文章编号: 1004-0609(2005)02-0192-06

Fe3Al-Cu基刹车材料的制备及其摩擦学特性

刘英才1, 李 静2, 尹衍升1, 2

(1. 中国海洋大学 材料科学与工程研究院, 青岛 266003;

2. 山东大学 材料液态结构与遗传性教育部重点实验室, 济南 250061)

摘 要: 采用机械合金化结合热压烧结法制备了一种新型Fe3Al-Cu基刹车材料, 并对其力学性能及摩擦学特性进行了研究。 结果表明, 相比Fe基材料, Fe3Al-Cu基刹车材料密度小, 强度高, 随着Cu含量的增加(6%~30%, 质量分数), 其硬度和强度降低, 摩擦系数和磨损率都升高。 Cu含量为12%~18%时摩擦系数高而稳定, 耐磨性好, 此时摩擦系数为0.5~0.55, 平均磨损率约1.5×10-5 mm3·N-1·m-1。 不同阶段材料的摩擦磨损机制不同, 摩擦初期以磨粒磨损为主; 中期主要包括塑性变形、 裂纹扩展和疲劳断裂; 后期主要是氧化磨损, 当Cu含量过高时(大于24%)会发生粘着磨损。

关键词: Fe3Al-Cu; 刹车材料; 力学性能; 摩擦磨损 中图分类号: TB174.442

文献标识码: A

Preparation and tribology properties of

Fe3Al-Cu base brake materials

LIU Ying-cai1, LI Jing2, YIN Yan-sheng1, 2

(1. Department of Materials Science and Engineering,

Ocean University of China, Qingdao 266003, China;

2. Key Laboratory for Liquid Structure and Heredity of Ministry of Education,

Shandong University, Jinan 250061, China)

Abstract: New Fe3Al-Cu base brake materials were prepared by mechanical alloying and hot pressing. The mechanical properties and dry sliding tribological properties were studied. The results show that in this experiment, compared with Fe-based material, Fe3Al-Cu based brake materials have lower density and higher strength. With the increase of Cu content (6%-30%), the hardness and strength of brake materials decrease, and the friction coefficient and wear rate increase. The brake materials with 12%-18% Cu have high and smooth friction coefficient, and excellent wear resistance, the friction coefficient of which is 0.50-0.55 and the average wear rate is about 1.5×10-5mm3/(N·m). There are different wear mechanisms during different friction stages. The first period is mainly abrasive wear, the latter includes plastic deformation, crack propagation and fatigue fracture, and the last is oxidation wear. When the content of Cu is more than 24%, the adhesion of brake material to the counterpart takes place, which leads to serious wear.

Key words: Fe3Al-Cu; brake material; mechanical property; friction and wear

刹车材料是制动系统中的关键部件, 其作用是通过与对偶材料的相对摩擦, 将大部分动能转化为热能, 经由刹车材料吸收与散发, 达到制动的目的。 目前使用较多的刹车材料为金属陶瓷复合材料, 是采用粉末冶金技术将金属基体与各种非金属组元加压烧结而成的, 主要包括铁基、 铜基和铁-铜基3种。 铁基刹车材料的优点是耐高温、 承受负荷大、 价格便宜, 但与钢铁对偶材料配对时, 由于具有亲和性, 易发生粘结且锈蚀现象严重; 铜基刹车材料由于其良好的导热性, 与钢对偶材料作用时摩擦系数高, 耐磨性好, 但其成本高且高温性能差。 随着速度和载荷的不断提高, 刹车副的接触面温度达到1000℃以上, 这对刹车材料的综合性能要求越来越高, 尤其是高温摩擦性能, 因此研究开发具有优异性能的新型刹车材料十分重要而又迫切[1-8]。

Fe3Al金属间化合物因其独特的长程有序结构成为近20年来材料界研究的热点, 它具有超点阵晶体结构, 原子间的结合既有金属键, 又有共价键和离子键, 这决定了它的特殊性能, 其抗氧化、 硫化性, 高温强度, 高温蠕变性以及耐磨性都优于大部分金属材料, 而导热性与塑性好于非金属材料, 是介于合金与陶瓷之间的一种新型廉价材料, 有望替代铁、 铜合金应用于摩擦材料领域[9-15]。 本文作者设计制备了一种以Fe3Al-Cu为基体, 添加润滑剂和摩擦剂的新型复合刹车材料, 并对其物理力学性能和摩擦磨损性能进行了初步探索。

