文章编号:1004-0609(2011)04-0848-08

AZ31镁合金等通道转角挤压变形均匀性有限元分析

任国成1, 2,赵国群1,徐淑波2,王桂青2

(1. 山东大学 模具工程技术研究中心,济南 250061;

2. 山东建筑大学 材料科学与工程学院,济南 250101)

摘 要:以AZ31镁合金为研究对象,通过对不同模具外角ECAP变形过程的有限元模拟,研究不同模具外角下AZ31镁合金ECAP变形的等效应变分布。利用微观组织观察以及硬度测试,分析等效应变分布对微观组织及力学性能影响。结果表明:当模具外角ψ为20°时,工件可以获得均匀的等效应变分布。AZ31镁合金经过ECAP挤压后,微观组织显著细化,力学性能明显改善,但平均晶粒尺寸及微观维氏硬度在工件横截面上分布不均匀,等效应变分布的不均匀性是导致材料微观组织和力学性能不均匀的主要因素之一。

关键词:等通道挤压;有限元模拟;变形均匀性分析;AZ31镁合金

中图分类号:TG379 文献标志码:A

Finite element analysis of homogeneous deformation of AZ31 magnesium during equal channel angular pressing process

REN Guo-cheng1, 2, ZHAO Guo-qun1, XU Shu-bo2, WANG Gui-qing2

(1. Engineering Research Center for Mould and Die Technology, Shandong University, Jinan 250061, China;

2. School of Materials Science and Engineering, Shandong Jianzhu University, Jinan 250101, China)

Abstract: The effective strain size and distribution of AZ31 magnesium deformed by equal channel angular pressing (ECAP) for different die corner angles were investigated through the finite element simulation. The effect of the stain distribution in pressed workpiece on the microstructure and mechanical properties of the pressed workpiece was explored by optical observation and micro-hardness testing. The results show that the effective strain distribution in the samples is more homogeneous at 20° than those at other angles. After the AZ31 magnesium alloy is processed by ECAP, its microstructure is significantly refined and its mechanical property is improved, but the distribution of the grain size and micro-hardness in the cross-section of the pressed samples is inhomogeneous. The inhomogeneous distribution of the effective strain is one of the main factors that lead to the uneven microstructure and property.

Key words: equal channel angular pressing; finite element simulation; homogenous deformation analysis; AZ31 magnesium alloy

镁及镁合金是迄今在工程应用中最轻的金属结构材料,近年来变形镁合金的塑性成形技术已经成为世界镁工业的重要研究领域,如何提高镁合金的塑性成形能力已成为镁合金研究的热点[1-2]。已有研究表明,经等通道转角挤压(Equal channel angular pressing,ECAP)后的镁合金具有极细的晶粒结构并表现出与 众不同的力学行为[3-5],但是,在ECAP挤压过程中,应变分布不均匀和工件变形分布的均匀性一直是影响ECAP挤压材料性能的主要原因之一,提高ECAP工艺的变形均匀性对改善工件的微观组织及力学性能具有重要的研究意义。NAGASEKHAR和TICH-HON[6]以及WEI等[7]在对方形件ECAP挤压过程的研究中提出,模具外转角半径是影响试样变形不均匀的重要因素,设置适当的模具外转角可以有效地改善变形体应变分布[6-7],李继忠等[8]在对纯钛的方形件ECAP挤压中也得出了相似的结论,BASAVARAJ等[9]利用ABAQUS软件分析了不同模具拐角圆形通道ECAP挤压件应变均匀性,而对于模具外角ψ对圆形通道ECAP挤压过程中应变均匀性的影响,迄今还未见报道。本文作者利用有限元分析软件Deform-3D对AZ31镁合金的ECAP变形过程进行动态仿真,了解模具外角ψ对ECAP的变形均匀性影响,并通过光学组织观察以及微观硬度测试,分析ECAP变形过程中等效应变分布对AZ31镁合金微观组织以及力学性能影响规律。

