等通道挤压变形结合中间退火制备Al-7Mg合金的组织、硬度演变及热稳定性

来源期刊:中国有色金属学报(英文版)2014年第7期

论文作者:查敏 李彦军 Ragnvald MATHIESEN Ruben BJ?RGE Hans J ROVEN

文章页码:2301 - 2306

关键词:铝-镁合金;等通道挤压变形(ECAP);变形组织;硬度演化;强化;热稳定性

Key words:Al-Mg alloys; equal channel angular pressing (ECAP); as-deformed microstructure; hardness evolution; strengthening; thermal stability

摘 要:在室温条件下采用Bc模式等通道挤压变形 (ECAP) 结合中间退火方法制备二元Al-7Mg 合金。经6道次ECAP变形后, 该材料硬度高达 HV218。透射电镜 (TEM) 表征揭示该Al-7Mg合金的晶粒得到明显细化。经5或6道次变形后得到的超细晶组织平均尺寸为100~200 nm。 X射线衍射分析表明Mg主要以固溶原子的形式存在。因此,由于Mg偏析或析出相造成的可能强化影响均忽略不计。经6道次ECAP变形后的Al-7Mg合金的高硬度主要来自于晶界强化,大约占总强度的 41%, 其次,位错强化及Mg原子的固溶强化分别约占总强度的24%和35%。此外,通过测量硬度变化研究了该Al-7Mg合金的热稳定性。结果表明在250 °C退火处理时该材料相对稳定,然而当温度升至300 °C 时,该Al-7Mg合金的软化趋势明显加快。

Abstract: A binary Al-7Mg alloy was processed by equal channel angular pressing (ECAP) at room temperature via route Bc, combined with intermediate annealing. After 6 passes, a high hardness of 218 HV is achieved. Transmission electron microscopy (TEM) observations demonstrate that ECAP leads to a significant grain refinement and ultrafine grains down to 100-200 nm are developed after 5 or 6 passes. X-ray diffraction (XRD) analysis indicates that the major part of Mg atoms are in solid solution in the deformed material, and the possible strengthening effect of Mg solute atom clusters or precipitates is neglected. The high hardness of the 6 pass-treated materials comes mainly from grain boundary strengthening, which contributes about 41% to the total strength, while dislocations and Mg solid solution contribute about 24% and 35% to the remaining strength, respectively. Also, the thermal stability of this severely deformed material was investigated by hardness measurements. The material is relatively stable when annealed at a temperature lower than 250 °C, while annealing at 300 °C leads to a rapid softening of the material.

Trans. Nonferrous Met. Soc. China 24(2014) 2301-2306

Min ZHA1, Yan-jun LI1, Ragnvald MATHIESEN2, Ruben  2, Hans J. ROVEN 1,3

2, Hans J. ROVEN 1,3

1. Department of Materials Science and Engineering, Norwegian University of Science and Technology, Trondheim 7491, Norway;

2. Department of Physics, Norwegian University of Science and Technology, Trondheim 7491, Norway;

3. Center for Advanced Materials, Qatar University, Doha, Qatar

Received 17 October 2013; accepted 3 April 2014

Abstract: A binary Al-7Mg alloy was processed by equal channel angular pressing (ECAP) at room temperature via route Bc, combined with intermediate annealing. After 6 passes, a high hardness of 218 HV is achieved. Transmission electron microscopy (TEM) observations demonstrate that ECAP leads to a significant grain refinement and ultrafine grains down to 100-200 nm are developed after 5 or 6 passes. X-ray diffraction (XRD) analysis indicates that the major part of Mg atoms are in solid solution in the deformed material, and the possible strengthening effect of Mg solute atom clusters or precipitates is neglected. The high hardness of the 6 pass-treated materials comes mainly from grain boundary strengthening, which contributes about 41% to the total strength, while dislocations and Mg solid solution contribute about 24% and 35% to the remaining strength, respectively. Also, the thermal stability of this severely deformed material was investigated by hardness measurements. The material is relatively stable when annealed at a temperature lower than 250 °C, while annealing at 300 °C leads to a rapid softening of the material.

Key words: Al-Mg alloys; equal channel angular pressing (ECAP); as-deformed microstructure; hardness evolution; strengthening; thermal stability

1 Introduction

Ultrafine grained (UFG) metals and alloys produced by severe plastic deformation (SPD) have generally superior mechanical properties resulting from significant grain refinement together with dislocation strengthening [1]. The equal channel angular pressing (ECAP) technique is especially attractive for producing bulk UFG metals and alloys in comparison with other SPD techniques, as it allows a minimal change of external sample dimensions [1,2].

