DOI: 10.11817/j.issn.1672-7207.2021.02.004

轮胎粉含量对汽车摩擦材料性能的影响

杨阳1, 2,吴宏1,刘伯威1, 2,匡湘铭2

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 湖南博云汽车制动材料有限公司,湖南 长沙,410205)

摘要:在一种成熟低金属摩擦材料配方的基础上,通过调整配方中轮胎粉的质量分数,采用直接混合工艺制备不同组分的汽车摩擦材料,对其进行摩擦磨损性能、理化性能、力学性能以及振动噪声(NVH)性能测试,并用扫描电镜(SEM)和能谱仪(EDX)对不同试样摩擦表面进行表征,分析其摩擦磨损机制。研究结果表明:随着轮胎粉的质量分数从0增加到4%,材料的密度、硬度和内剪切强度减小;摩擦材料名义摩擦因数增大,噪声发生概率降低,磨损率先降低后增加。综合比较,当轮胎粉质量分数为2%时,摩擦材料综合性能最佳。

关键词:轮胎粉;摩擦材料;摩擦磨损;制动噪声

中图分类号:U465 文献标志码:A

文章编号:1672-7207(2021)02-0358-10

Effect of tyre powder content on properties of automotive friction materials

YANG Yang1, 2, WU Hong1, LIU Bowei1, 2, KUANG Xiangming2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Hunan Boyun Automobile Brake Material Co., Ltd., Changsha 410205, China)

Abstract: The waste tyre powder were prepared by hot-press method based on a basic formula, and the friction materials were prepared by directly mixed process. The tests for the tribological properties, physical and chemical properties, mechanical properties and noise vibration and hardness(NVH) were completed, and the friction surfaces and wear debris of friction materials were observed by using scanning electron microscopy(SEM) and energy dispersive X-ray microanalysis(EDX). And the friction and wear mechanism were discussed. The results show that with the mass fraction of tire powder increasing from 0 to 4%, the density, hardness and internal shear strength of the material decrease; the nominal friction coefficient of friction material increases, the probability of noise decreases, and the wear rate decreases first and then increases. Compared comprehensively, when the mass fraction of tire powder is 2%, the friction material has the best comprehensive properties.

Key words: waste tyre powder; friction material; friction and wear; brake noise

近年来,我国的汽车产业取得蓬勃发展,人们对车辆的性能也提出了更高的要求,希望新一代的汽车具有更高的环保和安全性能,舒适感更强。在某种程度上,汽车制动性能的优劣取决于汽车刹车片性能的好坏。因此,对于汽车制造业而言,不断提高汽车刹车片的综合性能意义非常重大[1-2]。研发寿命长、制动舒适、环保无噪声和价格适宜的刹车片成为当前摩擦材料领域的热点课题。废旧轮胎是一种由橡胶添加各类助剂发生硫化交联后组成的复合物,具有不溶、不熔的特性。目前,国内汽车保有量急剧增大,导致属于工业有害固体废弃物的废弃轮胎也日益增多,从而引起许多环境污染问题。据不完全统计,2018年,国内废轮胎产生量达到3.4亿条。废旧轮胎降解时间长、处理压力大,其造成的“黑色污染”已成为全球性治理难题。合理利用废弃轮胎是保护环境和促进国民经济可持续发展亟待解决的问题[3]。通过把废旧轮胎的胎胶面除去帘子午线,粉碎加工成轮胎粉,再将轮胎粉应用于铺装材料、建筑材料、公路建设等各大领域,可有效节约资源和解决废弃轮胎污染问题。同时,由于轮胎粉的价格远低于其他有机填料的价格,能有效降低摩擦材料噪声,长期以来被摩擦材料生产企业广泛使用[4]。国内外学者对轮胎粉在汽车摩擦材料上的应用进行了一些研究,如黄四平等[5]采用单因素法将摩擦材料中应用较广泛的轮胎粉、酚醛树脂作为黏结剂,结果表明,黏结剂含量对摩擦材料的力学性能和摩擦性能的影响显著,通过添加一定量的轮胎粉,摩擦材料可以达到较低的密度和硬度。陈东等[6]研究了轮胎粉作为有机填料在半金属摩擦材料配方的使用性能。SIVARAOS等[7]研究表明,增加轮胎粉质量分数可以提高聚丙烯摩擦材料摩擦因数。CHUNG等[8]为解决废轮胎的环境问题,研发了一种添加废轮胎粉新型摩擦材料,并对添加轮胎粉复合材料的摩擦学性能进行了研究。CHANG等[9]研究了轮胎粉颗粒的粒径对制动摩擦材料摩擦磨损的影响,试验选用粒径分别为75 μm和450 μm的轮胎粉颗粒进行试验,结果表明,与大颗粒相比,尽管细轮胎粉具有较大的接触面积,但含小颗粒轮胎粉摩擦材料摩擦因数更不稳定,磨损率更高,可通过调节轮胎粉粒径来提高摩擦材料摩擦因数稳定性。这些研究仅分析了轮胎粉对汽车摩擦材料摩擦学性能的影响,对于轮胎粉对汽车摩擦材料的理化性能、力学性能和噪声性能影响的研究较少。鉴于此,本文作者针对轮胎粉含量对汽车摩擦材料的力学性能和理化性能的影响进行研究,并通过台架试验数据分析其对摩擦材料摩擦磨损和噪声性能的影响。

