DOI: 10.11817/j.issn.1672-7207.2020.11.006

送粉式激光增材制造Al-Mg-Sc-Zr合金的微观组织与力学性能

林泽桓1,李瑞迪1,祝弘滨2,袁铁锤1,徐荣1,闫华3,叶兵4

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 中车工业研究院有限公司,北京,100000;

3. 上海工程技术大学 材料工程学院,上海,201620;

4. 武汉华工激光工程有限责任公司,湖北 武汉,215000)

摘要:采用送粉式激光增材制造方法制备Al-Mg-Sc-Zr合金试样,采用金相显微镜、X射线衍射分析、扫描电子显微镜、室温拉伸试验及显微硬度测量等手段研究送粉式激光增材制造Al-Mg-Sc-Zr合金时效前后的微观组织与力学性能。研究结果表明:打印态试样熔池边界附近存在细晶区,而熔池内部发现粗大的树枝胞状晶粒,粒径约为7 μm。试样拉伸强度(σuts)为(303.72±4.00) MPa,屈服强度(σ0.2)为(216.93±3.00) MPa,伸长率(εf)为7.65%±0.34%。试样XOZ面、XOY面和YOZ面的硬度(HV)分别为112.29±6.00,85.76±1.70和90.176±5.340。在325 ℃/4 h时效处理后,熔池边界附近晶粒发生了一定程度的长大,导致熔池边缘开始消失,但熔池内部晶粒尺寸和形状没有变化。试样拉伸性能有较为明显的提升,抗拉强度提升到(318.13±5.00) MPa,屈服强度提升到(234.84±1.90) MPa,而伸长率下降到6.96%±0.24%。试样XOZ面、XOY面和YOZ面的硬度(HV)分别提升到118.75±4.00,88.60±0.93和101.44±2.75。

关键词:激光送粉增材制造;铝钪合金;时效处理;微观组织;拉伸性能;显微硬度

中图分类号:TG146.2+1 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3055-09

Microstructure and mechanical properties of Al-Mg-Sc-Zr alloy by powder feeding laser additive manufacturing

LIN Zehuan1, LI Ruidi1, ZHU Hongbin2, YUAN Tiechui1, XU Rong1, YAN Hua3, YE Bing4

(1. State key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. CRRC Industrial Research Institute, Beijing 100000, China;

3. College of Materials Engineering, Shanghai University of Engineering Science, Shanghai 201620, China;

4. Wuhan Huagong Laser Engineering Co. Ltd., Wuhan 215000, China)

Abstract: Al-Mg-Sc-Zr alloy samples were prepared by powder feeding laser additive manufacturing method. And microstructure and mechanical properties of Al-Mg-Sc-Zr alloy were studied by means of metallographic microscope, X-ray diffraction analysis, scanning electron microscope, room temperature tensile test and microhardness measurement, etc. The results show that for the printed samples, fine grains are found on the boundary of the pools. And large dendritic cell grains with the size of about 7 μm exist inside the pools. The tensile strength(σuts) is (303.72±4.00) MPa, yield strength(σ0.2)is (216.93±3.00) MPa, and elongation(εf) is 7.65%±0.34%.The hardness on XOZ-plane, XOY-plane and YOZ-plane of the sample are 112.29±6.00, 85.76±1.70 and 90.176±5.340, respectively. After aging treatment at 325 ℃ for 4 h, the grain size at the edge of the pool grows to a certain extent, leading to the disappearance of the edge of the pool, but the grain size and shape inside the pool do not change. Tensile strength increases to (318.13±5.00) MPa, yield strength increases to (234.84±1.90) MPa, and elongation decreases to 6.96%±0.24%. The hardness on XOZ-plane, XOY-plane and YOZ-plane of the sample increase to 118.75±4.00, 88.60±0.93 and 101.44±2.75, respectively.

