DOI: 10.11817/j.issn.1672-7207.2018.04.011

超深矿井提升机盘形闸制动系统机电液仿真建模

王刚,狄亚鹏,李建涛

(中南大学 机电工程学院,湖南 长沙,410083)

摘要:为研究提升机盘形闸制动系统制动过程的动态性能,建立多绳缠绕式提升机制动系统动力学ADAMS模型,并将油压滞回仿真结果与实验测试结果进行对比验证,同时结合以钢丝绳连续弹性体模型为基础建立的制动负载模型,完成对盘形闸制动系统的动力学建模。建立盘形闸制动系统的液压系统仿真模型,并在Simulink中建立相应的二级制动及恒减速制动控制策略模型。以Simulink为集成环境,采用多软件联合仿真方式建立盘形闸制动系统的机电液一体化仿真系统。运用该系统对提升机重载下放超速工况下的二级制动和恒减速制动性能进行仿真研究。研究结果表明:设计的制动系统机电液各项运行参数合理有效,恒减速制动比二级制动的动态性能更平稳。

关键词:超深矿井;盘形闸;联合仿真;二级制动;恒减速制动

中图分类号:TD534 文献标志码:A 文章编号:1672-7207(2018)04-0848-09

Mechanical-electrical-hydraulic modeling of disc braking system for ultra deep mine hoist

WANG Gang, DI Yapeng, LI Jiantao

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: To study the disc braking system dynamic performance during braking, multi-body dynamic model of the multi-rope winding hoist was established in ADAMS and verified by comparing the hydraulic hysteresis simulation results with the experimental results. Combined with the braking load based on the continuous elastic model of the wire rope, the hoisting system dynamic model was established in Simulink. Meanwhile, the hydraulic system model was established and the control strategy model of two-stage braking and constant decelerating braking were established in Simulink. Using the multi-software co-simulation technology, the mechanical-electrical-hydraulic simulation system of the disc braking system was formulated with Simulink as integrated environment. The dynamic performance of two-stage braking and constant decelerating braking at the heavy dropping overspeed was studied based on the simulation system. The results show that design operation parameters of the mechanical-electrical-hydraulic system are correct and effective, and the dynamic performance of constant decelerating braking is more stable than that of the two-stage braking.

Key words: ultra deep mine hoist; disc brake; co-simulation; two-stage braking; constant decelerating braking

在我国煤炭系统内通常将开采深度大于1.2 km的矿井划分为超深矿井[1],本文研究的超深矿井提升机最大提升深度为1.5 km,最大提升速度为18 m/s,有效载荷为50 t,是目前我国设计深度最深的矿井提升机。该提升机采用双卷筒多绳缠绕式的多点组合提升拓扑结构。该结构属布雷尔式提升机的一种布置形式[2]:2卷筒串联布置,主轴间使用联轴器相连以保证机械同步;同一卷筒上的2根钢丝绳缠绕方式相同,并采用浮动天轮和张力平衡装置以保证2绳张力均衡;不同卷筒上的钢丝绳缠绕方式相反,以分别实现上提和下放。当井深达1.5 km以上时,其提升能力比多绳摩擦式提升机的强,极限提升高度比多绳摩擦式提升机的高。在提升高度和容器系数均相同时,其提升能力是单绳缠绕式提升机的1倍[3],因而更适合用于超深矿井提升。盘形闸装置、液压站及其控制柜一起构成盘形闸制动系统。提升机在正常工况下一般按设定的速度曲线运行,运行过程中的加、减速主要通过电力制动完成,盘形闸制动系统起辅助作用并在安全停稳后实现抱闸。而在需要紧急制动场合,提升机则只能依靠盘形闸制动系统减速并停车,因此,它是保障矿井安全最关键的环节。由于超深矿井提升机在高速运行过程中常受到罐道卡阻、冲击和气流等复杂因素的干扰,其冲击和振动特性复杂,钢丝绳动载荷变化大,振动传播与作用路径长,空载、满载和换向等操作过程中提升系统动力学特性差异显著,具有高速、重载、大惯量、强时变的特点,因而,研究超深矿井提升机安全及动态性能,探寻高提升能力和装备安全性能之间的内在关系意义重大。近年来,许多研究者在提升机盘形闸制动系统方面开展了大量工作。刘劲军等[4]对我国单绳缠绕式提升机紧急制动减速度进行了理论分析,指出在满足煤矿安全规程对制动力矩的倍数要求时,减速度可能高于规定值。赵强[5]通过构建的多柔体动力学模型及液压系统模型搭建了提升机整机模型,着重分析了液压元件参数变化对紧急制动运行参数的影响,并开展了相关实验。麻慧君[6]提出釆用全数字控制、软硬件冗余的全时恒减速控制策略。BAO等[7]对盘形闸闸瓦在紧急制动过程中的摩擦磨损特性进行了研究。GRZEGORZEK等[8]运用神经网络算法预测盘形闸在制动过程中的摩擦磨损特性。上述研究大多集中在提升机紧急制动的某些方面,没有在综合条件下研究提升机盘形闸制动系统的制动安全性能,并且对超深矿井高速重载的作业工况针对性不强。鉴于超深矿井提升机是集机电液一体化的大型复杂装备,有必要从系统的角度研究超深矿井提升机盘形闸制动系统的制动性能。为此,本文作者分别建立相应的机械部分动力学模型、液压系统模型、控制策略模型,采用ADAMS,AMEsim及Simulink的多软件协同仿真方式建立盘形闸制动系统的机电液一体化仿真系统,并在此基础上对超深矿井提升机的二级制动和恒减速制动进行仿真研究。