1 实验

1.1 轮胎粉的理化性质

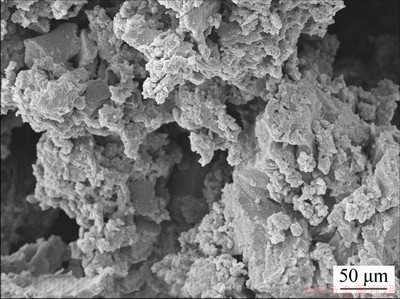

轮胎粉由大冶市都鑫摩擦粉体有限公司生产,粒径<380 μm,水分质量分数<0.5%,密度为1.15 g/cm3,pH为7.1,SEM形貌如图1所示,从图1可见:轮胎粉呈疏松多孔状态。

图1 轮胎粉SEM形貌

Fig. 1 SEM image of waste tyre powder

1.2 原料及试样配方

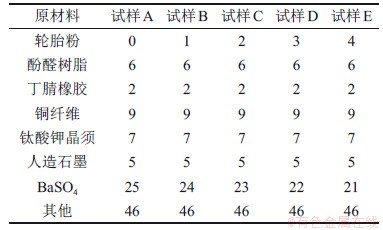

摩擦材料中包括摩擦性能调节剂、黏结剂、增强纤维、填料等,其组成(质量分数)如表1所示。调整配方中轮胎粉和沉淀硫酸钡的质量分数,其他各组分不变,配制成试样A,B,C,D和E,其中,配方中轮胎粉质量分数为0~4%。沉淀硫酸钡属化学沉淀物,稳定性好,硬度适中,是汽车摩擦材料常用的一种填料。沉淀硫酸钡含量的变化不会显著改变摩擦材料的性能,因此,可认为材料配方中轮胎粉的比例变化是影响摩擦材料性能变化的主要原因。

表1 摩擦材料的基本配方(质量分数)

Table 1 Basic formulations of friction material %

1.3 刹车片制备和配方

按照表1的配方称取相应的原材料,并用自主研制的简易立式搅拌机进行混合。搅拌速度为400 r/min,混料时间为3 min。以D1348为研究对象,选取旺达JFY60型等比压机,采用一次成型工艺,在热压温度为155~165 ℃,产品单位面积承受压力为40 MPa下,经过热处理、平磨、倒角,最终制成成品。

1.4 热分析及性能测试

在差示扫描量热仪(德国Netzsch公司生产)上进行热重分析,轮胎粉样品质量为6 mg,实验以高纯氮气为载气,以加热速率为10 ℃/min,从室温开始加热到700 ℃。

按JASO C441制动衬片孔隙率测量方法,样品开孔率采用排水法测量。试样硬度采用HRS标尺,在HR-150A洛氏硬度计上测试,压头材质为钢球,直径为1.27 cm,施加力为980 N。按照GB/T 22311—2008,采用Link-1620型试验机,测试刹车片样品的可压缩性;按照GB/T 22309—2008,在万能剪切试验机上进行内剪切强度测试,样品长×宽×高为25 mm×25 mm×10 mm;按照JC/T 685—2009,利用排水法检测摩擦材料的密度;按照JASO C458—1986,利用pH计检测摩擦材料的pH;采用美国林克公司生产的3000型摩擦试验机,按照SAE J2522—2003进行摩擦性能试验,考察摩擦材料在不同制动工况(速度、温度、压力)下摩擦磨损性能;采用美国林克公司生产的3900型噪声台架试验机,按照SAE J2521—2013,在不同试验条件(速度、温度、压力、方向)下进行噪声测试。

2 结果与分析

2.1 轮胎粉热重分析

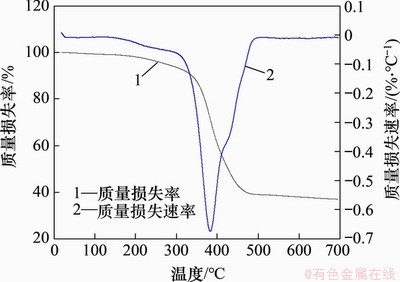

热重分析主要用于评价材料在受热状态下的稳定性。轮胎粉是一种有机物,在高温中会热分解,对摩擦材料性能影响较大。由于废弃轮胎中的有机成分在高温状态下具有不稳定性,将这些废弃的材料置于无氧或者少氧的环境下进行高温处理,此时,有机物的化学键就会被打开,轮胎粉就会被分解为液态油以及气态的碳氢化合物等[10-11]。轮胎粉在N2氛围中的热质量损失就是轮胎粉的热解。

