文章编号:1004-0609(2010)09-1795-07

氢气浓度对常压化学气相沉积ZrC涂层的影响

李国栋, 郑湘林, 熊 翔, 孙 威

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用ZrCl4-CH4-H2-Ar体系在C/C材料基体上进行常压化学气相沉积(APCVD)制备碳化锆(ZrC)涂层。通过X射线衍射技术(XRD)和扫描电镜(SEM)对不同H2浓度下制备的ZrC涂层进行分析。对H2在沉积过程中的作用机制进行了讨论。结果表明:H2浓度对涂层的相组成、晶体的择优取向和结构形态有重要影响;无H2或H2浓度较低时,涂层含有大量的热解碳,由ZrC和碳两相组成,涂层呈多孔颗粒状;当H2浓度(体积分数)增加到30%以上时,涂层的相成分变为单一ZrC相;当H2的浓度增加到90%时,ZrC晶体取向由(111)、(200)转变为强烈的(220)择优取向,晶粒形貌变为纳米针状。

关键词:ZrC涂层;常压化学气相沉积;H2浓度;择优取向

中图分类号:TQ134.1 文献标志码:A

Effect of hydrogen concentration on preparation of

ZrC coating by APCVD

LI Guo-dong, ZHENG Xiang-lin, XIONG Xiang, SUN Wei

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Zirconium carbide (ZrC) coatings were prepared on carbon-carbon composites substrates by means of atmospheric pressure chemical vapor deposition (APCVD). ZrCl4-CH4-H2-Ar system was used in this deposition process. And the effect of different hydrogen concentration on coating properties was studied by X-ray diffractometry (XRD) and scanning electron microscopy (SEM). The mechanism of hydrogen in the deposition process was also studied. The results show that the coating phase composition, preferential growth and structure morphology change significantly as the hydrogen concentration increasing. With pure argon or less hydrogen, ZrC coating is porous, which is made up of ZrC and C two-phase, and is contained by lots of pyrocarbon. When the hydrogen concentration reaches more than 30%(volume fraction), there is only ZrC phase in the coating. When the hydrogen concentration reaches 90%, ZrC crystal preferential growth changes from (111) plane and (200) plane to intensive (220) plane, and the crystal morphology turns into nano-needle-like morphology.

Key words: ZrC coatings; atmospheric pressure chemical vapor deposition; H2 concentration; preferential growth

C/C复合材料的起始氧化温度为370 ℃,高于500 ℃会迅速氧化,使其强度大幅降低甚至丧失,极大地制约了该材料的进一步应用。相关研究表明[1-3],在C/C复合材料表面制备抗氧化涂层能有效提高其抗氧化和耐烧蚀性能。在使用温度高于1 800 ℃的高温环境下,常用涂层材料有HfC、TaC、ZrC、NbC、HfB2、ZrB2和TaB2等难熔金属碳化物和硼化物[4-6]。其中ZrC的熔点高(3 540 ℃),高温力学性能优异,化学性能稳定,与C/C材料基体化学物理相容性好,成本低,是C/C材料理想的高温涂层材料。

目前,ZrC涂层的制备方法有磁控溅射、脉冲激光沉积(PLD)、化学气相沉积(CVD)等[7-10]。由于

CVD工艺制备ZrC涂层具有沉积速率高、膜层均匀、附着性好等优点而得到广泛应用。CVD法制备的ZrC涂层的结构与性能取决于诸多因素,包括沉积温度、系统压力、反应物浓度、气体流量比、沉积时间以及基体类型等[11-15]。其中,H2浓度对涂层的成分、结构、形貌与性能有非常重要的影响。如黄浩等[16]采用CVD工艺在CH3SiCl3-Ar-H2体系下制备SiC涂层中指出:H2浓度可以影响涂层结构、表面致密性。王辉等[17]采用热丝化学气相沉积工艺(HFCVD)在SiH4-CH4-H2体系中制备SiC薄膜时,发现H2浓度可以影响薄膜晶粒的择优生长和表面微观形貌。但采用常压化学气相沉积(APCVD)制备ZrC涂层的相关研究未见报道。本文作者采用APCVD工艺,以ZrCl4-CH4-H2-Ar为反应体系沉积ZrC涂层,研究H2浓度对ZrC涂层的相成分、结构形貌和择优生长的影响。