1 盘形闸制动系统工作原理

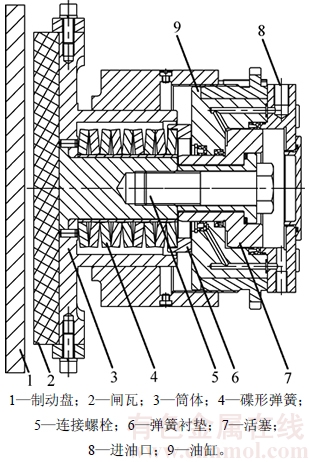

系统运行中主闸的最低压力下降、电源中断、操作人员或安全装置的干预都会引起制动系统紧急制动抱闸。超深矿井提升机采用油缸后置式盘形闸进行制动,如图1所示。盘形闸靠碟形弹簧产生制动力,靠油压松闸。当油压增大时,活塞受液压站压力油作用带动连接螺栓右移,从而压缩碟形弹簧并带动闸瓦与制动盘分离,制动器处于松闸状态。当油压降低时,在碟形弹簧回复力作用下,闸瓦靠近并贴上制动盘产生正压力,制动器处于制动状态。碟形弹簧的制动力计算公式为

式中:FN为盘形闸的制动力;ks为碟形弹簧刚度;Δx为碟形弹簧压缩量;p为油液压力;Ap为制动器油缸活塞有效面积;fz为碟形弹簧综合阻力。

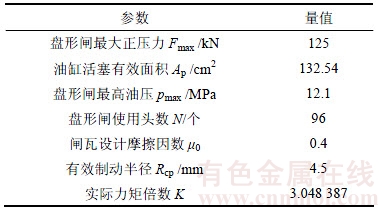

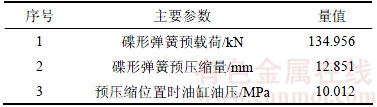

提升机紧急制动主要有二级制动和恒减速制动2种方式。二级制动是指在紧急制动开始时,一部分制动头(一般为制动头总数的一半)完全施加制动力,产生符合安全规定的制动减速度;另一部分制动头则受液压站控制只提供部分制动力,经过整定的延时后,再全部施加到制动盘上,使提升机迅速停车并安全可靠地将其闸住。恒减速安全制动是指提升机以制动减速度恒定为控制目标,通过自动调节制动力矩,使提升机按照设定的减速度进行制动的制动方式。我国煤矿安全规程规定提升机的盘形闸总制动力矩不得小于实际提升最大静荷重旋转力矩的3倍;立井提升上提重物减速度不高于5.0 m/s2,下放重物减速度不低于1.5 m/s2;制动盘与闸瓦的间隙最大不超过2 mm,盘形闸空动时间不得超过0.3 s。为满足规定要求,超深矿井提升机盘形闸制动系统的主要技术参数如表1所示。