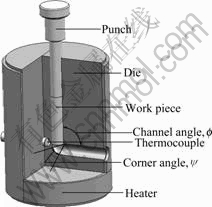

1 镁合金ECAP变形的技术原理

AZ31镁合金ECAP工艺的基本原理如图1所示,模具中两个等截面通道互相交截,冲头将试样挤到出口通道内。当经过两通道的交截面时,试样产生近似理想的剪切变形,晶粒发生塑性变形,形成位错缠结,进而形成位错胞;随着ECAP过程的继续进行,位错胞数量逐渐增加,尺寸逐渐减少,胞壁的位错密度逐渐提高,位错发生交滑移,胞壁位错缠结不断集聚,形成小角度的织构界面。在剪应力作用下,小角度织构发生旋转,成为大角度晶界的亚晶粒,并一定程度地破碎原晶粒,在随后的再结晶转变中,于原晶界和亚晶界处产生新的细小等轴晶粒,从而使晶粒细化[10]。

图1 AZ31镁合金ECAP工艺示意图

Fig.1 Schematic diagram of ECAP die of AZ31 magnesium alloy

由于镁合金在室温下塑性极差,所以镁合金的ECAP挤压加工需要在模具的外部设置加热保温装置。挤压温度也是影响镁合金显微组织和力学性能的重要因素,温度过高会使位错消失的速度加快,不利于大角度晶界的形成,从而减弱晶粒的细化效果。而温度过低又会引起镁合金表面开裂,甚至无法实现挤压[11]。因此,在ECAP过程中,要严格控制工件的变形温度。本研究构建的AZ31镁合金的ECAP实验装置采用J型热电偶实时监测工件变形温度,控温精度可达±1 ℃。

2 AZ31镁合金ECAP工艺变形的数值模拟

ECAP挤压过程中产生的剪切变形是镁合金晶粒细化的主要原因,等效应变直接影响晶粒细化和合金性能。圆形通道ECAP工艺为三维变形问题,采用经典塑性力学求解圆形挤压件挤压过程变形分布比较困难,而有限元计算模拟则提供一个有效的研究途径,其有效性和正确性也已被许多研究所证实[12]。因此,采用三维刚塑性有限元方法研究AZ31镁合金在不同模具外角ψ圆形通道弯角挤压过程,可以获得模具外角ψ对AZ31镁合金在ECAP形变过程中的应变分布的影响。

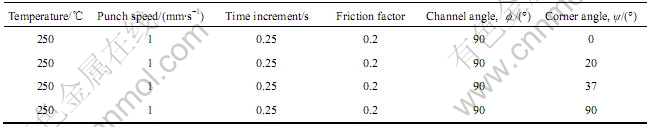

2.1 AZ31镁合金ECAP模拟参数的设定

Deform-3D的自带材料库中并没有提供AZ31镁合金的具体参数,因此,首先要确定AZ31镁合金的本构关系。由于高温下金属的变形是一个热激活过程,其变形温度和应变速率均对流变应力产生影响,本构关系可用Arrhenius方程表示:

式中: 为应变速率,适用范围为0.01~1.0 s-1;Q为变形激活能,对于AZ31镁合金,Q取252 kJ/mol;σ为流变应力;n为应力指数取9.13;T为温度,适用温度范围为250~350 ℃;R为摩尔气体常数,取8.314 J/(mol·K);A和α为与材料有关的常数,对于AZ31镁合金分别取5.718×1020和0.008[13]。在实际加工过程中,模具几乎不发生变形,可将模具设定为刚性材料。由于加热套对模具和工件进行加热和保温,挤压过程中温度恒定,因此,可以忽略工件和模具间热交换,设定工件变形在恒温条件下进行。挤压件为直径12 mm,长度70 mm的圆棒料,单元数为7 672个。其他模拟参数由表1给出。

为应变速率,适用范围为0.01~1.0 s-1;Q为变形激活能,对于AZ31镁合金,Q取252 kJ/mol;σ为流变应力;n为应力指数取9.13;T为温度,适用温度范围为250~350 ℃;R为摩尔气体常数,取8.314 J/(mol·K);A和α为与材料有关的常数,对于AZ31镁合金分别取5.718×1020和0.008[13]。在实际加工过程中,模具几乎不发生变形,可将模具设定为刚性材料。由于加热套对模具和工件进行加热和保温,挤压过程中温度恒定,因此,可以忽略工件和模具间热交换,设定工件变形在恒温条件下进行。挤压件为直径12 mm,长度70 mm的圆棒料,单元数为7 672个。其他模拟参数由表1给出。

