文章编号:1004-0609(2015)-11-3155-09

超重力强化结晶硅与熔析剂的高温分离

陈 杭1, 2,王 志1,池汝安3,靖青秀2,孙丽媛1,杜 冰1

(1. 中国科学院 过程工程研究所,北京 100190;

2. 江西理工大学 冶金与化学工程学院,赣州 341000;

3. 武汉工程大学 绿色化工过程教育部重点实验室,武汉 430073)

摘 要:针对熔析结晶精炼冶金硅过程中硅与熔析剂分离难的问题,采用高温离心装置通过超重力作用强化固-液相分离过程,研究高温离心分离效率及其影响因素,并探讨高温熔体液固分离过程的物理作用机理。结果表明:增大超重力系数和延长处理时间能提高分离效果,提高处理温度将导致硅收率降低。在600 ℃、400 G(超重力系数)操作1 h时,分离硅的质量分数高达95%,硅的回收率为95%。与直接酸洗分离工艺相比将减少90%以上的耗酸量,并实现熔析剂的直接回收。最后,分析超重力分离过程中的液体赋存状态及其的物理作用机制。

关键词:铝硅合金;熔析剂;超重力;离心分离

中图分类号:TF114 文献标志码:A

High temperature separation between silicon and liquation agent after solvent refining enhanced by super gravity force

CHEN hang1, 2, WANG zhi1, CHI Ru-an3, JING Qing-xiu2, SUN Li-yuan1, DU Bing1

(1. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,

Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100190, China;

2. School of Metallurgy and Chemical Engineering,

Jiangxi University of Science and Technology, Ganzhou 341000, China;

3. Key Laboratory for Green Chemical Process, Ministry of Education,

Wuhan Institute of Technology, Wuhan 430073, China)

Abstract: For the difficult separation problem of silicon and liquation agent in solvent refining of metallurgical silicon, high temperature centrifugal device was employed to intensify the separation process by super-gravity. The efficiency and its influence factors of high temperature centrifugal separation were studied, and the physical mechanism of high temperature separation process of molten liquid and solid was also explored. The results show that the increase of super-gravity coefficient and processing time can improve the effect of separation, whereas increasing the temperature leads to decline of silicon yield. Under 600 ℃ and 400 G (supergravity coefficient) for 1 h, the separation of silicon (mass fraction is up to 95%, and the recovery rate of silicon is 95%. Compared with the direct pickling process, there is a reduction in acid consumption more than 90%, and the solvent can be directly recycled. Finally, the liquid state and physical mechanism of super gravity separation process were briefly demonstrated.

Key words: Al-Si alloy; solvent refining; super-gravity; centrifugal separation

随着地球上化石能源的日益减少,新能源受到人们越来越多的重视。太阳能以其分布广泛储量丰富清洁无污染等优点备受人们的关注,太阳能的研究和应用也成为人类能源发展的主要方向之一[1-4]。

制备太阳能电池的主要原料是高纯太阳能级多晶硅。目前,太阳能级硅的制备工艺主要采用改良西门子法[5],该工艺生产流程长、成本高、污染重。因此,国内外都在积极寻找新的提纯硅工艺,如造渣精炼[6-10]、定向凝固[11-12]、等离子体精炼[13]、真空电子束精炼[14-16]、熔析精炼[17-19]等。熔析精炼作为一种新的提纯工艺,可以使冶金硅在低温下结晶,使净化实现低温操作,在一定温度范围内可以降低硅中杂质的固溶度[20],提高净化除杂的效果,降低除杂过程的总能耗。

熔析精炼法可有效去除硅中杂质,但其面临诸多问题,包括结晶硅与熔析剂的高效分离问题。熔析精炼后析出硅弥散分布在合金熔剂中,如何将其与熔剂有效分离是关键环节。国内外学者采用多种方法来解决这个问题:JUNEJA等[21]和GUMASTE等[22]采用直接酸洗的办法来去除熔析剂,酸洗除去合金介质虽然有效但因耗费大量的酸液,并损失大量的熔析剂,造成生产成本的增加和资源的浪费。YOSHIKAWA等[23]和MA等[24]利用交变磁场洛伦兹力的作用,将形成的硅颗粒富集至坩埚底部,此后采用感应定向凝固对Al-Si和Sn-Si体系进行了分离实验,实现了初步粗分离。ESFAHANI 等[25]将熔析后的铁硅合金淬火破碎,再采用液体重介质选矿的方法,利用硅与铁硅的密度差实现了二者的分离。LI等[26-27]在Al-Si合金的重结晶过程中施加超重力,使熔体中的晶体硅富集到坩埚底部,实现了硅与合金的预分离。HU等[28]采用离心分离的工艺来实现硅与熔析剂的一次分离。为了明确高温离心分离的影响因素,探索高温超重力下硅与熔析剂的分离机制,本文作者着重研究超重力分离硅与熔析剂的效果,并解析其分离机理。

