文章编号:1004-0609(2013)12-3267-08

剧塑性变形及退火后Mg-Li合金的组织与力学性能

林 楷1, 2,康志新1, 2,方 强1, 2,张俊逸1, 2

(1. 华南理工大学 机械与汽车工程学院,广州 510640;

2. 华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640)

摘 要:采用剧塑性变形工艺(等通道转角挤压和轧制)以及随后的短时间退火制备高性能Mg-Li合金,通过显微组织观察、扫描电镜分析、X射线衍射仪测试和室温拉伸测试等研究变形前后合金组织、力学性能及强化机制。结果表明:合金铸态晶粒粗大,主相为β相,α相分布于β相的晶界以及晶内;同时,晶内存在大量Al2Y和AlLi析出相。由于动态回复作用显著,合金变形时并未发生明显的动态再结晶现象;经短时间退火后,合金组织发生完全再结晶,其晶粒细化至27.1 μm(12pra工艺,即等通道转角挤压、轧制及退火)。铸态合金的抗拉强度和伸长率分别为131.1 MPa和47.1%;经12pr(等通道转角挤压及轧制)变形后,合金的伸长率达到90.5%,而抗拉强度稍有提高,这主要受位错协调变形及动态回复作用的影响;退火后合金的伸长率显著降低而强度提高至237.6 MPa (12pra),出现退火致强化现象,其主要的机制是有限位错源强化及晶界强化。

关键词:Mg-Li合金;等通道转角挤压;轧制;退火;显微组织;力学性能

中图分类号:TG146.22;TG113 文献标志码:A

Microstructure and mechanical properties of Mg-Li alloy processed by severe plastic deformation and annealing

LIN Kai1, 2, KANG Zhi-xin1, 2, FANG Qiang1, 2, ZHANG Jun-yi1, 2

(1. School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China;

2. National Engineering Research Center of Near-Net-Shape Forming for Metallic Materials, South China University of Technology, Guangzhou 510640, China)

Abstract: The microstructure, mechanical properties and strengthening mechanism of Mg-Li alloys processed by severe plastic deformation (equal channel angular pressing (ECAP) and rolling) and subsequent annealing were analyzed by OM, SEM, XRD and tensile testing. The results show that the initial grains of the as-cast alloy are coarse and β phase occupies the main position, while α phase distributes inside or in the boundary. Meanwhile, there are lots of precipitate phases Al2Y and AlLi in the grain. Obvious dynamic recrystallization (DRX) does not occur during the deformation due to the significant effect of dynamic recovery (DR). After a short time annealing, the alloy is completely recrystallized with grain size refined to 27.1 μm (process of 12pra: ECAP, rolling and annealing). The tensile strength and elongation of the as-cast alloy are 131.1 MPa and 47.1%, respectively. After the process of 12pr (ECAP and rolling), the elongation of the alloy reaches 90.5%, while the tensile strength is improved slightly. This can be explained based on the effect of DR and dislocation-coordinated deformation. Subsequent annealing treatment results in an increase in tensile strength (12pra: 237.6 MPa) and a significant decrease in elongation because of the dislocation source-limited hardening and grain boundary strengthening mechanism.

Key words: Mg-Li alloy; equal channel angular pressing; rolling; annealing; microstructure; mechanical property

Mg-Li合金是当今密度最低的金属结构材料之一,具有较高的比刚度,良好的切削性能、电磁屏蔽性能和阻尼性能等一系列优点[1-2]。Li元素的存在提高了镁合金的塑性,然而,由于强度低和耐腐蚀性能差等缺点,因此,Mg-Li合金一直未能得到广泛的应用。

通常,提高Mg-Li合金强度的方法有合金化法、颗粒复合强化法等。而这些方法在提高Mg-Li合金强度的同时,往往导致塑性的降低[3-5]。由于双相Mg-Li合金(5%<w(Li)<11%[6])存在密排六方以及体心立方两种晶体结构,因此,其塑性变形机制与一般密排六方晶体结构的镁合金有所不同。等通道转角挤压(Equal channel angular pressing,ECAP)可在一定程度上提高材料的强度和塑性[7-8],但难以获得抗拉强度超过200 MPa且同时具备良好塑性的Mg-Li合金[9]。