图2所示为轮胎粉TG-DTG曲线图。由图2可知,轮胎粉在热解过程中主要有2个质量损失区。第一阶段为干燥阶段,TG-DTG 曲线波动不明显,说明轮胎粉中含水量较少;当温度升高到200 ℃左右时,质量开始下降,此时失去的是轮胎粉中的水分、焦油、挥发分、塑化剂及其他一些添加剂;在300~500 ℃范围内,轮胎粉质量损失明显,为主质量损失区[12],轮胎粉中橡胶主要成分为天然橡胶和合成橡胶,崔洪等[13]对废轮胎进行热解研究发现:天然橡胶在385.5 ℃时有最大质量损失率,这与图2中DTG曲线峰顶温度383 ℃基本符合,表明此温度下轮胎粉中的天然橡胶剧烈分解。在420 ℃左右又出现1个明显的质量损失峰,这时主要是合成橡胶的分解,500 ℃以后,质量损失率平缓,表明轮胎粉基本分解完毕,到终止温度700 ℃时,轮胎粉热质量损失后固体残余物质量分数为原来的40%。其中,热解炭是轮胎粉热失重残余物的主要成分,质量分数为70%以上,主要来源于橡胶中添加的炭黑[14]。DARMSTADT等[15]研究表明:热解炭除了含C,N,O和S元素外,还含有杂质元素,杂质元素在热解残留物中以灰分形式存在,灰分来源于轮胎添加的配合剂和助剂。灰分组成中主要含有Zn,Fe,Ca,Si,Al和Na等元素,灰分质量分数为12%~16%,并以ZnO、钢纤维为主,分别来自于轮胎橡胶生产中加入的ZnO及轮胎粉原料中未除尽的钢丝。

图2 轮胎粉的TG-DTG曲线

Fig. 2 TG-DTG curves of waste tyre powder

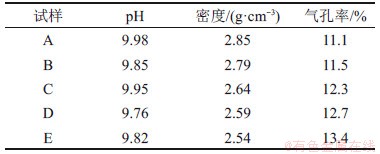

2.2 轮胎粉质量分数对摩擦材料理化性能的影响

轮胎粉质量分数对摩擦材料理化性能的影响见表2。从表2可以看出:随着轮胎粉质量分数的增加,摩擦材料的pH基本保持不变,原因是轮胎粉与沉淀硫酸钡均为中性物质,pH为7.1,两者质量分数的增减对材料的pH没有显著影响。由于轮胎粉的密度(0.15 g/cm3) 比硫酸钡的密度(4.5 g/cm3)小很多,随着轮胎粉含量的增加及沉淀硫酸钡含量减少,摩擦材料的密度减小。随着轮胎粉质量分数增加,摩擦材料的气孔率逐渐增大。其一是因为轮胎粉疏松多孔并具有弹性等特性,本身孔隙率较大;其二是因为轮胎粉主要成分为天然橡胶和合成橡胶,热膨胀系数较大,在经过热压和热处理后,颗粒状轮胎粉热胀冷缩情况要比摩擦材料中大多数组分的大,在摩擦材料生产过程中,轮胎粉和摩擦材料其他组分间较易形成间隙,所以加入轮胎粉可有效提高摩擦材料气孔率。

表2 不同轮胎粉质量分数试样的理化性能

Table 2 Physical and chemical properties of samples with different waste tyre powder contents

2.3 轮胎粉质量分数对摩擦材料力学性能的影响

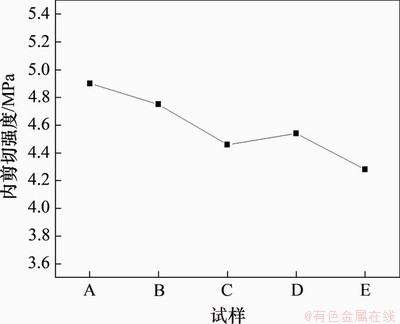

图3所示为轮胎粉质量分数对摩擦材料内剪切强度的影响。由图3可知:随轮胎粉质量分数的增加,摩擦材料内剪切强度整体上呈下降趋势。其一是因为加入轮胎粉,能降低摩擦材料的体积密度,气孔率增大(由表2可知),因而摩擦材料结构强度降低;其二是因为轮胎粉属硫化橡胶,官能团被封锁,与其被代替的化合物硫酸钡一样都不能与摩擦材料其他组分形成有效化学键。