1 实验

本实验在小型竖式电磁感应加热反应炉中进行,基体为C/C复合材料。锆源为ZrCl4固体粉末,经特制的螺旋送粉装置由反应炉上方加入,同时通入CH4、H2和稀释气体Ar混合反应气体进入反应区间,反应生成物在C/C复合材料基体上沉积。

ZrCl4-CH4-H2-Ar体系常压化学气相沉积ZrC的工艺如下:沉积温度为1 600 ℃,不抽真空,控制CH4流量和(H2+Ar)总流量沉积180 min。通过调节H2和Ar流量占总流量的比例来改变体系中H2的浓度,其中[FH2/(FH2+FAr)]为H2的浓度,F(H2)为体系中H2的体积流量,FAr为体系中Ar的体积流量。本实验选择在H2浓度(体积分数)分别为0、15%、30%、50%和90%的条件下进行沉积。

采用日本理学D/max2550VB+ 18 kW转靶X射线衍射仪(XRD)分析涂层的相成分和ZrC晶粒的择优生长;用扫描电子显微镜(SEM)观察ZrC涂层表面和断面的微观形貌。

2 结果与讨论

2.1 H2浓度对涂层相组成的影响

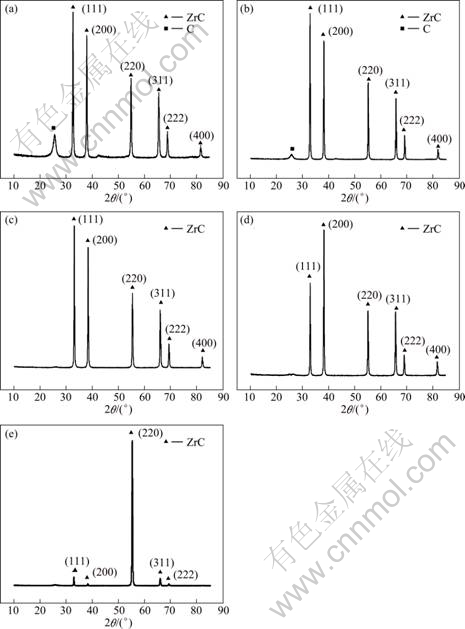

图1所示为不同H2浓度下ZrC涂层的XRD谱。从图1可以看出:当H2浓度为0,即化学反应体系中缺少H2时,涂层XRD谱中除了有ZrC的衍射峰外还有C的衍射峰,而且C峰的强度较大,说明涂层由ZrC和C两相组成且C的含量比较大。同时C的衍射峰形较宽,有可能形成非晶碳;当H2浓度为15%时,C峰的峰值强度明显减弱,涂层中的C含量减少;而当H2浓度达到30%时C峰基本消失;当H2浓度为50%和90%时,涂层由单一ZrC相组成。实验结果表明:H2浓度可以改变ZrC涂层的相成分,且随体系中H2浓度的增加到30%以上时,涂层的相成分由ZrC和C两相逐渐变为单一ZrC相。扫描电镜背散射图象观测和元素面扫描分布也证实这一实验结果。

2.2 H2浓度对ZrC涂层晶粒择优取向的影响

H2浓度变化,涂层中ZrC相不同晶面的峰值强度发生了明显变化。当H2浓度为0、15%、30%时,ZrC相的(111)面的峰值强度最高,(200)面的峰值强度次之;当H2浓度为50%时刚好相反,(200)面的峰值强度最高,(111)面次之;而当H2浓度为90%时,(220)面的峰值强度最高。ZrC不同晶面的峰值强度的变化说明涂层中ZrC晶粒的生长择优取向随H2浓度的变化发生明显改变。IMAI等[18]报导了晶粒生长择优取向和反应气体过饱和度之间的联系。H2浓度的变化使不同晶面ZrC晶粒形核能发生变化,从而导致ZrC晶粒的择优取向情况发生改变。