表1 AZ31镁合金等圆形截面通道弯角挤压数值模拟参数

Table 1 Simulations parameters of round-section channel of ECAP process for AZ31 magnesium

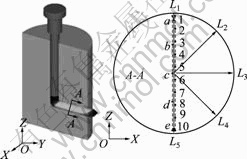

为了后续有限元分析及实验研究方便,根据挤压过程的几何特征,图2所示为ECAP数值模拟过程中挤压件截取的A-A截面位置示意图。欲获得挤压件挤压主要变形区横截面的应变分布规律,可取如图2所示挤压件A-A截面沿L1~L5 5条直线进行分析;欲获得挤压件主要变形区微观组织,可沿a~e点进行观测;沿1~10点进行微观硬度测试,分析其力学性能的变化。

图2 ECAP挤压件截取A-A截面的示意图

Fig.2 Schematic diagram of A-A cross-section setting on ECAP processed samples

2.2 模具外角对工件纵截面等效应变分布的影响

圆形通道的ECAP挤压变形为三维变形,且变形关于X面左右对称,因此,要了解模具外角ψ对工件长度方向(Y向)等效应变分布的影响,只需分析工件纵截面上的等效应变分布即可。图3所示为模具拐角为90°、模具外角ψ分别为0°、20°、37°、90°时AZ31镁合金挤压件对应工件纵截面上的等效应变分布。通过分析其应变分布可以了解挤压件的变形分布均匀程度。由图3可以看出,ECAP挤压件变形过程分为3个区域:Ⅰ区为料头区,这部分挤出过程中首先发生变形,变形自由度较大,变形情况复杂,因此变形分布极不均匀,应变分布梯度大,在实际应用过程中,这部分材料作为工艺废料通常需要去除;Ⅱ区为主要变形区,等效应变沿挤压管道方向分布基本均匀,经过一道次挤压变形,主变形区的等效应变集中在0.438~1.75。

图3 不同模具外角下AZ31镁合金ECAP挤压件纵截面等效应变分布

Fig.3 Effective strain distribution in longitudinal cross- section of AZ31 magnesium samples processed by ECAP for different corner angles

但是,对于不同的模具外角,应变在竖直方向(Z向)具有明显的梯度变化,由图3(a)可以看出,当模具外角ψ=0°时,在模具的底部出现了剧烈塑性变形区,材料在挤压过程极易引起破坏。由图3(b)可看出,当ψ=20°时,主变形区的等效应变分布几乎完全一致,只有在模具的底部出现了少量的小变形区,应变分布均匀性良好。由图3(c)和(d)可以看出,随着模具外角的增大,等效应变在竖直方向上的变形不均匀性增大,且等效应变的数值减小,表明在ECAP挤压过程中,挤压效率随着模具外角ψ的增大而降低。Ⅲ区为正在变形区。由图3(b)可以看出,当ψ=20°时,工件在变形区呈现明显的剪切变形特征,变形带剪切梯度分布良好,这也是在主变形区应变分布均匀性良好的主要原因。由于这部分区域正在发生变形,变形不完全,随着变形的进行,这部分金属将进入主变形区,其应变分布特点与主变形区的一致,挤压件主要变形部分的均匀程度在长度方向(Y向)基本一致,截取挤压件主变形区横截面进行详细分析,即可获得挤压件挤压过程的横向变形分布规律。因此,沿图2所示A-A截面的L1、L2、L3、L4、L5分析模具外角ψ对工件横截面等效应变分布的影响。