1 实验

1.1 实验原料及设备

试验用原料为工业级冶金硅,纯度为99.8%(质量分数),高纯铝,纯度为99.999%。试验设备主要有真空管式炉和高温超重力装置。

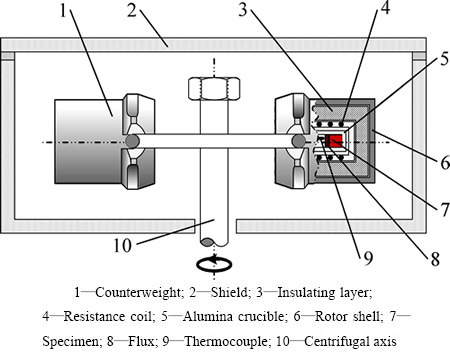

图1 高温超重力相分离装置示意图

Fig. 1 Schematic diagram of high-temperature super-gravity equipment

高温超重力装置如图1所示。该装置主要由离心旋转系统与加热系统两部分组成。通过离心旋转的方式产生超重力,离心旋转速度N最高可达5000 r/min,最高试验温度为1200 ℃。定义超重力系数G为离心旋转状态下重力系数与静止状态下重力系数之比,如式(1)所示:

(1)

(1)

式中:N为离心机转速,r/min;R为旋转轴与试样间距离,0.25 m;g为重力加速度,9.8 m/s2。

1.2 实验步骤

将Si-Al按一定配比混匀,装入石墨坩埚。再将样品放入管式炉,进行熔析精炼形成合金锭块。取出合金块锭破碎成小颗粒后放入自制的过滤坩埚,将过滤坩埚放入图1的高温超重力装置中,升至一定温度后采用不同强度的超重力进行分离。自制分离装置如图2所示。对图2(a)~(c)中的样品分别进行研磨和抛光处理,利用XRD进行物相分析。将图2(b)中的样品溶样后,利用ICP分析物料中熔析剂中金属铝的含量。

图2 超重力相分离坩埚示意图

Fig. 2 Schematic diagram of homemade super-gravity equipment

1.3 数据处理方法

为了方便描述实验过程,采用表达式如式(2)和(3)所示:

1) 结晶硅的回收率(ηre)表达式为

(2)

(2)

式中: 为由相图计算得出理论可被富集结晶硅的质量;

为由相图计算得出理论可被富集结晶硅的质量; 为酸洗后得到结晶硅的质量。

为酸洗后得到结晶硅的质量。

2) 合金去除率(η)表达式为

(3)

(3)

式中: 为由相图计算得出理论可被分离合金熔剂的质量;

