文章编号:1004-0609(2015)09-2358-08

过共晶铝硅合金的高温力学性能及显微组织演变

刘 芳1,于福晓1,张祎玲2,赵大志1,许 茜1,左 良3

(1. 东北大学 材料与冶金学院,沈阳 110819;

2. 上海空间推进研究所,上海 201112;

3. 东北大学 材料各向异性与织构教育部重点实验室,沈阳 110819)

摘 要:研究温度、保温时间及拉伸速度对半连续铸造Al-13.7Si合金高温力学性能和显微组织的影响。结果表明:半连续铸造Al-13.7Si合金在450℃拉伸时伸长率达到85.34%;Al-13.7Si合金表现出较高的高温塑性主要是由整个铝基体向细化的等轴晶转变引起的;Al-13.7Si合金适宜的热变形温度为450~500 ℃;当热变形温度高于450 ℃时,随着温度的升高或保温时间的延长,合金的伸长率和抗拉强度均呈下降趋势;随着拉伸速度的降低,各温度下合金的抗拉强度下降,而伸长率呈上升趋势。

关键词:铝硅合金;高温力学性能;组织演变;过共晶

中图分类号:TG146.2 文献标志码:A

High-temperature mechanical properties and microstructure evolution of hypereutectic Al-Si alloy

LIU Fang1, YU Fu-xiao1, ZHANG Yi-ling2, ZHAO Da-zhi1, XU Qian1, ZUO Liang3

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China;

2. Shanghai Institute of Space Propulsion, Shanghai 201112, China;

3. Key Laboratory for Anisotropy and Texture of Materials, Ministry of Education,

Northeastern University, Shenyang 110819, China)

Abstract: The high-temperature mechanical properties and microstructure of DC cast hypereutectic Al-13.7Si alloy were investigated at different temperatures, holding time and tensile velocities. The results show that the elongation of Al-13.7Si alloy is 85.43% at 450℃. Excellent ductility of the studied alloy at high temperature is due to the transformation of fine equiaxed grains in the whole Al matrix. The suitable hot deformed temperature of Al-13.7Si alloy is from 450 ℃ to 500 ℃. When the temperature of tensile is higher than 450 ℃, with increasing the temperature or prolonging the holding time, the elongation and tensile strength of the Al-13.7Si alloy decrease. With decreasing the tensile velocity, the tensile strength decreases while the elongation of the Al-13.7Si alloy increases.

Key words: Al-Si alloy; high temperature mechanical property; microstructure evolution; hypereutectic

铝硅合金具有密度低、热膨胀系数小、尺寸稳定、铸造性能、耐磨性及耐蚀性良好等优点,因此被广泛应用于汽车、摩托车、航空航天工业等领域[1-3]。铸造铝硅合金特别是过共晶铝硅合金组织中硅相难以细化,变形时由于脆性的初晶硅和共晶硅易于断裂导致材料塑性差,限制了合金作为变形合金使用。对于普通凝固主要采用添加变质剂的方式改善合金的显微组织,从而提高合金的塑性[4-5]。通过快速凝固/粉末冶金技术也可显著细化铝硅合金组织,使过共晶Al-Si合金成为变形合金[6-7],但是这些方法过程复杂、成本高。目前,本文作者所在课题组利用半连续铸造(DC)技术在不添加变质剂的条件下已经获得具有组织显著细化的铝硅合金铸锭,通过热变形获得了组织和性能良好的变形铝硅合金型材[8-9],打破了铝硅合金作为铸造合金使用的工业格局。DC铸造铝硅合金热变形后原铸态组织中α(Al)枝晶完全消失,变形铝硅合金的组织特点是大量细小的硅颗粒均匀、弥散地分布在等轴晶铝基体上[8]。

为全面了解DC铸造铝硅合金的热变形组织特点以及高温变形过程的力学行为,本文作者对半连续铸造Al-13.7Si合金进行高温拉伸实验,探讨高温拉伸时温度、保温时间、拉伸速度对合金组织演变和高温力学性能的影响,为过共晶铝硅合金热加工工艺提供理论依据。

