文章编号:1004-0609(2013)07-1789-07

变形温度对AZ31镁合金等通道转角挤压变形行为的影响

任国成1, 2,赵国群1

(1. 山东大学 模具工程技术研究中心,济南 250061;

2. 山东建筑大学 材料科学与工程学院,济南 250101)

摘 要:通过建立镁合金等通道转角挤压过程的热力耦合有限元分析模型,对其变形过程中的温度场分布进行分析,并通过微观组织观察和XRD分析,获取变形温度对镁合金变形行为的影响规律。结果表明:等通道挤压过程中试件温度分布不均匀,在模具转角剪切部位温度显著升高,且存在明显的温度梯度。XRD分析和微观组织观察显示,AZ31镁合金变形后,锥面衍射强度显著增强,且镁合金的再结晶速度随着变形温度的升高而显著加快。结合变形过程中温度场的分布状况,建议AZ31镁合金等通道转角挤压的合理变形温度设定为250 ℃。

关键词:AZ31镁合金;等通道挤压;有限元模拟;变形温度

中图分类号:TG379 文献标志码:A

Effects of deformation temperature on deformation behavior of AZ31 magnesium alloy during equal channel angular pressing

REN Guo-cheng1, 2, ZHAO Guo-qun1

1. Engineering Research Center for Mould and Die Technology, Shandong University, Jinan 250061, China;

2. School of Materials Science and Engineering, Shandong Jianzhu University, Jinan 250101, China)

Abstract: A thermomechanical coupled finite element model was established and the temperature distribution of the magnesium work-piece during equal channel angular pressing (ECAP) was analysed. The effect of deformation temperature on deformation behavior of magnesium alloy was acquired by XRD analysis and microscopic examination. The results show that the distribution of temperature is not uniform during equal channel angular pressing, there exists obvious temperature gradient and the temperature increases significantly in the mold angle shear part. The XRD analysis and microscopic examination show that the pyramidal face diffraction intensity enhances significantly, the recrystallization rate of magnesium alloy increases obviously with the increase of deformation temperature. The optimal deformation temperature of 250 ℃ is obtained according to the temperature distribution.

Key words: AZ31 magnesium; equal channel angular pressing; finite element simulation; deformation temperature

在日益追求产品轻量化的今天,镁合金作为最轻的金属结构材料,广泛应用于汽车、电子、航空航天、国防军工等工业领域以及运动器材和家庭用品等生活领域,被誉为“21世纪最具发展前途的绿色工程材料”[1]。但其低温下塑性成形能力较差,应用范围受到严重限制。有研究表明[2-4],晶粒细化可以促进镁合金非基面滑移系的开动,是提高镁合金塑性成形能力及力学性能的重要手段。20世纪90年代初,VALIEV等[5]发现等通道转角挤压技术(Equal channel angular pressing,ECAP )可实现粗晶金属或合金的晶粒超细化,但目前所建立的ECAP晶粒细化模型基本上都是依据Al 和Cu 等金属在常温下变形而建立起来的,大多没有考虑温度对晶粒细化过程的影响。对于镁合金等容易发生再结晶的材料,温度对于位错的回复和再结晶过程都具有非常重要的影响,单纯用机械剪切模型尚无法完全解释其晶粒细化过程[6-8]。SU等[9] 在研究AZ31镁合金的ECAP变形过程的基础上指出,镁合金的晶粒细化机制主要为动态再结晶和机械剪切共同作用,而镁合金动态再结晶的速度以及变形过程中的剪切滑移机制与温度密切相关。温度变化及其分布会影响金属的流动及其内部晶粒的细化效果,进而影响变形后的晶粒尺寸及材料组织,而工件在ECAP变形过程中所产生的大量变形热会导致其温度场变化,因此,掌握等通道挤压过程中工件的变形热和温升,获取温度的变化及分布规律,选择合适的挤压温度对研究镁合金ECAP加工工艺具有重要意义。由于通过实验方法获得试样的瞬时温度分布十分困难,而有限元分析的方法可以有效获取工件变形过程中温度的变化规律[10-11],因此,本文作者采用有限元分析软件Deform-3D研究镁合金工件变形过程中的温度变化,并结合不同变形温度下工件的微观组织观察和X射线衍射分析建立变形温度对镁合金变形行为的影响规律。