Key words: laser powder feeding additive manufacturing; aluminum-scandium alloy; aging treatment; microstructure; tensile property; microhardness

铝及其相关合金因具备优秀的耐蚀性、高导热性等被广泛运用于工业、军事以及生活之中。随着零构件的推陈出新以及对性能要求的不断提高,钪元素被广泛应用于铝合金改性,生成的Al3Sc相能够促进非均质形核,同时能在高温处理中析出起到对晶界的钉轧作用,使得晶粒细化,从而能够有效提升铝合金的性能[1-2]。而在传统的铝合金生产中,一般都是采用熔铸或者塑性变形的方法,这就使得在制备形状复杂的金属零件时,造成大量的材料浪费,制备周期较长,同时,在零件材料要求日益提高的环境下,传统工艺愈加无法满足[3]。目前,激光增材制造受到广泛了关注。相较于传统工艺,激光增材制造具有节省材料、缩短成形周期以及能够制备形状更复杂的成形零件等优势,能够实现高性能复杂结构金属零件的无模具全致密近净成形[4-8]。该技术成形过程中较快的凝固速度(103~108 K/s)能够有效地抑制晶粒长大及元素偏析,使得成形的合金试样组织细小,具有较高力学性能[9],在铝合金的轻量化生产应用中有着巨大的潜力。激光送粉增材制造(laser metal deposition, LMD)是一项基于送粉工艺的近净成形技术,又被称为直接金属沉积(direct metal deposition,DED),拥有能够自由移动的粉末喷嘴和激光器以及较大的成形舱,能够有效地制造形状复杂、尺寸较大的零件。

关于含Sc和Zr的铝合金的激光送粉增材制造的研究已经引起了许多国内外学者的关注。WANG等[10]采用激光送粉增材制造技术成形了经Sc和Zr改性的铝镁合金,发现在低Sc和Zr含量下,快速凝固有效抑制了Al3(Sc, Zr)初生相析出,在熔池内部仍可得到粗柱状晶组织。熔池边界较低的熔体温度不可避免地促进了Al3(Sc, Zr)初生相析出,在熔池边缘形成了细小的等轴晶带。随着Sc和Zr含量的增加,凝固冷却速度不足以使得Al3(Sc, Zr)初生相析出,得到了完全等轴的晶粒组织。KURNSTEINER等[11]研究了激光送粉增材制造工艺过程中存在的固有热处理(IHT)对含Sc铝合金的影响,发现在激光成形过程中,快速冷却速率导致的过饱和Al-Sc矩阵的固态相变可以使纳米沉淀物得密度达到1023个/m3。由于Sc和Zr在Al中的极限固溶度有限[12],时效处理对铝钪合金性能有一定的影响,如激光粉末床成形(laser powder bed forming, LPBF)成形的铝钪合金在时效处理后性能得到了有效的提升[13]。但是,对LMD成形铝钪合金时效处理前后性能和组织的研究较少。在此,本文作者针对采用LMD成形的铝钪合金,选取较为合适的热处理参数,通过力学性能测试和显微组织分析探讨时效处理对铝钪合金的影响,以期为后续的LMD成形铝钪合金结构件的研究提供数据和理论支持。

1 实验方法

1.1 材料和样品的制备

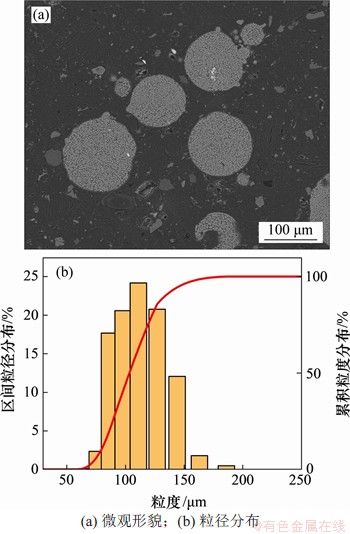

采用真空感应熔炼惰性气体雾化法(VIGA)制备的Al-Mg-Sc-Zr预合金粉末,保护气为氩气。初始Al-Mg-Sc-Zr粉末经磨抛之后形貌和粒径分布,如图1所示。从图1可见:粉末粒径分布较为均匀,大多呈现规则的球状,存在少量空心粉末颗粒。粉末粒径为75~150 μm,满足同轴送粉器对粉末的要求。

图1 预合金粉末微观形貌和粒径分布图

Fig.1 Microstructure and particle size distribution of pre-alloy powder

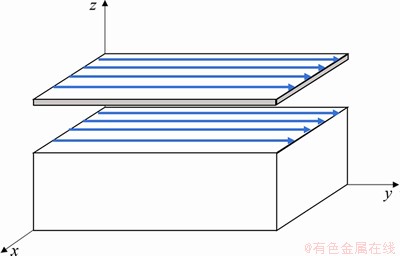

本实验使用煜宸激光LDM 8060 成形设备,配备2 kW光纤激光器,光斑直径为2 mm。激光功率为1 400 W,扫描速度为600 mm/min,扫描间距为1 mm,层厚为0.5 mm,成形气流量为7~9 L/min。为防止试样被氧化,成形过程在氮气为保护气氛的环境中进行。扫描方式采用平行于长边的单向扫描(如图2所示),2个连续层之间无旋转。每层为1个扫描周期,周期之间无停留时间。