1 实验

1.1 原料及制备方法

Fe3Al粉采用机械合金化法合成, 是将Fe粉(纯度98%, 约80μm)、 Al粉(纯度99%, 约80μm)按Fe70Al30成分摩尔比配比在球磨机中进行高能球磨, 然后经退火处理后得到。 由于Fe3Al的导热性比一般合金稍差, 且硬度较高, 分别加入6%、 12%、 18%、 24%和30%(质量分数)的Cu粉共同作为基体来改善其性能, 另外选用鳞片石墨(8%)作为润滑剂以及Al2O3(3%)作为增摩剂。 将Fe3Al粉、 Cu粉、 鳞片石墨、 Al2O3 粉均匀混合后, 在Multi-5000多功能真空烧结炉(日本富士株式会社)中进行加压烧结(真空度为3×10-3 Pa)获得尺寸为d42mm×7mm的块体试样, 烧结温度为1050℃, 压力为10MPa, 保温保压时间为30min。 同时制备了Fe基刹车材料进行性能对比。

1.2 材料性能测试

在HD-187.5型布洛维硬度计上测试材料的表观硬度; 用CMT-5105电子万能试验机测量试样的抗弯强度和室温压缩强度, 加载速率为0.5mm/min, 试样尺寸分别为3mm×4mm×36mm和4mm×4mm×10mm; 用XJ-40冲击强度试验机测量试样的冲击强度, 试样尺寸为4mm×4mm×40mm。

室温条件下的干摩擦磨损实验在MM-200环-块式磨损试验机上进行, 将烧结后的块体试样加工成尺寸为30mm×6mm×5mm的试块, 对偶磨轮尺寸为d40mm×10mm, 材质为45#钢, 硬度为HRC55。 实验过程中试块固定不动, 对偶磨轮以400r/min的速度转动, 试样与对偶之间形成相对速度为0.84m/s的干滑动摩擦, 施加载荷为100N, 摩擦周期为30min。 试样摩擦系数通过摩擦力矩求得; 用精度为0.1mg的分析天平测量试样的磨损质量损失, 并根据试样的真实密度换算为试样的体积磨损量。 用扫描电子显微镜(SEM)观察试样摩擦磨损后的表面形貌。

2 结果与讨论

2.1 力学性能

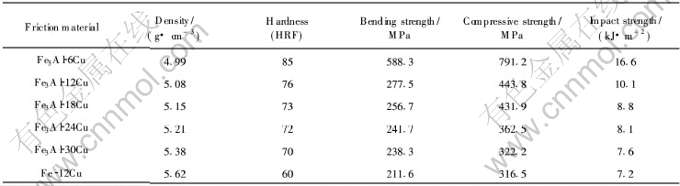

不同Cu含量的Fe3Al基刹车材料的力学性能列于表1中。 由表1可以看出, 相同Cu含量时Fe3Al基刹车材料的密度明显小于Fe基材料。 这是由于Fe3Al金属间化合物的密度在6g/cm3左右, 而Fe的密度为7.86g/cm3, 这对于降低刹车材料的密度具有十分重要的意义。 随着Cu含量的增加, Fe3Al基刹车材料的密度逐渐提高。 由表1还可以知道, Fe3Al-Cu刹车材料的硬度、 抗弯强度、 压缩强度以及冲击强度都随着Cu含量的增加而降低, 尤其是当Cu的含量由6%增加到12%时, 硬度和强度有很大的下降。 这可能是因为当Cu含量小于6%时, 烧结过程中大部分Cu原子固溶于基体中, 除Fe3Al基体本身较高的硬度和强度外, 固溶的Cu原子也对基体起到了一定的强化作用; 而当材料中Cu的含量超过12%时, 除少量Cu原子固溶外, 大部分Cu以游离态存在于基体中, 游离Cu相对于Fe3Al为较软相, 而且使复合材料中出现了更多而复杂的界面, 从而导致了材料硬度和强度的降低, 且随着Cu含量的增加下降幅度越大。