为由相图计算得出理论可被分离合金熔剂的质量; 为实际分离出的合金熔剂的质量。

为实际分离出的合金熔剂的质量。

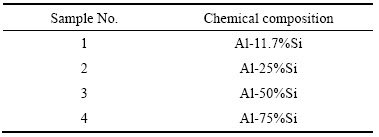

3) 采用编号来代表不同的合金比例试样,如表1所列。

表1 合金比例试样与编号对应表

Table 1 Alloy ratio corresponding to serial number

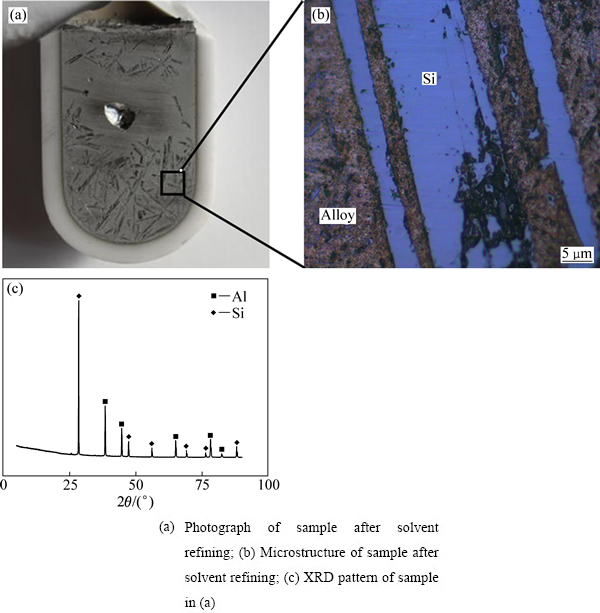

图3 常重力合金形貌及XRD谱

Fig. 3 Photographs and XRD pattern of sample before centrifugal separation

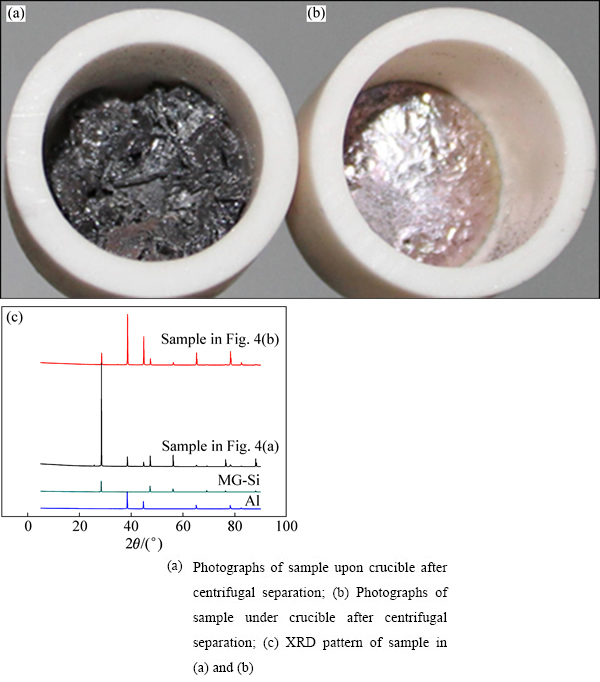

图4 超重力处理后样品形貌和XRD谱

Fig. 4 Photographs and XRD pattern of sample after centrifugal separation

2 结果与分析

2.1 实验样品的表征

Al-50%Si(摩尔分数)合金在真空管式炉中进行熔析精炼后形成的合金锭如图3(a)所示,可以看出常重力精炼后有针状物弥散分布在合金锭中。光学显微分析显示针状物质为结晶硅,如图3(b)所示。铝硅合金包围在针状结晶硅四周并粘连在一起,难以借助密度差等性质实现有效相分离。对合金锭进行XRD物相分析,如图3(c)所示。由图3(c)可以看出,其中硅与铝都显示出较强的衍射峰。

图4所示为Al-50%Si合金物料在600 ℃、超重力系数为300 G时处理1 h后的样品。为了验证超重力的分离效果,对图4(a)和(b)中的取样进行了XRD物相分析,实验结果如图4(c)所示。与图3(c)相比图4(c)中样品a的Si衍射峰变强,Al的衍射峰变弱,这表明图4(a)样品中结晶硅实现富集。与图3(c)相比图4(c)中样品b的Al衍射峰明显得到加强,这表明图4(b)样品中合金液实现富集。

