文章编号:1004-0609(2014)07-1871-07

Si-Sn合金精炼-定向凝固过程硅的分离和提纯

巫 剑1, 2,王 志2,胡晓军1,郭占成1,范占军3,谢永龙3

(1. 北京科技大学 钢铁冶金新技术国家重点实验室,北京 100083;

2. 中国科学院过程工程研究所 绿色过程与工程重点实验室 湿法冶金清洁生产技术国家工程实验室,北京 100190;

3. 宁夏银星多晶硅有限公司,吴忠 751100)

摘 要:采用Sn-Si熔析体系,利用工业规模多晶硅铸锭炉通过控制温度梯度和热场上移速率进行定向凝固处理,研究硅锭的形貌特征、组织结构和提纯效果。结果表明:在定向凝固过程中析出了连续密实的硅晶,且晶体硅与金属熔析剂之间形成了平坦稳定的相界面,实现晶体硅与金属熔析剂的有效分离。晶体硅经过混酸酸洗后,总金属杂质含量由58.3×10-6降低为7.6×10-6,去除率可以达到87%;非金属P含量由50.12×10-6降低为8.48×10-6,去除率大于80%。因此,Si-Sn合金精炼与定向凝固过程复合,解决了硅与金属熔析剂的有效分离问题,同时也实现了杂质的高效去除。

关键词:硅;分离;提纯;合金精炼;定向凝固;晶体生长

中图分类号:TF805 文献标志码:A

Separation and purification of silicon by combined Si-Sn alloy refining and directional solidification process

WU Jian1, 2, WANG Zhi2, HU Xiao-jun1, GUO Zhan-cheng1, FAN Zhan-jun3, XIE Yong-long3

(1. State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, Beijing 100083 China;

2. National Engineering Laboratory for Hydrometallurgical Cleaner Production Technology,

Key Laboratory of Green Process and Engineering, Institute of Process Engineering,

Chinese Academy of Sciences, Beijing 100190, China;

3. Ningxia Yingxin Polycrystalline Silicon Co. Ltd, Wuzhong 751100, China)

Abstract: The directional solidification of Si-Sn melt was carried out by controlling the temperature gradient and the moving velocity of thermal field in the ingot furnace. The morphology characteristics, structure and purification effect of the silicon ingot were studied. The results indicate that the growth of bulk Si is achieved from Si-Sn melt, and a flat and stable phase interface forms between the silicon and solvent by directional solidification, resulting in an effective separation. Meanwhile, purification of the refined Si by acid-leaching shows that metallic impurities decrease from 58.3×10-6 to 7.6×10-6, and the removal rate reaches 87%. Non-metallic P content decreases from 50.12×10-6 to 8.48×10-6, and the removal rate is over 80%. Therefore, not only the effective separation of silicon and solvent, but also the efficient removal of impurities is realized through Sn-Si alloy refining and directional solidification process.

Key words: silicon; separation; purification; alloy refining; directional solidification; crystal growth

太阳能光伏发电产业因其取之不尽、用之不竭、清洁环保和安全可靠等独特优势而被誉为21世纪的朝阳产业。随着光伏产业的快速发展,对太阳能级多晶硅的需求急剧增大。长期以来,太阳能级多晶硅的原料主要来自西门子法生产中的过剩产能、废料和碎料[1-2]。然而,西门子法等化学法生产太阳能级多晶硅工艺存在能耗高、成本高和污染严重等问题,这种借用半导体工业满足光伏产业需求的方式显然是不合理的,因此,开发低成本、低能耗和环境友好型的太阳能级多晶硅生产技术迫在眉睫。冶金法以其潜在的成本低和能耗低的优势,受到越来越多的重视[3-4]。冶金法提纯是利用硅和杂质元素物化性质的差异,通过逐级净化达到杂质元素与硅的分离,最终满足太阳能级多晶硅纯度要求。主要包括酸洗、吹气、造渣、真空处理、定向凝固和熔析精炼等工艺[5-8]。

近年来,熔析精炼受到了越来越多的关注,研究者对其进行了广泛的研究。熔析精炼类似于化工领域的重结晶净化,可以在硅熔点以下实现硅中微量杂质的快速去除。杂质在析出硅与合金液之间的分凝系数将不同于纯硅中的分凝系数,通过高温合金液化与凝固偏析分凝,改变了杂质存在的形式和位置,可将金属熔剂作为典型的熔析剂,也可作为杂质陷阱或杂质捕收剂。