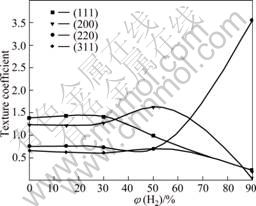

为进一步说明涂层中ZrC晶粒的择优取向情况,根据不同H2浓度下ZrC相不同晶面的衍射峰强度和Harris公式计算晶面织构系数TC(hkl)。TC(hkl)值越大则表明ZrC晶粒在该晶面方向的择优取向程度越高。图2是ZrC不同晶面的织构系数与H2浓度的关系曲线。从图2可看出:当H2浓度在0和30%之间时,TC(111)>TC(200)>1,表明体系在无H2或仅有少量H2存在时,ZrC晶粒同时存在(111)和(200)两个择优取向,且(111)择优取向程度稍高于(200);当H2浓度为50%时,TC(111)值降低,相反TC(200)值增大,此时ZrC晶粒形成以(200)为主的择优取向;当H2浓度到达90%时,TC(111)和TC(200)值都迅速降低并接近于0,TC(220)值急剧上升,形成强烈的(220)择优取向。说明此时ZrC晶体结构已发生了重大变化。

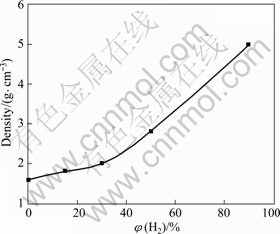

2.3 H2浓度对ZrC涂层表观密度的影响

由于在不同H2浓度下制备的ZrC涂层相的组成和ZrC晶粒生长情况不同,导致涂层的密度也会发生相应的变化。根据ρ=Δm/V=Δm/S×h,计算ZrC涂层表观密度,其中ρ代表涂层表观密度,Δm是沉积后试样的增质,h是涂层的厚度,S是试样的底面积。

图1 不同H2浓度下制备的ZrC 涂层XRD谱

Fig.1 XRD patterns of ZrC coatings prepared with different H2 concentrations: (a) 0; (b) 15%; (c) 30%; (d) 50%; (e) 90%

图2 H2浓度与ZrC晶面织构系数关系

Fig.2 Relation ship between ZrC texture coefficients and of H2 concentration

图3所示为不同H2浓度下涂层密度的变化曲线。当H2浓度低于30%时,涂层密度小于2 g/cm3,而且密度和H2浓度基本呈线性关系,涂层密度随H2浓度的增加只有少量的增大;当H2浓度高于30%后,涂层密度和H2浓度依然基本呈线性关系,但涂层密度伴随H2浓度的增加而迅速上升。当H2浓度为90%时,涂层密度到达最大值,接近5 g/cm3(ZrC理论密度为6.66 g/cm3)。

这主要与高温下甲烷热分解生成碳和氢有关,如反应式(1),900 ℃以上反应迅速,1 600 ℃时反应生成热解碳的速率非常大,当反应体系中加入H2时,H2对甲烷热分解起到抑制作用[19]。由图1也可看出,不加H2或H2的浓度小时,涂层中含有大量的碳,说明甲烷热分解速率快,H2对其抑制的程度低。热解碳的密度要远小于ZrC的密度,且多孔,导致了涂层的密

度小;但当H2浓度增大时(高于30%),涂层中碳的含量减少,ZrC的含量增大,涂层密度增加。

CH4 → C + H2 (1)