1 热力耦合有限元分析模型的建立

1.1 AZ31镁合金等通道挤压的模具结构

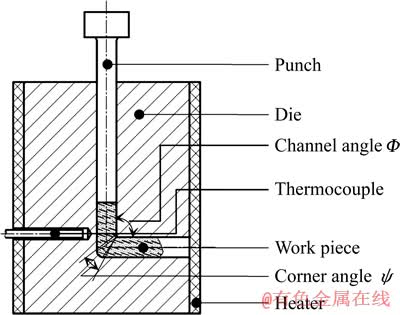

本研究分析所选用的模具结构如图1所示,模具拐角为90°,模具外圆角为20°,圆柱形镁合金试样的直径为12 mm,长度70 mm。由于镁合金在常温下塑性较差,本文作者在常规的ECAP加工模具的基础上增设了加热装置,变形过程中的模具温度通过热电偶实时监测,研究的变形温度范围为150~300 ℃。

图1 AZ31镁合金ECAP加工模具简图

Fig. 1 Schematic diagram of ECAP die for AZ31 magnesium

1.2 AZ31镁合金的材料模型的建立

要实现AZ31镁合金的有限元模拟,就要首先建立其适用的本构关系模型。材料的本构关系是有限元模拟的重要依据,它是用来描述工件过程中流变应力与应变关系的数学方程。Arrhenius方程可以反映变形温度、应变速率等对材料流变应力的影响,而镁合金高温下变形是一个热激活的过程,因此,其本构关系可采用Arrhenius方程进行描述[12]:

(1)

(1)

式中: 为应变速率,Q为变形激活能,σ为流变应力,n为应力指数,T为绝对温度,R为摩尔气体常数。参照王忠堂等[13]对AZ31镁合金本构关系的研究成果,式中Q取252 kJ/mol,n取9.13,R值为8.314 J/(mol·K);A和α为与材料有关的常数,其值分别取5.718×1020和0.008[13]。为了解不同温度对变形过程的影响,在Deform-3D 中建立分析模型时同时选择热传递和变形两种分析模式,所采用的热挤压工艺参数如表1所列。

为应变速率,Q为变形激活能,σ为流变应力,n为应力指数,T为绝对温度,R为摩尔气体常数。参照王忠堂等[13]对AZ31镁合金本构关系的研究成果,式中Q取252 kJ/mol,n取9.13,R值为8.314 J/(mol·K);A和α为与材料有关的常数,其值分别取5.718×1020和0.008[13]。为了解不同温度对变形过程的影响,在Deform-3D 中建立分析模型时同时选择热传递和变形两种分析模式,所采用的热挤压工艺参数如表1所列。