图2 扫描策略图

Fig. 2 Scanning strategy diagram

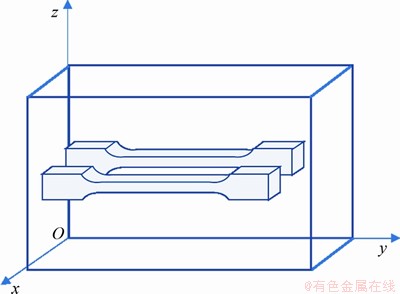

本研究制备长×宽×高为70 mm×10 mm×30 mm的长方试样。在试样中部采用线切割截取拉伸试样,取样方式如图3所示。将对比试样进行325 ℃/4 h的时效处理。试样经过表面磨抛后,进行室温拉伸试样和显微硬度检测。拉伸试样侧面使用不同规格砂纸打磨,直至出现金属光泽。

图3 拉伸试样示意图

Fig. 3 drawing sample diagram

1.2 微观结构和机械性能的表征

样品采用不同规格砂纸逐级打磨,用粒径0.5 μm的氧化铝悬浊液进行抛光,至表面无明显划痕后,采用徕卡DM4000M光学显微镜(optical microscope,OM)观察时效前后试样的抛光表面,用Rigaku D/max 2550VB型X射线衍射仪(X-ray diffractometer,XRD)进行X射线衍射分析,扫描速率为5 (°)/min,2θ为10°~80°,利用Quanta 200 FEI型扫描电子显微镜(scanning electron microscope,SEM)观察试样表面形貌。拉伸试验采用美国Instron3369型万能力学试验机,加载速率为1 mm/min。显微硬度测试使用显微维氏硬度机(ASTME 384-08),负载200 g,持续15 s,每个试样测试5个硬度再求平均值。

2 结果与讨论

2.1 LMD成形铝钪合金物相分析

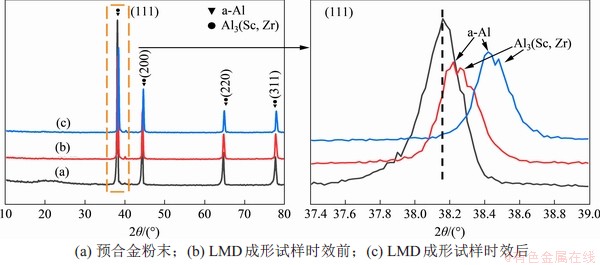

图4所示为原始粉末和LMD成形的铝钪合金时效处理前后的XRD图谱。由图4可以看到,时效前后的样品皆检测出了ɑ-Al和Al3(Sc, Zr)的衍射峰。LMD成形的样品的衍射峰相较于原粉末的衍射峰有一定的偏移。这是由于在LMD成形过程中,快速的加热和冷却导致了较大的温度梯度和热波动,使得成形样品中产生了热应力和残余应力。残余应力作用于晶界,并伴随微观体积膨胀,影响了成形样品的晶格参数。经过时效处理后,其衍射峰进一步的偏移,衍射角有较为明显的升高,表明残余应力有了一定程度的松弛[3]。同时,在ɑ-Al衍射峰的旁边还有Al3(Sc, Zr)的二次峰,这是因为样品截取自成形样品的中部,而LMD成形是经过了不断的反复重熔,在成形过程中,顶部的成形对中部进行了反复加热,使得一定量的Al3(Sc, Zr)相从过饱和的ɑ-Al基体中析出。经过时效处理后,Al3(Sc, Zr)相进一步析出,致使时效后样品的XRD衍射也有二次峰的出现。