2.4 H2浓度对ZrC涂层形貌结构的影响

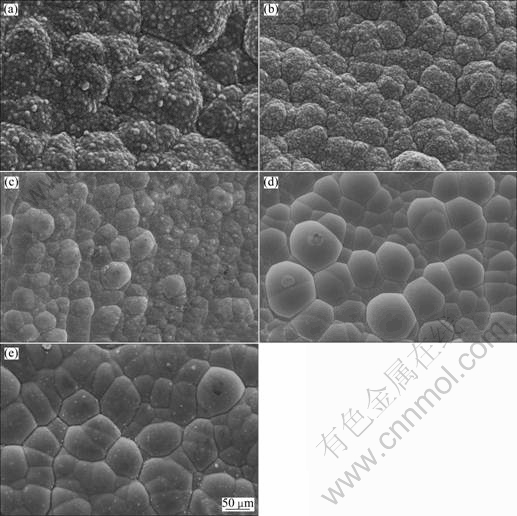

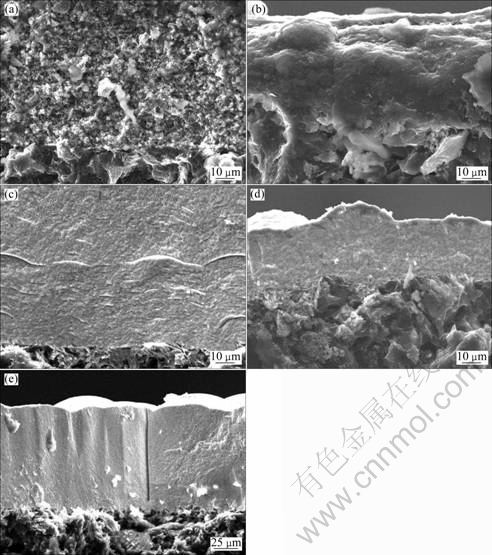

图4所示为不同H2浓度下制备的ZrC涂层表面SEM像。从图4(a)和(b)可看出,涂层表面有大量球形一次粒子,并且一次粒子之间相互连接,堆积成较大二次颗粒,二次颗粒之间存在空隙,涂层表面粗糙。

从图4(c)可看出,加入30%的H2后,涂层中的一次粒子基本消失,相互融合成大颗粒,颗粒间出现明显的界面。这主要是由于体系中通入H2的量少,在1600℃的高温下,甲烷热分解形成的大量原子碳首先在基体表面吸附、迁移和聚集,成为ZrC的形核核心[20]。从图4(d)和(e)可看出,随H2浓度的增大,H2对甲烷热解的抑制作用逐渐得到体现。由于甲烷热分解速率降低,首先吸附到基体表面的原子碳减少,直接导致ZrC的形核率降低,此时涂层的主要生长机制由形核生长

图3 ZrC涂层密度和H2浓度的关系

Fig.3 Relationship between ZrC coating density and H2 concentration

图4 不同H2浓度下制备的ZrC涂层表面SEM像

Fig.4 SEM images of surface morphologies of ZrC coatings prepared with different H2 concentrations: (a) 0; (b) 15%; (c) 30%; (d) 50%; (e) 90%

转变为长大生长。ZrC涂层颗粒逐渐长大,涂层表面孔洞基本消失,涂层变得致密。

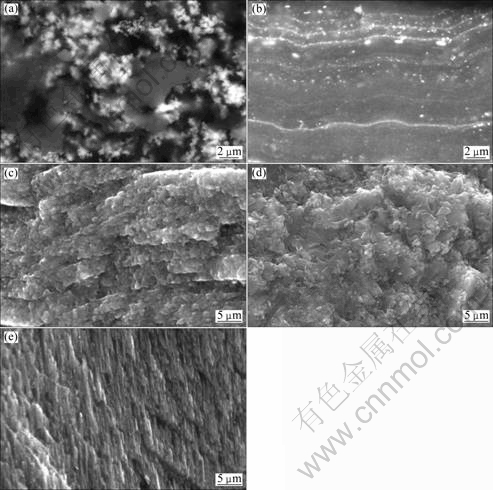

图5和6所示为不同H2浓度下制备的ZrC涂层自然断面的SEM像。图5所示为低倍SEM像,图6所示为高倍SEM像。由图5和6可知,无H2制备的涂层较为疏松,有较多孔隙,其他H2浓度制备的涂层都很致密;各涂层与基体连接紧密,与基体连接处及涂层内部都无可见裂纹;组织形貌随H2浓度变化相差很大。