Al-Mg alloys are among the most widely used and most extensively studied solid solution hardening Al alloys. They are considered especially attractive for production of high strength UFG materials through ECAP [3] because Mg has very high solubility in Al. The role of Mg in obtaining UFG structures in Al matrix by RT-ECAP has been clearly demonstrated [3,4]. The mechanical properties of Al-Mg alloys (≤3% Mg) subjected to RT-ECAP has been investigated in detail, based mainly on the hardness measurements and compression tests [4-6]. In addition, UFG materials processed by ECAP appear to retain high levels of internal strain and most of the grain boundaries are in non-equilibrium configurations [7], which necessitates further evaluation of their thermal stability [2]. Generally, an increase in Mg content decreases the stacking fault energy, normally resulting in low recovery rates and therefore smaller grain sizes after the SPD process [4]. With the Mg content increasing up to 4%, however, the material presents challenges with regard to workability at ambient temperature with cracking and failure occurring during ECAP [8]. In contrast, by increasing the pressing temperature, the plastic workability of Al-Mg alloys is improved [9,10]. However, hot ECAP leads to a tremendous expense of strength [11]. To the best of our knowledge, yet little effort has been devoted to binary Al-Mg alloys containing above 4% Mg processed by RT-ECAP.

To further exploit the strengthening potential of aluminium alloys containing a high content of Mg, a combination of RT-ECAP with intermediate annealing, similar to that introduced by FURUKAWA et al [12], has been applied in the present work. With this approach, 6 passes of RT-ECAP have been achieved successfully in the Al-7Mg alloy. The corresponding mechanical properties and the annealing response of the material were investigated and briefly reported.

2 Experimental

Materials used in the present work were taken from cast Al-7Mg ingots supplied by hydro aluminium having chemical composition (mass fraction, %): Mg 7.0, Fe 0.05, Si 0.06, Al in balance. ECAP was performed with route Bc, using a 100 mm × 19.5 mm × 19.5 mm bar in a 90° die, which leads to an imposed strain of about 1.0 per pass. All ECAP experiments were carried out at room temperature. However, the ECAP process at room temperature was interrupted after 3 passes, since severe cracks extended to the center thickness of the samples. By applying intermediate annealing at 300 °C for 120 s on samples between selected pressings, the Al-7Mg alloy was pressed successfully to 5 and 6 passes, respectively. Samples from the uniformly deformed central region of the ECAP billets were chosen for microstructure observation, hardness measurement and post annealing experiment. The intermediately annealed samples were labeled as 5P and 6P (5P=2 passes + annealing +3 passes; 6P=2 passes + annealing + 2 passes + annealing + 2 passes). Intermediate and post-ECAP annealing treatments were performed using two different furnaces depending on the applied temperature range: air circulated furnace (≤275 °C), and molten salt baths (~300 °C). The temperature error was controlled within ±3 °C in all cases. Immediately after annealing, samples were water-quenched to room temperature. The TEM foils were prepared by twin-jet electro polishing in a solution of 33% nitric acid-methanol at -30 °C. TEM analysis was performed with a Philips CM30 operating at 150 kV and with a JEOL* 2010 at 200 kV. Samples for X-ray diffraction analysis (XRD) were prepared by standard metallographic techniques followed by electro polishing with a solution of 80% C2H5OH + 20% HClO4 at 20 V for 15 to 25 s at -30 °C. XRD was undertaken with a Siemens D5000 at 40 kV, Cu Kα radiation, with 0.02 step size and 20 s/step. Vickers microhardness measurements were preformed under a 4.9 N load applied for 15 s. At least six separating measurements were conducted for each condition.