图1 油缸后置式盘形闸结构简图

Fig. 1 Structure diagram of disc brake with cylinder rear-mounted

表1 盘形闸制动动系统主要技术参数

Table 1 Main technical parameters of disc braking system

2 制动系统动力学建模

2.1 盘形闸制动装置动力学模型

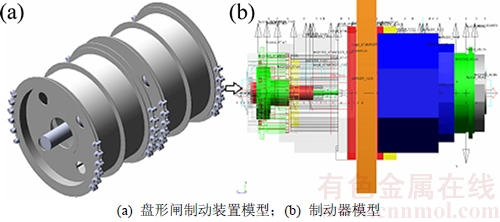

根据超深矿井提升机的主要技术参数,在Solidworks中建立包含提升机卷筒、制动盘、主轴及盘形闸的装配体模型。将模型导入ADAMS中,在ADAMS/view平台上,考虑各部件的接触力、阻尼和摩擦力,建立盘形闸制动装置动力学模型,如图2所示。

提升机天轮和电动机转子按变位质量换算到2个卷筒圆周上,忽略传动部分的变位质量。换算后的变位质量如表2所示。

图2 盘形闸制动装置多刚体动力学模型

Fig. 2 Multi-body dynamic model of disc braking device

表2 天轮和电动机转子的变位质量

Table 2 Deflection qualities of head sheaves and motor rotors

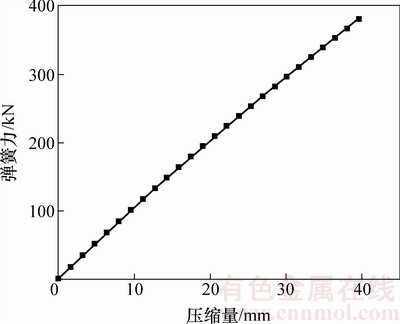

盘形闸中的碟形弹簧产生抱闸制动力,每个盘形闸内有1个碟形弹簧组,由9片碟形弹簧对合而成。碟形弹簧组的装配长度为148.5 mm,其压缩特性近似呈线性关系,如图3所示。在ADAMS中没有建立碟形弹簧的实体模型,而是以弹簧力的形式添加在弹簧衬垫和筒体之间并将弹簧特性输入。

图3 碟形弹簧压缩特性

Fig. 3 Compression characteristic of disk spring

碟形弹簧在产生正压力时,不仅要克服液压油的作用,而且要克服综合阻力的影响。本文采用在碟形弹簧上施加线性阻尼及在活塞与油缸移动副施加库仑摩擦力的方式来模拟综合阻力。参考ADAMS帮助文件,得到综合阻力的计算公式为

式中:Cv为黏性阻尼系数;r为碟形弹簧实际长度;dr/dt为弹簧长度对时间的变化率;l为弹簧初始长度;Fpre为初始长度下弹簧的预压缩力;fc为移动副的库仑摩擦力。

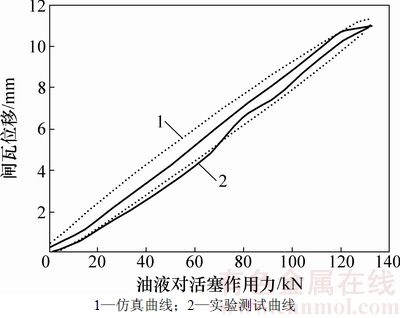

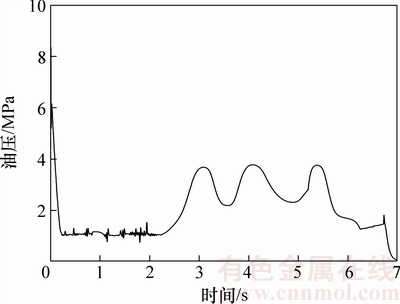

调节后的盘形闸油压滞回仿真结果与实验测试结果对比如图4所示,可见仿真结果与实验结果相吻合。

假设盘形闸与制动盘的间隙为1 mm,盘形闸处于正确安装位置时的主要参数设置如表3所示。

2.2 制动负载分析及模拟

钢丝绳将提升机、天轮和提升容器连接在一起,具有柔性振动特性,处在纵向、横向和扭转特性耦合作用的复杂振动状态下[9]。提升机在制动过程中惯性负载的减速度是引起振动的主要因素,此外,提升容器的结构形状、罐道形式、罐耳与罐道间的摩擦因数、风流速度、提升速度等其他因素同样会对振动造成影响。由于其他因素造成的影响难以精确计算,在提升机设计中通常按提升货物的质量分数w来估算,其计算公式为[10]