近年来,发现纯铝、钛、镍和铜等金属材料剧塑性变形后发生退火致强化的现象[10-13];而HUANG等[12]发现了纯铝累积叠轧焊变形后退火致强化以及随后的小变形软化现象,并提出了“有限位错源”强化机制[14],引起了广泛关注。退火致强化现象的出现需要金属材料达到一定的变形量[15],同时,随着变形量的增加,强化现象更明显。但是,目前这种现象在镁合金上仍鲜有报道。

本文作者针对Mg-Li合金进行ECAP变形及ECAP+轧制变形,为了获得较大的累积变形量,ECAP工艺采用多步法进行(即先高温再低温变形);并对变形后的Mg-Li合金进行短时间退火处理,制备高强度高和塑性优的Mg-Li合金。通过对变形前后Mg-Li合金组织的观察与力学性能测试,探索其组织演变及强化机制。

1 实验

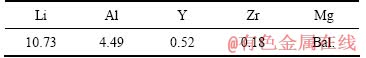

材料为铸态Mg-10.73Li-4.49Al-0.52Y合金。该合金铸锭采用真空感应电炉在氩气保护下进行熔炼后浇铸获得,合金的化学成分如表1[16]所列。

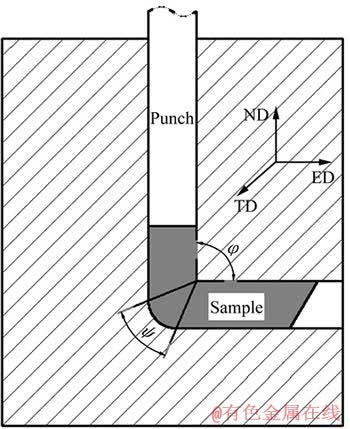

将铸锭加工成d 20 mm×70 mm规格的棒材试样进行挤压变形,ECAP模具如图1所示,其通道内角φ=90°,外角ψ=45°,该模具每道次等效应变量约为1。

表1 Mg-Li合金的化学成分[16]

Table 1 Chemical composition of Mg-Li alloy (mass fraction, %)[16]

图1 等通道转角挤压(ECAP)原理示意图

Fig. 1 Schematic diagram of equal channel angular pressing (ECAP)

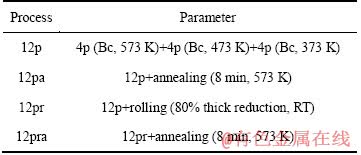

试样的挤压路径为Bc路径,即每道次挤压后试样按同一个方向旋转90°进行下一道次的挤压;挤压速度为1.5 mm/s;采用降温挤压方法进行变形:首先在573 K下进行4道次挤压,然后在473 K下进行4道次挤压,最后在373 K下进行4道次挤压,试样挤压总道次为12道次;挤压时,采用石墨机油混合液进行润滑,以改善试样变形时的应力状态。将ECAP变形后的试样在室温下进行轧制变形,道次变形率为15%~20%,压下总量为80%。对变形后的材料进行退火处理,退火温度为573 K,退火时间为8 min。表2所列为相关的加工工艺,其中,12p表示为12道次ECAP变形,12pa为12p后退火处理,12pr为12p后轧制变形,12pra为12pr后退火处理。

表2 Mg-Li合金对应的加工工艺参数(ECAP变形、轧制或两者结合)

Table 2 Conditions of Mg-Li alloys (worked by ECAP, rolling or combination of both techniques) with their respective processing parameters

采用DMI 5000的Leica金相显微镜进行显微组织观察,观察面取TD面(见图1),铸态和退火态的Mg-Li合金分别采用硝酸酒精溶液和苦味酸溶液进行侵蚀。晶粒尺寸大小采用直线截点法(GB/T 6394—2002)进行测量,所选取的截点数为80~100。利用SANSCMT 5105微机控制万能材料试验机进行室温拉伸力学性能测试,采用线切割机平行于ED方向切取拉伸试样,其标距尺寸为5 mm,宽度为3 mm,厚度为2 mm,拉伸应变速率为2.0×10-3 s-1。通过Bruker D8 ADVANCE衍射仪对试样TD面进行分析,采用Cu Kα辐射,管电压为40 kV,扫描速度为0.2 (°)/s。通过NOVA NANOSEM 430扫描电镜进行能谱分析以及拉伸试样断口形貌观察,加速电压为10 kV。