1 实验

本实验中以工业纯铝和硅为原料,采用半连续铸造制备直径为50 mm的Al-13.7Si合金圆锭坯,沿圆锭坯铸造方向心部切取高温拉伸试样,拉伸试样以相同的升温速度40 ℃/min加热至不同温度(400、450、500和550 ℃)、进行未保温(t=0 min)和保温时间t=60 min、随后进行拉伸速度(v)分别为0.5和1 mm/min的高温拉伸实验。

在铸锭纵向面心部和高温拉伸试样变形后的变形区、未变形区截取金相试样, 经研磨抛光后,用Leica DMI5000M型金相显微镜观察试样的显微组织;选3个随机视场利用Image-Pro Plus软件统计硅颗粒和等轴晶粒的尺寸;用SANS型微机控制电子万能试验机进行拉伸实验,力学性能指标取4个拉伸试样力学性能的平均值;用SSX-500型扫描电镜观察拉伸试样的断口形貌。

2 结果与分析

2.1 合金的高温力学性能

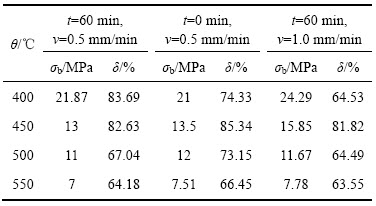

表1所列为DC铸造Al-13.7Si合金在不同高温拉伸条件下的力学性能。由表1可知,当保温时间为60 min、拉伸速度为0.5 mm/min时,随着温度的升高,合金抗拉强度和伸长率降低;当保温时间为0 min、拉伸速度为0.5 mm/min 时,随着保温时间的延长,除400 ℃外,各温度下合金的伸长率和抗拉强度均呈下降趋势;当保温时间为60 min、拉伸速度为1.0 mm/min 时,随着拉伸速度的增加,各温度下合金的抗拉强度增大,而伸长率呈下降趋势。

从DC铸造Al-13.7Si合金的高温力学性能看,在所选取的4个温度下进行拉伸实验时,合金均显示出高伸长率,特别是其在450 ℃热变形所得到的伸长率相对最高,为85.34%,此时合金的抗拉强度为13.5 MPa,尚未见文献报道其他铸态铝合金具有如此高的高温塑性。铸坯塑性好且抗拉强度比较低时的温度区间能达到合金强度和塑性的最佳配合,有利于进行热加工。因此,DC铸造Al-13.7Si合金适宜的热加工温度为450~500 ℃。

表1 不同高温拉伸条件下DC铸造Al-13.7Si合金的力学性能

Table 1 Mechanical properties of DC cast Al-13.7Si alloy under different high temperature tensile conditions

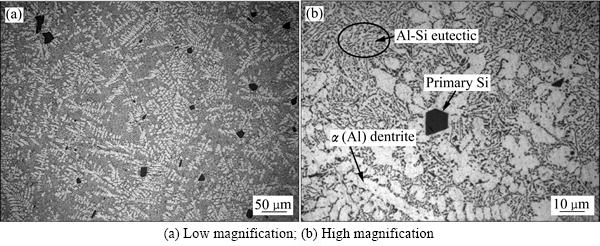

2.2 合金的铸态显微组织

半连续铸造Al-13.7Si合金的组织如图1所示。由图1可知,合金组织主要由初晶硅、α(Al)枝晶和(α+Si)共晶组织组成。初晶硅平均尺寸为10 μm,共晶硅呈纤维状或针状,针状的共晶硅分布在α(Al)枝晶之间,而在没有α(Al)枝晶的区域则为纤维状共晶硅。