2.3 模具外角ψ对工件横截面等效应变分布的影响

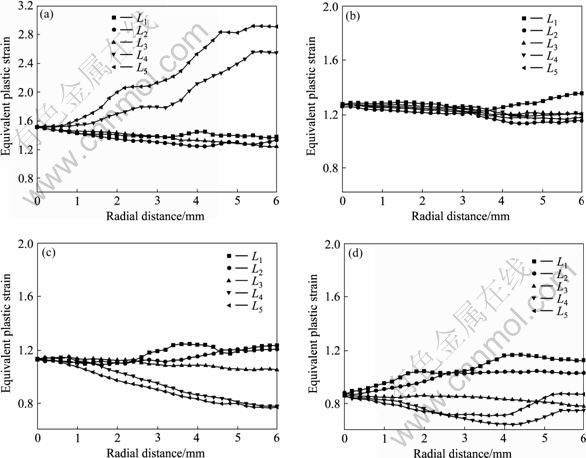

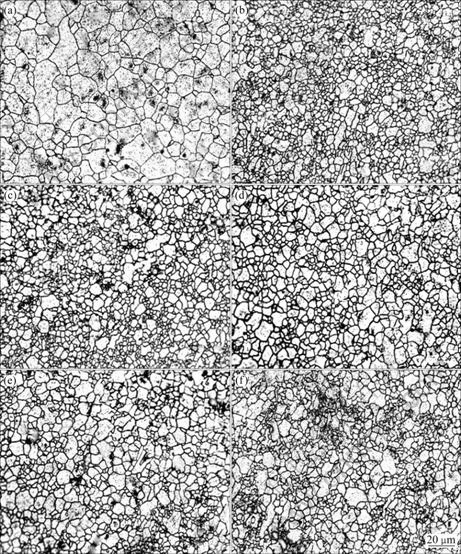

图4所示为不同模具外角ψ的ECAP挤压件在主变形区A-A截面沿L1~L5进行分析所获得的等效应变分布曲线。由图4可见,当模具外角ψ=0°时,直线L4和L5呈明显增长的趋势,表明当模具外角为零时,工件下部应变变化剧烈,工件的下半部分为主要变形部分;当ψ=20°时,等效应变沿L1到L5的分布基本重合,这表明ψ=20°的等效应变在整个横截面上变化不大,等效应变分布均匀。由图4(c)和(d)看出,当ψ为37°和90°时,直线L1和L2位于直线L3的上面,这说明随着模具外角的变大,模具外侧对工件的反作用力加大,从而使得工件下侧变形减弱。

为了更加直观地分析挤压件横截面上的等效应变分布均匀程度,可以计算代表等效应变不均匀程度的参数C i[9]:

(1)

(1)

式中: 、

、 和

和 分别代表沿A-A截面上等效应变的最大值、最小值和平均值,其中等效应变平均值可由下式求得:

分别代表沿A-A截面上等效应变的最大值、最小值和平均值,其中等效应变平均值可由下式求得:

(2)

(2)

等效应变不均匀程度参数Ci的计算结果列于 表2。

由表2可知,当模具外角ψ=0°时,A-A截面上的平均等效应变为1.652,而当ψ=90°时,平均等效应变则降为0.883,平均等效应变随着ψ角的增大而减小。但就等效应变不均匀程度Ci而言,当ψ=0°时,Ci的值高达0.94,虽然获得了高的等效应变,但变形均匀程度却是最差的。比较ψ为20°、37°和90°时的变形情况可以发现,随着ψ角的增大,A-A截面的平均等

图4 不同模具外角 AZ31镁合金ECAP挤压件A-A横截面的等效应变分布

Fig.4 Effective strain distribution in A-A cross-section of AZ31 magnesium samples processed by ECAP for different corner angles: (a) ψ=0°; (b) ψ=20°; (c) ψ=37°; (d) ψ=90°

表2 主变形区A-A截面等效应变不均匀程度参数

Table 2 Equivalent strain inhomogeneity index across section A-A in steady-state zone

效应变减小,且不均匀变形程度逐渐增大。当ψ=20°时,既可获得比较大的平均等效应变,又可获得良好的等效应变分布。

3 AZ31镁合金的ECAP变形实验结果及分析

3.1 实验装置及实验方法

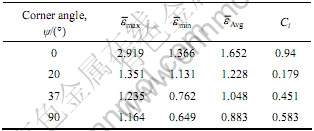

为验证有限元分析结果,选用d 12 mm×70 mm的工业AZ31B型镁合金ECAP进行加工试验,试样采用MoS2润滑剂,试验前将试样和模具预热,随后由YL-32型液压机加载,由冲头将试样从出口通道挤出,挤压装置如图5(a)所示,图5(b)和(c)所示分别为通过有限元模拟和实验得到的等径角挤压工件。由图