研究者对不同的熔析体系开展了大量的研究工作。JUNEJA等[9]研究铜硅合金体系净化冶金硅,合金化后采用电解来分离铜。 等[10]也利用铜作为熔析介质精炼提纯硅。由于铜在硅中较低的固溶度,并且铜与硅的密度相差很大,因此可利用重介质分离的方法实现提纯硅与硅铜合金的分离。但在熔析过程中铜与硅形成了中间化合物,造成净化后铜与硅分离难度很大。MORITA等[11-12]通过电磁感应加热的方式凝固硅铝合金,在实现硅从合金分离方面取得了一定的进展,并且得到了很好的提纯效果,但由于铝与硅之间的亲和力较大,两者密度相近,一般要利用多次酸洗的方式才能将其去除,在一定程度上增加了成本。LI等 [13]在铝硅体系中引入超重力,在硅结晶析出的过程中实现了硅和铝的分离,但提纯效果不是很理想。ESFAHANI等[14-15]采用铁作为熔析介质提纯硅,铁与硅的密度差较大,利用重介质分离的方法,可以使残留的硅铁合金循环使用。但也存在着分离效果不太理想的问题,加上重介质成本高等原因,在一定程度上增加了分离成本。总之,上述研究都缺乏对熔析体系的凝固过程进行有效控制。定向凝固提纯主要是在凝固的过程中采用热场控制,在固相与液相之间建立起沿特定方向的温度梯度,根据溶质分凝理论即杂质在固液相之间的分凝系数不同,从而去除硅中的杂质。

等[10]也利用铜作为熔析介质精炼提纯硅。由于铜在硅中较低的固溶度,并且铜与硅的密度相差很大,因此可利用重介质分离的方法实现提纯硅与硅铜合金的分离。但在熔析过程中铜与硅形成了中间化合物,造成净化后铜与硅分离难度很大。MORITA等[11-12]通过电磁感应加热的方式凝固硅铝合金,在实现硅从合金分离方面取得了一定的进展,并且得到了很好的提纯效果,但由于铝与硅之间的亲和力较大,两者密度相近,一般要利用多次酸洗的方式才能将其去除,在一定程度上增加了成本。LI等 [13]在铝硅体系中引入超重力,在硅结晶析出的过程中实现了硅和铝的分离,但提纯效果不是很理想。ESFAHANI等[14-15]采用铁作为熔析介质提纯硅,铁与硅的密度差较大,利用重介质分离的方法,可以使残留的硅铁合金循环使用。但也存在着分离效果不太理想的问题,加上重介质成本高等原因,在一定程度上增加了分离成本。总之,上述研究都缺乏对熔析体系的凝固过程进行有效控制。定向凝固提纯主要是在凝固的过程中采用热场控制,在固相与液相之间建立起沿特定方向的温度梯度,根据溶质分凝理论即杂质在固液相之间的分凝系数不同,从而去除硅中的杂质。

综上所述,熔析精炼提纯方法仍然存在众多问题需要解决,尤其是精炼提纯后如何实现硅晶与介质的高效分离问题。针对上述问题,本文作者提出在熔析精炼的过程结合定向凝固热场控制的思路,选择在Si-Sn熔析体系下,采用定向凝固的方法,通过控制合金体系硅的定向生长,重点研究硅与金属熔剂的有效分离,同时探讨定向凝固过程中杂质的提纯效果。

1 实验

1.1 实验原料与设备

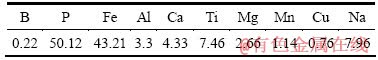

本研究所用硅的纯度为99.988%,产地为宁夏,其主要杂质含量见表1。实验采用金属锡作为熔析剂,其纯度为99.9%。实验所用盐酸、硝酸、氢氟酸均为分析纯试剂,生产厂家为北京化学试剂厂。

表1 硅原料的杂质含量

Table 1 Contents of impurities from Si (mass fraction, 10-6)