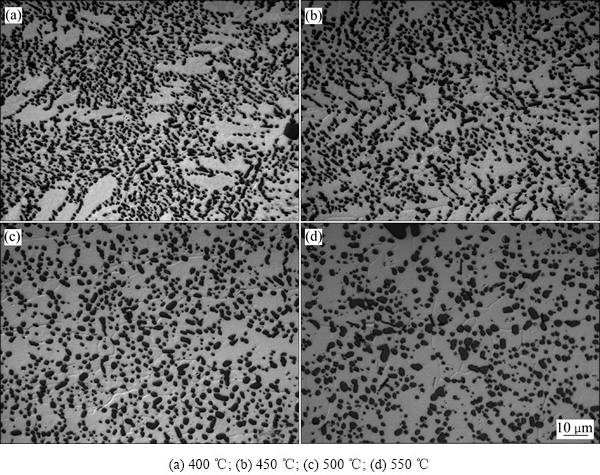

2.3 Al-13.7Si合金高温拉伸试样的显微组织

图2所示为合金拉伸试样加热至不同加热温度后保温60 min、再以拉伸速度为0.5 mm/min进行拉伸实验后变形区的显微组织。经不同温度高温拉伸后,初晶硅形貌尺寸在整个拉伸过程中未发生变化。共晶硅经历了熔断、颗粒化及粗化的过程,其过程主要受硅原子活动和扩散能力的控制,因而明显地受拉伸时的加热温度影响。硅颗粒尺寸随着温度的升高而增大。纤维状共晶硅相在加热保温过程中的颗粒化是一普遍现象[10-12]。从图2可以观察到α(Al)枝晶随温度升高沿着拉伸方向伸长并逐渐消失。铝基体上出现等轴晶粒,铝等轴晶的产生,意味着合金中发生了再结晶。再经400 ℃热变形后,在共晶组织的铝基体上有少量尺寸较小的等轴晶粒出现。经450 ℃热变形后,显然α(Al)枝晶的数量较400 ℃时的大幅度减少,发生再结晶的范围有所扩展。经500 ℃热变形后,组织中α(Al)枝晶已基本消失不见,再结晶范围继续扩大。经550 ℃热变形后等轴晶晶粒尺寸更大,这是因为550 ℃温度很高,合金变形时晶体内部储能大,原子扩散速率高,晶界迁移速率也高。因此,晶粒生长更快,尺寸也更大。

图1 DC铸造Al-13.7Si合金的显微组织

Fig. 1 Microstructures of DC cast Al-13.7Si alloy

图2 DC铸造Al-13.7Si合金高温拉伸后变形区的显微组织

Fig. 2 Microstructures of DC cast Al-13.7Si alloy in deformed area after high temperature tensile (v=0.5 mm/min, t=60 min)

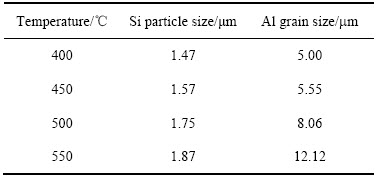

为了更好地分析不同热变形条件对硅颗粒和等轴晶粒的影响,利用Image-Pro Plus软件统计并计算出硅颗粒和等轴晶粒的平均尺寸,结果如表2所列。从表2中可以看出,硅颗粒尺寸和铝等轴晶粒尺寸随着温度的升高而增加。硅颗粒的粗化过程主要依靠大晶粒吞食小晶粒来进行,这会导致硅颗粒分布的均匀性变差和硅形貌的恶化。因此,过高加热温度的热变形,对于硅相形态的改善实际上起到消极的影响[13]。合金中的共晶组织在450 ℃已完成了颗粒化;随着温度继续升高,硅颗粒粗化,等轴晶粒尺寸增大,导致合金强度和伸长率均降低。对于半连续铸造过共晶铝硅合金热变形时加热温度适宜在450~500 ℃之间进行。在制定热变形方案时,加热温度高时,应选择较短的保温时间,以控制硅颗粒和等轴晶粒的尺寸。

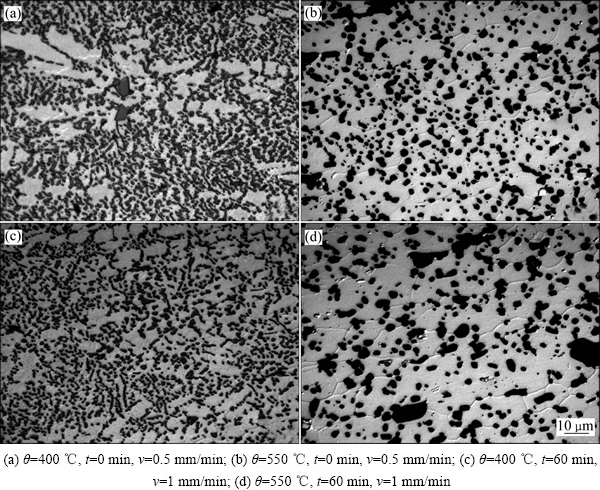

拉伸试样加热至不同温度进行未保温以及改变拉伸速度的拉伸试验,拉伸后合金变形区域的显微组织变化趋势与图2中的基本相同。在此,仅给出合金经400 ℃和550 ℃未保温以及改变拉伸速度拉伸后合金变形区域的显微组织,结果如图3所示。经400 ℃热变形组织中依然存在α(Al)枝晶(见图3(a)和(c));经 550 ℃拉伸后合金组织中α(Al)枝晶已基本消失不见,再结晶范围扩大(见图3(b)和(d))。

