文章编号:1004-0609(2010)04-0613-07

挤压和等通道角挤压制备高强度Mg97Y2Zn1镁合金

陈 彬1,2,3,4,林栋樑1,曾小勤1,3,4,卢 晨1,3,彭颖红2

(1. 上海交通大学 材料科学与工程学院,上海 200240;

2. 上海交通大学 机械与动力工程学院,上海 200240;

3. 上海交通大学 轻合金精密成型国家工程研究中心,上海 200240;

4. 上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:采用常规挤压和等通道角挤压工艺加工得到高强度Mg97Y2Zn1镁合金。结果表明:常规挤压后,镁合金晶粒尺寸为0.5~2.0 μm,屈服强度、抗拉强度和伸长率分别达到352 MPa、413 MPa和10%。常规挤压后再经过等通道角挤压,晶粒尺寸被进一步细化到300~400 nm,屈服强度和抗拉强度进一步提高到400 MPa和450 MPa。在铸态、常规挤压态和等通道角挤压态的Mg97Y2Zn1合金中,都发现有长周期有序的精细层状结构存在,其产生与基体中溶有少量Y和Zn元素有关。晶粒细化和精细层状结构的存在是材料高强度的原因。

关键词:镁合金;Mg97Y2Zn1;等通道角挤压;力学性能;高强度;长周期有序结构

中图分类号:TG146.2 文献标志码:A

High strength Mg97Y2Zn1 alloy processed by extrusion and equal channel angular pressing

CHEN Bin1, 2, 3, 4, LIN Dong-liang1, ZENG Xiao-qin1, 3, 4, LU Chen1, 3, PENG Ying-hong2

(1. School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

2. School of Mechanical and Power Engineering, Shanghai Jiao Tong University, Shanghai 200240, China;

3. National Engineering Research Center for Light Alloy Net Forming, Shanghai Jiao Tong University, Shanghai 200240, China;

4. National Key Laboratory of Metallic Matrix Composite Material, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: The high strength Mg97Y2Zn1 alloy processed by extrusion and equal channel angular pressing was investigated. The results show that after extrusion, the processed Mg97Y2Zn1 alloy obtains ultrafine grains with average grain size of 0.5-2.0 μm, and exhibits excellent mechanical properties with yield strength, ultimate tensile strength and elongation of alloy of 352 MPa, 413 MPa and 10%, respectively. After extrusion and equal channel angular pressing, the average grain size is 300-400 nm, the yield strength and ultimate tensile strength of the alloy are 400 MPa and 450 MPa, respectively. The long-period stacking lamellar structure is observed in the as-cast, extruded and ECAP processed Mg97Y2Zn1 alloy, the formation of which is due to the solid solution of Y and Zn. The excellent mechanical properties of Mg97Y2Zn1 alloy are attributed to the grain refinement and the long-period stacking structure.

Key words: Magnesium alloy; Mg97Y2Zn1; equal channel angular pressing; mechanical properties; high strength; long-period stacking structure

镁合金是密度最低的金属结构材料,在汽车、国防军工和航空航天领域有着十分广泛的应用前景。但镁合金存在强韧性低以及塑性差等缺点,制约了镁合金材料的应用。最近,人们发现在快速凝固和粉末冶金条件下制取的Mg97Y2Zn1(摩尔比为97?2?1)合金具有很高的强度并具有一定的伸长率,分别达到610 MPa

和5%[1],这是目前制成的强度最高的镁合金。然而,快速凝固和粉末冶金的加工过程比较复杂,镁合金粉末又具有很强的活性,由于爆炸等安全问题以及投资风险比较高,该加工方法还不能进行批量生产。

等通道角挤压法(Equal channel angular pressing,ECAP)是由前苏联的SEGAL等[2]于20世纪80年代初首次提出的,经发展,近几年来在国内外引起重视,被用于加工超细晶粒材料的研究。LEE等[3]利用等通道角挤压法制备了晶粒尺寸约为350 nm的1050铝合金。ZHAO等[4]利用等通道角挤压法制备了晶粒尺寸小于300 nm的等轴超细晶7075铝合金。此外,还有一些关于对AZ系列和ZK系列镁合金等通道角挤压的研究[5-11]。经等通道角挤压加工得到的纯金属、合金、金属间化合物和陶瓷基复合材料等已经开始投入到实际应用中[12-14]。

本文作者采用常规挤压和等通道角挤压等方法,取代快速凝固和粉末冶金技术,制取块体高强度、超高强度Mg97Y2Zn1镁合金,并研究常规挤压和等通道角挤压工艺对Mg97Y2Zn1合金的组织结构和力学性能的影响,探讨该合金的强化机理。