式中:K0为矿井阻力系数,采用罐笼提升时,K0=1.2;Q0为提升货物质量;ρ为钢丝绳单位长度的质量;△H为提升侧和下放侧高度差。

图4 盘形闸仿真模型油压实测结果与实验结果对比

Fig. 4 Comparison of hydraulic hysteretic curve between simulation results and measured results

表3 闸瓦间隙为1 mm时盘形闸主要参数

Table 3 Main parameters of disc brake when disc clearance is 1 mm

钢丝绳张力包括静张力和动张力,振动的复杂性使得钢丝绳张力不断变化。提升机在提升或下降过程中,钢丝绳与卷筒不断地接触或分离,接触或分离点处钢丝绳的张力直接作用于卷筒上,因此,可将提升机制动系统的负载变化等效为钢丝绳在与卷筒接触或分离点处的张力变化。本文在Simulink中以S-function的形式单独建立绳系动态计算模型,并进行以下假设:

1) 由于提升深度大,浮动天轮与卷筒之间的弦绳长度较短,因此,忽略该段提升钢丝绳惯性的影响[9]。

2) 由于弦绳是产生横向振动的主要区域,同时罐笼受罐道约束,并且选用扭转运动并不显著的三角股钢丝绳[9, 11],因此,忽略钢丝绳横向运动和扭转运动对钢丝绳张力的影响。

3) 由于紧急制动时间较短,因此,忽略紧急制动过程中因缠绕导致的钢丝绳悬垂长度的变化,并假设钢丝绳与卷筒分离或接触点是1个固定点。

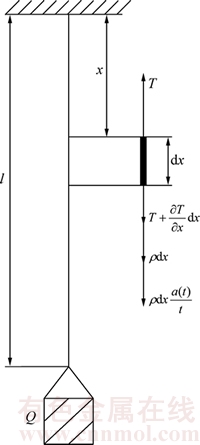

目前,求解钢丝绳纵向张力的模型主要有集中参数的离散模型、连续弹性体模型、有限元模型及基于ADAMS绳索类建模技术的轴套力离散模型[12]。在上述方法中,基于连续弹性体模型建立一类非齐次边界条件混合问题的波动方程,并用离散方法将非齐次项线性化,得到波动方程的近似解析解,解决了在加、减速度为任意连续函数形式时方程无法求得精确解的问题[13]。由于该方法能够比较准确地反映钢丝绳的纵向振动的特性,还容易与联合仿真模型相结合,因此,本文采用连续弹性体模型计算钢丝绳张力。钢丝绳的动张力简化计算示意图如图5所示。

以提升侧为例,当制动减速度a(t)为任意连续函数时,钢丝绳任意截面处动位移uk(x,t)为[13]:

图5 钢丝绳张力计算示意图

Fig. 5 Calculation diagram of wire rope tension

其中:

;

;

;

;

。

。

超越方程为

考虑到

钢丝绳任意截面处的动张力Td(x,t)为[13]

其中:x为钢丝绳截面到分离或接触点的距离;Ank和Bnk为计算引入的变量;Q为钢丝绳的终端质量; E为钢丝绳的弹性模量;As为钢丝绳的横截面积;g为重力加速度;c为弹性波在钢丝绳中的传播速度;α为钢丝绳质量与终端质量之比;βn为超越方程的根;a为提升机卷筒的制动减速度;k为离散直线的段编号;τ为离散时间间隔即步长。当x=0时,求得钢丝绳与卷筒的接触点或分离点处的动张力Td(0,t)为[13]