实验主要设备:多晶硅铸锭炉(JJL500,浙江精功科技股份有限公司生产)、线切割机(G544090A,石家庄威锋机械制造有限公司生产)等。

分析检测仪器:金相磨抛机(UNIPOL-830,沈阳科晶科学仪器有限公司生产)、光学显微镜(Axio Imager A1型,Carl Zeiss公司生产)、扫描电镜和能谱仪(SEM-EDS,日本电子JSM-6480扫描电镜配备牛津INCA Energy 350能谱仪)、电感耦合等离子体发射光谱仪(ICP-OES,Perkin Elmer Optima 5300DV)。

1.2 Sn-Si熔析体系定向凝固实验

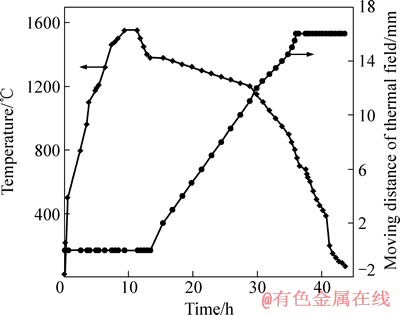

按质量比55:45称取总质量为184.7 kg金属锡和硅,然后装料于坩埚中,接着用升降机将坩埚升入多晶硅铸锭炉中。开启机械泵-罗茨泵抽真空,改变铸锭炉的功率进行加热,直到加热到1175 ℃,进入熔化阶段。之后采用程序加热(见图1)的方法进行熔化,在1550 ℃持续恒温3 h,再经过2 h降温至1380 ℃,开始调控热场上移(见图1),每降温20 ℃,热场上移1 mm,直到温度降至1150 ℃,每降温50 ℃,热场上移0.5 mm,一直到温度降至680 ℃,停止上移热场。冷却至室温,将样品从坩埚里取出,采用切割机进行切割,金相磨抛机抛光,金相显微镜和扫描电镜观察。

1.3 酸洗实验

称取2 g定向凝固后得到的硅粉,采用HCl-HF混酸体系在70 ℃、200 r/min水浴恒温振荡器中酸洗6 h。然后用去离子水将酸洗后的冶金硅粉清洗至中性止,最后将得到的样品烘干。杂质元素分析采用电感耦合等离子体发射光谱仪(ICP-OES)分析。

图1 Si-Sn熔析体系定向凝固实验温度与热场上移距离

Fig. 1 Directional solidification temperature of Si-Sn alloy refining and moving distance of thermal field

2 结果与分析

2.1 合金定向凝固过程硅的晶体生长

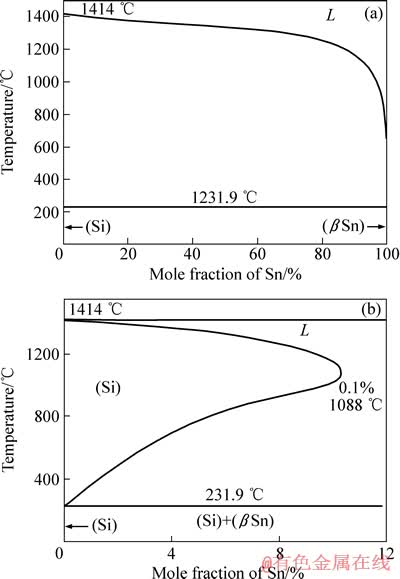

图2所示为Si-Sn相图。由图2可知,在熔融状态下,硅锡可互溶形成硅锡合金,而在凝固过程中并没有共晶合金相形成。因此,本研究设计了Si-Sn合金定向凝固实验。在温度梯度G=1×104 K/m,热场移动速率v=1.84 μm/s条件下,对硅的晶体生长进行了研究。图3所示为Si-55%Sn(质量分数)合金定向凝固后所得硅锭的剖面图。由图3可知,在生成硅锭底部的区域,有气孔生成,从硅锭底部向上的区域,气孔逐渐消失,从中部到顶部生成了连续密实的硅晶。原因有:一方面,在结晶初期,Sn和Si的合金液处在恒温区,随着热场的上移,由于坩埚底部散热最快,温度最低,因此,在坩埚底部和顶部之间形成温度梯度,进而熔点较高的硅相从底部开始凝固。热场上移速率较快,使得固液界面发生波动,硅晶的选择性成核与异常长大造成硅晶之间存在物理缺陷,包括气孔的生成和熔析剂的夹带。而随着结晶的继续进行,由于固液界面前沿的温度梯度始终是正的,而热场上移的速率变慢,使得硅熔体在高温区内的停留的时间增长,因而优先结晶析出的硅晶的生长速率明显下降,或是被后面的固液界面所追及,或是被熔化,因而,界面恢复平坦,气孔消失,进而生成了连续密实的硅晶[16]。另一方面,由于先结晶析出的硅晶对后续硅生长具有晶种诱导作用,也促进了连续密实硅晶的生成。

