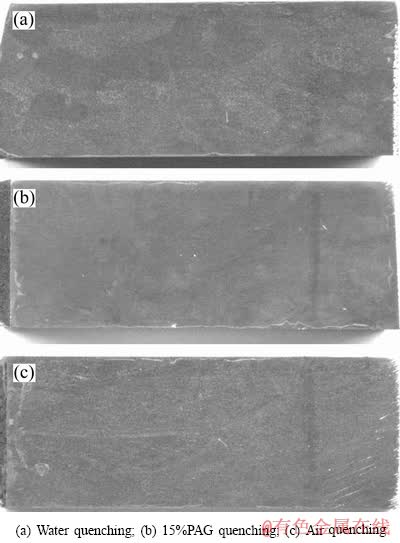

2.2 金相组织观察

图2所示为不同淬火介质淬火处理后圆盘的低倍组织相片。从图2中可以看出,3种介质淬火热处理工艺对应合金的低倍组织均为模糊晶,说明板材轧制过程中粗大的晶粒已被充分破碎,若后续热处理温度选择合理[8],则冷却速率对合金淬火后低倍组织影响小。

图2 不同冷却方式处理的合金

Fig. 2 Macrostructure of TC4 alloy with different cooling modes

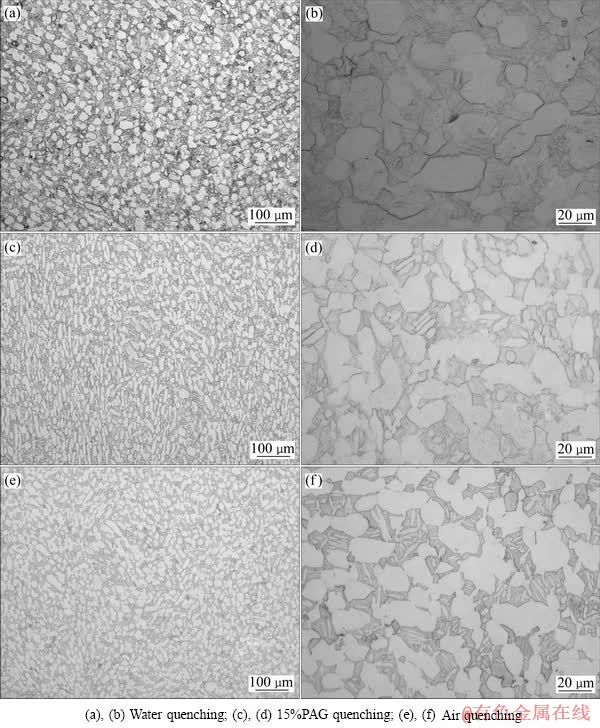

图3所示为3种冷却介质淬火后合金的高倍组织。观察结果表明,3种热处理工艺处理合金的中等轴组织约占70%,这是由于固溶热处理温度较低,940 ℃的固溶温度处于合金的两相区下部,该温度下仅有少量初生α相转变为β相。在水冷+时效的组织中,固溶处理保留了大量β相,β相在后续时效过程中转变为细小的α相[9],在金相组织中难以看清。在15%PAG淬火试样对应的照片中,能够观察到少量的片层状β转变组织,而强制风冷对应的合金组织为典型的双态组织,片层状的β转变组织较为明显。