3 Results and discussion

3.1 As-deformed microstructure

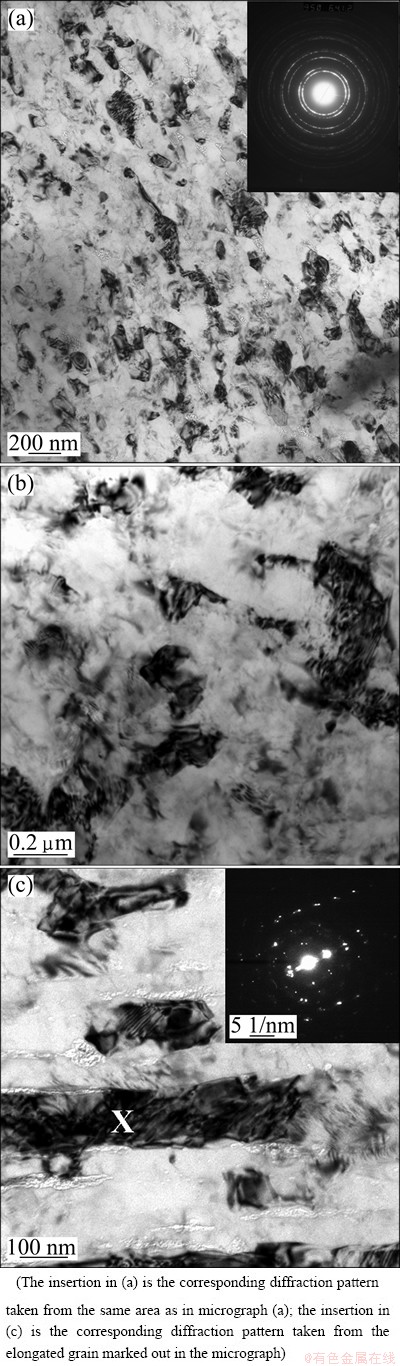

TEM observations were carried out in order to investigate the microstructures of the 5P and 6P treated samples and the corresponding micrographs are shown in Fig. 1. The adjoining selected area diffraction patterns (SAD) in Fig. 1(a) indicate that a submicron sized polycrystalline structure is developed. No Mg-containing precipitates, such as Al3Mg2 phase, were detected by diffraction patterns. However, this might be due to their small volume fraction and extremely fine size [13]. It is therefore believed that the effect from Al3Mg2 precipitation, if any, should be weak and negligible.

Fig. 1 Typical TEM images of 5P (a) and 6P (b) treated samples and higher magnification micrograph of elongated UFG grains (c)

Also, the 6P treated sample has similar microstructures to that of the 5P treated sample, but with an obvious further grain refinement (Fig. 1(b)). Most ultrafine grains in both samples appear elongated, with 50-100 nm in width and 200-500 nm in length. Figure 1(c) shows a higher magnification micrograph of the elongated grains in the 5P treated sample, and shows apparent extinction contours and dislocation tangles inside the grains at the grain boundaries. The inserted SAD pattern in Fig. 1(c) reveals some misorientations inside the elongated grains, indicating the formation of sub-boundaries.

Note that grain boundaries (GBs) frequently appear curved and poorly defined, or show a strong spread in terms of thickness extinction contours (Fig. 1), indicating a high level of internal stresses and elastic lattice distortions due to the presence of a high density of dislocations in boundary regions. Figure 1 also reveals the presence of extensive dislocation tangles in grain interiors and at grain boundaries. Apparently, the elongated ultra-fine grains are in a non-equilibrium state, as evidenced by the fuzzy GBs [14,15].

3.2 Hardness evolution during processing

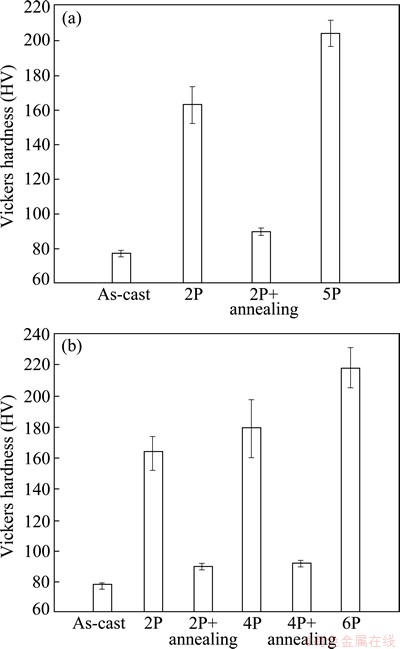

The evolutions of Vickers hardness (HV) of the 5P and 6P treated samples during the whole ECAP + intermediate annealing procedure are illustrated in Figs. 2(a) and (b), respectively. Obviously, the hardness increases significantly after 2 passes, i.e., from ~77 HV in the as-cast state to ~165 HV in the 2 passes treated sample. The large increase in hardness after 2 passes probably originates from a significant substructure refinement and the introduction of a high density of dislocations. After intermediate annealing, the hardness decreases significantly, though still slightly higher than that in the as-received state. With another 2 or 3 ECAP passes, the hardness increases again, to ~180 HV and ~205 HV in the 4 and 5 passes treated sample, respectively. With another round of intermediate annealing and another 2 ECAP passes performed after 4 passes, a peak hardness of ~218 HV is achieved in the 6P treated sample. It is here interesting to note that a HPT-processed Al-4.1Mg alloy obtained ~191 HV [16]. Hence, the high hardness in the present Al-7Mg alloy is probably strongly affected by the enhanced Mg concentration, facilitating large strain hardening during ECAP.