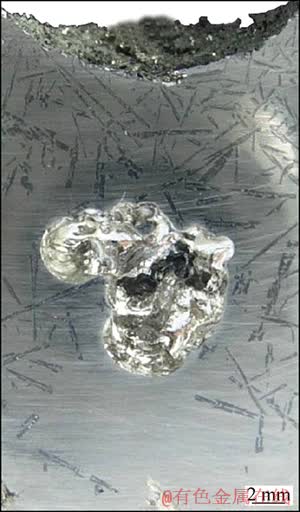

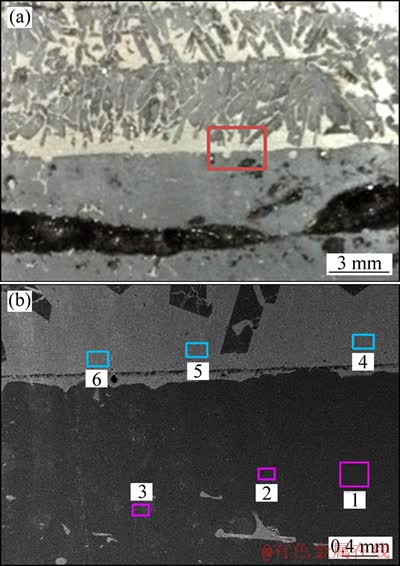

图4所示为Si-94%Sn(质量分数)合金熔析精炼后的剖面图[17]。图5所示为Si-Sn合金定向凝固后所得硅锭顶部的剖面图和SEM像。由图4可知,由于没有对熔析精炼凝固过程进行有效控制,造成树枝状硅弥散分布在硅锭的各个位置,即Si中有Sn、而Sn中有Si,进而导致Si与金属熔析剂难以分离。由图5可知,由于Si-Sn熔析精炼过程中采用了定向凝固的方法,在硅锭的顶部可明显看到生成了一条平坦稳定的相界面分界线,上部是Si-Sn合金,下部是Si相,Si-Sn合金相与Si相之间有明显的相界面,实现了很好的分离。MA等[18]的研究表明,在同样的温度梯度和下拉移动速率下,由相图知,随着硅含量的增加,相界面将变得更加稳定和平缓。然而在快速下拉的条件下,Si在定向凝固过程生成大量的片状硅晶,不利于生成稳定平缓的相界面分界线。

图2 Si-Sn相图

Fig. 2 Phase diagrams of Si-Sn

图3 Si-55%Sn合金定向凝固后的剖面图

Fig. 3 Cross-section of Si-55%Sn alloy after directional solidification

图4 Si-94%Sn合金熔析精炼后的剖面图[17]

Fig. 4 Cross-section of Si-94%Sn alloy after solvent refining[17]

图5 Si-55%Sn合金定向凝固后的上部剖面图和SEM像

Fig. 5 Top-cross-section and SEM image of Si-55%Sn alloy after directional solidification

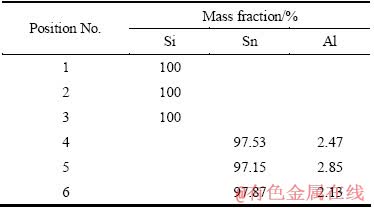

表2 图5(b)中Si-55%Sn合金定向凝固后上部剖面的EDS分析结果

Table 2 EDS analysis results of top-cross-section of Si-55%Sn alloy after directional solidification in Fig. 5(b)