根据文献[10],动位移及载荷方程的求和部分可以忽略级数负项的影响。

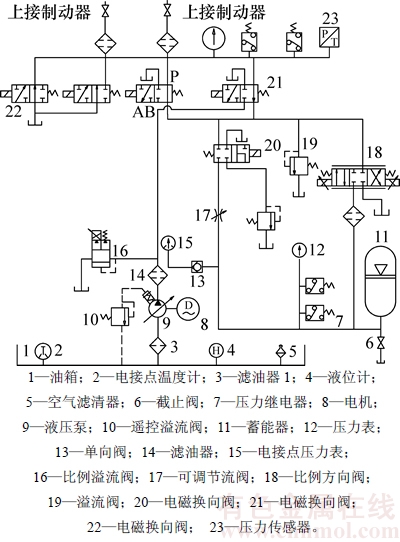

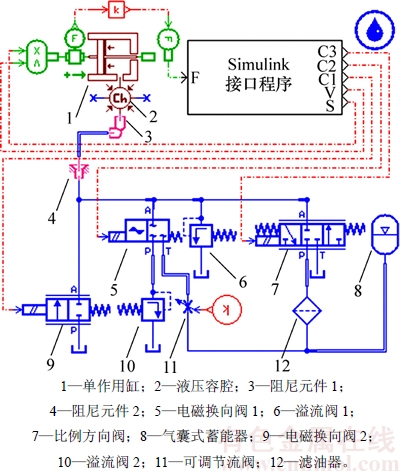

3 液压系统模型的建立

超深矿井提升机盘形闸制动系统的液压站原理图如图6所示。该液压站可实现工作制动、二级制动、恒减速制动、井口一级制动的功能并进行了多通道冗余设计,即若第1通道发生故障,则第2通道将立即开始工作。本文没有考虑冗余部件,只对与紧急制动相关的油路部分进行建模。

图6 液压系统原理图

Fig. 6 Schematic diagram of hydraulic system

3.1 液压系统工作原理

在AMEsim平台上建立液压系统模型,如图7所示。系统的输入为液压换向阀与方向阀的阀控信号c1,c2和c3以及盘形闸活塞的位移s和速度v,输出为计算后得到的油液对活塞作用力F。电磁换向阀1上电时各口均连通,掉电时各口均不连通。

二级制动时,比例方向阀保持中位,电磁换向阀1接通,电磁换向阀2延时接通。油液通过溢流阀2后形成二级制动的第一级制动油压,经整定延时后,由电磁阀2回到油箱从而产生全部制动力,完成二级制动过程。在此过程中,蓄能器应急供油,起到稳压补油的作用,根据整个系统的控制流程,该应急供油过程应维持3~7 s(依据运行速度)。可调节流阀控制蓄能器向系统的补油速度,若开口太小,则补油不足;若开口太大,则持续时间不够。恒减速制动开始后,电磁换向阀1和2均断电,比例方向阀受c3控制,不断通过油箱泄油或蓄能器补油产生维持恒减速制动所需要的力矩。

图7 液压系统AMEsim仿真模型

Fig. 7 Simulation model of hydraulic system in AMEesim

3.2 主要元件参数计算与选取

单作用缸和液压容腔是ADAMS和AMEsim数据交互的环节。一方面,根据输入的盘形闸活塞的速度v和位移s,动态地计算盘形闸液压缸内部容腔体积、流量;另一方面,将计算得到的油液对活塞作用力返回给ADAMS。两元件参数则按照表3中有关内容设置。液压缸容腔体积V和油液对活塞作用力F的计算公式为:

式中:xpre为弹簧预压缩量;dp为油缸直径;dr为活塞杆直径。

溢流阀1设定的贴闸油压px为9.43 MPa,用于消除制动盘与闸瓦的1 mm间隙,使制动开始后盘形闸迅速动作,防止飞车和速度超调。贴闸油泵计算公式为[14]