表2 DC铸造Al-13.7Si合金高温拉伸后的硅颗粒和铝等轴晶粒尺寸

Table 2 Size of Si particle and Al grain in DC cast Al-13.7Si alloy under different high temperature tensile conditions (v=0.5 mm/min, t=60 min)

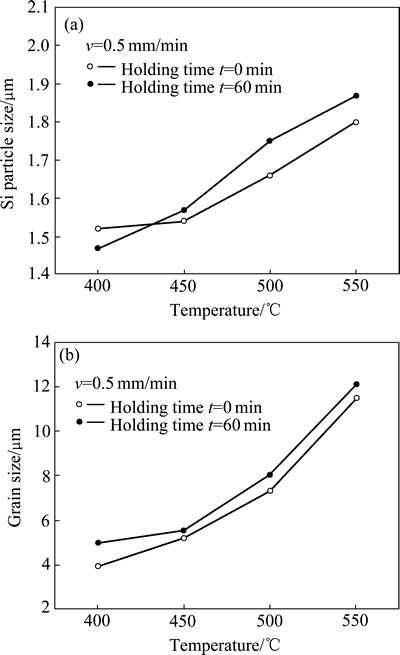

图4所示为合金拉伸试样在选取温度下拉伸、保温不同时间后变形区硅颗粒和铝等轴晶粒的尺寸曲线图。从图4可以看出,硅颗粒尺寸和铝等轴晶粒尺寸均随着温度的升高而增大。硅颗粒尺寸和铝等轴晶粒尺寸随保温时间的延长而增大,但只有在400 ℃保温60 min进行拉伸后的硅颗粒尺寸小于未保温拉伸后的尺寸。这是由于拉伸试样加热至 400 ℃未保温,不能提供充足的能量使所有共晶硅都发生熔断,共晶硅没有完全熔断,Si尺寸较大,而在400 ℃保温60 min后共晶硅熔断尺寸减小。400 ℃未保温拉伸时伸长率为74.33%,明显低于400 ℃保温60 min拉伸时的伸长率(83.69%)。这说明DC铸造Al-13.7Si合金变形前共晶硅相的形态是纤维状或针状(见图1),大小及分布不均匀的硅相严重地割裂了基体,降低了合金塑性。通过热变形改变共晶硅相的形态,以减小其对铝基体性能的削弱作用[10]。由表1可知,当加热温度高于450 ℃拉伸时,延长保温时间,硅颗粒和晶粒长大,合金高温塑性和强度降低。因此,铝硅合金热变形时加热的保温时间一方面与实际样品尺寸有关,另外一方面需根据Si相的形态确定,保温时间不宜过长。

图3 DC 铸造Al-13.7Si合金经不同保温时间及拉伸速度高温拉伸后变形区的显微组织

Fig. 3 Microstructures of DC cast Al-13.7Si alloy in deformed area after high temperature tensile under different holding time and different stretching velocities

图4 DC铸造Al-13.7Si合金保温不同时间高温拉伸后共晶硅和晶粒尺寸曲线

Fig. 4 Curves of Si particle sizes and grain size of DC cast Al-13.7Si alloy after high temperature tensile for different holding time