2 结果与分析

2.1 铸态Mg-Li合金的显微组织

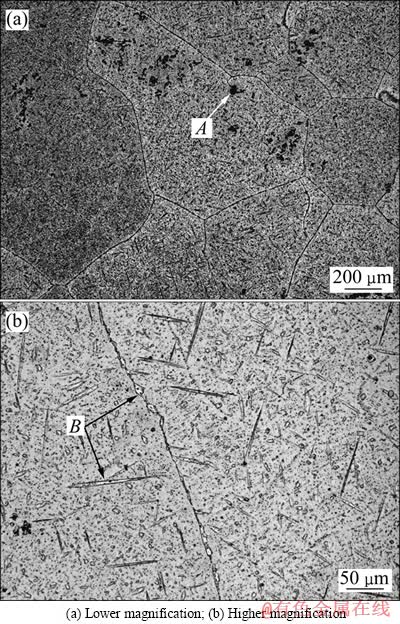

图2所示为铸态Mg-Li合金的显微组织。根据Mg-Li合金的二元相图[17]并结合杠杆原理分析可知,Mg-10.73Li-4.49Al-0.52Y合金组织以β相为主。原始铸态合金的β相晶粒粗大,尺寸为300~1 000 μm,呈等轴状分布。而α相以片状沿着β相的晶界分布或呈针状(魏氏组织[18])分布在β相的晶粒内部(图2(b)中B处所示)。同时,在β相晶粒内部杂乱分布着大量粗大的黑色块状化合物(图2(a)中A处所示)及灰色小颗粒状相。

图2 铸态Mg-Li合金的显微组织

Fig. 2 Optical microstructures of as-cast Mg-Li alloy

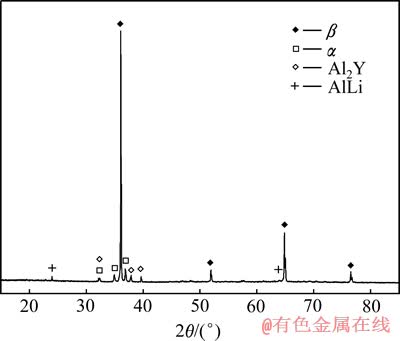

由图3所示合金的X射线衍射谱分析可知,铸态Mg-Li合金中主要存在β相(以Li为基的体心立方固溶体)、α相(以Mg为基的密排六方固溶体)、Al2Y相和AlLi相。

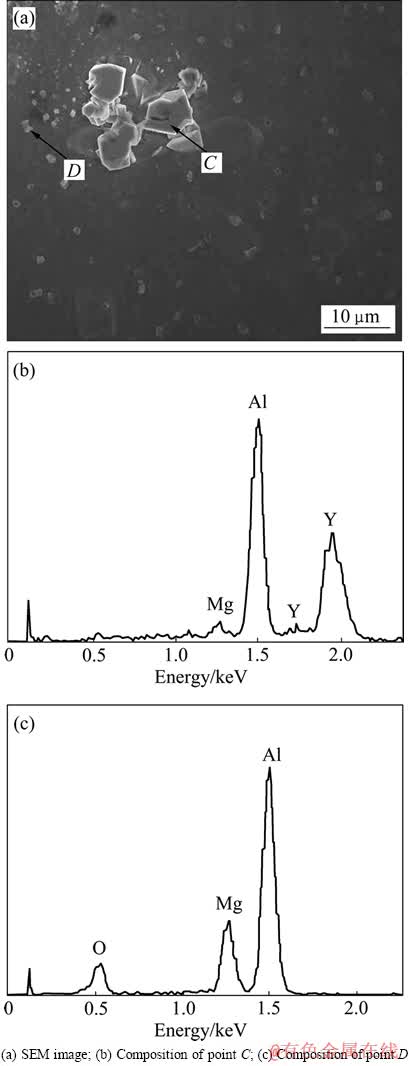

元素间形成化合物的难易程度可以根据电负性差值的大小进行判断,电负性差值越大,元素间结合力就越大,越容易形成稳定的金属间化合物。而根据Mg、Al和Y的电负性差值判断,Y与Al的电负性差值大于其与Mg、Li的电负性差值[19],所以,Al优先与Y形成Al2Y稀土相。对合金的析出相进行能谱分析(见图4和表3)结果表明,组织内部黑色块状化合物主要含有Al和Y两种元素,其摩尔比为2:1,结合XRD谱可判断合金显微组织内黑色块状化合物为Al2Y稀土相。