3.3 Strengthening mechanisms

Undoubtedly, the high hardness obtained in the present material is substantially beyond what can be achieved in conventionally-deformed bulk Al-Mg alloys, as well for ECAP treated Al-Mg alloys with lower Mg concentrations [4,17]. In the present study, the 6P treated sample gives the highest hardness and accordingly, represents an interesting process scheme and a preferred template for evaluating roles of various potential strengthening factors. However, careful examinations in high-resolution TEM, indicate that no potential contribution to the strengthening seems to occur from precipitated Mg-containing intermetallics.

Fig. 2 Evolution of Vickers hardness of 5P (a) and 6P (b) treated samples with increasing passes and intermediate annealing

In the present alloy, where grains are refined into UFG structures with an average size down to 100-200 nm, grain boundary strengthening is expected to have a prominent influence, as indicated by the Hall-Petch relationship [18]:

ΔHVGB=kHd-1/2 (1)

where ΔHVGB is the contribution from grain boundaries to the overall strength; d is the grain size; kH is a constant of HV ~35 μm-1/2 . The average grain size d of the UFG grains in the present material was determined by measuring the length and width of about 100 individual grains from six TEM micrographs. Then the equivalent diameter was calculated to be ~150 nm. With an average grain size of 150 nm, the strength contribution from grain boundaries is ~90 HV. However, it should be noted that the actual grain boundary strengthening contribution is probably somewhat lower than that predicted from this value, due to the existence of some coarser grains, which might not be easily detected by TEM.

Magnesium is known to strengthen Al through solid solution hardening, reducing dislocation mobility by atom-dislocation interactions [3,18]. The atom- dislocation interactions consist of both in the form of dislocation “pinning” in lattice positions occupied by solute atoms, and by the diffusion of solute atoms to dislocations, retarding their mobility [18]. According to results of RYEN et al [19] and HUSKINS et al [18], the solute strengthening increment, σSS, due to a concentration C of solid solution atoms can be expressed as

Δσss=HCn (2)

where H and n are constants [18]. At the yield point εys= 0.002, commercial Al alloys take values H=13.8 (MPa/%) and n=1.14 under a strain rate of 6×10-3 s-1 [19]. All the parameters in Ref. [19] are determined from tensile experiments conducted on coarse grained Al-based alloys and the strain rate (6×10-3 s-1) in Ref. [19] is about ten times that used in the present work (5×10-4 s-1). Hence, one may speculate that this would represent an uncertainty since H and n are sensitive to strain rate. However, according to Ref. [19], the Mg concentration may be disregarded, within the strain rate range of 1×10-3 s-1-1×10-4 s-1, and the yield stress keeps almost constant.

Before calculating the strengthening contribution from Mg in solid solution, one has to mention that there might be some Mg segregation, according to XRD analysis. The latter indicates a decrease in the lattice parameter from (4.0860±0.0002)  in the as-homogenized state to (4.0824±0.0004)

in the as-homogenized state to (4.0824±0.0004)  in the as-deformed state. Such a feature could be the result of deformation-induced segregation or precipitation at grain boundaries [20]. However, Mg-containing precipitates were neither observed by TEM nor detected by XRD. Moreover, it is very difficult to calculate the strengthening contribution from SPD-induced Mg segregation. For convenience, one assumed that the 7% of Mg atoms are kept in solid solution. The increment in hardness due to solid solution is therefore estimated to be ΔHvss= ~51 HV (assuming that σb=2.5VH, where VH is ~218 HV giving a yield strength σb of ~538 MPa). Nevertheless, the assumption that 7.0% of Mg is solved may slightly overestimate the contribution from solid solution.

in the as-deformed state. Such a feature could be the result of deformation-induced segregation or precipitation at grain boundaries [20]. However, Mg-containing precipitates were neither observed by TEM nor detected by XRD. Moreover, it is very difficult to calculate the strengthening contribution from SPD-induced Mg segregation. For convenience, one assumed that the 7% of Mg atoms are kept in solid solution. The increment in hardness due to solid solution is therefore estimated to be ΔHvss= ~51 HV (assuming that σb=2.5VH, where VH is ~218 HV giving a yield strength σb of ~538 MPa). Nevertheless, the assumption that 7.0% of Mg is solved may slightly overestimate the contribution from solid solution.