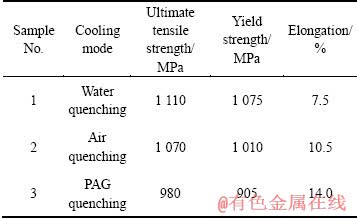

2.3 常规力学性能测定

测定了3种冷却方式处理的淬火圆盘的常规力学性能,其试验结果如表2所列。从测试结果可以看出,水冷试件的性能强度最好,15%PAG冷却试件的性能强度次之,风冷试件的性能强度最低,但伸长率呈现相反顺序。这主要是由于合金在高温固溶时,部分初生α相转变为β相,随后的快速冷却使得β相来不及向α相转变,形成过饱和固溶体,并在后续的时效过程中形成细小的次生α相分布于β基体上,使得合金的强度升高。冷却速率越大,形成的过饱和固溶体中的固溶度越高,时效析出动力学越大,形成的析出强化相越多,合金的强度越高。当固溶-时效工艺采用水冷时,合金具有最高的强度,但其伸长率较低,综合性能相对较差。采用风冷时,合金虽然具有较高的塑性,但屈服强度、抗拉强度均较低,仅略高于退火态合金的[10]。15%PAG冷却由于冷却速度介于空冷和风冷之间,其综合力学性能最好。

图3 不同冷却方式处理的合金的显微组织

Fig. 3 Microstructures of TC4 alloy with different cooling modes

表2 不同冷却速率对圆盘的常规力学性能的影响

Table 2 Effect of cooling rate on mechanical properties of TC4 alloy

3 结论

1) PAG溶液可以在保证组织、力学性能变化不大的前提下,尽可能减小钛合金构件的淬火变形。

2) 与室温水冷、强制风冷淬火相比,采用15% PAG溶液(25 ℃)冷却,TC4合金圆盘的形变小,综合性能好。

3) 钛合金薄壁圆盘件采用室温水淬火后,合金的翘曲大、伸长率低,综合性能差。

REFERENCES

[1] LUTJERING G, WILLIAMS J C. Titanium[M]. Germany: Springer, 2003.

[2] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Materials Science and Engineering A, 2002, 325: 3219-3229.

[3] 史小云, 付宝全, 王文盛, 唐晓东, 陈小苗. 锻造温度对TC4-DT 钛合金棒材力学性能及显微组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s79-s82.

SHI Xiao-yun, FU Bao-quan, WANG Wen-sheng, TANG Xiao-dong, CHEN Xiao-miao. Effect of forging temperature on mechanical property and microstructure of TC4-DT titanium[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(S1): s79-s82.

[4] 王大刚, 陈明和, 王 宁, 谢兰生. 基于激光预焊芯板夹层的超塑成形/扩散连接先进工艺[J]. 中国有色金属学报, 2013, 23(6): 1536-1541.

WANG Da-gang, CHEN Ming-he, WANG Ning, XIE Lan-sheng. Advanced technology of superplastic forming and diffusion bonding with laser prewelding core sheets[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1536-1541.

[5] 李培跃, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 淬火介质对7050铝合金末端淬特性的影响[J].中国有色金属学报, 2011, 21(3): 513-521.

LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Effect of quenching media on Jominy end quench behavior of 7050 Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(3): 513-521.

[6] TANNER D A, ROBINSON J S. Effect of precipitation during quenching on the mechanical properties of the aluminium alloy 7010 in the W-temper[J]. Journal of Materials Processing Technology, 2004, 153/154: 998-1004.

[7] 李培跃, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋, 刘红伟. 7050铝合金淬火特性与微观组织[J]. 中国有色金属学报, 2011, 21(5): 961-967.

LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Precipitation behavior of quench-induced precipitates of 7050 alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 961-967.

[8] GIL F J, GINEBRA M P, MANERO J M. Formation of a- structure: Effects of grain size and cooling rate on the

structure: Effects of grain size and cooling rate on the  morphologies and on the mechanical properties in Ti6Al4V alloy[J]. Journal of Alloys and Compounds, 2001, 329(1/2): 142-152.

morphologies and on the mechanical properties in Ti6Al4V alloy[J]. Journal of Alloys and Compounds, 2001, 329(1/2): 142-152.

[9] AHMED T, RACK H J. Phase transformations during cooling in α+β titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 206-211.

[10] LUTJERING G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-45.

(编辑 杨 华)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:李培跃,高级工程师,博士;电话:0379-67256964;E-mail: lpy110015@163.com