对图4(a)中D处灰色小颗粒状析出相进行能谱分析,仅检测到Mg、Al和O,其中Al含量最高,Mg可能是来自基体的影响,由于能谱仪无法检测出Li元素,且AlLi容易被氧化,所以能谱仪检测到了O元素,结合XRD谱,推断该相为AlLi相。在Mg-Li-Al系合金中,Li2MgAl是一种典型的强化相,同时也是一种亚稳相,在室温下可分解为AlLi稳定相[20],产生时效软化效应,从而降低Mg-Li合金的强度。因此,稀土Y的添加及Al2Y稀土相的产生,可降低基体中Al的含量,造成AlLi相减少[21],从而削弱了时效软化效应,有利于提高材料强度的稳定性。

图3 铸态Mg-Li合金的XRD谱

Fig. 3 XRD pattern of as-cast Mg-Li alloy

图4 铸态Mg-Li合金析出相的能谱分析

Fig. 4 Energy spectrum analysis of precipitate phase in as-cast Mg-Li alloy

表3 Mg-Li合金(图4(a))的微区化学成分分析结果

Table 3 Micro-area chemical composition analysis results of Mg-Li alloy in Fig. 4(a)

2.2 Mg-Li合金变形及退火后的显微组织

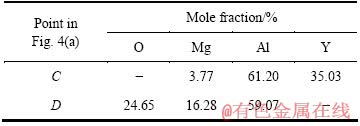

图5(a)所示为经过ECAP工艺12p变形后Mg-Li合金的显微组织。由图5(a)可知,合金的晶粒并未发生明显细化,并且晶界严重扭曲,这说明合金并未发生明显的动态再结晶;Al2Y析出相在剪切应变作用下,与挤压方向(如图5(d)中白色箭头所示)约成45°夹角,平行于剪切应力作用的平面。经退火处理后Mg-Li合金的显微组织如图5(b)所示。由图5(b)可以看出,Mg-Li合金晶粒发生了显著的细化,尺寸达到34.1 μm,同时晶界平直,晶粒呈等轴状分布,合金发生了完全再结晶;而Al2Y析出相仍沿着与挤压方向成45°夹角的方向分布。对经ECAP变形后的Mg-Li合金直接进行冷轧制处理,合金的组织沿变形方向分布,呈现典型的纤维状“流线”(见图5(c));经热处理后,合金的纤维状“流线”特征消失,组织发生完全再结晶,晶粒呈等轴状分布,大小为27.1 μm,同时Al2Y析出相沿着轧制方向分布(见图5(d))。

Mg-Li合金在逐道次降温ECAP变形时,未发生显著的动态再结晶现象,这在Mg-Li合金高温ECAP变形时也有类似现象[22]。这主要是因为:1) 该合金以体心立方结构的β相为主,其层错能较高,位错容易发生交滑移和攀移而有利于动态回复的进行,使得变形金属内的位错密度始终比较低,难以提供足够的动态再结晶形核所需要的驱动力;2) Li的扩散系数远大于Mg的扩散系数,β相的扩散系数大于α相的扩散系数[23],这有利于动态回复的进行,从而导致大量位错消失而无法提供动态再结晶形核核心[24]。Mg-Li合金虽然难以发生显著的动态再结晶,但是在剧烈塑性变形特别是冷变形后,其内部具有较高的畸变能,在随后的退火过程中,容易发生静态再结晶,产生无畸变等轴晶粒。同时,变形量越大,提供的再结晶形核核心越多,则退火后Mg-Li合金的晶粒越细小,所以经12pr变形后退火合金的晶粒尺寸明显小于经12p变形后退火合金的晶粒尺寸。

2.3 Mg-Li合金的力学性能

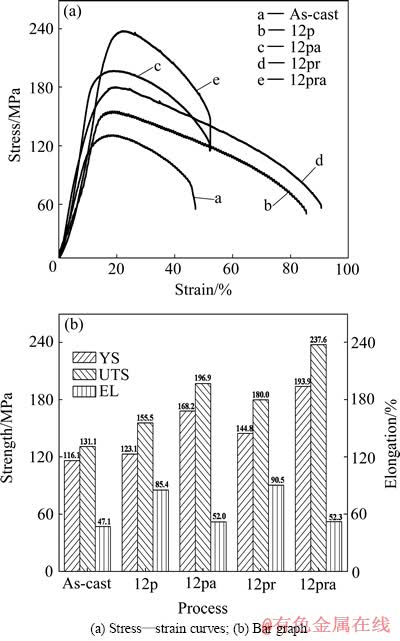

图6所示为铸态及经不同工艺处理后Mg-Li合金的室温拉伸力学性能。经过ECAP工艺12p变形后,合金的伸长率提高至85.4%,抗拉强度稍有提高;而对合金进行进一步的轧制变形后,其伸长率达到最大值90.5%,比铸态合金的提高了92.1%,抗拉强度则提高至180.0 MPa。分别对经12p和12pr工艺变形后的Mg-Li合金进行退火处理,结果表明,两种工艺的抗拉强度和屈服强度大幅度提高,其中,12pra的抗拉强度和屈服强度比铸态合金的分别提高了81.2%和67.0%,达到237.6 MPa和193.9 MPa,而合金仍具有良好的塑性,其伸长率为52.3%。