式中:Fc为提升系统静张力差;R为卷筒半径;μ为闸瓦摩擦因数,计算时一般取0.35。

溢流阀2调定的油压p1为4.3 MPa。根据立井提升的作业工况,在计算二级制动的第一级制动油压时,原则上按下放重载允许的制动减速度计算[14],计算公式为

蓄能器预充气体积Vpre选为4 L,预充气压力ppre为5.16 MPa,计算公式为

由于蓄能器做辅助动力源用,故可按绝热过程来计算,蓄能器的工作容积Vw为

式中:pmax为蓄能器完全放液时的体积;pmin为蓄能器完全充液状态时的体积,在绝热过程中,n=1.4。

模型中比例方向阀取线性流量特性,控制信号与阀的开口度和流量成正比。由孔口流量公式得阀的流量q为

式中:Cq为流量系数;A(c3)为阀的节流边开口量,它是控制信号c3的函数;ω为线性流量特性时的线性系数;ρL为油液密度;△p为节流边前后的压力差。

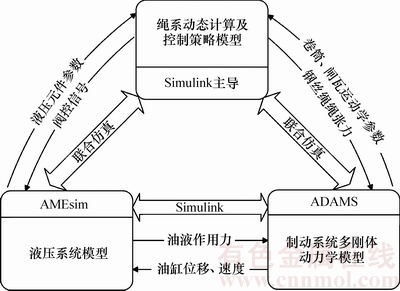

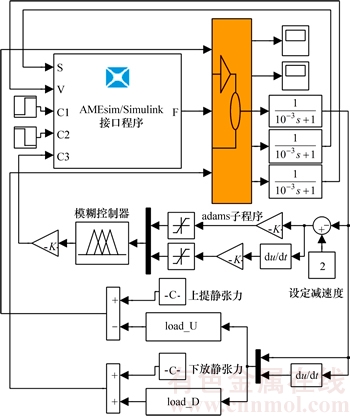

4 机电液联合仿真

ADAMS,AMEsim和Matlab/Simulink均为其他2款软件提供了高效、多样的接口以实时交换数据[15],接口可分为完全输出及联合仿真2种模式。选择以Simulink作为集成环境并在与ADAMS和AMEsim交互时,均采用以Simulink为主导的联合仿真方式进行仿真,联合仿真原理如图8所示。由于输出的AMEsim和ADAMS中的模型都以S-function的形式存在,因此,两者可以Simulink为媒介自动实现数据交换,从而达到联合仿真的目的。

根据图8所示原理,在Simulink中搭建联合仿真程序,如图9所示。图9中“adam子程序”是ADAMS输出到Simulink的子系统,包含表示ADAMS非线性模型的S-Function及用于与Simulink交换数据,联合仿真以Simulink为主导,采用变步长仿真的方式进行,其中的传递函数则用于消除代数环的影响。

图8 联合仿真原理

Fig. 8 Schematic principle of co-simulation

图9 Simulink联合仿真框图

Fig. 9 Block diagram of co-simulation in Simulink

系统输入为制动减速度的设定值、制动开始时卷筒圆周处的线速度、上提和下放侧初始绳长及负载。系统输出为卷筒圆周处的线速度、实际制动减速度、钢丝绳的张力及盘形闸内油压。

在制动控制策略上,二级制动控制只需设定2个换向阀的接通或断电的延时时间。设定二级制动的第一级制动时间为12 s,以下放重载的规定为计算依据,制动时间t1计算公式为

其中:vm为速度最大值;amin为加速度最小值。

恒减速制动控制则采用在Simulink中建立mamdani模糊控制器的方式实现。选取卷筒制动减速度与设定减速度的偏差以及偏差的变化率为模糊控制器的输入,以与比例方向阀控制信号相关的控制量作为模糊控制器的输出。

引起提升机紧急制动的工况有很多,本文选取重载下放超速工况进行超深矿井提升机紧急制动仿真。制动开始时,卷筒圆周处的线速度取为20 m/s,下放侧负载为490 kN,初始绳长为1 km,上提侧空载,初始绳长为500 m。

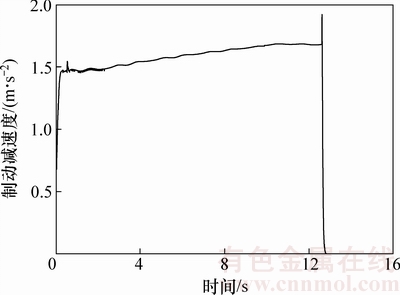

二级制动的仿真结果如图10所示,恒减速制动的仿真结果如图11~14所示。从图10可见:在二级制动过程中,卷筒的制动减速度由1.50 m/s2到1.75 m/s2缓慢增加,在接近13 s时二级制动进入第二阶段,此时,全部制动力矩施加在制动盘上以满足制动力矩不小于实际提升最大静荷重旋转力矩的3倍要求,同时卷筒得到1个较大的瞬时减速度,待其被盘形闸抱死后又迅速降低为0 m/s2。