An increase in dislocation density is expected to be the main mechanism responsible for the rapid increase in strength of severely deformed Al-Mg alloys with increasing Mg content [21], as the relationship between strength increment and the dislocation density (ρ) for plastically deformed metals can be characterized by the Taylor equation [22]:

(3)

(3)

where α1 =0.3 is a constant, G=27 GPa is the shear modulus, b=2.86×10-10 m is the length of the Burgers vector for Al and M=3 is the Taylor factor [22]. To the best of the present authors’ knowledge, applicable dislocation densities for ECAP-processed Al-Mg alloys are not available in the literature. Also, it is quite difficult to assess reliable dislocation densities for the present material due to the heterogeneous microstructure. However, since all contributions to the present total flow stress are calculated at the onset of yield (0.2% strain) and are referred to as increments in yield strength, ΔHvD may be estimated to be ~76 HV. This is obtained by employing a relationship for the total hardness Hvb=ΔHvGB+ΔHvD+ΔHvSS, where ΔHvGB=90 HV, ΔHvSS= 51 HV, Hvb=218 HV. As the possible Mg segregation may cause some influence on the strengthening mechanisms, the contribution from the dislocation strengthening might be somewhat overestimated. Segregated Mg atoms might form clusters at grain boundaries and provide an additional strengthening effect as discussed earlier and as proposed in Ref. [23].

Nevertheless, based on the above analyses, the high hardness of the 6 passes material comes mainly from the enhanced grain boundary strengthening σGB, i.e., carrying ~41% to the total strength, while the dislocation density and Mg solid solution contribute ~24% and ~35% to the remaining strength, respectively, if the additional strengthening effect of clusters formed by segregated Mg atoms is neglected.

3.4 Hardness evolution upon annealing

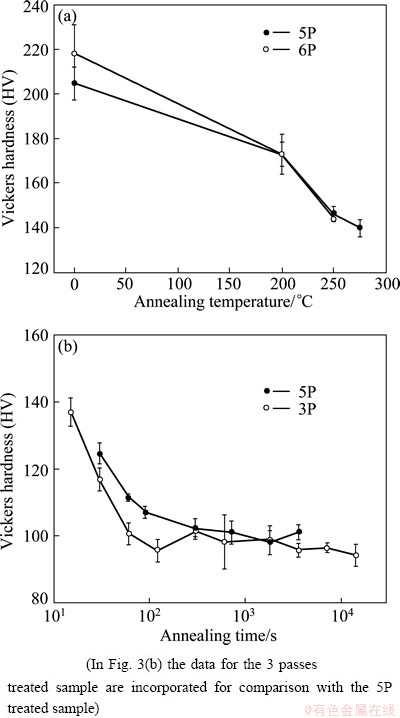

To evaluate the thermal stability of the present Al-7Mg alloy, the evolution of hardness of the 5P and 6P treated samples upon annealing at different temperatures for 30 min, and for various time at ~300 °C, was plotted in Figs. 3(a) and (b), respectively. In Fig. 3(b), the data for the 3P treated sample are incorporated for comparison. After annealing at ~200 °C for 30 min, a significant portion of the enhanced hardness from ECAP is still retained, e.g., decreasing from >200 HV to ~180 HV (see Fig. 3(a)). With the temperature increasing to ~250 °C and further to 275 °C, the hardness decreases gradually to ~150 HV, most likely due to a more pronounced dislocation recovery process. At 300 °C, the decrease in hardness becomes sharp and completes more or less within 90 s (Fig. 3(b)), hence indicative of the occurrence and completion of recrystallization. The hardness evolution of the 5P treated sample at ~300 °C is quite similar to that of the 3 passes treated sample, i.e. changing drastically above ~300 °C. Therefore, ~300 °C seems to be more or less than the critical temperature for nucleation of recrystallization. However, further investigations on the recrystallization behaviour are still ongoing.