1 实验

选用纯镁(99.99%)、纯锌(99.99%)、Mg-25%Y中间合金为母合金进行熔炼制备Mg97Y2Zn1镁合金。熔炼保护气体是SF6和CO2的混合气体(0.3%SF6,99.7%CO2,体积分数)。熔炼制得的合金铸锭在560 ℃保温12 h后,在400 ℃温度下进行挤压比为12.25?1的热挤压实验。挤压后的材料在内角90?、外角0?的ECAP模具进行等通道角挤压,挤压方式为Bc[15-16],挤压速度为25.2 mm/min,挤压温度为350 ℃,二步降温ECAP是在350 ℃经过4道次ECAP后降温到330℃再进行2道次的ECAP。

本研究选用江南XJL-03光学显微镜对试样进行光学显微观察。高倍显微组织、第二相的组成和形貌采用LEO1450扫描电子显微镜(SEM)系统的二次电子探测器和四象限背散射电子探测器分析,加速电压为10~20 kV。能谱仪为OxfordINCA7500,分辨率为137 eV。合金的透射电子显微镜(TEM)观察在JEOL-2010透射电子显微镜上进行,观察用电压为200 kV。合金的常温拉伸试验在德国ZWICK公司生产的Zwick/Roell T1-FR020TN A50万能材料实验机上 进行。

2 结果与分析

2.1 材料的组织

2.1.1 铸态组织

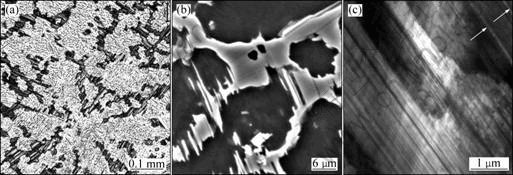

图1所示为铸态Mg97Y2Zn1合金的显微组织。从图1(a)和(b)可见,铸态Mg97Y2Zn1合金是典型的树枝状晶,第二相沿着晶界呈连续网状分布,其结构具有明显的层状结构特征,第二相和基体有交替生长现象。为了更仔细地分析这种现象,在透射电镜下对其进行观察(见图1(c))。由图1(c)可看出,在大块第二相的内部也存在着镁基体(见图中箭头)。除了第二相具有层状结构特征外,在靠近第二相的基体也存在精细层状结构,其方向和第二相一致(图1(c)左下半部)。Mg97Y2Zn1合金的这种情况有可能与Y和Zn元素在基体上的少量分布有关。

2.1.2 常规挤压态组织

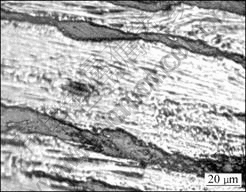

图2所示为Mg97Y2Zn1合金经过常规挤压后的金相照片。从图2可以看到,经过挤压变形后,合金呈现出典型的挤压组织形貌,原始组织被拉长,沿挤压方向排列呈现挤压流线状。经过挤压后的合金只有在原始晶界和第二相附近发生部分再结晶,晶粒尺寸非常细小,基体仍有大量未再结晶组织。原来呈网状分

图1 铸态Mg97Y2Zn1合金的显微组织

Fig.1 Microstructures of as-cast Mg97Y2Zn1 alloy: (a) OM; (b) SEM; (c) TEM

布的第二相被拉长呈长条状沿挤压方向分布,并没有出现明显的裂纹,这说明第二相具有较好的塑性[17]。

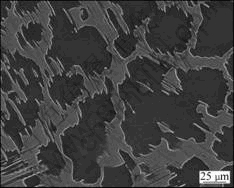

为了进一步研究Mg97Y2Zn1合金挤压后的组织,对挤压后的Mg97Y2Zn1合金进行扫描电镜观察(见图3)。从图3可以看到,基体只有部分区域发生再结晶,再结晶晶粒尺寸非常细小,材料还处于再结晶初期。这说明较高的Y元素含量提高了合金的再结晶温度,抑制了合金再结晶的发生。从形貌上看,再结晶区域呈长条带状分布在原始晶界处。这是因为原始晶界处存在的晶格畸变、元素偏析以及第二相等都能阻碍、塞积,因此会有很高的位错密度,进而形成高位错密度区,即高储能区,对再结晶的形核有利。另一方面,第二相和晶界也可以成为核的一部分界面,从而减小形核的阻力。