2.2 摩擦学特性

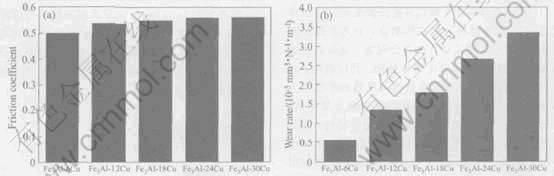

图1比较了不同Cu含量的Fe3Al-Cu基刹车材料在摩擦磨损实验过程中的平均摩擦系数和磨损率。 由图1可以看出, 当Cu含量为6%时, 材料的耐磨性能最好, 摩擦系数最小; 随着Cu含量的增加, 材料的平均摩擦系数有所提高, 而磨损加大。 Fe3Al金属间化合物由于其独特的长程有序结构, 原子间结合力强, 本身具有较高的强度和加工硬化率, 耐磨性好, 同时由于其硬度较高且与对偶的粘着和啮合性差, 使得其摩擦系数较低, 所以当Cu含量小于6%时, 加上Cu原子的固溶强化作用, 材料具有优异的耐磨性能, 但摩擦系数小。 当Cu含量大于12%时, 游离Cu的出现使得基体硬度和强度下降, 随着Cu含量的增加, 材料磨损越来越严重。 但材料中游离Cu的存在实际上增加了基体中软质点的数量, 因此除刹车材料中硬质点与对偶的啮合外, 又增加了对偶材料微凸体对基体的啮合作用, 所以平均摩擦系数随Cu含量的增加呈上升趋势。

表 1 刹车材料的力学性能

Table 1 Mechanical properties of brake materials

图1 刹车材料的平均摩擦系数(a)和磨损率(b)

Fig.1 Mean friction coefficient(a) and wear rate(b) of brake materials

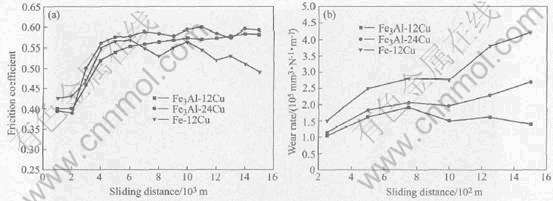

图2示出了Cu含量分别为12%、 24%的Fe3Al基刹车材料和Fe基材料的摩擦系数和磨损率随滑动距离变化的关系。

由图2(a)可以看出, 经过磨合期后, Cu含量为12%时, 刹车材料的摩擦系数较高而且十分平稳; 而Cu含量达到24%时, 虽然材料的平均摩擦系数高一些, 但有明显的波动, 稳定性差; Fe基刹车材料在摩擦初期也具有较高的摩擦系数, 但中后期的摩擦系数出现剧烈波动且有大幅度下降。

摩擦系数本质上是摩擦副之间粘着和摩擦表面凹凸不平引起的啮合大小及性质的函数。 摩擦实验过程中摩擦表面的状态不停发生变化, 导致摩擦系数随之而变。 摩擦初期, 3种材料的摩擦系数都比较高。 当摩擦连续进行时, 摩擦表面的温度不断升高, 基体软化, 材料中的硬质点开始脱落, 同时Fe3Al中的Al原子氧化形成Al2O3, Al2O3硬颗粒与对偶件的接触提高了摩擦系数, 少量游离Cu的存在也有利于摩擦系数的提高, 但摩擦表面的瞬时高温使得对偶件表面形成一层具有润滑作用的氧化膜又会导致摩擦系数的降低, 多方面的共同作用使得Cu含量为12%的Fe3Al基刹车材料的摩擦系数保持平稳。 而当Cu的含量过高时(24%), 经长时间摩擦后, 大量的游离态Cu易与对偶材料发生粘着, 在提高摩擦系数的同时降低了其稳定性, 出现波动。 而Fe基刹车材料的基体本身与对偶件晶格相似, 更易产生粘着, 长时间摩擦后的摩擦系数极不稳定, 同时基体软化以及摩擦表面氧化膜的出现使得摩擦系数明显降低。