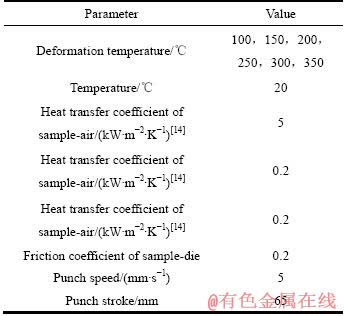

表1 ECAP模拟加工过程中的挤压工艺参数

Table 1 Parameters of ECAP simulation process

2 AZ31镁合金在ECAP挤压过程中的温度场分布

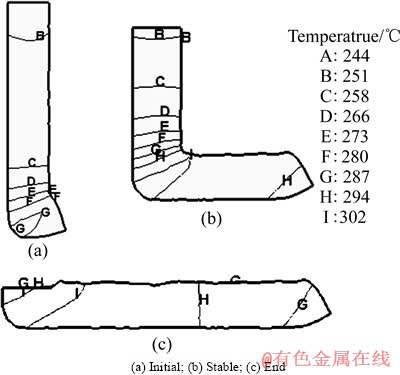

取变形体的轴截面进行分析以了解变形过程中的温度变化情况,其不同变形阶段的温度场分布如图2所示。由图2(a)可知,试样上部的温度在变形初期变化不大,而下部剪切变形区明显升高,导致变形区温度急剧升高的变形热一部分来自塑性变形能转化的热量,另一部分来自于工件与模具间的摩擦。图2(b)所示为试样变形中间阶段(冲头压下量50%)工件轴截面上的温度场分布,此阶段为挤压变形的稳定阶段,工件挤压力变化不大,变形在稳定的状态下持续进行,观察此阶段的温度场分布不难看出,变形主要集中在转角区域,该区域是整个试样中的最高温度区;与变形开始相比,此时高温区域的面积有所下降,这是因为随着变形进行,工件的剪切变形区趋于稳定,同时变形区的热量向其它区域传递,所以整个温度场呈现以拐角变形区为最高点,同时向两侧递减的趋势。图2(c)所示为变形结束时的温度场分布,不难看出,变形结束后,工件的温度场分布基本均匀;与变形前相比,此时温度有明显的提高。同变形前的温度场相比,变形后的温度区域更为均匀。随着工件与模具以及环境间热交换的持续进行,整个变形区的温度由左向右逐渐降低。剪切变形区温度在ECAP挤压过程中始终处于高温状态,成为决定挤压制品的最终组织和力学性能的关键因素。

图2 250 ℃下AZ31镁合金一道次ECAP变形不同阶段温度场分布

Fig. 2 Temperature distribution of AZ31 magnesium during different ECAP deformation stages at initial extrusion temperature of 250 ℃

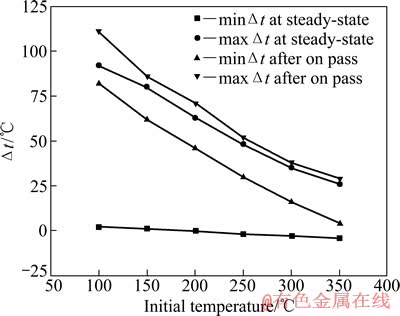

为了解不同初始温度下ECAP挤压过程中温度的变化情况,选取初始温度分别为100、150、200、250、300和350 ℃时ECAP稳定变形阶段和变形结束时段的温度分布与初始温度比较。挤压的峰值温升和最低温升情况如图3所示。由图3可知,当初始温度不同时,ECAP变形过程中的温度变化差别明显,总体来看,随着初始温度的升高,温升幅度逐渐降低,在变形稳定阶段,材料的最低温升差别不大,而最高温升随着初始变形温度的升高逐渐降低。在变形结束阶段,当初始变形温度为100 ℃时,变形所导致的最高温升为110 ℃,最低温升也达到82 ℃;而在同样的变形条件下,变形温度提高到300 ℃时,变形结束时,其峰值温升仅为29 ℃,最低温升为4 ℃;这表明随着初始变形温度的升高,变形对温度的影响逐渐降低。PEI等[15]利用二维有限元对Al-1%Mg等通道挤压中的试样中心温度变化进行模拟,而YAMAGUCHI等[16]则通过Chromel-Alumel热电偶测得试样中心位置在ECAP挤压过程中的实时温升在40 ℃左右且不同的铝镁合金材料差别不大,本研究在同等条件下的模拟结果与他们的结果吻合,表明本研究的模拟结果可信。

图3 AZ31镁合金不同初始温度一道次ECAP变形不同阶段温度变化

Fig. 3 Peak and minimum temperature rise of AZ31 magnesium at different stage first-pass ECAP processed for different initial extrusion temperatures