通过扫描电镜和能谱对硅样品进行表征。由图5(b)和表2可知,颜色较深(黑色)的区域是Si相,基本没发现杂质元素。但在Si相中也发现有少量熔析剂Sn被Si相包裹。而颜色较亮(灰色)的区域是Sn相,在Sn相区里也夹杂了少量Si。能谱分析表明,在熔析剂Sn的区域内,有少量金属杂质Al富集在Sn相,原因是在Si-Sn体系下,Al的分凝系数较固体中的Si的小,且其分凝系数随着温度降低也是减小的,因此,会有少量金属杂质Al富集在Sn相。一方面由于硅晶与Si-Sn熔体的密度差(ρSi(1689K,s)=2.29 g/cm3,ρSi(1555K,undercooling)= 2.60 g/cm3,ρSn(1555K,l)=6.32 g/cm3)[19-21],形核长大的Si晶由于密度差异产生的浮力作用在定向凝固过程时出现在Si锭的顶部。而Si锭的顶部也形成大量白色Sn相,这是因为随着加热体的缓慢上移,坩埚底部是散热最快的区域,熔点较高的Si相从温度最低的底部开始凝固,随着硅相的凝固,将液态的锡相逐渐推赶至坩埚的顶部。另一方面,由于较慢的热场移动速率降低了冷却速率,避免了成分过冷的出现。若晶体生长过程中出现了成分过冷,这意味着熔体处于过冷状态,这样在平坦界面由于干扰就会产生凸缘,而其尖端处于过冷度较大的熔体中,因而其生长速率比界面的快,凸缘不能自动消失,于是平坦界面的稳定性被破坏。晶体中形成胞状组织,溶质偏聚十分严重,同时导致在硅晶与Si-Sn熔体界面上硅的形核优于生长,难以形成稳定的相界面以实现硅与熔析剂的有效分离。因此,如何改变工艺条件避免成分过冷的出现是定向凝固的关键问题。通常,产生成分过冷的条件表示为[16, 18]

(1)

(1)

式中:G为温度梯度(K/m);v为生长速率(m/s);(G/v)c为临界条件下温度梯度与生长速率的比值;m为Si-Sn液相线的斜率(K);cSn,M是金属Sn在Si-Sn熔体中的平均浓度(mol/m3);cSn,S是金属Sn在固体Si中的平均浓度(mol/m3);D是在液体合金的扩散系数(m2/s)。

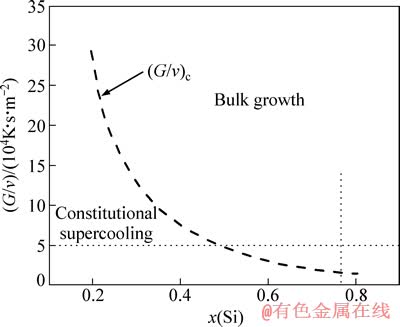

图6所示为G/v与x(Si)(Si在合金中的摩尔分数)的关系曲线。由图6可知,虚线是通过式(1)计算所得的(G/v)c临界值,虚线的下部是成分过冷出现的区域,在此区域可以生成连续密实的Si晶。在Si含量较低的条件下容易出现成分过冷,而成分过冷会导致Si的形核优先于平坦稳定相界面的形成。而虚线的上部是不出现成分过冷的区域,在此区域可以生成连续密实的硅晶。通过计算可知,在x(Si)=0.77时,本实验的G/v值(>5×104 K·s/m2)位于(G/v)c临界值的上部,在定向凝固的过程中没有出现成分过冷,实验结果也验证在虚线区域上部可以生成连续密实的Si晶。因此,可以通过控制工艺条件避免Si-Sn合金在定向凝固过程中由于成分过冷造成不稳定固液界面的形成。

图6 G/v与x(Si)的关系[18]

Fig. 6 Relationship between bulk Si growth with G/v and mole fraction of Si[18]