图4 预合金粉末及LMD成形试样时效前后的XRD图谱

Fig. 4 XRD patterns of pre-alloy powder and LMD samples before and after aging

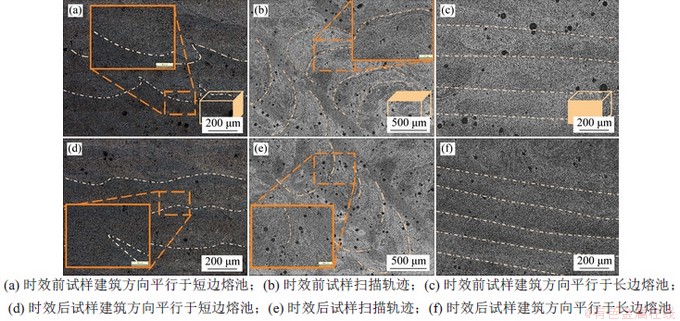

图5 时效前后试样建造方向和扫描方向的金相照片

Fig. 5 Metallographic diagram of specimen construction direction and scanning direction before and after aging

2.2 微观结构

采用光学显微镜对时效前后的LMD成形试样的显微组织进行了表征,如图5所示。从图5(a)和图5(d)可以看到:在垂线上,熔池排列对齐,这是由于样品打印扫描方式为单向打印,层与层之间没有角度变化,使得熔池呈现平行对齐的方式。样品中存在一定量的孔隙,熔池宽度约为400 μm,深度约为200 μm。同时,可以看到熔池形状并不规整,这是由于LMD工艺的固有热处理特征[11],由于上层的不断加热,对已成形的部分进行短时间的热处理,使得熔池边界发生变化,熔池之间的边界开始消失,这个现象在时效处理后更为明显,鳞片状熔池进一步消退,熔池边界转而形成条带波浪状的分布。

从图5(b)和图5(e)可以看到:熔池呈不规则半椭圆的形状沿扫描方向堆叠,熔池宽度约为1 mm,与工艺参数中扫描间距相当。相邻的扫描轨迹,熔池呈相反的方向堆叠,这是由于激光行走方式为平行于长边的单向扫描所致。而时效处理后,如图5(e)所示,同样发生熔池边界开始消失的现象,且由熔池顶端开始,向两边发展。这是由于在扫描方向的熔池顶端和建筑方向的相邻鳞片状熔池边缘细晶区较薄,在时效处理后,发生了一定程度的晶粒长大,使得该部分的细晶区开始消失。

从图5(c)和5(f)可以观察到:时效前后试样建筑方向平行于长边熔池的显微形貌并没有太大的区别,呈条带状分布,这是因为激光扫描方式为平行于长边所致。

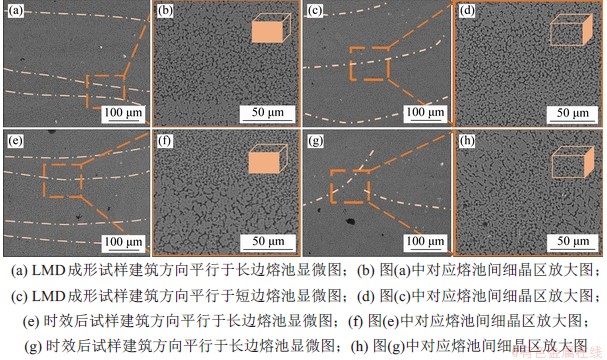

为进一步分析时效前后试样的组织,对时效前后的LMD成形试样进行了扫描电镜表征。图6所示为试样建筑方向熔池的扫描电镜照片。从图6(a)和6(e)能够看到熔池边界成条带状,进一步放大边界后发现较暗的区域是由微小的细晶粒组成,厚度约为40 μm。这一现象在热处理后更为明显,条带状分布也更为规整。同时,在熔池内部能够发现粗大的树突胞状晶粒,粒径约为7 μm。类似的现象在平行于短边方向的试样也能够发现(如图6(d)和6(h)所示),而且在时效前后,粗大的胞状晶粒并没有发生明显的尺寸变化。

图6 时效前后试样建筑方向熔池的扫描电镜照片

Fig. 6 Scanning electron microscopy (SEM) images of building direction of sample before and after aging