图2 Mg97Y2Zn1合金的挤压态金相照片

Fig.2 OM photographs of as-extruded Mg97Y2Zn1 alloy

2.1.3 等通道角挤压态

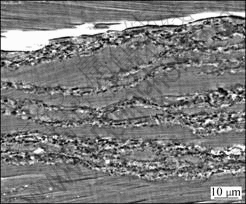

图4所示为常规挤压后的Mg97Y2Zn1合金在350 ℃下经过不同道次数等通道角挤压后的金相照片。从图4(a)和4(b)可看出,在350 ℃下经过等通道角挤压1道次后,第二相出现扭曲变形。随着等通道角挤压道次数的增加,第二相被不断切断,越来越细,同时更多的第二相碎片从第二相主体上脱离,分布也趋于更均匀(见图4(b)~(f))。从图4(f)可看到,第二相的分布已经非常均匀,已经看不出等通道角挤压前呈现的方向性。

图3 挤压态Mg97Y2Zn1合金的背散射电子像

Fig.3 BSE image of as-extruded Mg97Y2Zn1 alloy

图4 Mg97Y2Zn1合金在350 ℃下经过不同道次等通道角挤压层的组织演变

Fig.4 Microstructures evolution of Mg97Y2Zn1 alloy during ECAP process at 350 ℃: (a) 0 pass; (b) 1 pass; (c) 2 passes; (d) 4 passes; (e) 6 passes; (e) 8 passes

2.2 元素分布

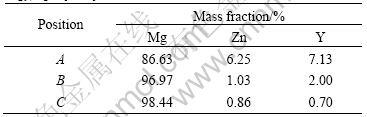

为了证实基体上形成的精细层状结构是因为Y和Zn元素在基体上少量分布所产生的,分别在第二相位置A、靠近第二相的基体位置B以及基体中心位置C进行能谱分析(见图5)。能谱分析结果如表1所列。由表1可以看出,第二相的Y和Zn元素含量要明显高于基体的Y和Zn元素含量;而同在基体上,靠近第二相位置的Y和Zn元素含量要略高于基体中心位 置的。

图6所示为合金的电子探针面扫描结果。由图6可看出,Y和Zn元素主要在第二相处偏析,而在基体上广泛分布着Y和Zn元素。结合前面的金相照片、扫描电镜照片以及能谱分析,可以说明基体上的精细层状组织与基体中溶有Y和Zn元素有关。

2.3 透射电镜

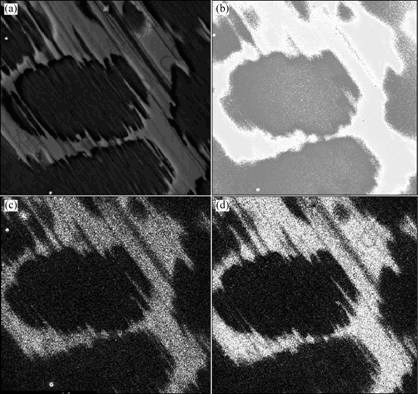

图7所示为铸态Mg97Y2Zn1合金的TEM及选区

图5 铸态Mg97Y2Zn1合金的SEM像

Fig.5 SEM image of as-cast Mg97Y2Zn1 alloy

表1 铸态Mg97Y2Zn1合金的化学成分分布

Table 1 Chemical composition distribution of as-cast Mg97Y2Zn1 alloy

图6 铸态Mg97Y2Zn1合金的电子探针分析

Fig.6 Electron probe microanalysis (EPMA) of as-cast Mg97Y2Zn1 alloy (a) and distribution of Mg (b), Y (c) and Zn (d)

图7 铸态Mg97Y2Zn1合金的TEM像及基体中心位置、第二相和靠近第二相基体的选区电子衍射花样

Fig.7 TEM image of as-cast Mg97Y2Zn1 alloy (a) and selected area diffraction (SAD) patterns of areas A (b), B (c) and C (d) in Fig.(a)

电子衍射花样照片。图7(a)中标有A、B、C的分别是基体中心位置、第二相以及靠近第二相的镁基体。图7(b)~(d)所示分别为A、B和C处的电子衍射花样。根据对选区电子衍射花样的分析,A处的是镁基体,而B处是具有长周期18R结构的X相—Mg12ZnY的超点阵晶格结构。值得注意的是,在位置C得到的电子衍射花样和A和B位置的不同,很明显在C的花样密度介于第二相和镁基体之间,说明基体可能形成了一种周期为6的长周期有序的6H结构。目前已发现,在Mg97Y2Zn1合金内有6H、10H、14H、18R和24R等多种长周期有序结构[18]。由此分析,由于合金的第二相Mg12YZn其本身具有18R长周期结构,当基体的某些部位由于也溶有Y和Zn元素,虽然浓度达不到第二相的,但如果条件合适,也可以形成介于2H与18R结构之间的长周期有序结构,正如在镁基体上可以看到精细层状结构。至于具体结论,还有待于进一步研究。