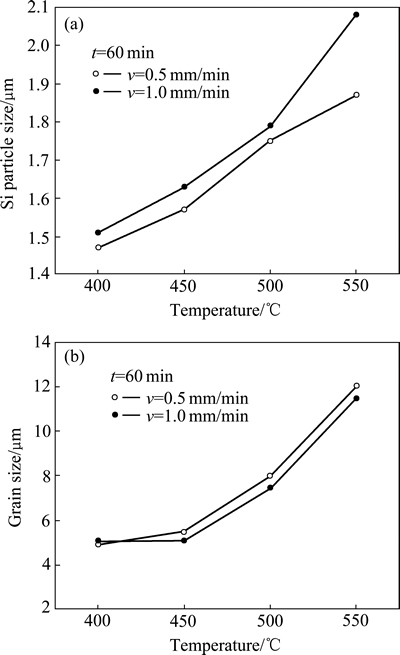

图5所示为合金拉伸试样经不同拉伸速度高温拉伸后硅颗粒和铝等轴晶粒的尺寸曲线。在温度和保温时间相同的情况下,拉伸速度大的试样热变形组织中的硅颗粒尺寸大。分别计算出0.5和1.0 mm/min两种拉伸速度所对应的起始应变速率,分别为5.56× 10-4 s-1和1.11×10-3 s-1。共晶硅熔断后的硅颗粒长大过程主要受扩散作用控制。在高温变形时,应变速率越大,合金内部组织协调性越差,这会导致大量晶体缺陷的产生,如空位和位错。位错的大量存在会对晶体中的扩散有明显的促进作用,随着位错密度的增加,晶体中的扩散速率加大[14],从而提高了硅颗粒的长大速率,所以拉伸速度相对较大时,硅颗粒的平均尺寸也略有增加。

图5 DC铸造Al-13.7Si合金以不同拉伸速度高温拉伸后共晶硅和晶粒尺寸曲线

Fig. 5 Curves of Si particle sizes and grain size of DC cast Al-13.7Si alloy after high temperature tensile at different stretching velocities

由图5可以看出,在温度和保温时间相同的情况下,除400 ℃外,拉伸速度为1 mm/min时的等轴晶粒尺寸都略小于0.5 mm/min时的。这是因为在400 ℃热拉伸时,0.5 mm/min时的变形量比1 mm/min时的大很多,高变形量增大了组织中的储能,有继续引发再结晶的可能,使未发生再结晶的共晶组织部位也产生小而密集的等轴晶粒,所以0.5 mm/min时的等轴晶平均尺寸比1 mm/min时的小。从图5还可以看出,分别在450、500和550 ℃热变形时,两种不同拉伸速度的晶粒随温度的升高具有相近的长大速率,这说明在此温度区间,合金的显微组织演变规律基本一致。在450、500和550 ℃下拉伸速度为1 mm/min时的晶粒尺寸分别比0.5 mm/min时的大0.38 μm、0.53 μm和0.56 μm,温度越高,尺寸相差越大。拉伸速度对再结晶的影响要从两个方面来考虑:首先,当拉伸速度较小时,再结晶晶界有足够的时间迁移;其次,形变速率低,可以使材料受力更均匀,热变形时组织协调性更好,所以体内位错密度低,晶界迁移所需的驱动力也就低,但研究表明,前者的影响占主导地位[15]。因此,在除400 ℃外的热变形条件下,拉伸速度越大,再结晶形成的等轴晶越小,降低合金的高温塑性。加热温度高于450 ℃时的拉伸力学性能显示,提高拉伸速率,合金强度增加、塑性降低,不利于热加工。

综上所述可知,对过共晶Al-Si二元合金来说,高温变形过程中的断裂主要起源于剪切应力作用下初生硅相的破碎,应力集中首先在大尺寸硅颗粒周围发生。当变形温度为400 ℃时,合金中共晶硅相颗粒化程度低,纤维状共晶硅相仍占据较大比例,合金流动应力高,初生硅容易出现破裂;当变形温度高于450 ℃时,共晶硅球化更完全,硅相对铝基体的割裂作用降低,合金流动应力减小,应力集中程度大幅减小。这是过共晶Al-Si合金的塑性随变形温度提高而增大的主要原因。热变形后出现了铝等轴晶,铝等轴晶尺寸对材料强度和塑性也起了至关重要的作用。由Hall-Petch公式σ=σ0+Kyd-1/2可知,晶粒越小,合金强度越高。由于细晶强化是唯一不以牺牲材料塑性为代价的强化机制,因此,当晶粒细小且分布均匀时,合金塑性变形分布越均匀,变形的大幅度集中引发微观裂纹形成的趋势也越小。因此,随变形温度的升高和保温时间的延长,硅颗粒和晶粒尺寸增加,合金强度和伸长率下降;随着拉伸速度的降低,晶粒长大,硅颗粒尺寸减小,合金强度降低,伸长率提高。