2.2 合金精炼-定向凝固复合提纯

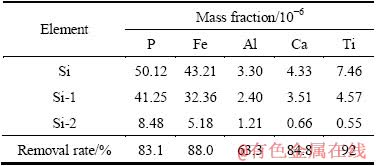

在本实验中,Si-Sn合金定向凝固后得到的硅锭在生长的过程中夹杂着少量的熔析剂Sn。酸洗由于其低成本、高效率的特点而被应用于冶金硅的提纯,但只能去除偏析在硅晶界的可溶性杂质,对在硅基体中的固溶杂质不能通过酸洗去除。因此,硅晶界中的杂质可以通过简单的酸洗达到去除的目的。表3所列为实验样品硅中典型杂质的含量,其中Si是原始硅样品,Si-1是直接混酸酸洗后的样品,Si-2是合金定向凝固再经过与Si-1同样酸洗后的样品。由表3可知,Si-Sn合金体系定向凝固酸洗后,Si中典型杂质含量较直接酸洗后的Si大幅度降低,Fe由32.36×10-6降为5.18×10-6,Al由2.40×10-6降为1.21×10-6,Ca由3.51×10-6降为0.66×10-6,Ti由4.57×10-6降为0.55×10-6,P由41.25×10-6降为8.48×10-6,尤其是Fe、Ca和P降幅最大,与原硅样品相比,降幅达到60%,由此充分说明Si-Sn合金精炼-定向凝固复合提纯实现了很好的除杂效果。定向凝固后的硅料经酸洗后铁含量为5.18×10-6,其他金属杂质含量基本在1×10-6以内,金属杂质的总去除率为87%。非金属杂质P由50.12×10-6下降至8.48×10-6,去除率超过80%。

表3 硅原料与定向凝固后的硅混酸酸洗后硅的杂质含量

Table 3 Concentration of impurities from Si and refined Si after acid leaching

2.3 杂质相的微观结构

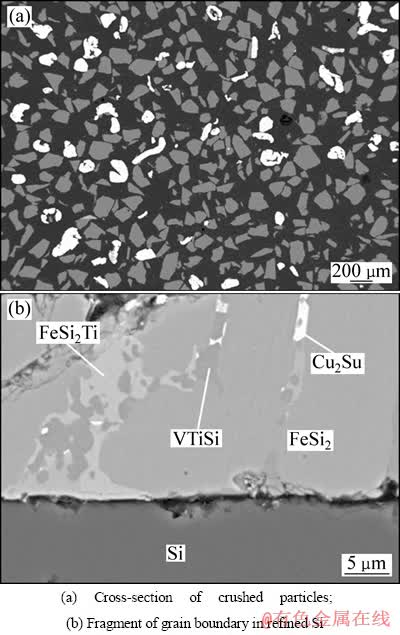

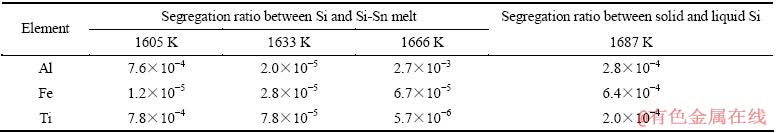

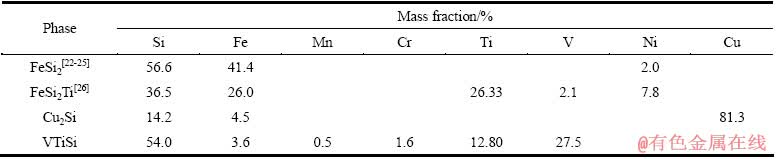

为进一步说明复合过程对杂质提纯的效果,图7(a)所示为Si-55%Sn的合金定向凝固后所得硅锭破碎分级后硅粉(74~150 μm)的SEM像。由图7(a)可知,颜色较深(灰色)的是Si相,颜色较亮(白色)的是金属Sn相,Si相和Sn相是单独分开的,没有出现Sn相包裹或夹带Si相,且之前Si相中夹带的Sn相也基本消失,从而为酸洗除Sn提供了有利条件。图7(b)是Si中杂质相的SEM像。由图7(b)可知,杂质相与Si相之间有明显的分界线。在熔析体系下,由于金属杂质的分凝系数较在纯硅体系下的分凝系数小(见表4[18]),在定向凝固的过程中,杂质相从Si基体中偏析到硅晶界,所以硅相中很少有杂质相存在。杂质相与Si相之间的有效分离为金属杂质的去除提供了有利条件,硅料酸洗的结果也验证了此结果。通过能谱分析可知(见表5),杂质相主要是FeSi2[22-25]、FeSi2Ti[26]、Cu2Si和VTiSi。在混酸体系下,偏析到硅晶界的杂质相能够得到很好的去除。在杂质相和硅相中都没有发现Sn相的存在,进一步表明熔析剂Sn可以通过定向凝固与Si实现有效的分离。而非金属P含量由定向凝固前的50.12×10-6降为8.48×10-6。MIN等[27]和MORITA[28]发现,Ca对P具有很大的亲和力,P可能与Ca形成杂质相,然后通过酸洗去除。由此可以推断出,P在定向凝固过程与金属杂质形成新的杂质相被熔析剂捕获进入熔析剂中,从而获得较好的去除效果。因此,在Si-Sn熔析体系下,P可以与金属杂质Al、Ca、Mg和Si形成新的杂质相[29],随着金属杂质偏析到晶界,然后通过酸洗实现去除。