图5 不同状态Mg-Li合金的显微组织

Fig. 5 Optical microstructures of Mg-Li alloys in different conditions

一般来说,冷塑性变形后金属材料会发生显著的加工硬化而具有较高的强度,与此同时,材料的塑性会有一定程度的降低;对经冷变形后的金属材料进行适当的退火处理,合金的强度会降低,但可以获得良好的塑性。然而,本实验条件下,Mg-Li合金冷变形后在强度略有增加的同时伴随着塑性的大幅度提高;而经再结晶退火处理后,合金的强度反而大幅度提高,伸长率却降低,与传统上的退火处理作用相反。

首先,Mg-Li合金经过12p工艺变形后,并未发生显著的动态再结晶,其晶粒尺寸仍比较大,根据Hall-Petch关系式,合金的强度不可能显著提高。而随后的轧制变形,其屈服强度比轧制前的仅提高了17.6%,加工硬化效果不显著,这主要是因为β相动态回复效应显著,会在一定程度上削弱加工硬化作用。李红斌等[25]对Mg-Li-Al合金进行冷轧变形后发现,合金的加工硬化效率会随着轧制变形量的增加而趋于平缓;而DONG等[5]也发现,轧制并不能提高β相的显微硬度,这都与β相的动态回复效应有关。其次,对于剧塑性变形后的金属材料,其晶界过度破碎,处于非平衡状态,组织内部具有高密度位错;同时,大量位错在晶界附近塞积,这些位错能协调其他的变形机制,如晶界的滑动和晶粒的转动,从而提高材料的塑性[26-30]。Mg-Li合金在经过12道次的ECAP变形后,由于变形温度逐渐降低,组织内部位错密度可以迅速增加并且在晶界附近塞积,在室温拉伸时,Mg-Li合金由于这些位错的协调作用,伸长率显著增大;随后的冷轧变形进一步增强这种位错协调变形的作用,使得合金获得最大的伸长率。

由于Mg-Li-Al系合金在室温或加热的条件下组织内部的不稳定相Li2MgAl会分解成AlLi稳定相,导致Mg-Li合金发生软化[20, 31-32],因此,冷变形后的Mg-Li合金经再结晶退火处理后,其强度大幅度提高,而伸长率显著降低,不可能是析出相强化的结果。退火后Mg-Li合金力学性能出现的现象可以归结于有限位错源强化[12-14]和晶界强化的作用。经冷变形的Mg-Li合金在短时间退火后发生了再结晶,其组织内部位错密度大幅度下降,位错源数目大量减少。因此,室温拉伸时,需要提供更大的应力才能驱动新的位错源产生可动位错,从而使得合金屈服强度和抗拉强度大幅度提高。与此同时,再结晶后的晶粒得到明显细化,根据Hall-Petch关系式,Mg-Li合金的屈服强度也因此得到提高。组织内部位错密度的降低使得退火前位错协调变形的作用减弱,导致冷变形的Mg-Li合金在退火后伸长率显著降低。但是,因为经退火处理后合金晶粒得到显著细化,提高了晶界对应力集中的承载能力以及对裂纹扩展的阻碍作用,所以,Mg-Li合金仍保持较高的塑性。