3 AZ31镁合金在不同温度下ECAP挤压实验结果分析

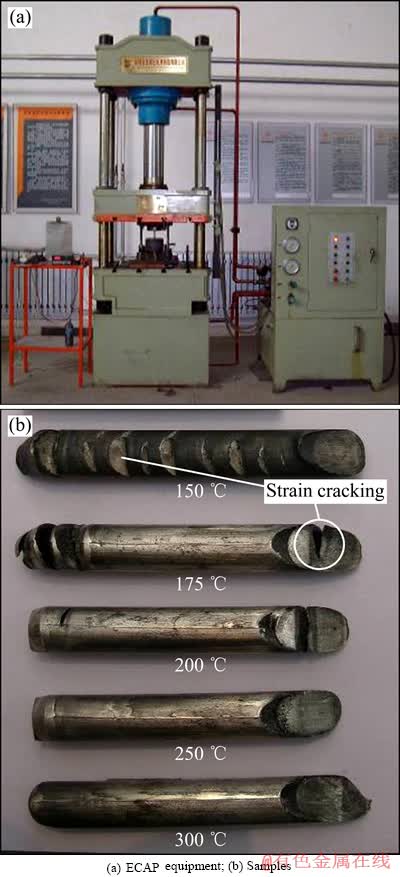

为验证变形温度对AZ31镁合金的影响,选用d12 mm×70 mm的工业AZ31B型镁合金在不同温度下进行ECAP挤压实验,试样表面涂抹MoS2润滑剂,实验前将试样和模具预热到不同的挤压变形温度,随后由YL-32型液压机加载将试样从出口通道挤出,挤压装置如图4(a)所示,不同温度下ECAP挤压工件的外观形貌如图4(b)所示。由图4(b)可见,当挤压温度在150 ℃时,变形工件的上表面出现明显的锯齿形开裂;当挤压温度在175和200 ℃时,材料的流动性能明显转好,上表面的锯齿形缺陷基本消失,但是在材料的头部和尾部区域仍存在比较明显的开裂缺陷;继续提高变形温度,当变形温度达到250和300 ℃时,镁合金的非基面滑移系启动,宏观缺陷基本消失,挤压件外观形貌良好。从ECAP挤压件的稳定变形区切取试样,采用D8ADVANCE型X射线衍射仪分析不同变形温度时晶面衍射强度,采用Epiphot300型尼康卧式金相显微镜观察其微观组织变化,以研究变形温度对镁合金变形织构及微观组织的影响规律。

图4 AZ31镁合金的ECAP挤压实验装置及不同温度一道次变形后的外观形貌

Fig. 4 Photographs of AZ31 magnesium after one-pass ECAP processed at different initial extrusion temperatures

3.1 AZ31镁合金不同温度下变形时的宏观织构演化

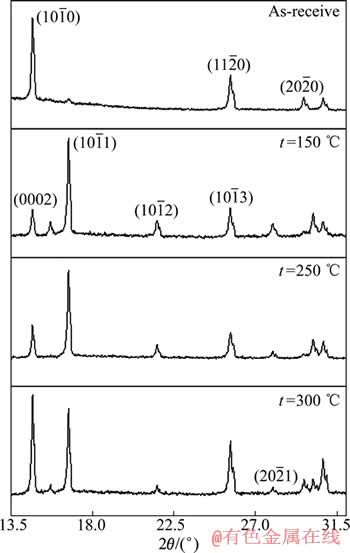

镁合金的变形织构是塑性变形过程中晶粒的转动和特定滑移系定向流动所形成的晶粒取向的宏观一致性。JEONG等[17]学者在研究镁合金时发现,温度不同时变形初期的滑移模式(变形机理)不同,当挤压温度低于250 ℃时,ECAP织构的形成主要是由拉伸孪生和基面滑移支配;而当挤压温度高于300 ℃时,变形初始阶段锥面滑移处于支配地位。镁合金在不同变形温度下所能开动的滑移系不相同,其形成的宏观织构也不相同。XRD衍射分析中晶面衍射峰的强弱反映了该晶面平行于表面分布的相对数量程度,最强峰对应的晶面即为该位置表面上择优分布最强的晶面[18], 因此,通过分析不同温度下ECAP挤压样件的衍射峰强度的变化可以了解不同变形过程中晶体取向的变化规律。

图5 不同温度一道次ECAP变形时AZ31 镁合金试样横截面XRD谱

Fig. 5 XRD patterns of cross-section of AZ31 magnesium after one-pass ECAP processed at different initial extrusion temperatures