2.2 超重力系数对分离效果的影响

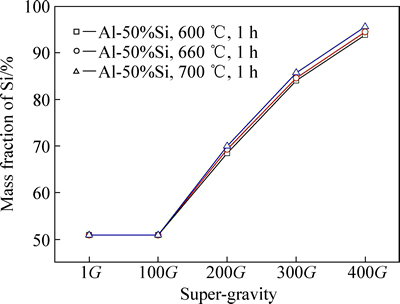

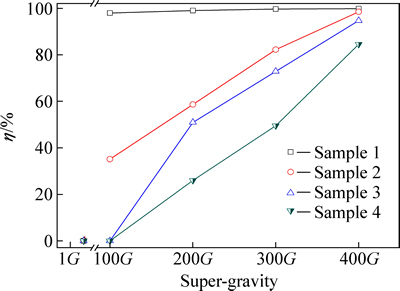

为了定量分析超重力分离的效果,采用上部坩埚中硅的质量分数作为衡量标准。本实验首先考察超重力系数对分离效果的影响,结果如图5所示。

图5 不同超重力系数下结晶硅质量分数的变化

Fig. 5 Variation of Si mass fraction at different super-gravities

由图5可以看出Al-50%Si在1 G和100 G下分离后Si的质量分数都为50.9%,即Al-50%Si,因此,没有实现分离。当超重力系数大于100 G时即出现相分离,在600~700 ℃范围内,结晶硅质量分数随着超重力系数的增大而提高。当超重力系数为200 G、300 G和400 G时,结晶硅质量分数分别提升至70%、85%和95%,即结晶硅中残留合金熔剂的量分别为30%、15%、5%。以Al-50%Si基准折算出合金去除率,400 G时合金熔剂去除率可达90%以上,即可直接回收合金熔剂的量大于90%。也就是说,与直接酸洗合金熔剂全部离子化进入溶液相比,400 G时超重力离心分离可节约酸消耗量90%以上。

2.3 温度对超重力分离效果的影响

在600~900 ℃范围内选取几组不同处理温度,考察了温度对高温超重力分离效果的影响,其结果如图6所示。

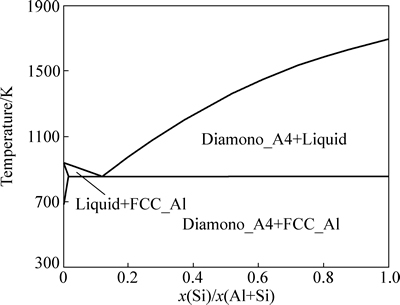

由图6(a)可以看出,在同一超重力系数下,分离结晶硅的质量分数受温度的影响变化不明显。当超重力系数为400 G时,结晶硅的质量分数在95%左右波动。图6(b)所示为不同温度下结晶硅的回收率。由图6(b)可知,在600~650 ℃条件下,随着超重力系数的增加,结晶硅的回收率出现小幅的下降。当温度大于650 ℃时,随着超重力系数的增加,结晶硅的回收率出现显著的下降。超重力系数为400 G时,600 ℃下结晶硅的回收率为97.1%,而850 ℃下硅的回收率仅为60%左右。为了解释这个现象,分析了 Al-Si二元合金相图,如图7所示。由杠杆原理可知,随着温度的增加,液相组成发生显著变化。当温度为650 ℃(823.15 K)时,液相组成为Al-13.8%Si,当温度为850 ℃(1023.15 K)时,液相组成为Al-31.3%Si。然而,由图6(b)可知,在650℃时,硅的回收率出现明显降低,与铝硅合金相同液相线的变化并不一致,这可能是由于不同温度条件下合金液相黏度和表面张力的变化所导致的,其机理有待进一步研究。

图6 不同温度条件下Al-50%Si分离1 h的效果

Fig. 6 Separation effects of Al-50%Si in different temperatures for 1 h

图7 Al-Si二元合金相图

Fig. 7 Binary phase diagram of Al-Si

从总体趋势来说,在高温超重力分离过程中,为了确保硅的回收率,应根据相图液相线组成,确定分离合适的温度。

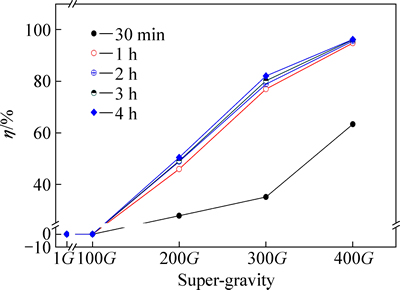

2.4 处理时间对超重力分离效果的影响

超重力分离过程中,处理时间对合金去除率有明显影响。本实验选取5个操作时间,在不同超重力系数下获得相应的合金去除率,如图8所示。由图8可以看出,在200 G条件下处理30 min时,合金去除率为35%左右。当操作时间延长至1 h时,合金去除率提升至42%。操作时间延长到1 h以上时,合金去除率逐步提升,但合金去除速率却不断下降,相同超重力系数下延长处理时间对分离效果影响不大。当操作时间达到4 h时,与3 h的效果相比,合金去除率仅提升不足1%。当超重力系数达到400 G时,处理时间超过1 h后合金去除率均在95%左右。