图5 AZ31镁合金等通道转角挤压设备及挤压后工件

Fig.5 ECAP equipment for AZ31 magnesium(a) and simulation(b) and experimental(c) samples after ECAP processed

5可以看出,通过有限元方法得到的工件的变形趋势与实际实验一致,有限元模拟分析结果和实验结果吻合良好。

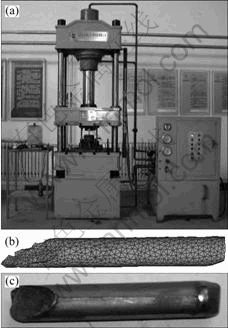

3.2 挤压试样的金相组织分析

从ECAP挤压件的稳定变形区切割试样,采用Epiphot300型尼康卧式金相显微镜观察ECAP过程中图2所示A-A截面点a~e所处位置的微观组织变化。图6所示为AZ31镁合金原试样及ECAP一次加工后试样A-A横截面上的光学显微组织。由图6(a)可见,初始材料的晶粒比较粗大,晶粒晶界明显呈等轴分布。由图6(b)~(f)可知,经过ECAP工艺一道次挤压后晶粒明显细化,但试样整体组织分布不均匀,试样局部仍然存在较粗大的晶粒。ECAP过程中的晶粒细化是由于剧烈塑性变形所引起的动态连续再结晶形成的,而镁合金的塑性变形机理包括晶界滑移、基面滑移、非基面滑移以及孪生等,基面滑移仍然是镁合金塑性变形的主要机制。

KOBAYASHI等[14]通过对AZ31镁合金在ECAP过程中所激活的滑移系研究发现,塑性变形过程中所激活的滑移系与晶粒大小有着重要关系。对于较粗的晶粒(约50 μm),晶界附近的非基面α位错被激活,而在晶粒内部的基面α位错处于支配地位;对于较细晶粒(约7 μm),整个区域的非基面α位错均被激活,并且α位错的密度约占整个位错密度的40%。对于粗晶,这种影响仅限于晶界附近,而对于细晶则扩大到整个晶粒内部。从AZ31B镁合金原始态光学微观金相组织来看,视场中存在部分粗大的晶粒,这也许就是在ECAP挤压后试样中仍然存在部分粗大晶粒的原因,STANFORD和RARNETT[15]在对AZ31镁合金的连续大变形轧制过程中也发现了类似结果。

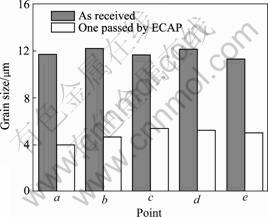

图7所示为AZ31镁合金原始试样及一道次挤压后试样在图2所示A-A面a~e所处位置的平均晶粒度分布。由图7可知,压缩试样各点的晶粒大小差别不大,整个截面的平均晶粒尺寸为12.5 μm。经过一道次ECAP挤压后,晶粒明显细化,平均晶粒尺寸迅速减小为4.89 μm。但是,比较挤压后各点的平均晶粒尺寸可以发现,a点靠近模具上边缘的晶粒细化最为明显,平均晶粒尺寸为4.02 μm,而心部组织细化稍慢,晶粒细化效果不如上边缘的,c和d位置的平均晶粒度大约为5.5 μm,而最下边缘所观测到的晶粒尺寸也比试样中部的略小,平均晶粒尺寸为5.04 μm;由有限元模拟分析可知,在ECAP挤压过程中试样纵截面靠上通道壁的等效应变较大,外层金属在剪切力及摩擦力作用下晶粒遭到较大破碎,再结晶程度大;

图6 AZ31镁合金原试样及ECAP一道次加工后试样A-A横截面上的光学显微组织

Fig.6 Optical microstructures in A-A cross-section of AZ31 magnesium alloys unprocessed and processed by one pass ECAP: (a) Unprocessed sample; (b) Point a; (c) Point b; (d) Point c; (e) Point d; (f) Point e

图7 AZ31镁合金ECAP一道次加工后试样A-A横截面上的晶粒度

Fig.7 Grain size distribution in A-A cross-section of AZ31 magnesium alloys processed by one pass ECAP