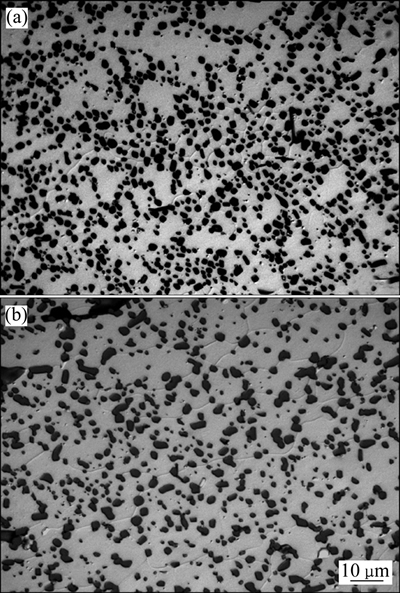

为进一步研究DC铸造Al-13.7Si合金可获得大塑性变形的原因,对高温拉伸后合金试样的未变形区、变形区的显微组织进行了对比观察,结果如图6所示。合金试样经历550 ℃拉伸后,在试样的未变形区,原来的共晶组织由于温度场的作用出现两个转变(即纤维状共晶硅相转变为颗粒状,共晶铝相转变成具有明显晶界的细小晶粒组织),但铝枝晶仍旧保留其铸态组织特征。由图6(b)可知,试样的变形区受温度场与力场的双重作用,除了发生上述两种转变外,其显微组织呈现出沿拉伸方向伸长的特征,由原共晶组织转变得到的铝细小晶粒仍然保存,且在原铝枝晶区域出现了新的等轴晶,但尺寸较共晶区域铝晶粒尺寸大。最终,硅颗粒均匀弥散地分布在铝等轴晶基体上。材料在高温下变形能否获得高塑性有赖于应变硬化指数。应变硬化指数和材料的晶粒尺寸有关,一般晶粒的尺寸越小,材料应变硬化指数越高,越有利于塑性变形。仅从Al-13.7Si合金的铸态组织看,该材料不具备获得高塑性的组织特征。然而,铝硅合金在塑性变形前加热保温,为后续塑性变形过程中整个铝基体向细化的等轴晶转变提供了良好的组织准备。这种等轴晶转变直接导致了铝硅合金高温塑性的提高。

图6 DC铸造Al-13.7Si合金高温拉伸后未变形区与变形区的显微组织(θ=550 ℃, t=0 min, v=0.5 mm/min)

Fig. 6 Microstructures of DC cast Al-13.7Si alloy in undeformed area(a) and deformed area(b) (θ=550 ℃, t=0 min, v=0.5 mm/min)