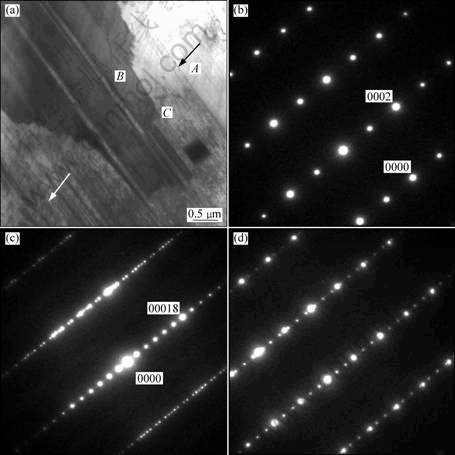

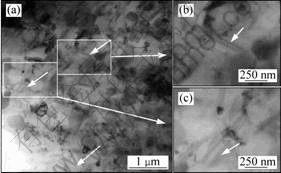

图8所示为挤压态Mg97Y2Zn1的TEM像。从图8

图8 挤压态Mg97Y2Zn1的TEM像

Fig.8 TEM image of extruded Mg97Y2Zn1 alloy

可以看出,材料经过挤压,组织被大大细化,平均晶粒尺寸为0.5~2.0 μm;在晶粒内部发现存在有精细层状结构,该结构在各晶粒内部的方向是一致的(见图中箭头)。

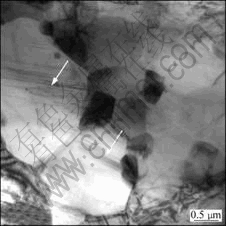

图9所示为经过常规挤压的Mg97Y2Zn1合金在350 ℃经过4道次等通道角挤压后降温到330 ℃再进行2道次等通道角挤压的Mg97Y2Zn1合金的TEM像。从图9可以看到,合金的晶粒尺寸被进一步细化到300~400 nm;在晶粒内部同样发现存在有精细层状结构。

图9 等通道角挤压态Mg97Y2Zn1的TEM像

Fig.9 TEM images of ECAP processed Mg97Y2Zn1 alloy

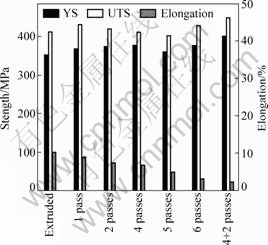

2.4 力学性能

图10所示为Mg97Y2Zn1合金经过常规挤压和不同道次等通道角挤压后的力学性能。由图10可以看出,经过常规挤压,合金的屈服强度和抗拉强度分别达到352.01 MPa和412.83 MPa,同时伸长率还有10%。再经过350 ℃等通道角挤压后,材料的强度得到进一步提高,特别是经过在350 ℃等通道角挤压4道次和330 ℃等通道角挤压2道次后,屈服强度和抗拉强度分别

图10 Mg97Y2Zn1合金常规挤压和不同道次等通道角挤压后的力学性能

Fig.10 Mechanical properties of Mg97Y2Zn1 alloys after extruded and ECAP processed different passes (4+2 passes: 2 passes at 330 ℃ after 4 passes at 350 ℃)

达到400和450 MPa。由此可见,经过常规挤压和等通道角挤压加工后,Mg97Y2Zn1合金具有较好的力学性能。

细晶强化和长周期有序结构被认为是快速凝固和粉末冶金技术制备得到高强度Mg97Y2Zn1合金的主要原因。而通过挤压和等通道角挤压制备的Mg97Y2Zn1合金,晶粒也被细化,甚至得到超细晶,在晶粒内部也存在有长周期有序结构。因此,其优异的力学性能与加工得到的超细晶以及晶粒内部存在有长周期有序结构有关。

3 结论

1) 等通道角挤压不仅可以碎化第二相,而且使第二相弥散分布。

2) 常规挤压后的Mg97Y2Zn1合金的平均晶粒尺寸为0.5~2 μm,再经等通道角挤压后,晶粒尺寸被进一步细化到为300~400 nm。

3) 在铸态、挤压态和等通道角挤压态的Mg97Y2Zn1合金中,发现有精细层状结构存在,其产生与基体中溶有少量Y和Zn元素有关。

4) 通过常规挤压和等通道角挤压工艺,可以得到高强度Mg97Y2Zn1合金。经过常规挤压,屈服强度、抗拉强度和伸长率分别达到352 MPa、413 MPa和10%。经过常规挤压后,再经过等通道角挤压后的Mg97Y2Zn1合金,屈服强度和抗拉强度分别提高到400 MPa和450 MPa。

5) 晶粒细化和精细层状结构的存在是导致材料高强度的原因。

REFERENCES

[1] KAWAMURA Y, HAYASHI K, INOUE A, MASUMOTO T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa[J]. Materials Transactions, 2001, 42(7): 1172-1176.