图8 不同处理时间时分离效果的变化(Al-50%Si,600 ℃)

Fig. 8 Variation of separation effect in different working time

2.5 合金比例对超重力分离效果的影响

图9所示为在600 ℃、1 h下不同合金比物料的超重力分离效果。由图9可以看出常重力条件下(超重力系数为1 G),4个试样均没有出现分离现象。而当超重力系数为100 G时,硅比例较低的样品1(Al-11.7%Si)与样品2(Al-25%Si)出现分离现象。样品1合金熔剂去除率高达98%,明显要高于样品2的,而样品3(Al-50%Si)与样品4(Al-75%Si)均未发生分离现象。当超重力系数大于200 G时,4个组成样品中均发生分离。由此可推测,随着合金中硅比例的升高,相分离所需的超重力系数逐渐增大,分离难度亦随之增加。

图9 在600 ℃、1 h下不同合金比物料的超重力分离效果

Fig. 9 Separation effect of sample with different alloy ratios at 600 ℃ for 1 h

2.6 超重力强化高温合金相分离过程作用机理

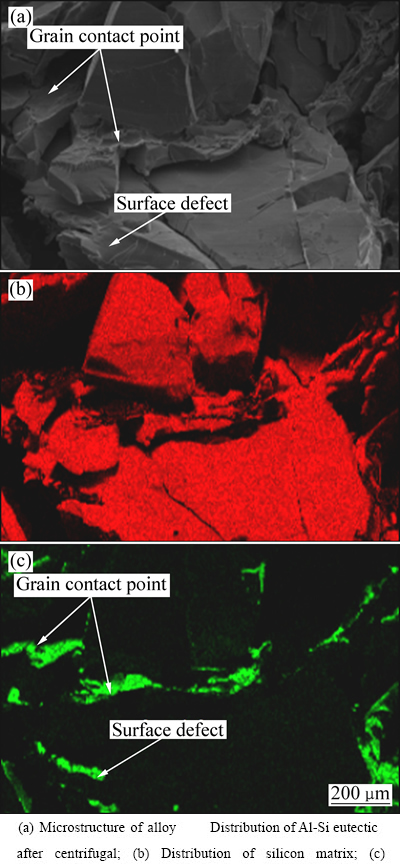

为了解释上述的现象,利用SEM对超重力处理后硅晶体表面残存的合金的赋存状态进行了分析,如图10所示。

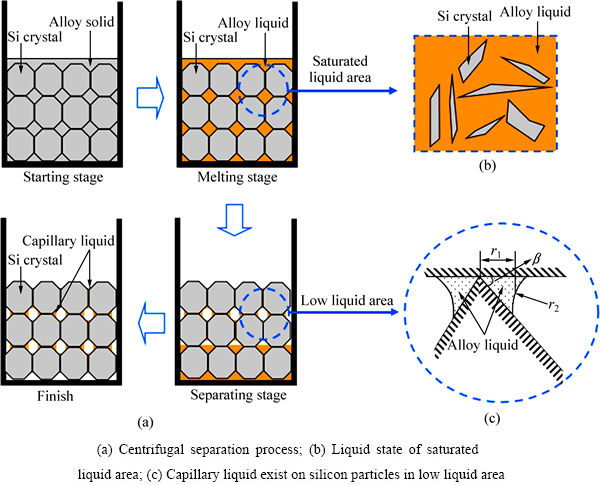

由图10可知,与图3(b)所示的常重力条件下结晶硅被合金熔剂完整包裹不同,超重力分离后的结晶硅中合金熔剂主要赋存于硅颗粒间的接触处和颗粒自身的表面缺陷处,合金熔剂的尺寸约为50~400 μm,并且这些合金熔剂的表面多为复杂曲面,与SOKOLOV等[29]所描述的离心固液分离后期液体在固体颗粒间形成凹形弯月形液面的赋存状态一致。结合实验结果与理论分析,建立了高温体系下超重力强化合金相分离过程模型,如图11所示。由图11(a)可知,整个分离过程可分为4个阶段:初始阶段、熔化阶段、分离阶段、分离结束。在一定温度下,合金锭中的熔析剂受热熔化成液相,并在超重力作用下,呈液相的合金熔剂将与固体结晶硅相分离。