图3 不同轮胎粉质量分数试样的内剪切强度

Fig. 3 Hear strength of samples with different waste tyre powder contents

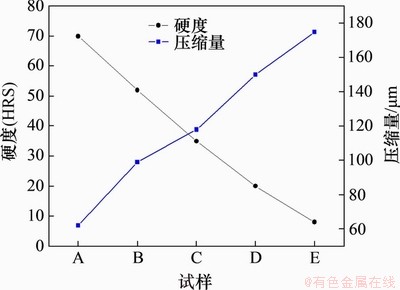

图4所示为轮胎粉质量分数对摩擦材料常温压缩和硬度的影响。由图4可知:轮胎粉的加入能明显降低摩擦材料的洛氏硬度,当轮胎粉质量分数从0增加到4%时,摩擦材料的洛氏硬度由70减小到5。这是因为轮胎粉具有良好的弹性,因而随着轮胎粉质量分数的增加,摩擦材料的弹性变形能力越强,硬度越低。在满足制动力的前提下,汽车摩擦材料的硬度越小越好,因为较低硬度的刹车片可以提高汽车制动的舒适性。从图4还可以看出:随着轮胎粉质量分数的增加,摩擦材料的压缩量也逐渐从62 μm增加到175 μm。究其原因,摩擦材料的常温压缩量和气孔率、硬度一般呈反比关系。气孔率越高,硬度越低,摩擦材料的压缩变形量越大。

图4 不同轮胎粉质量分数摩擦材料的硬度和压缩变形量

Fig. 4 Hardness and compression deformation of samples with different waste tyre powder contents

2.4 轮胎粉质量分数对摩擦材料摩擦、磨损性能的影响

刹车片在不同制动压力、速度和温度下的整体摩擦磨损性能按“SAE J2522—2003”标准进行测试。本文主要考察轮胎粉质量分数对摩擦材料名义摩擦因数(μnom)和衰退性能(μmin)的影响,并研究不同制动温度及制动压力条件下,轮胎粉质量分数对摩擦材料磨损的影响。

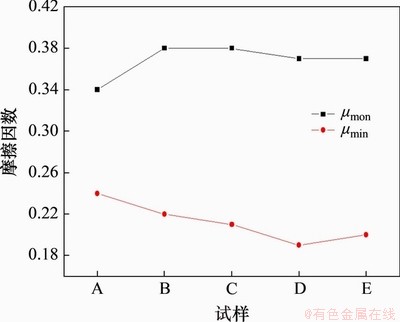

2.4.1 对摩擦材料名义摩擦因数和最低摩擦因数的影响

图5所示为不同轮胎粉质量分数试样的摩擦因数曲线。在SAE J2522—2003中,名义摩擦因数是指除去衰退和温度爬坡部分外其他所有制动条件下的平均摩擦因数μnom,衰退和高温阶段的最小摩擦因数定义为最低摩擦因数μmin。试样A的名义摩擦因数为0.34,加入质量分数1%轮胎粉后(试样B),名义摩擦因数增大至0.38,此后,随着轮胎粉质量分数的增加,名义摩擦因数基本保持稳定。未加轮胎粉的试样A摩擦因数的最低值是0.24,逐渐增加轮胎粉的含量,摩擦因数的最低值逐渐降低,最后趋于稳定。摩擦材料的真实接触面积是摩擦副表面微凸点的啮合,与名义接触面积相比,真实接触面积小于名义接触面积的30%[16],轮胎粉属有机填料,同摩擦材料其他组分相比,其弹性和柔韧性较好,在制动正压力作用下,添加轮胎粉的试样与对偶贴合性良好,真实接触面积大幅增加,提高了摩擦材料整体摩擦因数。因而,试样B的名义摩擦因数比无轮胎粉试样A的高。当轮胎粉含量继续增加,真实接触面积趋于稳定,试样的名义摩擦因数基本保持恒定。最低摩擦因数一般出现在高温衰退过程,轮胎粉属橡胶类有机复合物,在高温时会分解产生“热衰退”现象。因此,添加轮胎粉的试样和未添加的相比,最低摩擦因数整体下降。

图5 不同轮胎粉质量分数试样的摩擦因数

Fig. 5 Friction coefficient of samples with different waste tyre powder contents

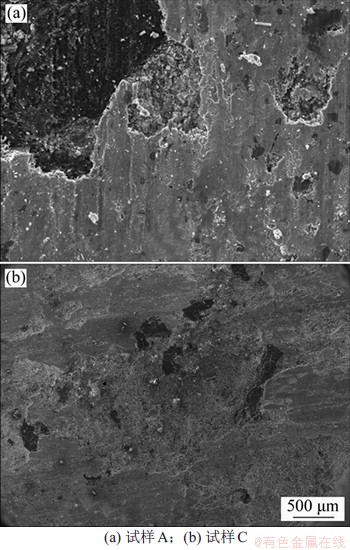

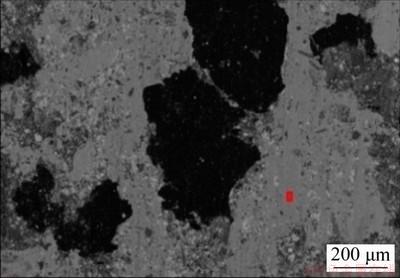

图6所示分别为试样A和试样C磨损试验后摩擦表面的扫描电镜照片。从图6(a)可见:试样A表面存在一定的摩擦膜,但不连续,有大量凹坑存在,对比图6(b),试样C摩擦层表面均匀完整,摩擦块和对偶真实接触面积更大,这也从侧面验证了加入轮胎粉能提高摩擦材料与对偶的真实接触面积。