图10 二级制动时卷筒制动减速度变化曲线

Fig. 10 Braking deceleration curve of drum under two-stage braking

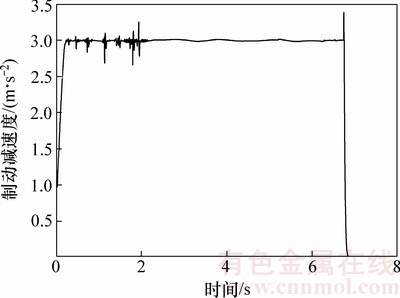

图11 恒减速制动时卷筒制动减速度变化曲线

Fig. 11 Braking deceleration curve of drum under constant decelerating braking

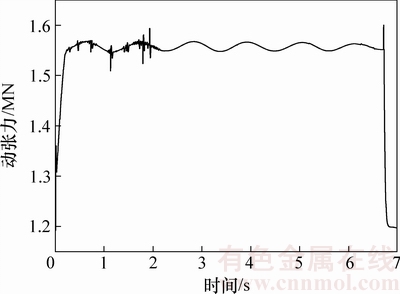

图12 恒减速制动时上提侧钢丝绳张力变化曲线

Fig. 12 Wire rope tension changing curve of lift side under constant decelerating braking

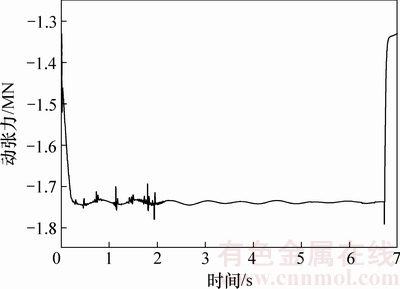

图13 恒减速制动时下放侧钢丝绳张力变化曲线

Fig. 13 Wire rope tension changing curve of drop side under constant decelerating brake

图14 恒减速制动时盘形闸内油压变化曲线

Fig. 14 Changing curve of oil pressure in disc brake under constant decelerating braking

从图11~14可见:在恒减速过程中,卷筒的减速度在3 m/s2附近小幅度波动,相比于二级制动,恒减速制动制动的动态性能更加平稳;上提侧钢丝绳的张力在1 550 kN处振荡变化。下放侧钢丝绳的张力在 -1 750 kN处振荡变化,负号表示与上提侧钢丝绳张力对卷筒产生的力矩方向相反。

5 结论

1) 基于超深矿井提升机的结构特点和工作载荷情况,建立了1.5 km超深矿井提升机盘形闸制动系统动力学模型,并将盘形闸油压滞回仿真结果与实验测试结果进行了对比验证。同时在AMEsim和Simulink中分别建立了制动系统的液压系统和控制模型。

2) 采用ADAMS,AMEsim和Simulink等多软件联合仿真方式建立的盘形闸制动系统机电液一体化仿真系统可以有效地对盘形闸制动系统开展机电液仿真研究。

3) 设计的机电液系统各项运行参数合理有效,恒减速制动比二级制动具有更加平稳的动态性能。

参考文献:

[1] 胡社荣, 戚春前, 赵胜利, 等. 我国深部矿井及其临界深度讨论[J]. 煤炭科学技术, 2010, 38(7): 10-13.

HU Sherong, QI Chunqian, ZHAO Shengli, et al. Discussion on China deep mine classification and critical depth[J]. Coal Science and Technology, 2010, 38(7): 10-13.

[2] ALFRED C. Mine hoisting in deep shafts in the 1st half of 21st century[J]. Acta Montanistica Slovaca, 2002, 7(3): 188-192.

[3] 刘劲军, 邹声勇, 张步斌, 等. 我国大型千米深井提升机械的发展趋势[J]. 矿山机械, 2012, 40(7): 1-6.

LIU Jinjun, ZOU Shengyong, ZHANG Bubin, et al. Discussion trend of domestic large hoisting equipments for deep shafts of thousands meters[J]. Mining & Processing Equipment, 2012, 40(7): 1-6.

[4] 刘劲军, 邹声勇, 张步斌, 等. 单绳缠绕式提升机紧急制动减速度分析[J]. 矿山机械, 2014, 42(10): 44-50.