在此分离过程中,液相在硅颗粒间的分布存在饱和液相区和低液相区两种状态。在饱和液相区中,充足的液体将每个硅颗粒都能很好地包裹起来,液体在硅颗粒中呈连续的状态,如图11(b)所示。去除饱和液相区的液体仅需克服硅与合金熔剂间的粘滞作用。而在低液相区,由于液体表面张力的作用,液体不能在硅颗粒中铺开,而是以弯月形聚集于各颗粒的接触处,如图11(c)所示。若要去除低液相区需先使液体从凹形弯液面中脱除,此时需克服毛细管压力p。该压力可利用拉普拉斯公式确定[30],如式(4)所示:

(4)

(4)

式中: ;σ为合金液表面张力;β为接触角度。

;σ为合金液表面张力;β为接触角度。

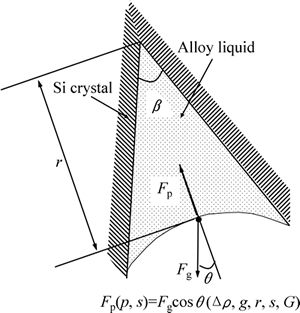

为了能更清晰的表达毛线管压力的作用,建立了合金熔剂在超重力与毛线管压力作用下的受力分析模型,如图12所示,假设在整个凹形弯月形液面中,液面高度r变化忽略不计,则可得

(5)

(5)

式中: 为合金熔剂与空气的密度差。结合式(4)与式(5)可知,残余合金熔剂量主要与熔体表面张力、固体硅颗粒接触角的方向与大小、超重力系数以及固体硅颗粒接触角有关。

为合金熔剂与空气的密度差。结合式(4)与式(5)可知,残余合金熔剂量主要与熔体表面张力、固体硅颗粒接触角的方向与大小、超重力系数以及固体硅颗粒接触角有关。

图10 400 G超重力分离后合金熔剂赋存状态的SEM像

Fig. 10 SEM images of occurrence state of Al-Si eutectic after 400 G centrifugal separation

图11 超重力分离行为示意图

Fig. 11 Schematic diagram of centrifugal separation behavior

图12 毛线管液体受力分析

Fig. 12 Force analysis of capillary liquid

当固体硅颗粒结点角度 时并且θ为0°时,可获得相应的r-G的对应关系,如图13所示。由图13可知,当毛细管液体高度为1000 μm时,分离所需的超重力系数仅为39 G。当毛细管液体高度为50 μm时,分离所需的超重力系数为15626 G。而从图13中右上角的内嵌图可知,当超重力系数为400 G时,毛细管液体的高度为300 μm,而从图10中可观察到的合金熔剂尺寸大都处于这一尺寸附近。

时并且θ为0°时,可获得相应的r-G的对应关系,如图13所示。由图13可知,当毛细管液体高度为1000 μm时,分离所需的超重力系数仅为39 G。当毛细管液体高度为50 μm时,分离所需的超重力系数为15626 G。而从图13中右上角的内嵌图可知,当超重力系数为400 G时,毛细管液体的高度为300 μm,而从图10中可观察到的合金熔剂尺寸大都处于这一尺寸附近。

由此可知,随着合金熔剂比例的减小,合金熔剂的赋存状态发生了改变,分离难度急剧增大。因此,图9中的高合金熔剂比例样品易分离,低合金熔剂比例样品难分离。张文军等[30]在研究非饱和阶段的滤渣脱水过程时也指出,提高超重力系数可以减少毛细液的含量,降低滤渣残余水分。但是,由图13可知,随着r的减小,G急剧增大并趋近无穷大。因此,最终无论如何增大超重力系数,毛细管液体都无法克服p而完全去除。

综上分析,在超重力分离过程中,随着分离过程的进行,结晶硅颗粒表面合金液体的存在形式也发生转变,这可能是导致物料中液体无法完全去除的主要原因。因此,超重力分离无法将物料中的合金熔剂完全去除,但少量残余的合金熔剂可通过后续的太阳能级多晶硅提纯工艺如酸洗来去除。