Fig. 3 Change of Vickers hardness with increasing annealing temperature for 30 min (a) and isothermal annealing at 300 °C with increasing time (b)

4 Conclusions

1) A binary Al-7Mg alloy with enhanced hardness was processed at room temperature by ECAP combined with intermediate annealing. After 5 or 6 passes, ultrafine grains down to 100-200 nm were developed. After 6 passes, a hardness of ~218 HV was achieved.

2) The major part of Mg atoms is in solid solution in the as-deformed material, and hence the possible strengthening effect of Mg solute atom clusters or precipitates is neglected. The high hardness of the 6 passes treated material comes mainly from grain boundary strengthening, which contributes ~41% to the total strength, while dislocation density and Mg solid solution contributes ~24% and ~35% to the remaining strength, respectively.

3) The thermal stability of this severely deformed alloy was investigated by hardness measurement. The material is relatively stable when annealed at temperatures lower than 200 °C, while annealing at 300 °C leads to rapid softening. The temperature of 300 °C seems to be the critical temperature for nucleation of recrystallization.

Acknowledgements

Financial support from the SUP Project ‘Improvement’ (Pnr. 192450) financed by the Research Council of Norway is gratefully acknowledged. The authors also thank Mr.  Skaret for assisting during ECAP experiments.

Skaret for assisting during ECAP experiments.

References

[1] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement [J]. Progress in Materials Science, 2006, 51(7): 881-981.

[2] MORRIS D G, MUNOZ-MORRIS M A. Microstructure of severely deformed Al-3Mg and its evolution during annealing [J]. Acta Materialia, 2002, 50(16): 4047-4060.

[3] IWAHASHI Y, HORITA Z, NEMOTO M, LANGDON T G. Factors influencing the equilibrium grain size in equal-channel angular pressing: Role of Mg additions to aluminum [J]. Metallurgical and Materials Transactions A, 1998, 29(10): 2503-2510.

[4] GUBICZA J, CHINH NQ, HORITA Z, LANGDON T G. Effect of Mg addition on microstructure and mechanical properties of aluminum [J]. Materials Science and Engineering A, 2004, 387(1): 55-59.

[5] FURUKAWA M, HORITA Z, NEMOTO M, VALIEV R Z, LANGDON T G. Factors influencing the flow and hardness of materials with ultrafine grain sizes [J]. Philosophical Magazine A, 1998, 78(1): 203-215.

[6] MUNOZ-MORRIS M A, OCA C G, MORRIS D G. Mechanical behaviour of dilute Al-Mg alloy processed by equal channel angular pressing [J]. Scripta Materialia, 2003, 48(3): 213-218.

[7] LIU M P, ROVEN H J, MURASHKIN M Y, VALIEV R Z, KILMAMETOV A, ZHANG Z, YU Y D. Structure and mechanical properties of nanostructured Al-Mg alloys processed by severe plastic deformation [J]. Journal of Materials Science, 2013, 48(13): 4681-4688.

[8] STOLYAROV V V, LAPOVOK R. Effect of backpressure on structure and properties of AA5083 alloy processed by ECAP [J]. Journal of Alloys and Compounds, 2004, 378(1-2): 233-236.

[9] SITDIKOV O, SAKAI T, AVTOKRATOVA E, KAIBYSHEV R, KIMURA Y, TSUZAKI K. Grain refinement in a commercial Al-Mg-Sc alloy under hot ECAP conditions [J]. Materials Science and Engineering A, 2007, 444(1-2): 18-30.

[10] SITDIKOV O, SAKAI T, AVTOKRATOVA E, KAIBYSHEV R, TSUZAKI K, WATANABE Y. Microstructure behavior of Al-Mg-Sc alloy processed by ECAP at elevated temperature [J]. Acta Materialia, 2008, 56(4): 821-834.

[11] KAIBYSHEV R, AVTOKRATOVA E, SITDIKOV O. Mechanical properties of an Al-Mg-Sc alloy subjected to intense plastic straining [J]. Thermec, 2009, 638-642:1952-1958.

[12] FURUKAWA M, UTSUNOMIYA A, MATSUBARA K, HORITA Z, LANGDON T G. Influence of magnesium on grain refinement and ductility in a dilute Al-Sc alloy [J]. Acta Materialia, 2001, 49(18): 3829-3838.

[13] STRAUMAL B B, BARETZKY B, MAZILKIN A A, PHILLIPP F, KOGTENKOVA O A, VOLKOV M N, VALIEV R Z. Formation of nanograined structure and decomposition of supersaturated solid solution during high pressure torsion of Al-Zn and Al-Mg alloys [J]. Acta Materialia, 2004, 52(15): 4469-4478.