图5所示为原始试样及不同变形温度下挤压件横截面的XRD谱。由图5可见,原始试样的衍射最强锋为{10 0},而其他晶面的衍射明显较弱,这说明试样中存在明显的滑移面择优取向。变形结束后,衍射峰的强度发生了明显变化,{10

0},而其他晶面的衍射明显较弱,这说明试样中存在明显的滑移面择优取向。变形结束后,衍射峰的强度发生了明显变化,{10 0}峰的强度明显减弱,而{10

0}峰的强度明显减弱,而{10 1}峰的强度显著增强。且当挤压速度不变时,随着温度的升高,{10

1}峰的强度显著增强。且当挤压速度不变时,随着温度的升高,{10 1}、{10

1}、{10 2}和{10

2}和{10 3}等锥面滑移系的衍射峰强度在变形之后趋于增强,这是因为温度越高,非基面滑移越容易启动,这也表明锥面滑移是镁合金ECAP高温变形时内部晶体主要的滑移形式。比较不同温度下各个晶面的XRD衍射峰强度可知,变形前衍射强度较弱的各峰在变形后均有不同程度的增强,表明镁合金高温变形时出现多种织构类型并存的状态,变形过程中晶粒转动及孪晶对变形的协调作用也在一定程度上削弱镁合金挤压材料的宏观各向异性,有利于改善材料的力学性能。这些现象同时也说明原子热激活能力随着变形温度升高逐渐增强,更多滑移系开始启动,从而使得镁合金在高温变形时的塑性大为改善,减少了剧烈变形时表面开裂的倾向。

3}等锥面滑移系的衍射峰强度在变形之后趋于增强,这是因为温度越高,非基面滑移越容易启动,这也表明锥面滑移是镁合金ECAP高温变形时内部晶体主要的滑移形式。比较不同温度下各个晶面的XRD衍射峰强度可知,变形前衍射强度较弱的各峰在变形后均有不同程度的增强,表明镁合金高温变形时出现多种织构类型并存的状态,变形过程中晶粒转动及孪晶对变形的协调作用也在一定程度上削弱镁合金挤压材料的宏观各向异性,有利于改善材料的力学性能。这些现象同时也说明原子热激活能力随着变形温度升高逐渐增强,更多滑移系开始启动,从而使得镁合金在高温变形时的塑性大为改善,减少了剧烈变形时表面开裂的倾向。

3.2 AZ31镁合金不同温度下变形时的微观组织形貌

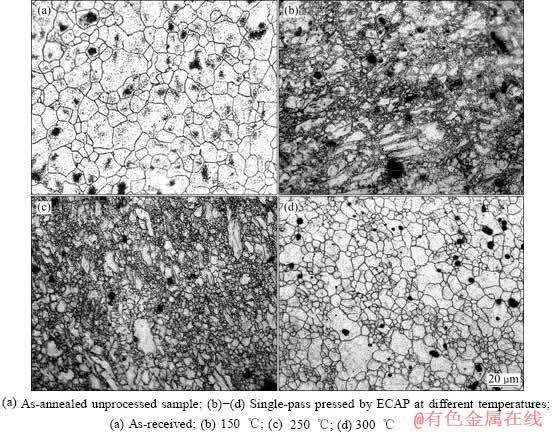

图6(a)所示为退火后AZ31B镁合金原始态光学微观金相组织。由图6(a)可见,初始材料的晶粒比较粗大,晶粒晶界明显呈等轴分布。图6(b)~(d)所示分别为变形温度为150、250和300 ℃时一道次ECAP挤压件稳定变形区轴截面中心位置的金相组织。由图6(b)~(d)可知,经过ECAP工艺挤压后,试样晶粒明显细化,但整体组织分布不均匀,局部存在较粗大的晶粒。