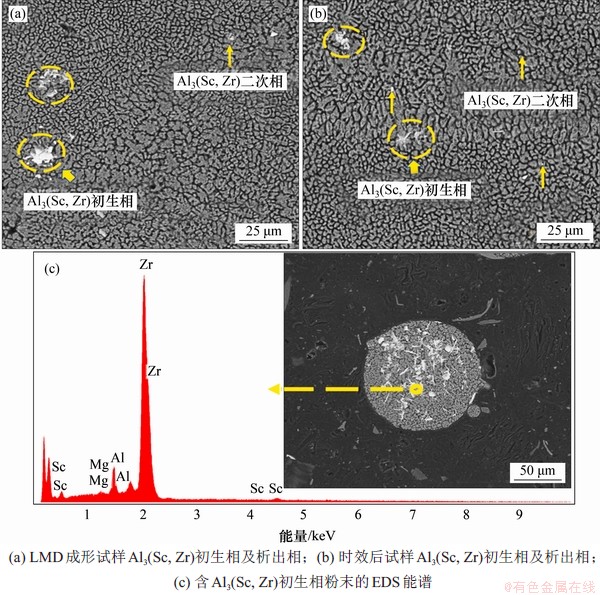

在扫描电子显微镜下发现,在LMD成形试样和经时效处理后试样的部分区域里,晶粒之间存在粒径约为10 μm的白色块状颗粒,如图7(a)和7(b)所示。这是由于气雾化的过程中,少量预合金粉末中形成Al3(Sc, Zr)初生相,如图7(c)所示。在成形过程中,LMD技术的激光能量密度不足以将这些Al3(Sc, Zr)初生相完全熔化,使其呈块状分布在试样中。同时,还观察到细小的白色颗粒存在于晶粒之间,这是Al3(Sc, Zr)析出相,其粒径为0.5~0.8 μm。这是由于LMD成形过程中,对样品进行反复重熔加热,使得基体中过饱和固溶的Al3(Sc, Zr)析出,形成Al3(Sc, Zr)二次相。而由图7(b)可以看到,时效处理促进了Al3(Sc, Zr)二次相的析出,图中的细小白色颗粒较于LMD成形试样中(图7(a)所示)明显增多。

图7 试样建筑方向存在Al3(Sc, Zr)初生相及析出相的扫描电镜照片

Fig. 7 Scanning electron microscope images of primary and precipitated phase regions of Al3(Sc, Zr) in architectural direction of sample

2.3 力学性能和显微硬度分析

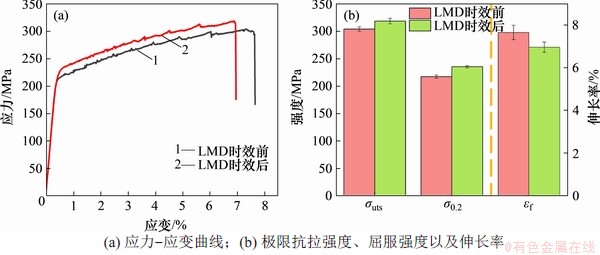

对时效处理前后的试样进行室温拉伸试验,变形应力-应变曲线如图8(a)所示。从图8可见,在应力-应变曲线中,塑性变形部分存在不稳定锯齿,这种现象被称为波特文-勒夏特列效应(Portevin-Le Chatelier effect,PLC[14]),该效应与局部非均质塑性变形有关,通常归因于动态应变时效机制(dynamic strain aging,DSA[15]),即在滑动路径上的障碍物暂时阻止了位错运动,致使曲线上锯齿的产生。在Al-Mg合金中PLC现象是普遍存在的,在采用SLM,SPS或传统铸造方式成形的零部件中都能够发现这一现象[16]。

从图8(b)可见,经时效处理后,样品的力学性能有了较为明显的提升,其抗拉强度(σuts)由(303.72±4) MPa提升到了(318.13±5) MPa,屈服强度(σ0.2)由216.93 3 MPa提升到了(234.84±1.9) MPa,伸长率(εf)由7.65%±0.34%下降到了6.96%±0.24%。这是由于在激光熔化过程中快速的凝固和冷却能够将更多的Sc和Zr融入试样中,从而使得样品经过时效处理后形成更多的Al3(Sc, Zr)析出相[17],阻碍了样品内部的位错运动和晶粒的长大,使得屈服强度和抗拉强度提高。同时,这也佐证了图8(a)中应力-应变曲线中锯齿出现的原因。同时,由于LMD工艺的固有热处理特征,使得LMD样品的冷却速率远小于SLM样品的冷却速度,热梯度越小,引起的残余应力较小,因此时效处理使残余应力松弛,提高伸长率[13]的现象并未出现。与此相反,由于析出相阻碍了位错运动,位错的堆积使得材料的伸长率下降。