图6(a)和(b)所示为SEM背散像,白色颗粒为ZrC晶粒,灰色为热解碳。由图6(a)和(b)可以看出,未加入H2时,涂层中热解碳多,且多呈块状,ZrC呈小晶粒不均匀分散状,涂层孔隙多,不致密,这是热解碳优先成核生长的结果。当H2浓度为15%时,涂层晶粒非常细小,且分布均匀,无明显孔洞,也无裂纹,这是涂层成核速度大,热解碳与ZrC均匀成核生长的结果。涂层沿表面出现分层现象,这是ZrCl4加入不均匀时造成的。当H2浓度为30%时,涂层致密,ZrC晶粒呈颗粒状,并出现沿基体表面分层的现象。当H2浓度为50%时,ZrC晶粒呈短柱状,颗粒间出现明显的融合长大现象。当H2浓度为90%时,涂层呈现典型的T型针状结构[21],即由垂直于基体表面的针状晶体紧密排列结构,这是ZrC晶体沿(220)方向强烈取向生长的结果。针状晶直径小于100 nm,为纳米晶结构。

2.5 H2的作用机制

APCVD法沉积ZrC是一个复杂的物理化学过程,一般主要分为以下几步:1) CH4、H2、ZrCl4和Ar分子经扩散到达基体表面;2) CH4热分解为原子碳和氢,气氛中的氢将高价Zr还原为低价Zr(ZrCl3、ZrCl2等);3) 原子碳首先吸附到基体表面作为形核活性点,并与锆的化合物反应生成ZrC;4) 气态产物HCl从基体表面解吸、扩散离开。其中主要的化学反应如反应式(1)~(4),反应式(5)为过程总反应式[22]:

图5 不同H2浓度下制备的ZrC涂层断面SEM像

Fig.5 Section SEM images of ZrC coatings prepared with different H2 concentrations: (a) 0; (b) 15%; (c) 30%; (d) 50%; (e) 90%

图6 不同H2浓度下制备的ZrC涂层断面高倍SEM像

Fig.6 High magnification section SEM images of ZrC coatings prepared with different H2 concentrations: (a) 0; (b) 15%; (c) 30%; (d) 50%; (e) 90%; (a), (b)BES; (c), (d), (e)SEI

ZrCl4+H2→ZrClx+HCl x=0~3 (2)

ZrClx+C→ZrC+Cl x=0~4 (3)

H2+Cl→HCl (4)

ZrCl4+CH4→ZrC+HCl (5)

从上述反应可看出:H2在整个制备ZrC的过程中有两方面作用,即:还原ZrCl4和抑制CH4热分解。其中式(1)为甲烷热分解过程,当体系中作为甲烷热分解产物的H的浓度增大时,不利于式(1)的正向进行,降低热分解速率,相反可以增加式(2)的反应速率。

反应体系在无H2或H2浓度较小时,热解碳的沉积占主导地位,作为ZrC的形核核心。由于反应温度过高,甲烷分解、生成热解碳速率过快,由于岛状生长的阴影效应,导致热解碳的沉积为多孔状,ZrC堆积其中,形成不均匀分布。当H2浓度增大,热分解生

成的原子碳减少,ZrCl4的还原程度增加,ZrC的沉积速率增大。无游离热解碳时,成核速率主要由温度和ZrC过饱和度决定。当体系中H2浓度不大时,ZrC过饱和度低,形核速率小,颗粒较大;H2浓度进一步增大,ZrC的形核速率大,ZrC晶粒变小。当H2浓度特别大时,ZrCl4很快被还原,ZrC过冷度大,ZrC形核速率大。由于原子的体扩散能力有限,大量ZrC晶核竞争生长,结果涂层形成针状结构。

3 结论

1) 以ZrCl4-CH4-H2-Ar为化学反应体系,采用常压气相沉积工艺,在1 600 ℃温度下能够在C/C材料基体上制备出致密无裂纹的ZrC涂层;无H2时,涂层由ZrC和C两相构成;随着H2浓度的增大,CH4分解为热解碳的速率降低,ZrCl4被还原的速率提高,涂层中的C含量逐渐减少,当H2浓度达到30%或更大时,涂层变为纯ZrC相。

2) H2浓度较小时,涂层表面起伏不平,涂层疏松,孔洞多,密度小;随H2浓度增大,ZrC晶粒长大,涂层表面变得平整,孔洞减少,致密度增大。

3) H2浓度在0和50%之间变化时,ZrC晶粒生长的择优取向为(111)和(200)双向,当H2浓度达到90%时,表现为强烈的(220)取向;相应地,涂层中ZrC晶粒由颗粒状、短柱状向针状转变。当H2浓度达到90%时,ZrC涂层呈典型的T型针状结构。

REFERENCES

[1] SMEACETTO F, SALVO M, FERRARIS M. Oxidation protective multilayer coatings for carbon-carbon composites[J]. Carbon, 2002, 40: 583-587.