[2] SEGAL V M, REZNILKOV V I, DROBYSHEKIJ A E. Plastic working of metals by simple shear[J]. Russian Metallurgy, 1981(1): 99-115.

[3] LEE J C, SUH J Y, AHN J P. Work-softening behavior of the ultrafine-grained Al alloy processed by high-strain-rate, dissimilar-channel angular pressing[J]. Metallurgical and Materials Transactions A, 2003, 34(3): 625-631.

[4] ZHAO Y H, LIAL X Z, JIN Z, VALIEV R Z, ZHU Y T. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing[J]. Acta Materialia, 2004, 52(15): 4589-4599.

[5] YAMASHITA A, HORITA Z, LANGDON T G. Improving the mechanical properties of magnesium and a magnesium alloy through severe plastic deformation[J]. Mater Sci Eng A, 2001, 300(1): 142-147.

[6] WATANABE H, MUKAI T, ISHIKAWA K, HIGASHI K. Low temperature superplasticity of a fine-grained ZK60 magnesium alloy processed by equal-channel-angular extrusion[J]. Scripta Materialia, 2002, 46(12): 851-856.

[7] KIM W J, HONG S I, KIM Y S, MIN S H, JEONG H T, LEE J D. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing[J]. Acta Materialia, 2003, 51(11): 3293-3307.

[8] CHUVIL’DEEV V N, NIEH T G, GRYAZNOV M Y, SYSOEV A N, KOPYLOV V I. Low-temperature superplasticity and internal friction in microcrystalline Mg alloys processed by ECAP[J]. Scripta Materialia, 2004, 50(6): 861-865.

[9] M?THIS K, GUBICZA J, NAM N H. Microstructure and mechanical behavior of AZ91 Mg alloy processed by equal channel angular pressing[J]. Journal of Alloys and Compounds, 2005, 394(1): 194-199.

[10] 姜巨福, 罗守靖. 等径角挤压对AZ91D镁合金力学性能的影响[J]. 热加工工艺, 2004(8): 3-8.

JIANG Ju-fu, LUO Shou-jing. Effect of equal channel angular on the mechanical properties of AZ91D magnesium alloy[J]. Hot Working Technology, 2004(8): 3-8.

[11] CHEN B, LIN D L, JIN L, ZENG X Q, LU C. Equal channel angular pressing of AZ91 and its effects on microstructure and mechanical properties[J]. Mater Sci Eng A, 2008, 483/484: 113-116.

[12] RUSLAN V. Nanostructuring of metals by severe plastic deformation for advanced properties[J]. Nature Materials, 2004, 3: 511-516.

[13] ZHERNAKOV V S, LATVSH V V, STOLYAROW V V, ZHRIKOW A T, VALIEV R Z. The developing of nanostructured SPD Ti for structural use[J]. Scripta Materialia, 2001, 44(8/9): 1771-1774.

[14] SRINIYASAN R, CHERUKURI B, CHAUDHURY P K. Scaling up of equal channel angular pressing (ECAP) for the production of forging stock[J]. Materials Science Forum, 2006, 503/504: 371-374.

[15] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation[J]. Progress in Materials Science, 2000, 45(2): 103-189.

[16] OHSHI K, HORITA Z, FURUKAWA M, NENOTO M, LANGDON T G. Optimizing the rotation conditions for grain refinement in equal-channel angular pressing[J]. Metallurgical and Materials Transactions A, 1998, 29(7): 2011-2013.

[17] YOSHIIMOTO S, YAMASAKI M, KAWAMURA Y. Microstructure and mechanical properties of extruded Mg-Zn-Y alloys with 14H long period ordered structure[J]. Materials Transactions, 2006, 47(4): 959-965.

[18] MATSUDA M, KAWAMURA S, IKUHARA Y, NISHIDA M. Variation of long-period stacking order structures in rapidly solidified Mg97Zn1Y2 alloy[J]. Mater Sci Eng A, 2005, 393(1/2): 269-274.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50471015)

收稿日期:2008-11-25;修订日期:2009-11-28

通信作者:陈 彬,博士;电话:021-34202765;E-mail:steelboy@sjtu.edu.cn