比较不同温度下挤压件的金相组织可以发现,当材料在150 ℃下变形时,在晶内滑移的作用下,原始晶粒沿着剪切面发生了明显的拉长和变形,形成了许多沿剪切方向的狭长晶粒;另外,由于受到强剪切作用且其层错能较低(约78 kJ/mol),在这些狭长晶粒的周围发生动态再结晶形成了“项链”结构的大量细小晶粒。图6(b)所示为镁合金晶粒内部沿滑移带的动态再结晶情况。由于位错滑移所导致的这些剪切带处于高能状态,从而为剪切带附近的金属晶粒提供了充分的再结晶动力,同时,相关晶界把剪切带分割成几部分,使得剪切变形带内发生再结晶,把原始态的大晶粒分解成若干个细小晶粒。这也是镁合金ECAP变形时的主要晶粒细化机制。

图6(c)所示为材料在250 ℃变形时的微观组织。由图6(c)可见,合金的晶粒组织仍然以狭长剪切晶粒和细小的再结晶晶粒为主,但与150 ℃变形时的微观组织相比,此时变形区内金属已经发生完全再结晶,一些稍宽的剪切带内已经被细小的再结晶晶粒取代,再结晶晶粒的比例有所提高,整个区域的变形组织相对比较均匀。

图6 AZ31镁合金未变形及不同变形温度ECAP一道次加工后试样横截面上的光学显微组织

Fig. 6 Optical microstructures in cross-section of AZ31 magnesium samples unprocessed and processed by one pass ECAP

如图6(d)所示,当变形温度提高到300 ℃时,可以发现变形区内的狭长金属完全消失,整个视场内的晶粒呈现等轴晶状态,但与250 ℃时的微观组织相比,此时晶粒尺寸明显变大。这是由于随着变形温度的升高,镁合金的晶界扩散能力增强,变形过程中形成的位错迅速被再结晶晶粒吸收,动态再结晶过程加快,使合金组织变成完全再结晶组织并迅速长大。这时虽然得到了完全均匀的等轴晶组织,但是由于晶粒在再结晶过程中迅速长大,也不利于晶粒的细化。

4 结论

1) AZ31镁合金在ECAP挤压过程中试件温度分布不均匀,在模具转角部位温度明显升高且存在明显的温度梯度。试样进入变形区后,强烈的塑性变形热导致试样温度急剧升高,变形热对挤压过程中的温度分布影响较大。当挤压速度不变时,随着初始变形温度的升高,变形对温度的影响逐渐降低。因此,在实际的变形过程中,应考虑变形热对镁合金材料实际变形温度的影响。

2) AZ31镁合金的塑性变形机制对温度敏感,当变形温度低于250 ℃时,变形过程中滑移和孪生的塑性变形机制共存。随温度的升高,非基面滑移的临界剪切应力开始降低,锥面滑移系逐渐增多并成为主要的变形机制,塑性变形能力显著增强,因此,提高变形温度可以很好地改善镁合金的塑性流动性能。

3) 当变形温度为250 ℃时,其微观组织明显细化且呈现等轴晶状态,晶粒内部位错的回复及再结晶随温度的升高而加强;当变形温度为300 ℃时,视场内的晶粒发生完全再结晶,与250 ℃时的微观组织相比尺寸明显变大,这在一定程度上影响了晶粒细化的效果。综上所述,AZ31镁合金较适宜的ECAP挤压温度为250 ℃左右,在该温度范围内挤压时,合金能获得较好的晶粒细化效果。

REFERENCES

[1] LUO A A, MISHRA R K, POWELL B R, SACHDEV A K. Magnesium alloy development for automotive applications[J]. Materials Science Forum, 2012, 706(1): 69-82.

[2] LEE J B, KONNO T J, JEONG H G. Grain refinement and texture evolution in AZ31 Mg alloys sheet processed by differential speed rolling[J]. Materials Science and Engineering B, 2009, 161(1/3): 166-169.

[3] ZHANG H, HUANG G, KONG D, SANG G, SONG B. Influence of initial texture on formability of AZ31B magnesium alloy sheets at different temperatures[J]. Journal of Materials Processing Technology, 2011, 211(10): 1575-1580.

[4] CHAO H Y, SUN H F, WANG E D. Working hardening behaviors of severely cold deformed and fine-grained AZ31 Mg alloys at room temperature[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S2): s235-s241.