[2] MORIMOTO T, OGURA Y, KONDO M, UEDA T. Multilayer coating for carbon-carbon composites[J]. Carbon, 1995, 33: 351-357.

[3] 黄剑锋, 李贺军, 熊信柏, 曾燮榕, 李克智, 付业伟, 黄 敏. 炭/炭复合材料高温抗氧化涂层的研究进展[J]. 新型炭材料, 2005, 20(4): 373-379.

HUANG Jian-feng, LI He-jun, XIONG Xin-bai, ZENG Xie-rong, LI Ke-zhi, FU Ye-wei, HUANG Min. Progress on the oxidation protective coating of carbon-carbon composites[J]. New Carbon Materials, 2005, 20(4): 373-379.

[4] 李国栋, 熊 翔, 黄伯云. 温度对CVD-TaC涂层组成、形貌与结构的影响[J]. 中国有色金属学报, 2005, 15(4): 565-571.

LI Guo-dong, XIONG Xiang, HUANG Bai-yun. Effect of temperature on composition, surface morphology and microstructure of CVD-TaC coating[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 565-571.

[5] 薛 晖, 李贺军, 付前刚, 李克智. 碳/碳复合材料防氧化涂层研究进展[J]. 固体火箭技术, 2007, 30(5): 427-432.

XUE Hui, LI He-jun, FU Qian-gang, LI Ke-zhi. Research on anti-oxidation coatings for C/C composites[J]. Journal of Solid Rocket Technology, 2007, 30(5): 427-432.

[6] 陈招科, 熊 翔, 李国栋, 肖 鹏, 张红波, 王雅雷, 黄伯云. 化学气相沉积TaC涂层的微观形貌及晶粒择优生长[J]. 中国有色金属学报, 2008, 18(8): 1377-1382.

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong, XIAO Peng, ZHANG Hong-bo, WANG Ya-lei, HUANG Bai-yun. Surface morphology of TaC coating prepared by chemical vapor deposition and preferential growth mechanism of TaC grains[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1377-1382.

[7] YANG J, WANG M X, KANG Y B, Li D J. Influence of bilayer periods on structural and mechanical properties of ZrC/ZrB2 superlattice coatings[J]. Applied Surface Science, 2007, 253: 5302-5305.

[8] CRACIUN V, CRACIUN D, HOWARD J M, WOO J. Pulsed laser deposition of crystalline ZrC thin films[J]. Thin Solid Films, 2007, 515: 4636-4639.

[9] WON Y S, KIM Y S, VARANASI V G, KRYLIOUK O, et al. Growth of ZrC thin films by aerosol-assisted MOCVD[J]. Journal of Crystal Growth, 2007, 304: 324-332.

[10] UETA S, AIHARA J, YASUDA A, ISHIBASHI H, TAKAYAMA T, HIROSAWA K. Fabrication of uniform ZrC coating layer for the coated fuel particle of the very high temperature reactor[J]. Journal of Nuclear Materials, 2008, 376: 146-151.

[11] 朱钧国, 杜春飙, 张秉忠, 杨 冰, 彭新立. 碳化锆镀层的化学气相沉积[J]. 清华大学学报: 自然科学版, 2000, 40(12): 59-62.

ZHU Jun-guo, DU Chun-biao, ZHANG Bing-zhong, YANG Bing, PENG Xin-li. Chemical vapor deposition of zirconium carbide coatings[J]. J Tsinghua Univ (Sci and Tech), 2000, 40(12): 59-62.