图6 不同工艺下Mg-Li合金的力学性能

Fig. 6 Mechanical properties of Mg-Li alloys in different processes

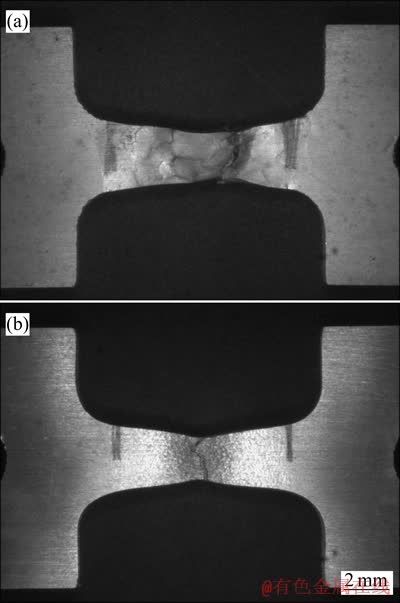

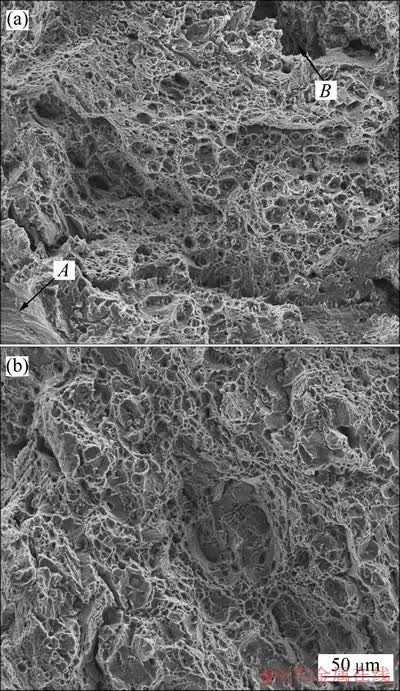

图7所示为铸态及12pra变形Mg-Li合金室温拉伸变形后的宏观形貌。由图7可知,虽然两种状态下的Mg-Li合金具有相近的伸长率,但是经过12pra工艺处理后的Mg-Li合金与铸态Mg-Li合金相比,其标距部分变形较均匀。两者的拉伸断口形貌如图8所示。由图8可知,铸态Mg-Li合金的断口虽然存在大量韧窝,但是同时存在大量粗大的解理台阶(见图8(a)中A处箭头所指)和铸造所产生的孔洞缺陷(见图8(b)中B处箭头所指);而经过12pra工艺处理后,合金的晶粒尺寸得到显著的细化,粗大的解理台阶以及孔洞缺陷消失,表明合金塑性变形的均匀性得到了较好的改善。

图7 铸态及12pra变形Mg-Li合金室温拉伸变形后的宏观形貌

Fig. 7 Macrographs of specimens for as-cast (a) and 12pra deformed (b) Mg-Li alloys after being stretched at room temperature

图8 铸态及12pra变形Mg-Li合金的拉伸断口形貌

Fig. 8 Tensile fractured morphologies of as-cast (a) and 12pra deformed (b) Mg-Li alloys

3 结论

1) 铸态Mg-10.73Li-4.49Al-0.52Y合金的显微组织以大小分布不均的粗大β相等轴晶粒为主,α相则以片状沿着β相的晶界分布或呈针状分布在β相晶粒内部。同时,在β相晶粒内部杂乱分布着大量粗大的Al2Y和小颗粒状的AlLi析出相。

2) Mg-Li合金剧塑性变形时并未发生显著的动态再结晶现象,变形后短时间退火再结晶明显,晶粒得到显著细化,其中经12pra工艺处理后合金的晶粒尺寸达到27.1 μm。Mg-Li合金剧塑性变形时未发生明显的动态再结晶现象,其主要原因是β相动态回复作用显著,从而抑制动态再结晶的发生。

3) Mg-Li合金在12p以及12pr变形后,伸长率得到显著提高,分别为85.4%和90.5%,但抗拉强度和屈服强度提高幅度不大;而对变形后的合金进行退火处理后,合金的强度大幅度增加,其中12pra工艺处理的Mg-Li合金抗拉强度和屈服强度分别达到237.6 MPa和193.9 MPa,而伸长率显著下降,接近铸态Mg-Li合金的伸长率,但合金的塑性变形更加均匀。

4) Mg-Li合金剧塑性变形后,强度稍有增加,而伸长率大幅度提高,主要与β相动态回复对加工硬化的削弱作用和高密度位错对合金塑性变形的协调作用有关;而退火后Mg-Li合金的强度显著提高,但伸长率下降,主要是有限位错源强化机制和晶界强化共同作用的结果。

REFERENCES

[1] CRAWFORD P, BARROSA R, MENDEZ J, FOYOS J, ES-SAID O S. On the transformation characteristics of LA141A (Mg-Li-Al) alloy[J]. Journal of Materials Processing Technology, 1996, 56(1): 108-118.

[2] WANG T, ZHANG M L, NIU Z Y, LIU B. Influence of rare earth elements on microstructure and mechanical properties of Mg-Li alloys[J]. Journal of Rare Earths, 2006, 24(6): 797-800.