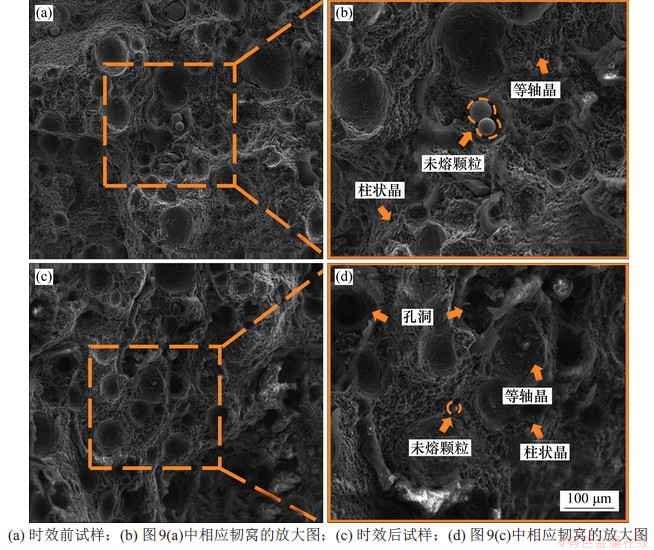

时效处理前后试样的断口形貌如图9所示。从图9可见:样品断后的表面有大量尺寸不一的韧窝分布,属于典型的韧性断裂。样品断口处出现了空洞、柱状晶和等轴晶以及少量的未熔粉末颗粒(图9(b)和9(d))。时效处理后,断裂表面显现出河流状且韧窝尺寸明显增大,这就使得其延展性能降低,抗拉强度提高。

图8 时效前后试样应力-应变曲线及其力学性能

Fig. 8 Stress-strain curves of samples before and after aging and mechanical property

图9 时效前后拉伸试样的断口扫描电镜照片

Fig. 9 Scanning electron microscopy images of tensile specimens before and after aging

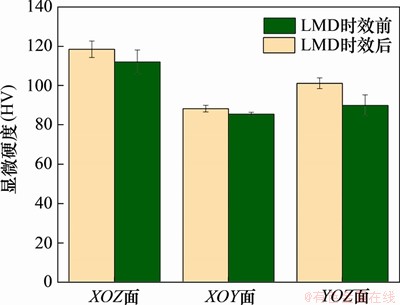

对时效处理前后的试样进行显微硬度测试,如图10所示。由图10可见,从整体来看,无论是时效前还是时效后,成形试样建筑方向的硬度要高于扫描方向的硬度。325 ℃/4 h时效处理后,每个面的硬度有了一定的提升,XOZ面的硬度(HV)由112.29±6提升到了118.75±4,XOY面的硬度(HV)由85.76±1.7提升到了88.6±0.93,YOZ面的硬度由90.176±5.34提升到了101.44±2.75。这是由于时效后析出相的增多(如图7所示),进一步阻碍了位错运动,从而使样品硬度提升。

图10 时效前后试样显微硬度

Fig. 10 Microhardness of samples in all directions before and after aging

3 结论

1) 时效后,在扫描方向的熔池顶端和建筑方向的相邻鳞片状熔池边缘细晶区发生了一定程度的晶粒长大,使得该部分的细晶区开始消失。在建筑方向熔池面可以明显观察到2种晶粒形态:细等轴胞状晶粒和树突粗胞状晶粒。

2) 时效前后的样品皆存在明显的Al3(Sc, Zr)初生相,这是由于激光送粉沉积技术无法完全固溶预合金粉末中的Sc和Zr所致。同时,还发现了Al3(Sc, Zr)二次相的析出。时效加剧了二次相的析出,增强了合金样品的析出强化。

3) 经过时效处理后,样品力抗拉强度(σuts)由(303.72±4) MPa提升到了(318.13±5) MPa,屈服强度(σ0.2)由216.93±3 MPa提升到了(234.84±1.9) MPa;伸长率(εf)由7.65%±0.34%下降到了6.96%±0.24%。XOZ面的硬度(HV)由112.29±6提升到了118.75±4,XOY面的硬度(HV)由85.76±1.7提升到了88.6±0.93,YOZ面的硬度由90.176±5.34提升到了101.44±2.75。

参考文献:

[1] LI Lanbo, LI Ruidi, YUAN Tiechui, et al. Microstructures and tensile properties of a selective laser melted Al-Zn-Mg-Cu (Al7075) alloy by Si and Zr microalloying[J]. Materials Science and Engineering A, 2020, 787: 139492.

[2] 陈勇, 张军, 滕广标, 等. Sc 和 Zr 对 7055 合金铸态及热处理态组织和性能的影响[J]. 特种铸造及有色合金, 2018, 38(10): 1130-1133.