[12] PARK J H, JUNG C H, KIM D J, PARK J Y. Temperature dependency of the LPCVD growth of ZrC with the ZrCl4-CH4-H2 system[J]. Surface & Coatings Technology, 2008, 203: 324-328.

[13] LIU C, LIU B, SHAO Y L, LI Z Q, TANG C H. Preparation and characterization of zirconium carbide coating on coated fuel particles[J]. Am Ceram Soc, 2007, 90(11): 3690-3693.

[14] WONNA Y S, VARANNASIA V G, KRYLIOUK O. Equilibrium analysis of zirconium carbide CVD growth[J]. Journal of Crystal Growth, 2007, 307: 302-308.

[15] PARK J H, JUNG C H, KIM D J, PARK J Y. Effect of H2 dilution gas on the growth of ZrC during low pressure chemical vapor deposition in the ZrCl4-CH4-Ar system[J]. Surface & Coatings Technology, 2008, 203: 87-90.

[16] 黄 浩, 陈大明, 仝建峰, 李宝伟. 石墨表面CVD SiC涂层微观结构研究[J]. 航空材料学报, 2008, 28(2): 50-54.

HUANG Hao, CHEN Da-ming, TONG Jian-feng, LI Bao-wei. Microstructure study of the SiC coatings on graphite by CVD[J]. Journal of Aeronautical Materials, 2008, 28(2): 50-54.

[17] 王 辉, 宋 航, 金亿鑫, 蒋 红, 缪国庆. H2稀释度对HFCVD法沉积SiC薄膜结晶度的影响[J]. 长春理工大学学报, 2005, 28(1): 90-92.

WANG Hui, SONG Hang, JIN Yi-xin, JIANG Hong, MIAO Guo-qing. H2 dilution ratio (H2/H2 +CH4+SiH4) determining crystallinity in SiC thin films by HFCVD[J]. Journal of Changchun University of Science and Technology, 2005, 28(1): 90-92.

[18] IMAI Y, MUKAIDA M, WATANABE A, TSUNODA T. Formation energies of two-dimensional nuclei randomly-generated on (001), (110), and (111) planes of a face-centered-cubic crystal[J]. Thin Solid Films, 1997, 300: 305-313.

[19] 赵 星, 叶志镇, 吴贵斌, 刘国军, 赵炳辉, 唐九耀. H2对UHV/CVD低温选择性外延生长Si1-xGex的影响[J]. 半导体学报, 2006, 27(1): 78-81.

ZHAO Xing, YE Zhi-zhen, WU Gui-bing, LIU Guo-jun, ZHAO Bing-hui, TANG Jiu-yao. Effect of hydrogen on the low temperature selective epitaxial growth in Si1-xGex by UHV/CVD[J]. Journal of Semiconductors, 2006, 27(1): 78-81.

[20] 陈招科, 熊 翔, 李国栋, 肖 鹏, 张红波, 尹 健, 黄伯云. 工艺参数对CVI-TaC沉积速率的影响[J]. 中国有色金属学报, 2006, 16(12): 2047-2053.

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong, XIAO Peng, ZHANG Hong-bo, YIN Jian, HUANG Bai-yun. Influence of process parameters on deposition rate of CVI-TaC[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2047-2053.

[21] 唐伟忠. 薄膜材料制备原理、技术及应用[M]. 北京: 冶金工业出版社, 2003: 178-181.

TANG Wei-zhong. Preparation of principles of thin film materials, technology and application[M]. Beijing: Metallurgical Industry Press, 2003: 178-181.

[22] WANG Y G, LIU Q M, LIU J L, ZHANG L T, CHENG L F. Deposition mechanism for chemical vapor deposition of zirconium carbide coatings[J]. Am. Ceram. Soc, 2008, 91(4): 1249-1252.

(编辑 何学锋)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z110);国家自然科学基金创新研究群体项目 (50721003);国家重点基础研究发展计划资助项目(2011CB605805);

收稿日期:2009-03-09;修订日期:2010-04-07

通信作者:李国栋,教授;博士;电话:0731-88836864;E-mail:lgd63@163.com