[3] WU G Q, LING Z H, ZHANG X, WANG S J, ZHANG T, HUANG J. Research on YAl2 intermetallics particles reinforced Mg-14Li-3Al matrix composites[J]. Journal of Alloys and Compounds, 2010, 507(1): 137-141.

[4] MENG X R, WU R Z, ZHANG M L, WU L B, CUI C L. Microstructures and properties of superlight Mg-Li-Al-Zn wrought alloys[J]. Journal of Alloys and Compounds, 2009, 486(1/2): 722-725.

[5] DONG H W, XU S W, WANG L D, KAMADO S, WANG L M. Microstructures and mechanical properties of as-cast and hot-rolled Mg-8.43Li-0.353Ymm (Y-riched mischmetch) alloy[J]. Metallurgical and Materials Transactions A, 2012, 43(2): 709-715.

[6] CAO F R, DING H, LI Y L, ZHOU G, CUI J Z. Superplasticity, dynamic grain growth and deformation mechanism in ultra-light two-phase magnesium-lithium alloys[J]. Materials Science and Engineering A, 2010, 527(9): 2335-2341.

[7] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[8] 康志新, 彭勇辉, 赖晓明, 李元元, 赵海东, 张卫文. 剧塑性变形制备超细晶/纳米晶结构金属材料的研究现状和应用展望[J]. 中国有色金属学报, 2010, 20(4): 587-598.

KANG Zhi-xin, PENG Yong-hui, LAI Xiao-ming, LI Yuan-yuan, ZHAO Hai-dong, ZHANG Wei-wen. Research status and application prospect of ultrafine grained and/or nano-crystalline metallic materials processed by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 587-598.

[9] XU D K, LIU L, XU Y B, HAN E H. The strengthening effect of icosahedral phase on as-extruded Mg-Li alloys[J]. Scripta Materialia, 2007, 57(3): 285-288.

[10] VALIEV R Z, SERGUEEVA A V, MUKHERJEE A K. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium[J]. Scripta Materialia, 2003, 49(7): 669-674.

[11] JIA N, ZHAO X, SONG D, ZHOU M H, WANG Y D. On the anomalous hardening during annealing of heavily deformed fcc metals[J]. Materials Science and Engineering A, 2010, 527(4): 1143-1150.

[12] HUANG X X, HANSEN N, TSUJI N. Hardening by annealing and softening by deformation in nanostructured metals[J]. Science, 2006, 312(5771): 249-251.

[13] ZENG W, SHEN Y, ZHANG N, HUANG X X, WANG J, TANG G Y, SHAN A D. Rapid hardening induced by electric pulse annealing in nanostructured pure aluminum[J]. Scripta Materialia, 2012, 66(3/4): 147-150.

[14] KAMIKAWA N, HUANG X X, TSUJI N, HANSEN N. Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed[J]. Acta Materialia, 2009, 57(14): 4198-4208.

[15] TERADA D, HOUDA H, TSUJI N. Effect of strain on “hardening by annealing and softening by deformation” phenomena in ultra-fine grained aluminum[J]. Journal of Materials Science, 2008, 43(23): 7331-7337.

[16] 康志新, 孔 晶, 侯文婷, 李永新. 不同路径等通道转角挤压双相Mg-10.73Li-4.49Al-0.52Y合金的组织与力学性能[J]. 材料研究学报, 2011, 25(5): 500-508.

KANG Zhi-xin, KONG Jing, HOU Wen-ting, LI Yong-xin. Microstructure and mechanical properties of two-phase Mg-10.73Li-4.49Al-0.52Y alloy processed by ECAP at different routes[J]. Chinese Journal of Materials Research, 2011, 25(5): 500-508.

[17] 潘复生, 韩恩厚. 高性能变形镁合金及加工技术[M]. 北京: 科学出版社, 2007: 36.

PAN Fu-sheng, HAN En-hou. High performance wrought magnesium alloys and processing technology[M]. Beijing: Science Press, 2007: 36.

[18] WANG J Y. Mechanical properties of room temperature rolled MgLiAlZn alloy[J]. Journal of Alloys and Compounds, 2009, 485(1): 241-244.

[19] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2005: 2-4.

LI Wen-xian. Magnesium and magnesium alloys[M]. Changsha: Central South University Press, 2005: 2-4.