内层比外层晶粒遭到破碎的程度小,再结晶程度变小,而心部的更小。从整个横截面的平均晶粒尺寸来看,晶粒细化对应变累积的变化敏感,晶粒细化的趋势与有限元模拟所得到的应变累积的变化规律相同。

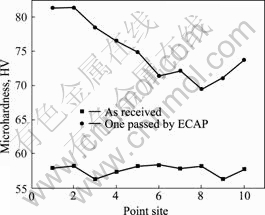

3.3 挤压试样的显微硬度变化分析

YOSHIDA等[16]研究显示,对于经过ECAP挤压的镁合金,其强度与晶粒尺寸之间的关系式为:σ0.2= 30+0.17d-1/2。可见,合金的晶粒细化应该对镁合金的强度的提高具有明显效果。硬度是材料弹性、塑性、强度和韧性等力学性能的综合指标,通过分析试样ECAP挤压前后显微硬度变化,可以推断ECAP变形对镁合金强度的影响。

采用FM-700型数显式显微硬度计测量图2所示1~10所处不同位置的显微维氏硬度。图8所示为AZ31镁合金一道次ECAP挤压件变形前后图2所示A-A横截面1~10点所示位置的显微维氏硬度。由图8可知,材料原始试样的硬度在整个横截面上分布均匀,硬度值相差不大,硬度分布在56~58之间,平均值为57.668。经过一道次ECAP挤压后,材料的硬度有了明显的提升,平均值升至79.091。这是由于ECAP前,材料内部存在大量的缺陷,晶粒较粗大,宏观上反映出材料的力学性能较低。在ECAP过程中产生的纯剪切力的作用下,材料内部的孔隙等得到闭合,内部缺陷减少,显微组织得到改善,从而使材料的力学性能得到改善,硬度提高。但从AZ31镁合金经ECAP变形后不同位置的硬度分布来看,硬度在整个横截面上分布并不均匀,靠近上部的部分硬度最高,达81.4;而沿横截面向下硬度逐渐降低,最小为69.4;而靠近下表面附近,由于摩擦的作用,应变积累有所上升,表现为硬度有所上升,为73.7。从图3也可以看出,试样横截面上部的变形最剧烈,等效应变最大,然后自上而下呈减小的趋势分布,从分析来看,应变分布与硬度分布相当吻合。

图8 AZ31镁合金ECAP挤压件A-A横截面不同位置的微观维氏硬度

Fig.8 Microhardness in different sites of A-A cross-section for AZ31 magnesium alloys processed by ECAP

4 结论

1) 在ECAP挤压过程中,工件的平均等效应变随着模具外角ψ的增大而减小。当模具外角ψ≥20°时,工件的不均匀变形程度随ψ的增大而逐渐增大;当ψ=20°时,既可以获得比较大的平均等效应变,又可以获得良好的等效应变分布。

2) 由于受到剧烈剪切塑性变形,AZ31镁合金晶粒在首道次ECAP工艺挤压后细化明显,但组织在整个横截面分布不均匀,且晶粒的细化程度与变形过程中的应变累计趋势一致。

3) 经过一道次ECAP变形后,AZ31镁合金的晶粒尺寸明显减少,但仍然有部分大尺寸晶粒存在,小晶粒分布在大晶粒周围,晶粒尺寸跨度较大。因此,要获得组织均匀的超细晶材料,可采取多次ECAP变形的方式,以使晶粒充分破碎。

4) AZ31镁合金晶粒经ECAP挤压后硬度明显提高,表明ECAP工艺可以明显改善镁合金的力学性 能,但在ECAP挤压后微观硬度在工件横截面上分布不均匀,挤压过程中应变分布的不均匀性是造成试样横截面上硬度分布不均的主要原因,在挤压过程中采用合适的变形工艺以获得更为均匀的应变累积,仍然是ECAP工艺获取均匀块体超细晶材料的重要研究 方向。

REFERENCES

[1] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP[J]. Acta Materialia, 2003, 51(11): 3073-3084.

[2] 陈振华, 刘俊伟, 陈 鼎, 严红革. 镁合金超塑性的变形机理、研究现状及发展趋势[J]. 中国有色金属学报, 2008, 18(2): 193-202.