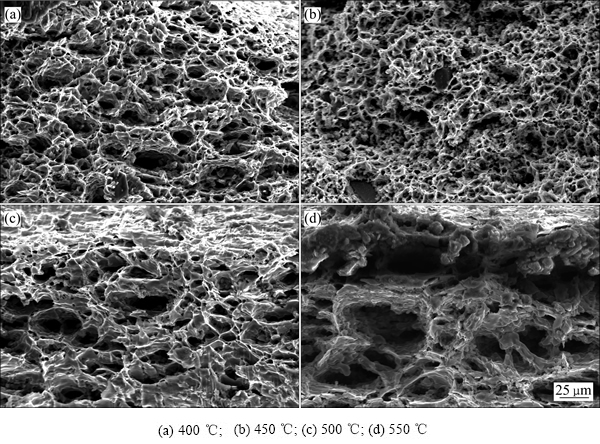

对经各温度热变形后的拉伸试样断口进行了扫描电镜观察,在此仅给出保温时间为60 min、拉伸速度为1.0 mm/min 时各温度下热变形拉伸试样的断口相貌,结果如图7所示。由图7可以看出,热变形试样的拉伸断口具有许多细小密集的韧窝,断裂均以裂纹沿着晶界扩展的方式发生,所以为沿晶断裂。韧窝的深度主要受材料塑性变形能力的影响,材料塑性变形能力大,韧窝深度较深,反之韧窝深度较浅。在热变形过程中,合金趋于沿着硅相与铝基体的界面开裂,因此韧窝大小、深浅及数量还取决于材料断裂时第二相粒子的大小、间距和数量等。在其他实验条件都相同的情况下,第二相粒子越大,韧窝也越大;反之,粒子越小,韧窝也越小[16-17]。在所选取的实验温度范围内,加热温度为450 ℃的拉伸实验所得断口的韧窝最深,韧窝分布最均匀、大小均一、数量最多,且绝大多数的韧窝都是等轴韧窝,此种韧窝是在单向拉伸正应力作用下形成的,应力在整个断口表面上分布均匀,显微空洞沿空间的3个方向上均匀长大,形成等轴韧窝,此时材料的塑性和韧性良好。这也从另一个角度说明了在450 ℃时热变形合金出现较高伸长率的原因。400 ℃时合金中韧窝尺寸不均匀,小尺寸的韧窝占据较大比例。500和550 ℃热变形时随着硅颗粒的粗化,断口韧窝数量明显减少,尺寸大幅增加,韧窝浅,这从另一角度解释了铝硅合金的高温力学行为。

图7 保温时间60 min、拉伸速度1.0 mm/min下不同温度热变形时DC铸造Al-13.7Si合金的拉伸试样断口形貌

Fig. 7 Fractographs of DC cast Al-13.7Si alloy at t=60 min, v=1.0 mm/min and different hog deformed temperatures

3 结论

1) 半连续铸造Al-13.7Si合金在选取温度拉伸变形后均显示出高伸长率。450 ℃拉伸时合金伸长率达到85.34%,抗拉强度为13.5 MPa。

2) 热变形过程中变形区整个铝基体向细化的等轴晶转变,这种转变直接导致半连续铸造Al-13.7Si合金高温塑性的提高。

3) 根据高温力学性能及组织特点,确定DC铸造Al-13.7Si合金适宜的热变形温度为450~500 ℃。

4) 当热变形温度高于450 ℃时,随着温度的升高或保温时间的延长,合金抗拉强度和伸长率降低;随着拉伸速度的降低,各温度下合金抗拉强度下降,伸长率呈上升趋势。

REFERENCES

[1] XIU Zi-yang, CHEN Guo-qin, WANG Xiao-feng, WU Gao-hui, LIU Yan-mei, YANG Wen-shu. Microstructure and performance of Al-Si alloy with high Si content by high temperature diffusion treatment[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2134-2138.

[2] 武玉英, 刘相法, 戴 勇, 姜炳刚, 边秀房. 硅相形态及含量对Al-Si合金线膨胀系数的影响[J]. 中国有色金属学报, 2007, 17(5): 688-692.

WU Yu-ying, LIU xiang-fa, DAI Yong, JIANG Bing-gang, BIAN Xiu-fang. Influence of morphology and content of silicon phase on CET of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 688-692.

[3] 何克准, 于福晓, 赵大志, 左 良. 磷变质对Al-17.5Si-4.5Cu-1Zn-0.7Mg-0.5Ni变形合金初晶硅形貌与室温拉伸性能的影响[J]. 中国有色金属学报, 2010, 20(11): 2082-2087.

HE Ke-zhun, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Effects of phosphorus modification oil morphology of primary silicon particles and mechanical properties of wrought Al-17.5Si-4.5Cu-1Zn-0.7Mg-0.5Ni alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2082-2087.

[4] GUIGLIONDA G, POOLE W J. The role of damage on the deformation and fracture of Al-Si eutectic alloys[J]. Materials Science and Engineering A, 2002, 336: 159-169.

[5] 刘相法, 乔进国, 刘玉先, 李士同, 边秀房. Al-P 中间合金对共晶和过共晶Al-Si 合金的变质机制[J]. 金属学报, 2004, 40(5): 471-476.

LIU Xiang-fa, QIAO Jing-guo, LIU Yu-xian, LI Shi-tong, BIAN Xiu-fang. Modification performance of the Al-P master alloy for eutectic and hypereutectic Al-Si alloys[J]. Acta Metallurgica Sinica, 2004, 40(5): 471-476.