图6 试样摩擦表面形貌

Fig. 6 Friction surface morphology of samples

2.4.2 对摩擦材料抗热衰退性能的影响

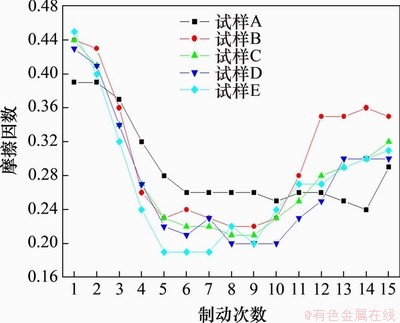

可以通过分析在衰退试验过程中,样品摩擦因数的变化考察轮胎粉质量分数对摩擦材料热衰退性能的影响。按照SAE J2522—2003,试验要执行2次热衰退过程。其中,轮胎粉试样在第一次衰退程序摩擦因数的变化曲线如图7所示。从图7可知,在衰退开始阶段,试样A的摩擦因数逐步降低,到后期摩擦因数趋于平稳;在衰退初期,加入轮胎粉的试样B,C,D和E的摩擦因数降低,在衰退后期,摩擦因数逐渐升高。比较含有轮胎粉和不含轮胎粉试样可知:在第一次衰退初期,含有轮胎粉试样摩擦因数更高;但在第一次衰退中期,摩擦因数比不含轮胎粉试样A更低;在衰退后期,加轮胎粉试样摩擦因数有所恢复。根据第一次衰退试验数据发现:第3次制动时,摩擦块的表面温度在280 ℃以上。根据热重分析,此温度轮胎粉已经开始分解产生焦油状物质及小分子气体,它们覆盖在摩擦材料表面产生润滑,使干摩擦变为混合摩擦,导致摩擦因数显著降低。试样A的最低摩擦因数为0.24,而含轮胎粉试样在第一次衰退阶段的最低摩擦因数都要比试样A的小。第12次制动时,摩擦块表面初始温度超过500 ℃,摩擦块表面轮胎粉等有机物基本分解完成,轮胎粉分解产生的残留物包括SiO2、CaO、钢丝和炭黑成分,在摩擦块表面形成连续摩擦面,对提高摩擦材料摩擦因数占主导作用。

图7 不同质量分数轮胎粉试样在第一次衰退程序摩擦因数的变化曲线

Fig. 7 Friction coefficient of samples with different waste tyre powder contents in Fade 1

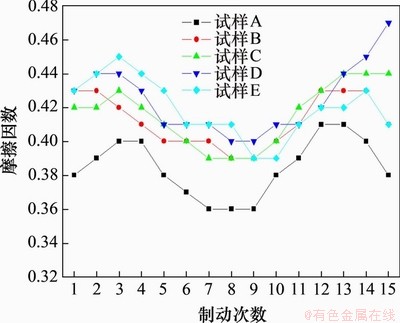

在第二次衰退试验过程中,不同质量分数轮胎粉试样的摩擦因数曲线见图8。试样A,B,C,D和E的摩擦因数范围分别为0.36~0.41,0.39~0.43,0.39~0.44,0.40~0.47和0.39~0.45。添加轮胎粉试样B,C,D和E的摩擦因数均比试样A的高。这是因为加入轮胎粉后,有效提高了试样与对偶材料的贴合性,大幅增大了真实接触面积。试样A,B,C,D和E的摩擦因数的波动幅度Δμ分别为0.05,0.04,0.05,0.07和0.06,可以看出:试样B的波动幅度最小;随着试样中轮胎粉含量增加,波动幅度增大,这主要是由于轮胎粉自身热分解和摩擦材料接触面变化2个因素共同导致。

图8 不同质量分数轮胎粉试样在第二次衰退程序摩擦因数的变化曲线

Fig. 8 Friction coefficient of samples with different waste tyre powder contents in Fade 2

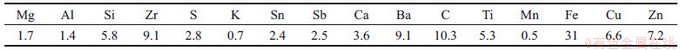

试样D在摩擦性能试验后的SEM形貌和能谱分析分别如图9和表3所示。由表3可知,Fe元素的质量分数最大,达到31%,比摩擦材料原始组分中Fe元素的含量高很多,这是因为摩擦材料中的有机成分在外部高温环境下不断被分解成小分子,在摩擦材料的表面留下来的主要是不能挥发的无机物或者金属材质的成分。

表3 试样D在摩擦性能试验后主要元素含量(质量分数)