[14] LIU M, SUN S C, ROVEN H J, YU Y D, ZHANG Z, MURASHKIN M, VALIEV R Z. Deformation defects and electron irradiation effect in nanostructured Al-Mg alloy processed by severe plastic deformation [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1810-1816.

[15] LIU M, ROVEN H J, LIU X T, MURASHKIN M, VALIEV R Z, TAMAS U, BALOGH. Special nanostructures in Al-Mg alloys subjected to high pressure torsion [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 2051-2056.

[16] ROVEN H J, LIU M, MURASHKIN M, VALIEV R Z, KILMAMETOV A R, UNGAR T, BALOGH L. Nanostructures and microhardness in Al and Al-Mg alloys subjected to SPD [J]. Materials Science Forum, 2009, 604-605: 179-185.

[17] KAPOOR R, KUMAR N, MISHRA R S, HUSKAMP C S, SANKARAN K K. Influence of fraction of high angle boundaries on the mechanical behavior of an ultrafine grained Al-Mg alloy [J]. Materials Science and Engineering A, 2010, 527(20): 5246-5254.

[18] HUSKINS E L, CAO B, RAMESH K T. Strengthening mechanisms in an Al-Mg alloy [J]. Materials Science and Engineering A, 2010, 527(6): 1292-1298.

[19] RYEN O, NIJS O, SJOLANDER E, HOLMEDAL B, EKSTROM H E, NES E. Strengthening mechanisms in solid solution aluminum alloys [J]. Metallurgical and Materials Transactions A, 2006, 37(6): 1999-2006.

[20] VALIEV R Z, ENIKEEV N A, MURASHKIN M Y, KAZYKHANOV V U, SAUVAGE X. On the origin of the extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation [J]. Scripta Materialia, 2010, 63(9): 949-952.

[21] LIU M, ROVEN H J, LIU X, MURASHKIN M, VALIEV R Z, UNGAR T, BALOGH L. Grain refinement in nanostructured Al-Mg alloys subjected to high pressure torsion [J]. Journal of Materials Science, 2010, 45(17): 4659-4664.

[22] GUBICZA J, CHINH N Q, LABAR J L, DOBATKIN S, HEGEDUS Z, LANGDON T G. Correlation between microstructure and mechanical properties of severely deformed metals [J]. Journal of Alloys and Compounds, 2009, 483(1-2): 271-274.

[23] SABIROV I, MURASHKIN M Y, VALIEV R Z. Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development [J]. Materials Science and Engineering A, 2013, 560(1): 1-24.

查 敏1,李彦军1,Ragnvald MATHIESEN2, Ruben  2, Hans J ROVEN 1,3

2, Hans J ROVEN 1,3

1. Department of Materials Science and Engineering, Norwegian University of Science and Technology, Trondheim 7491, Norway;

2. Department of Physics, Norwegian University of Science and Technology, Trondheim 7491, Norway;

3. Center for Advanced Materials, Qatar University, Doha, Qatar

摘 要:在室温条件下采用Bc模式等通道挤压变形 (ECAP) 结合中间退火方法制备二元Al-7Mg 合金。经6道次ECAP变形后, 该材料硬度高达 HV218。透射电镜 (TEM) 表征揭示该Al-7Mg合金的晶粒得到明显细化。经5或6道次变形后得到的超细晶组织平均尺寸为100~200 nm。 X射线衍射分析表明Mg主要以固溶原子的形式存在。因此,由于Mg偏析或析出相造成的可能强化影响均忽略不计。经6道次ECAP变形后的Al-7Mg合金的高硬度主要来自于晶界强化,大约占总强度的 41%, 其次,位错强化及Mg原子的固溶强化分别约占总强度的24%和35%。此外,通过测量硬度变化研究了该Al-7Mg合金的热稳定性。结果表明在250 °C退火处理时该材料相对稳定,然而当温度升至300 °C 时,该Al-7Mg合金的软化趋势明显加快。

关键词:铝-镁合金;等通道挤压变形(ECAP);变形组织;硬度演化;强化;热稳定性

(Edited by Xiang-qun LI)

Corresponding author: Min ZHA; Tel: +4773597092; E-mail: min.zha@material.ntnu.no

DOI: 10.1016/S1003-6326(14)63348-3