图13 r-G关系图

Fig. 13 r-G diagram

3 结论

1) 超重力作用可有效实现结晶硅与铝硅合金的高温相分离。Al-50%Si经过超重力分离,获得的结晶硅中仅夹带3.58%的合金熔剂,分离获得的96.24%的合金熔剂可有效回收进行循环利用。此方法与直接酸洗离子化分离合金熔剂相比,可减少90%以上的耗酸量。

2) 重点考察超重力系数、分离温度、分离时间及合金熔剂比例对高温相分离的影响。其中,超重力系数的提高能显著改善高温相分离效果。分离温度的改变会影响合金熔剂相组成,从而导致结晶硅回收率的变化,在600 ℃温度下可获得最佳回收率为97.1%。分离时间的延长并未提高分离效率,反而使得合金熔剂的含量将不断减少,分离难度增大,分离速率急剧下降。

3) 在高温合金相分离后期,随着合金熔剂含量的减少,液体将集结在结晶硅颗粒表面缺陷处和结晶硅颗粒间的接触处,形成毛线管液体。毛细管液体的减少导致毛细管压力急剧增大,从而使得残余液体难以分离。

REFERENCES

[1] FERRAZZA F. Large size multicrystalline silicon ingots[J]. Solar Energy Materials and Solar Cells, 2002, 72(1): 77-81.

[2] YANG H,WANG H, YU H, XI J, CUI R, CHEN G. Status of photovoltaic industry in China[J]. Energy Policy, 2003, 31(8): 703-707.

[3] ZHAO Y. The present status and future of photovoltaic in China[J]. Solar Energy Materials and Solar Cells, 2001, 67(1): 663-671.

[4] PENG K Q, LEE S T. Silicon nanowires for photovoltaic solar energy conversion[J]. Advanced Materials, 2011, 23(2): 198-215.

[5] ZULEHNER W. Historical overview of silicon crystal pulling development[J]. Materials Science and Engineering B, 2000, 73(1): 7-15.

[6] 蔡 靖, 陈 朝, 罗学涛. 高纯冶金硅除硼的研究进展[J]. 材料导报, 2009, 23(12): 81-100.

CAI Jing, CHEN Chao, LUO Xue-tao. Research process in boron removal of UMG silicon[J]. Materials Review, 2009, 23(12): 81-100.

[7] 龙桂华, 吴 彬, 韩 松, 邱克强. 太阳能级多晶硅生产技术发展现状及展望[J]. 中国有色金属报, 2008, 18(1): 386-392.

LONG Gui-hua, WU Bin, HAN Song, QIU Ke-qiang. Development status and prospect of solar grade silicon production technology[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 386-392.

[8] JOHNSTON M D, BARATI M. Effect of slag basicity and oxygen potential on the distribution of boron and phosphorus between slag and silicon[J]. Journal of Non-Crystalline Solids, 2011, 357(3): 970-975.

[9] KRYSTAD E, TANG K, TRANELL G. The kinetics of boron transfer in slag refining of silicon[J]. JOM, 2012, 64(8): 968-972.

[10] WU Ji-jun, LI Yan-long, MA Wen-hui, WEI Kui-xian, YANG Bin, DAI Yong-nian. Boron removal in purifying metallurgical grade silicon by CaO-SiO2 slag refining[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1231-1236.

[11] MA X, ZHENG L, ZHANG H, ZHAO B, WANG C, XU F. Thermal system design and optimization of an industrial silicon directional solidification system[J]. Journal of Crystal Growth, 2011, 318(1): 288-292.

[12] MARTORANO M A, NETO J B, OLIVEIRA T S, TSUBAKI T O. Refining of metallurgical silicon by directional solidification[J]. Materials Science and Engineering B, 2011, 176(3): 217-226.

[13] NAKAMURA N, BABA H, SAKAGUCHI Y, HIWASA S, KATO Y. Boron removal in molten silicon with steam added plasma melting method[J]. Journal of the Japan Institute of Metals, 2003, 67(10): 583-589.

[14] YUGE N, HANAZAWA K, KATO Y. Removal of metal impurities in molten silicon by directional solidification with electron beam heating[J]. Materials Transactions-JIM, 2004, 45(3): 850-857.

[15] HANAZAWA K, YUGE N, HIWASA S, KATO Y. Evaporation of phosphorus in molten silicon with electron beam irradiation method[J]. Journal of the Japan Institute of Metals, 2003, 67(10): 569-574.