Table 3 Major elements content and of D after friction performance test %

图9 试样D在摩擦性能试验后的SEM照片

Fig. 9 SEM image of Sample D after friction performance test

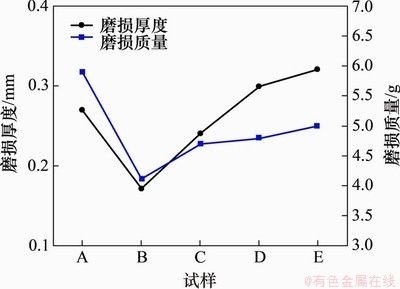

2.4.3 对摩擦材料磨损性能的影响

不同质量分数轮胎粉试样的厚度磨损及质量磨损如图10所示。从图10可知:随着轮胎粉质量分数增多,摩擦材料的厚度和质量磨损先显著降低,然后又逐步增加。完整执行1次摩擦试验程序后,试样A的厚度磨损为0.27 mm,质量磨损为5.9 g;试样B的磨损最小,厚度磨损为0.17 mm。质量磨损为4.1 g。这是因为轮胎粉热分解后残余物主要成分为炭黑,也就是准石墨晶体。准石墨晶体层间分子作用力较弱,层间容易滑动,在摩擦材料中属于润滑剂,润滑剂剪切强度低,对摩擦层的形成具有重要作用。加入轮胎粉能使摩擦块表面更均匀连续,可有效减小摩擦过程磨粒磨损现象。与试样A相比,试样D的磨损厚度较大,但其质量磨损却较小,这是因为,一方面,试样D的密度要比试样A的小;另一方面,试样A中有机化合物热分解质量更大,能够有效降低磨损。在试样中继续加入轮胎粉,过量轮胎粉的热分解起主导作用,摩擦材料磨损增大。

图10 不同试样的厚度磨损及质量磨损

Fig. 10 Wear-thickness and mass loss of different samples

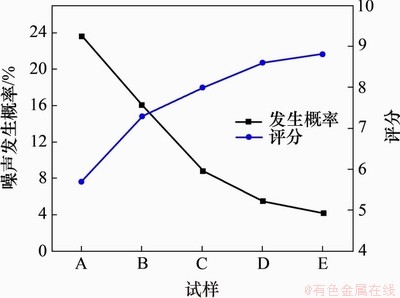

2.5 轮胎粉质量分数对摩擦材料制动噪声的影响

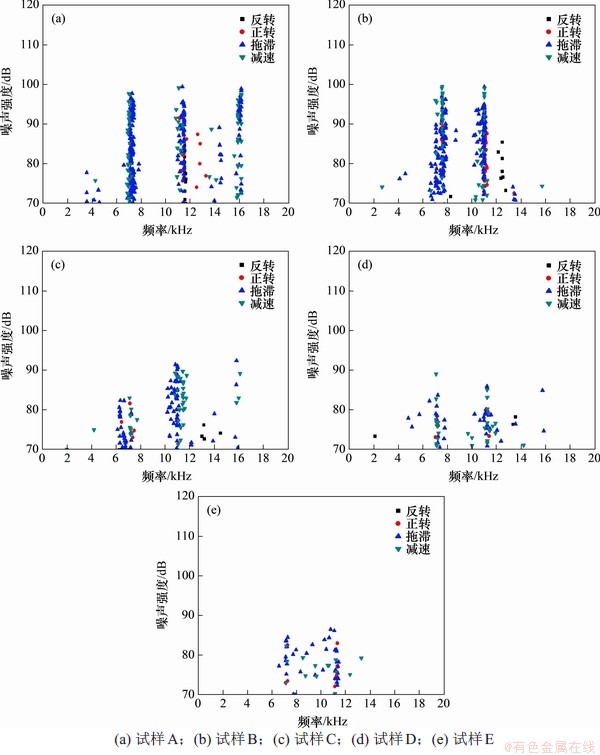

为了尽可能接近实际工况,按照SAE J2521—2006,在不同的实验条件(制动压力、制动温度、制动速度、制动方向等)下测试摩擦材料整体噪声发生概率。声音采集频率为2~17 kHz,噪声强度大于70 dB时记为制动噪声。不同试样的制动噪声发生概率及评分如图11所示,其制动噪声发生情况如图12所示。评分与制动噪声强度及其发生概率有关,评分越高,表明刹车片噪声性能越好。

从图11可以看出:当轮胎粉质量分数由0增加到4%时,摩擦材料制动噪声发生的概率由大变小,综合评分逐步提高。试样A的噪声发生概率为23.6%,综合评分为5.7分。5个试样中,噪声发生率最低、评分最高的是试样E,其制动噪声发生概率为4.2%,噪声评分为8.8分。与试样A相比,噪声发生率降低了19.4%。

图11 不同试样的制动噪声发生概率及评分

Fig. 11 Brake noise probability of occurrence and noise index of different samples