CHEN Zhen-hua, LIU Jun-wei, CHEN Ding, YAN Hong-ge. Deformation mechanisms, current status and development direction of superplastic magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(2): 193-202.

[3] JIN Y G, SON I H, KANG S H, IM Y T. Three-dimensional finite element analysis of multi-pass equal-channel angular extrusion of aluminum AA1050 with split dies[J]. Materials Science and Engineering A, 2009, 503(1/2): 152-155.

[4] DJAVANROODI F, EBRAHIMI M. Effect of die channel angle, friction and back pressure in the equal channel angular pressing using 3D finite element simulation[J]. Materials Science and Engineering A, 2010, 527(4/5): 1230-1235.

[5] de VALLE J A, RUANO O A. Superplasticity in a magnesium alloy prepared with bimodal grain size distributions developed by dynamic recrystallisation[J]. Materials Letters, 2008, 62(19): 3391-3394.

[6] NAGASEKHAR A V, TICK-HON Y. Optimal tool angles for equal channel angular extrusion of strain hardening materials by finite element analysis[J]. Computational Materials Science, 2004, 30(3/4): 489-495.

[7] WEI W, NAGASEKHAR A V, CHEN G, TICK-HON Y, WEI K X. Origin of inhomogenous behavior during equal channel angular pressing[J]. Scripta Materialia, 2006, 54(11): 1865-1869.

[8] 李继忠, 丁 桦, 赵文娟, 陈彦博. 数值模拟外转角半径及背压对纯钛ECAP变形的影响[J]. 中国有色金属学报, 2008, 18(12): 2178-2184.

LI Ji-zhong, DING Hua, ZHAO Wen-juan, CHEN Yan-bo. Simulations of influence of outer angular radius and back pressure on ECAP of pure titanium[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2178-2184.

[9] BASAVARAJ V P, CHAKKINGAL U, KUMAR T S P. Study of channel angle influence on material flow and strain inhomogeneity in equal channel angular pressing using 3D finite element simulation[J]. Journal of Materials Processing Technology, 2009, 209(1): 89-95.

[10] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[11] WATANABE H, MUKAI T, HIGASHI K. Influence of temperature and grain size on threshold stress for superplastic flow in a fine-grained magnesium alloy[J]. Metallurgical and Materials Transactions A, 2008, 39(10): 2351-2362.

[12] SMOLYAKOV A A, SOLOVYEV V P, KORSHUNOV A I, ENIKEEV N A. Three-dimensional numerical simulations of multi-pass equal-channel angular pressing by a variation difference method and comparison with experiment[J]. Materials Science and Engineering A, 2008, 493(1/2): 148-159.

[13] 王忠堂, 张士宏, 齐广霞, 王 芳, 李艳娟. AZ31 镁合金热变形本构方程[J]. 中国有色金属学报, 2008, 18(11): 1977-1982.

WANG Zhong-tang, ZHANG Shi-hong, QI Guang-xia, WANG Fang, LI Yan-juan. Constitutive equation of thermal deformation for AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1977-1982.

[14] KOBAYASHI T, KOIKE J, YOSHIDA Y. Grain size dependence of active ship systems in an AZ31 magnesium alloy[J]. Journal of the Japan Institute of Metals, 2003, 67(4): 149-152.

[15] STANFORD N, BARNETT M R. Fine grained AZ31 produced by conventional thermo-mechanical processing[J]. Journal of Alloys and Compounds, 2008, 466(1/2): 182-188.

[16] YOSHIDA Y, CISAR L, KAMADO S, KOJIMA Y. Effect of microstructural factors on tensile properties of an ECAE- processed AZ31 magnesium alloy[J]. Materials Transactions, 2003, 44(4): 468-475.

(编辑 李艳红)

基金项目:山东省自然科学基金资助项目(Y2007F39);山东省中青年科研奖励基金资助项目(2008BS05002);山东省优秀中青年科学家科研奖励基金资助项目(2007BS05004)

收稿日期:2010-04-20;修订日期:2010-06-28

通信作者:赵国群,教授;电话:0531-88393238;E-mail: zhaogq@sdu.edu.cn