CHEN Yong, ZHANG Jun, TENG Guangbiao, et al. Effects of Sc and Zr on microstructure and properties of as-cast and heat-treated state 7055 aluminum alloy[J]. Special Casting & Nonferrous Alloys, 2018, 38(10): 1130-1133.

[3] LI Xiaopeng, WANG Xiaojun, SAUNDERS M, et al. A selective laser melting and solution heat treatment refined Al-12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility[J]. Acta Materialia, 2015, 95: 74-82.

[4] DAI Donghua, GU Dongdong, ZHANG Han, et al. Influence of scan strategy and molten pool configuration on microstructures and tensile properties of selective laser melting additive manufactured aluminum based parts[J]. Optics and Laser Technology, 2018, 99: 91-100.

[5] LI Ruidi, WANG Minbo, YUAN Tiechui, et al. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: processing, microstructure, and properties[J]. Powder Technology, 2017, 319: 117-128.

[6] LI Ruidi, WANG Minbo, LI Zhiming, et al. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: crack-inhibiting and multiple strengthening mechanisms[J]. Acta Materialia, 2020, 193: 83-98.

[7] NIU Pengda, LI Ruidi, ZHU Shuya, et al. Hot cracking, crystal orientation and compressive strength of an equimolar CoCrFeMnNi high-entropy alloy printed by selective laser melting[J]. Optics and Laser Technology, 2020, 127: 106-117.

[8] 张文奇, 朱海红, 胡志恒, 等. AlSi10Mg的激光选区熔化成形研究[J]. 金属学报, 2017, 53(8): 918-926.

ZHANG Wenqi, ZHU Haihong, HU Zhiheng, et al. Study on the selective laser melting of AlSi10Mg[J]. Acta Metallurgica Sinica, 2017, 53(8): 918-926

[9] LI Ruidi, SHI Yusheng, WANG Zhigang, et al. Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting[J]. Applied Surface Science, 2010, 256(13): 4350-4356.

[10] WANG Zihong, LIN Xin, TANG Yao, et al. Laser-based directed energy deposition of novel Sc/Zr-modified Al-Mg alloys: columnar-to-equiaxed transition and aging hardening behavior[J], Journal of Materials Science & Technology, 2020, 59: 134-148.

[11] KURNSTEINER P, BAJAJ P, GUPTA A, et al. Control of thermally stable core-shell nano-precipitates in additively manufactured Al-Sc-Zr alloys[J]. Additive Manufacturing, 2020, 32: 100910.

[12] FORBORD B, HALLEM H, ROYSET J, et al. Thermal stability of Al3(Scx,Zr1-x)-dispersoids in extruded aluminium alloys[J]. Materials Science and Engineering A, 2008, 475 (1/2): 241-248.

[13] LI Ruidi, CHEN Hui, ZHU Hongbin, et al. Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting[J]. Materials and Design, 2019, 168: 107668.

[14] MCCORMIGK P G. A model for the Portevin-Le Chatelier effect in substitutional alloys[J]. Acta Materialia, 1972, 20(3): 351-354.

[15] MOGUCHEVA A, YUZBEKOVA D, KAIBYSHEV R, et al. Effect of grain refinement on jerky flow in an Al-Mg-Sc alloy[J]. Materials Science and Engineering A, 2016, 47(5): 2093-2106.

[16] WANG Minbo, LI Ruidi, YUAN Tiechui, et al. Microstructures and mechanical property of AlMgScZrMn: a comparison between selective laser melting, spark plasma sintering and cast[J]. Materials Science and Engineering: A, 2019, 756: 354-364.

[17] SHI Yunjia, YANG Kun, KAIRY S K, et al. Effect of platform temperature on the porosity, microstructure and mechanical properties of an Al-Mg-Sc-Zr alloy fabricated by selective laser melting[J]. Materials Science and Engineering: A, 2018, 732: 41-52.

(编辑 赵俊)

收稿日期: 2020 -08 -21; 修回日期: 2020 -09 -03

基金项目(Foundation item):国家自然科学基金资助项目(51871249);湖南省自然科学基金资助项目(2020JJ2046) (Project(51871249) supported by the National Natural Science Foundation of China; Project(2020JJ2046) supported by the Science and Technology Program of Hunan Province)

通信作者:李瑞迪,博士,教授,博士生导师,从事激光增材制造粉末材料研究;E-mail:liruidi@csu.edu.cn