由图12可看出:试样A在正转(Foward)、反转(Reverse)、拖滞(Drag)和减速(Decel)制动工况下都出现制动噪声,当频率为7.2,11.5和16 kHz左右时,噪声发生概率大,最高噪声强度达100 dB。试样中加入轮胎粉后,减速、拖滞过程中的噪声减少,其中,在频率为16 kHz左右时,噪声减少最明显。随着轮胎粉质量分数继续增加,在频率为7.2 kHz和11 kHz时,噪声发生概率和强度都逐渐降低,表明轮胎粉降噪波段较宽。综上所述,在摩擦材料中加入轮胎粉可有效降低噪声发生的频率,同时能吸收振幅,使噪声强度有所降低。究其原因,这主要与轮胎粉能提高摩擦材料的孔隙率及压缩形变有关。随着轮胎粉质量分数增加,试样的气孔率不断变大。随着摩擦材料气孔率的变大,材料具有较好的阻尼特性,其吸收制动过程中所产生振动的能力也得到增强[17-18],这是因为振动波在孔隙中经多次反射会逐渐衰减,气孔中气体与孔壁之间的热交换会引起热损失从而使声能衰减[19]。

因此,提高材料气孔率可以改善摩擦材料的声学性能,降低制动噪声。

图12 不同摩擦材料制动噪声发生情况

Fig. 12 Brake noise occurence of different friction materials

材料的压缩变形量反映的是材料的弹-塑性变形能力,增大材料的弹性可有效降低噪声的声压级。弹塑性变形能力越大,材料的阻尼性能越好,对声波的阻尼性和衰减性也越好[20],试样E的压缩变形量从62 μm增加到175 μm,对降低制动噪声发生概率具有明显作用。因此,从提高摩擦材料可压缩性角度出发,在一定程度上能有效降低制动噪声的发生概率[21]。

3 结论

1) 随着轮胎粉质量分数增加,摩擦材料的孔隙率、常温压缩增大,硬度、密度和内剪切强度降低,pH基本保持不变。

2) 添加轮胎粉能够有效提升摩擦材料的摩擦因数,添加质量分数1%~2%轮胎粉时,摩擦材料的名义摩擦因数最高为0.38,但加入轮胎粉会导致摩擦材料第一衰退阶段的最低摩擦因数降低。加入质量分数1%~2%的轮胎粉可以减小摩擦材料的磨损。

3) 添加轮胎粉有利于减少摩擦材料的制动噪声,随着轮胎粉质量分数增加,制动噪声发生概率和噪声强度逐步降低。

4) 在汽车摩擦材料中加入2%质量分数的轮胎粉时,摩擦材料具有最佳的综合性能。

参考文献:

[1] THAKARE M R, WHARTON J A, WOOD R J K, et al. Effect of abrasive particle size and the influence of microstructure on the wear mechanisms in wear-resistant materials[J]. Wear, 2012, 276/277: 16-28.

[2] 崔艳芹, 刘学庆. 汽车制动摩擦材料的性能要求及影响因素[J]. 材料导报, 2014, 28(S1): 413-416, 421.

CUI Yanqin, LIU Xueqing. Performance requirements and effect factors of automotive brake friction material composites[J]. Materials Review, 2014, 28(S1): 413-416, 421.

[3] 孔德森, 贾腾, 王晓敏, 等. 废弃轮胎橡胶颗粒混合土无侧限抗压强度试验研究[J]. 中南大学学报(自然科学版), 2016, 47(1): 225-231.

KONG Desen, JIA Teng, WANG Xiaomin, et al. Test on unconfined compressive strength of lightweight soil mixed with rubber chips of scrap tires[J]. Journal of Central South University(Science and Technology), 2016, 47(1): 225-231.

[4] 罗玮. 利用回收轮胎粉和PCB粉增韧增强PVC复合材料的研究[D]. 长沙: 湖南师范大学化学化工学院, 2015: 1-44.

LUO Wei. Study on the application of ground rubber tyre and PCB improving toughness and strength of PVC composites[D]. Changsha: Hunan Normal University. College of Chemisty and Chemical, 2015: 1-44.

[5] 黄四平, 于占江, 刘洋, 等. 粘结剂含量对摩擦材料摩擦性能的影响研究[J]. 合成材料老化与应用, 2015, 44(6): 16-19, 56.

HUANG Siping, YU Zhanjiang, LIU Yang, et al. Effect the content of binder on the properties of the paper-based friction material[J]. Synthetic Materials Aging and Application, 2015, 44(6): 16-19, 56.

[6] 陈东, 黄平, 王欢. 用正交设计优化半金属摩擦材料的配方[J]. 机械工程材料, 2004, 28(5): 35-37.

CHEN Dong, HUANG Ping, WANG Huan. Optimized formulation of the semi-metallic friction materials by orthogonal design[J]. Materials for Mechanical Engineering, 2004, 28(5): 35-37.

[7] SIVARAOS, YAP T C, QUMRUL, et al. Friction performance analysis of waste tire rubber powder reinforced polypropylene using pin-on-disk tribometer[J]. Procedia Engineering, 2013, 68: 743-749.

[8] CHUNG K, HONG Y. Friction and wear properties of scrap tire/potassium hexatitanate whisker composites[J]. Journal of Industrial and Engineering Chemistry, 2013, 19(4): 1234-1240.

[9] CHANG Y H, JOO B S, LEE S M, et al. Size effect of tire rubber particles on tribological properties of brake friction materials[J]. Wear, 2018, 394/395: 80-86.