图7 定向凝固后硅的SEM像

Fig. 7 SEM images of refined Si after directional solidification

表4 杂质在固体硅与Si-Sn熔体的分凝系数[18]

Table 4 Segregation ratios of impurities between solid Si and Si-Sn melts[18]

表5 定向凝固后硅中主要的杂质相及其含量

Table 5 Average composition of main impurity phase in refined Si

3 结论

1) Si-Sn合金定向凝固,由于合金精炼和Si的晶体生长作用,调控G/v值可避免成分过冷的出现,进而通过控制Si晶的定向生长,生成平坦稳定的相界面,从而实现Si晶体和金属熔析剂分离的目的。

2) Si-Sn合金定向凝固后,由于合金精炼的作用,金属杂质的分凝系数较在纯硅体系下的分凝系数小,在定向凝固的过程中杂质随着熔析剂从Si基体偏析到硅晶界中,经过混酸酸洗后金属杂质的去除率可以达到87%。

3) P在定向凝固过程与金属杂质形成新的杂质相被熔析剂捕获进入熔析剂中,从而获得较好的去除效果,P的含量由50.12×10-6降低为8.48×10-6,去除率超过了80%。

REFERENCES

[1] MURRAY D J, LEILI T K, MARK L, SAMIRA S, MANSOOR B. High-temperature refining of metallurgical-grade silicon: A review[J]. JOM, 2012, 64(8): 935-945.

[2] CIFTJA A. Refining of solar cell silicon through metallurgical routes[J]. JOM, 2012, 64(8): 933-934.

[3] BRAGA A F B, MOREIRA S P, ZAMPIERI P R, BACCHIN J M G, MEI P R. New processes for the production of solar grade polycrystalline silicon: A review[J]. Solar Energy Materials and Solar Cells, 2008, 92: 418-424.

[4] 李成义, 赵立新, 王 志, 郭占成, 王永刚. 酸洗去除冶金硅中的典型杂质[J]. 中国有色金属学报, 2011, 21(8): 1988-1996.

LI Cheng-yi, ZHAO Li-xin, WANG Zhi, GUO Zhan-cheng, WANG Yong-gang. Removal of representative impurities from metallurgical grade silicon by acid leaching[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1988-1996.

[5] MORITA K, MIKI T. Thermodynamics of solar grade silicon refining[J]. Intermetallics, 2003, 11: 1111-1117.

[6] 蔡 靖, 陈 朝, 罗学涛. 高纯冶金硅除硼的研究进展[J]. 材料导报, 2009, 23(12): 81-100.

CAI Jing, CHEN Chao, LUO Xue-tao. Research process in boron removal of UMG silicon[J]. Materials Review, 2009, 23(12): 81-100.

[7] 龙桂华, 吴 彬, 韩 松, 邱克强. 太阳能级多晶硅生产技术发展现状及展望[J]. 中国有色金属报, 2008, 18(1): 386-392.

LONG Gui-hua, WU Bin, HAN Song, QIU Ke-qiang. Development status and prospect of solar grade silicon production technology[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 386-392.

[8] YOSHIKAWA T, MORITA K. An evolving method for solar-grade silicon production: Solvent refining[J]. JOM, 2012, 64(8): 946-951.

[9] JUNEJA J M, MUKHERJEE T K. A study of the purification of metallurgical grade silicon[J]. Hydrometallurgy, 1986, 16(1): 69-75.

[10]  A M, UTIGARD T A. Refining silicon for solar cell application by copper alloying[J]. Silicon, 2009(1): 239-248.

A M, UTIGARD T A. Refining silicon for solar cell application by copper alloying[J]. Silicon, 2009(1): 239-248.

[11] YOSHIKAWA T, MORITA K. Refining of Si by the solidification of Si-Al melt with electromagnetic force[J]. ISIJ Inter, 2005, 45(7): 967-971.

[12] YOSHIKAWA T, MORITA K. Refining of silicon during its solidification from a Al-Si melt[J]. Journal of Crystal Growth, 2009, 311(3): 776-779.