LIU Jinjun, ZOU Shengyong, ZHANG Bubin, et al. Analysis on emergency braking deceleration of single-rope winding hoist[J]. Mining & Processing Equipment, 2014, 42(10): 44-50.

[5] 赵强. 提升机制动系统动态特性仿真及试验研究[D]. 太原: 太原理工大学机械工程学院, 2016: 45-65.

ZHAO Qiang. Simulation and experimental study on dynamic characteristics of hoist braking system[D]. Taiyuan: Taiyuan University of Technology. School of Mechanical Engineering, 2016: 45-65.

[6] 麻慧君. 矿用提升机全数字软硬件冗余恒减速制动系统研究[D]. 太原: 太原理工大学机械工程学院, 2013: 1-5.

MA Huijun. Research of mine hoist constant deceleration braking system[D]. Taiyuan: Taiyuan University of Technology. College of Mechanical Engineering, 2013: 1-5.

[7] BAO Jiusheng, LIU Jinge, YIN Yan, et al. Characterization and experiments on the friction catastrophe behaviors of brake material during emergency braking[J]. Engineering Failure Analysis, 2015, 55(9): 55-62.

[8] GRZEGORZEK W,  S. Prediction on friction characteristics of mine hoist disc brakes using artificial neural networks[J]. Scientific Problems of Machines Operation & Maintenance, 2011, 38(7): 27-42.

S. Prediction on friction characteristics of mine hoist disc brakes using artificial neural networks[J]. Scientific Problems of Machines Operation & Maintenance, 2011, 38(7): 27-42.

[9] 曹国华. 矿井提升钢丝绳装载冲击动力学行为研究[D]. 北京: 中国矿业大学机电工程学院, 2009: 5-12.

CAO Guohua. Impact dynamic behaviors of mine hoisting rope during loading process[D]. Beijing: China University of Mining and Technology. College of Mechanical and Electrical Engineering, 2009: 5-12.

[10] 李玉瑾. 多绳摩擦提升系统动力学研究与工程设计[M]. 北京: 煤炭工业出版社, 2008: 16-21.

LI Yujin. Dynamics of multi-rope friction hoist system research and design[M]. Beijing: China Coal Industry Publishing House, 2008: 16-21.

[11] KACZMARCZYK S, OSTACHOWICZ W. Transient vibration phenomena in deep mine hoisting cables. Part 1: mathematical model[J]. Journal of Sound and Vibration, 2003, 262(2): 219-244.

[12] 晋民杰, 刘华伟, 裴培, 等. 基于ADAMS宏程序的矿井提升机钢丝绳建模研究[J]. 矿山机械, 2011, 39(12): 46-49.

JIN Minjie, LIU Huawei, PEI Pei, et al. Study on modeling of wire ropes of mine hoists based on ADAMS macro programs[J]. Mining & Processing Equipment, 2011, 39(12): 46-49.

[13] 梁兆正. 提升钢丝绳动态分析的分段线性化解法[J]. 应用数学与计算数学学报, 1996, 10(2): 35-43.

LIANG Zhaozheng. The segmented linear solutions of hoisting wire rope dynamic analysis[J]. Communication on Applied Mathematics and Computation, 1996, 10(2): 35-43.

[14] 刘明志, 江洪杰, 张新民. 矿井提升机安全制动油压的确定与调整[J]. 煤矿机械, 2004, 7(8): 13-15.

LIU Mingzhi, JIANG Hongjie, ZHANG Xinmin. Determination and adjustment of oil pressure of safe braking system of mine hoist[J]. Mining & Processing Equipment, 2004, 7(8): 13-15.

[15] 马长林, 李锋, 郝琳, 等. 基于Simulink的机电液系统集成化仿真平台研究[J]. 系统仿真学报, 2008, 20(17): 4578-4581.

MA Changlin, LI Feng, HAO Lin, et al. Study of integrated simulation platform for mechanical electro-hydraulic system based on Simulink[J]. Journal of System Simulation, 2008, 20(17): 4578-4581.

(编辑 陈灿华)

收稿日期:2017-05-29;修回日期:2017-07-22

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2014CB049402)(Project(2014CB049402) supported by the National Basic Research Development Program(973 Program) of China)

通信作者:王刚,博士,副教授,从事工程装备设计与控制研究;E-mail:wg@csu.edu.cn