[10] 孙承亮, 许江林, 于佳雪, 等. 废轮胎热解工艺的热平衡分析[J]. 上海节能, 2018(11): 856-860.

SUN Chengliang, XU Jianglin, YU Jiaxue, et al. Heat balance for pyrolysis technology of waste tyre[J]. Shanghai Energy Conservation, 2018(11): 856-860.

[11] 孙蓉, 朱宝忠, 孙运兰. 热分析-质谱法研究汽车废轮胎热解行为及反应动力学[J]. 过程工程学报, 2016, 16(6): 966-971.

SUN Rong, ZHU Baozhong, SUN Yunlan. Pyrolysis and reaction kinetics of automobile waste tire with TG-DSC-MS technique[J]. The Chinese Journal of Process Engineering, 2016, 16(6): 966-971.

[12] 吴凯, 朱锦娇, 朱跃钊, 等. 废轮胎与生物质共热解特性研究[J]. 林产化学与工业, 2018, 38(5): 53-60.

WU Kai, ZHU Jinjiao, ZHU Yuezhao, et al. Co-pyrolysis process of waste tire and biomass[J]. Chemistry and Industry of Forest Products, 2018, 38(5): 53-60.

[13] 崔洪, 杨建丽, 刘振宇. 废旧轮胎热解行为的TG/DTA研究[J]. 化工学报, 1999, 50(6): 826-833.

CUI Hong, YANG Jianli, LIU Zhenyu. Pyrolysis of tires and tire components by tg/dta analyzer[J]. Journal of Chemical Industry and Engineering (China), 1999, 50(6): 826-833.

[14] 杜爱华, 牛斌, 刘双喜.废橡胶热解与热能利用[M].北京: 化学工业出版社, 2015: 1-213.

DU Aihua, NIU Bin, LIU Shuangxi. Pyrolysis of waste tire andutilizationofheatenergy[M]. Beijing: Chemical Industry Press, 2015: 1-213.

[15] DARMSTADT H, ROY C, KALIAGUINE S. Characterization of pyrolytic carbon blacks from commercial tire pyrolysis plants[J]. Carbon, 1995, 33(10): 1449-1455.

[16] ERIKSSON M, BERGMAN F, JACOBSON S. On the nature of tribological contact in automotive brakes[J]. Wear, 2002, 252(1/2): 26-36.

[17] KIM Y C, CHO M H, KIM S J, et al. The effect of phenolic resin, potassium titanate, and CNSL on the tribological properties of brake friction materials[J]. Wear, 2008, 264 (3/4): 204-210.

[18] 王尚, 张玉军, 赵东亮. 六钛酸钠(钾)混合晶须对树脂基摩擦材料性能的影响[J]. 中国陶瓷, 2010, 46(6): 11-13.

WANG Shang, ZHANG Yujun, ZHAO Dongliang. Effect of sodium (potassium) titanate whiskers on the property of resin-based friction materials[J]. China Ceramics, 2010, 46(6): 11-13.

[19] 王海鹏, 王俊元, 王洪福, 等. 陶瓷吸声材料的研究进展[J]. 中国陶瓷, 2014, 50(6): 1-4.

WANG Haipeng, WANG Junyuan, WANG Hongfu, et al. Research progress of the ceramic sound-absorbing materials[J]. China Ceramics, 2014, 50(6): 1-4.

[20] 贾宏禹. 材料的粘弹性对摩擦片振动与制动噪声的影响研究[D]. 武汉: 武汉理工大学机电工程学院, 2003: 1-66.

JIA Hongyu. Research on the effects of viscoelasticity of material on brake-shoe′s vibration and braking noise[D]. Wuhan: Wuhan University of Technology. School of Mechanical and Electronic Engineering, 2003: 1-66.

[21] 王亚南, 王冬成, 齐智国, 等. 摩擦片压缩比对低频制动抖动的影响[J]. 桂林电子科技大学学报, 2012, 32(2): 114-117.

WANG Yanan, WANG Dongcheng, QI Zhiguo, et al. Experimental research on the vehicle steering wheel wobbling induced by brake judder[J]. Journal of Guilin University of Electronic Technology, 2012, 32(2): 114-117.

(编辑 赵俊)

收稿日期: 2020 -03 -14; 修回日期: 2020 -09 -26

基金项目(Foundation item):国家重点研发计划项目(2016YFB1100103) (Project(2016YFB1100103) supported by the National Key Research and Development Program)

通信作者:吴宏,博士,教授,从事生物医用材料、高性能汽车摩擦材料研究;E-mail:hwucsu@csu.edu.cn

引用格式:杨阳, 吴宏, 刘伯威, 等. 轮胎粉含量对汽车摩擦材料性能的影响[J]. 中南大学学报(自然科学版), 2021, 52(2): 358-367.

Citation:YANG Yang, WU Hong, LIU Bowei, et al. Effect of tyre powder content on properties of automotive friction materials[J]. Journal of Central South University(Science and Technology), 2021, 52(2): 358-367.