[13] LI Jing-wei, GUO Zhan-cheng, TANG Hui-qing, WANG Zhi, SUN Shi-tong. Si purification by solidification of Al-Si melt with super gravity[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(4): 958-963.

[14] ESFAHANI S, BARATI M. Purification of metallurgical silicon using iron as an impurity getter. part Ⅰ: Growth and separation of Si[J]. Met Mater Int, 2011, 17(5): 823-829.

[15] ESFAHANI S, BARATI M. Purification of metallurgical silicon using iron as an impurity getter part Ⅱ: Extent of silicon purification[J]. Met Mater Int, 2011, 17(6): 1009-1015.

[16] 闵乃本. 晶体生长的物理基础[M]. 上海: 上海科学技术出版社, 1982: 189-441.

MIN Nai-ben. The physical basis of crystal growth[M]. Shanghai: Shanghai Science and Technology Press, 1982: 189-441.

[17] ZHAO Li-xin, GUO Zhan-cheng, WANG Zhi. Low-temperature purification process of metallurgical silicon[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 1185-1192.

[18] MA Xiao-dong, YOSHIKAWA T, MORITA K. Si growth by directional solidification of Si-Sn alloys to produce solar-grade Si[J]. Journal of Crystal Growth, 2013, 377: 192-196.

[19] GLAZOV V M, SHCHELIKOV O D. Volume changes during melting and heating of silicon and germanium melts[J]. High Temperature, 2000, 38 (3): 405-412.

[20] HIGUCHI K, KIMURA K, MIZUNO A, WATANABE M, KATAYAMA Y, KURIBAYASHI K. Precise measurement of density and structure of undercooled molten silicon by using synchrotron radiation combined with electromagnetic levitation technique[J]. Measurement Science and Technology, 2005, 16(2): 381-385.

[21] ALCHAGIROV B B, CHOCHAEVA A M. Temperature dependence of the density of liquid tin[J]. High Temperature, 2000, 38(1): 44-48.

[22] ANGLEZIO J C, SERVANT C, ANSARA I. Contribution to the experimental and thermodynamic assessment of the Al-Ca-Fe-Si system, Al-Ca-Fe, Al-Ca-Si, Al-Fe-Si and Ca-Fe-Si systems[J]. Calphad, 1994, 18(3): 273-309.

[23] LINDHOLM M. A thermodynamic description of the Fe-Cr-Si system with emphasis on the equilibria of the sigma (Σ) phase[J]. Journal of Phase Equilibria, 1997, 18(5): 432-440.

[24] ARONSSON B. A note on the compositions and crystal structures of MnB2, Mn3Si, Mn5Si3 and FeSi2[J]. Acta Chemical Scandinavica, 1960, 14(6): 1414-1418.

[25] GAFFET E, MALHOUROUX N, ABDELLAOUIET M. Far from equilibrium phase transition induced by solid-state reaction in the Fe-Si system[J]. Journal of Alloys and Compounds, 1993, 194(2): 339-360.

[26] ANGLEZIO J C, SERVANT C, DUBROUS F. Characterization of metallurgical grade silicon[J]. International Journal of Materials Research, 1990, 5(9): 1894-1899.

[27] MIN D, SANO N. Determination of standard free energies of formation of Ca3P2 and Ca2Sn at high temperatures[J]. Metallurgical and Materials Transactions B, 1988, 19(3): 433-439.

[28] MORITA K. Effects of Ca addition of the thermodynamic properties of P and B in molten silicon alloy, model, control, and optimization in ferrous and nonferrous industry[C]//132nd Annual Meeting & Exhibition of the Minerals, Metals & Materials Society. Warrendale, PA: TMS, 2003: 49-60.

[29] HU Lei, WANG Zhi, GONG Xu-zhong, GUO Zhan-cheng, ZHANG Hu. Impurities removal from metallurgical-grade silicon by combined Sn-Si and Al-Si refining process[J]. Metallurgical and Materials Transactions B, 2013, 44(4): 828-836.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51174187);国家“十二五”科技支撑计划项目(2011BAE03B01)

收稿日期:2013-08-27;修订日期:2014-01-06

通信作者:王 志,研究员,博士;电话:010-82544818;传真:010-82544818;E-mail:zwang@home.ipe.ac.cn