[16] GUMASTE J L,MOHANTY B C,GALGALI R K, SYAMAPRASAD U,NAYAK B B,SINGH S K,JENA P K. The characterization of high quality multicrystalline silicon by the electron beam induced current method[J]. Journal of Physics: Condensed Matter, 2004, 16(2): 211.

[17] 巫 剑, 王 志, 胡晓军, 郭占成, 范占军, 谢永龙. Si-Sn合金精炼-定向凝固过程硅的分离和提纯[J]. 中国有色金属学报, 2014, 24(7): 1871-1877.

WU Jian, WANG Zhi, HU Xiao-jun, GUO Zhan-cheng, FAN Zhan-jun, XIE Yong-long. Separation and purification of silicon by combined Si-Sn alloy refining and directional solidification process[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1871-1877.

[18] YOSHIKAWA T, MORITA K. Refining of silicon during its solidification from a Si-Al melt[J]. Journal of Crystal Growth, 2009, 311(3): 776-779.

[19] YOSHIKAWA T, MORITA K. Removal of phosphorus by the solidification refining with Si-Al melts[J]. Science and Technology of Advanced Materials, 2003, 4(6): 531-537.

[20] TANG K,  J,TRANELL G, TANGSTAD M. Thermochemical and kinetic databases for the solar cell silicon materials[M]//Crystal growth of Si for solar cells. Berlin: Springer, 2009: 219-251.

J,TRANELL G, TANGSTAD M. Thermochemical and kinetic databases for the solar cell silicon materials[M]//Crystal growth of Si for solar cells. Berlin: Springer, 2009: 219-251.

[21] JUNEJA J M, MUKHERJEE T K. A study of the purification of metallurgical grade silicon[J]. Hydrometallurgy, 1986, 16(1): 69-75.

[22] GUMASTE J L,MOHANTY B C,GALGALI R K, SYAMAPRASAD U,NAYAK B B,SINGH S K,JENA P K. Solvent refining of metallurgical grade silicon[J]. Solar Energy Materials, 1987, 16(4): 289-296.

[23] YOSHIKAWA T, MORITA K. Cutting edge of electromagnetic processing for materials: Refining of Si by the solidification of Si-Al melt with electromagnetic force[J]. ISIJ International, 2005, 45(7): 967-971.

[24] MA X, YOSHIKAWA T, MORITA K. Si growth by directional solidification of Si–Sn alloys to produce solar-grade Si[J]. Journal of Crystal Growth, 2013, 377: 192-196.

[25] ESFAHANI S, BARATI M. Purification of metallurgical silicon using iron as an impurity getter part I: Growth and separation of Si[J]. Metals and Materials International, 2011, 17(5): 823-829.

[26] LI J, GUO Z,TANG H, ZHI W, SUN S. Si purification by solidification of Al-Si melt with super gravity[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 958-963.

[27] LI J, GUO Z. Thermodynamic evaluation of segregation behaviors of metallic impurities in metallurgical grade silicon during AlSi solvent refining process[J]. Journal of Crystal Growth, 2014, 394: 18-23.

[28] HU L,WANG Z, GONG X, GUO Z,ZHANG H. Impurities removal from metallurgical-grade silicon by combined Sn-Si and Al-Si refining processes[J]. Metallurgical and Materials Transactions B, 2013, 44(4): 828-836.

[29] SOKOLOV B. 离心分离原理及设备[M]. 汪泰临, 等译. 北京: 机械工业出版社, 1986: 274-327.

SOKOLOV B. The principle and equipment of centrifugal separation[M]. WANG Tai-lin, et al, translate. Beijing: China Machine Press, 1986: 274-327.

[30] 张文军, 欧泽深, 李延锋, 高 敏. 煤泥离心甩干过程的综合助滤机理研究[J]. 中国矿业大学学报, 2003, 32(6): 705-708.

ZHANG Wen-jun, OU Ze-shen, LI Yan-feng, GAO Min. Study into mechanism of strengthening centrifugal filtering of coal slime[J]. Journal of China University Mining & Technology, 2003, 32(6): 705-708.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51174187,51422405,51404229)

收稿日期:2015-03-13;修订日期:2015-08-10

通信作者:王 志,研究员,博士;电话:010-82544818;E-mail:zwang@home.ipe.ac.cn