[6] SRIVASTAVA A K, SRIVASTAVA V C, GLOTER A, OJHA S N. Microstructural features induced by spray processing and hot extrusion of an Al-18%Si-5%Fe-1.5%Cu alloy[J]. Acta Materialia, 2006, 54(7): 1741-1748.

[7] MA A B, TAKAGI M, SAITO N, IWATA H, NISHIDA Y, SUZUKI K, SHIGEMATSU I. Tensile properties of an Al-11mass%Si alloy at elevated temperatures processed by rotary-die equal-channel angular processing[J]. Materials Science and Engineering A, 2005, 408: 47-153.

[8] YU Fu-xiao, PEI Jian-hua, HE Ke-zhun, ZHAO Da-zhi, ZUO Liang. Solidification microstructure and temperature field during direct chill casting of Al-16Si alloy[J]. Transactions of the Indian Institute of Metals, 2009, 62(4/5): 347-351.

[9] LIU Fang, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Microstructure and mechanical properties of an Al-12.7Si-0.7Mg alloy processed by extrusion and heat treatment[J]. Materials Science and Engineering A, 2011, 528: 3786-3790.

[10] OGRIS E, WAHLEN A, LUCHINGER H, UGGOWITZER P J. On the silicon spheroidization in Al-Si alloys[J]. Journal of Light Metals, 2002, 2(4): 263-269.

[11] 戴洪尚, 刘志勇, 王明星, 翁永刚, 刘忠侠, 宋天福, 左秀荣. 固溶处理对电解制备的A356合金硅颗粒的影响[J]. 中国有色金属学报, 2004, 14(7): 1201-1205.

DAI Hong-shang, LIU Zhi-yong, WANG Ming-xing, WENG Yong-gang, LIU Zhong-xia, SONG Tian-fu, ZUO Xiu-rong. Influence of solution treatment on eutectic silicon of A356 alloy made of electrolysis aluminum[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1201-1205.

[12] TIRYAKIOGLU M. The effect of solution treatment and artificial aging on the work hardening characteristics of a cast Al-7%Si-0.6%Mg alloy[J]. Materials Science and Engineering A, 2006, 427(1/2): 154-159.

[13] DIGHE M, GOKHALE A, HORSTEMEYER M. Effect of loading condition and stress state on damage evolution of silicon particles in an Al-Si-Mg-Base cast alloy[J]. Metallurgical and Materials Transactions A, 2002, 33(3): 555-565.

[14] 凌 闯, 王敬丰, 赵 亮, 潘复生, 朱学纯. 高硅铝合金标准样品的热变形行为[J]. 中国有色金属学报, 2010, 20(5): 833-837.

LING Chuang, WANG Jing-feng, ZHAO Liang, PAN Fu-sheng, ZHU Xue-chun. Hot deformation behavior of high silicon aluminum alloy as standard sample[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 833-837.

[15] WANG Chun-xia, YU Fu-xiao, ZHAO Da-zhi, ZHAO Xiang, ZUO Liang. Effect of strain rate on the microstructural development in DC cast Al-15Si alloy[C]// SUAREZ C E. Light Metal 2012, Orlando: Minerals, Metals and Materials Society, 2012: 403-406.

[16] CACERES C H, DAVIDSON C J, GRIFFITHS J R. The deformation and fracture behaviour of an A1-Si-Mg casting alloy[J]. Materials Science and Engineering A, 1995, 197(2): 171-179.

[17] 刘 刚, 张国君, 丁向东, 孙 军, 陈康华. 含有不同尺度量级第二相的高强铝合金断裂韧性模型[J]. 中国有色金属学报, 2002, 12(4): 706-713.

LIU Gang, ZHANG Guo-jun, DING Xiang-dong, SUN Jun, CHEN Kang-hua. A model for fracture toughness of high strength aluminum alloys containing second particles of various sized scales[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(4): 706-713.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51401047);中央高校基本科研业务费项目青年教师科研启动基金资助项目(N130302002)

收稿日期:2014-11-17;修订日期:2015-06-18

通信作者:于福晓,教授,博士;电话:024-83687411;E-mail: fxyu@mail.neu.edu.cn