[5] VALIEV R Z, KRASILNOKOV N A, TSENEV N K. Plastic deformation of alloys with submicron grained structure[J]. Materials Science and Engineering A, 1991, 137(1): 35-40.

[6] 刘 庆.镁合金塑性变形机理研究进展[J]. 金属学报, 2010, 46(11): 1458-1472.

LIU Qing. Research progress on plastic deformation mechanism of Mg alloys[J]. Acta Metallurgica Sinica, 2010, 46(11): 1458-1472.

[7] 何运斌, 潘清林, 刘晓艳, 李文斌. 镁合金等通道转角挤压过程中的晶粒细化机制[J]. 中国有色金属学报, 2011, 21(8): 1785-1793.

HE Yun-bin, PAN Qing-lin, LIU Xiao-yan, LI Wen-bin. Grain refinement mechanism of magnesium alloy during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1785-1793.

[8] JIN L, LIN D L, MAO D L, ZENG X Q, DING W J. An electron back-scattered diffraction study on the microstructure evolution of AZ31 Mg alloy during equal channel angular extrusion[J]. Journal of Alloys and Compounds, 2006, 426(1/2): 148-154.

[9] SU C W, LU L, LAI M O. A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies[J]. Materials Science and Engineering A, 2006, 434(1): 227-236.

[10] ONO N, NOWAK R, MIURA S. Effect of deformation temperature on Hall-Petch relationship registered for polycrystalline magnesium[J]. Materials Letters, 2004, 58(1/2): 39-43.

[11] JIANG H, FAN Z G, XIE C Y. Finite element analysis of temperature rise in CP-Ti during equal channel angular extrusion[J]. Materials Science and Engineering A, 2009, 513/514: 109-114.

[12] 孙朝阳, 栾京东, 刘 赓, 李 瑞, 张清东. AZ31镁合金热变形流动应力预测模型[J]. 金属学报, 2012, 48(7): 853-860.

SUN Chao-yang, LUAN Jing-dong, LIU Geng, LI Rui, ZHANG Qing-dong. Predicted constitutive modeling of hot deformation for AZ31 magnesium alloy[J]. Acta Metallurgica Sinica, 2012, 48(7): 853-860.

[13] 王忠堂, 张士宏, 齐广霞, 王 芳, 李艳娟. AZ31 镁合金热变形本构方程[J]. 中国有色金属学报, 2008, 18(11): 1977-1982.

WANG Zhong-tang, ZHANG Shi-hong, QI Guang-xia, WANG Fang, LI Yan-juan. Constitutive equation of thermal deformation forAZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1977-1982.

[14] 陈振华. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 24-32.

CHEN Zhen-hua. Wrought magnesium alloys[M]. Beijing: Chemical Industry Press, 2005: 24-32.

[15] PEI Q X, HU B H, LU C, WANG Y Y. A finite element study of the temperature rise during equal channel angular pressing[J]. Scripta Materialia, 2003, 49(4): 303-308.

[16] YAMAGUCHI D, HORITA Z, NEMOTO M, LANGDON T G. Significance of adiabatic heating in equal-channel angular pressing[J]. Scripta Materialia, 1999, 41(8): 791-796.

[17] JEONG H T, KIM W J. Mechanical properties and texture evolution of AZ31 Mg alloy during equal channel angular pressing[J]. Materials Science Forum, 2005, 475/479: 545-548.

[18] 郭廷彪, 丁雨田, 袁训锋, 胡 勇. 等通道角挤压中纯铜的晶粒取向演变及织构起伏效应[J]. 中国有色金属学报, 2011, 21(2): 384-391.

GUO Ting-biao, DING Yu-tian, YUAN Xun-feng, HU Yong. Grain orientation evolution and texture fluctuation effect of pure copper during equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 384-391.

(编辑 何学锋)

基金项目:教育部“长江学者和创新团队发展计划”创新团队资助项目(IRT0931);山东省自然基金资助项目(ZR2012EMM014)

收稿日期:2012-10-08;修订日期:2013-01-26

通信作者:赵国群,教授,博士;电话:0531-88393238;E-mail:zhaogq@sdu.edu.cn