[20] WU R Z, ZHANG M L. Microstructure, mechanical properties and aging behavior of Mg-5Li-3Al-2Zn-xAg[J]. Materials Science and Engineering A, 2009, 520(1/2): 36-39.

[21] LI R H, PAN F S, JIANG B, YIN H M, LIU T T. Effects of yttrium and strontium additions on as-cast microstructure of Mg-14Li-1Al alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 778-783.

[22] 孔 晶, 刘 秦, 康志新. 等通道转角挤压双相Mg-10.73Li-4.49Al-0.52Y合金的组织与力学性能[J]. 中国有色金属学报, 2012, 22(9): 2415-2423.

KONG Jing, LIU Qin, KANG Zhi-xin. Microstructure and mechanical properties of two-phase Mg-10.73Li-4.49Al-0.52Y alloy processed by ECAP[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2415-2423.

[23] 曹富荣, 丁 桦, 李英龙, 周 舸. 超轻双相镁锂合金的超塑性, 显微组织演变与变形机理[J]. 中国有色金属学报, 2009, 19(11): 1908-1916.

CAO Fu-rong, DING Hua, LI Ying-long, ZHOU Ge. Superplasticity, microstructure evolution and deformation mechanism of super-light two-phase Mg-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 1908-1916.

[24] SIVAKESAVAM O, PRASAD Y V R K. Characteristics of superplasticity domain in the processing map for hot working of as-cast Mg-11.5Li-1.5Al alloy[J]. Materials Science and Engineering A, 2002, 323(1): 270-277.

[25] 李红斌, 姚广春, 刘宜汉, 吉海滨. 超轻Mg-Li-Al系变形镁合金冷轧及热处理后的组织和性能[J]. 功能材料, 2005, 36(4): 525-528.

LI Hong-bin, YAO Guang-chun, LIU Yi-han, JI Hai-bin. Microstructures and properties of superlight Mg-Li-Al wrought alloys as cold-rolling and annealing states[J]. Journal of Functional Materials, 2005, 36(4): 525-528.

[26] VALIEV R Z, ALEXANDROV I V, ZHU Y T, LOWE T C. Paradox of strength and ductility in metals processed by severe plastic deformation[J]. Journal of Materials Research, 2002, 17(1): 5-8.

[27] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation[J]. Progress in Materials Science, 2000, 45(2): 103-189.

[28] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

LU Jun, JIN Li, DONG Jie, ZENG Xiao-qin, DING Wen-jiang, YAO Zhen-yi. Deformation behaviors of AZ31 magnesium alloy by equal channel angular extrusion[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 424-432.

[29] WANG X, JIN L, LI Y, GUO X. Effect of equal channel angular extrusion process on deformation behaviors of Mg-3Al-Zn alloy[J]. Materials Letters, 2008, 62(12/13): 1856-1858.

[30] 康志新, 彭勇辉, 孔 晶, 简炜炜, 李元元. 等通道转角挤压变形Mg-1.5Mn-0.3Ce镁合金的组织、织构与力学性能[J]. 稀有金属材料与工程, 2012, 41(2): 215-220.

KANG Zhi-xin, PENG Yong-hui, KONG Jing, JIAN Wei-wei, LI Yuan-yuan. Microstructure, texture and mechanical properties of Mg-1.5Mn-0.3Ce magnesium alloy deformed by equal channel angular pressing[J]. Rare Metal Materials and Engineering, 2012, 41(2): 215-220.

[31] GUANG S S, STAIGER M, KRAL M. Some new characteristics of the strengthening phase in β-phase magnesium-lithium alloys containing aluminum and beryllium[J]. Materials Science and Engineering A, 2004, 371(1/2): 371-376.

[32] 李劲风, 郑子樵, 李世晨. 热处理对Mg-10.02Li-3.86Zn- 2.54Al-1.76Cu合金力学性能的影响[J]. 稀有金属材料与工程, 2005, 34(11): 1770-1773.

LI Jin-feng, ZHENG Zi-qiao, LI Shi-chen. Effect of heat treatment on mechanical properties of Mg-10.02Li-3.86Zn- 2.54Al-1.76Cu alloy[J]. Rare Metal Materials and Engineering, 2005, 34(11): 1770-1773.

(编辑 陈卫萍)

基金项目:广州市科技支撑计划项目(2009Z2-D811)

收稿日期:2013-01-21;修订日期:2013-05-20

通信作者:康志新,教授,博士;电话:020-87113851;E-mail: zxkang@scut.edu.cn