由图2(b)可以看出, 含Cu量为12%的刹车材料耐磨性最好, 而且随着滑动距离的增加, 磨损率有降低的趋势; 而当Cu含量较高时(24%), 虽然在摩擦过程中也出现了磨损减小的现象, 但摩擦进行一定阶段时, 磨损加剧; Fe基刹车材料在整个摩擦过程中磨损率始终较高, 后期由于高温强度下降以及强烈的粘着现象, 磨损尤为严重。

图2 刹车材料的摩擦系数(a)和磨损率(b)随滑动距离的变化

Fig.2 Variations of friction coefficient(a) and wear rate(b) with sliding distance

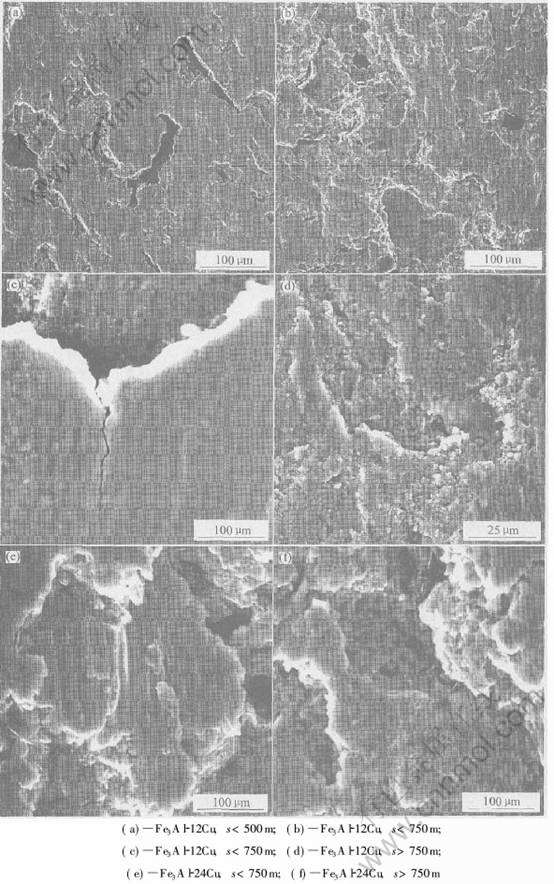

摩擦初期, Fe3Al-Cu基刹车材料主要以磨粒磨损为主。 图3(a)为含Cu量12%的刹车材料在初始阶段(s〈500m)的磨损形貌, 图中可以很清楚地看到磨粒在试样表面微切削形成的犁沟以及表面颗粒脱落后留下的凹坑。 随着摩擦的进行, 由于磨轮对摩擦表面快速反复冲击磨削, 摩擦表层发生塑性变形和加工硬化, 界面处应力集中易产生微裂纹, 裂纹扩展导致摩擦表面局部剥落, 磨损加快。 图3(b)和(c)分别示出了Cu含量为12%的刹车材料在摩擦中期(s〈750m)的形貌以及裂纹的形成。 当摩擦进一步进行时, 长时间的作用使得摩擦表面温度急剧升高, Fe3Al中的Al原子首先氧化, 在试样与对偶件之间形成一层Al2O3膜, 氧化膜的出现分离了摩擦副之间的接触, 降低了磨损, 但同时破碎的Al2O3颗粒脱落时又会划伤摩擦表面。 随着摩擦表面温度持续上升, Fe3Al中的Fe原子也开始氧化形成Fe2O3, 同时对偶件表面也形成一层以Fe2O3、 Fe3O4为主要成分的氧化膜, 这些氧化膜的出现起到一定的润滑作用, 使磨粒磨损、 疲劳磨损减轻, 此时材料表面是以氧化物颗粒及氧化膜剥落为特征的氧化磨损为主(图3(d), s>750m)。 Al2O3、 Fe2O3等氧化膜的交替形成和剥落导致了材料磨损出现了升高、 降低的反复现象, 但总的来说磨损率有所下降。 当Cu含量过高时, 由于基体中游离Cu的大量存在, 不仅使得刹车材料在磨轮的反复作用下出现严重塑性变形, 导致摩擦表面疲劳断裂, 大块材料剥落, 更为严重的是摩擦表面的瞬时高温会使基体中的游离Cu软化而与对偶发生粘着磨损, 因此Cu含量为24%的刹车材料虽然在摩擦过程中也由于氧化膜的形成一定程度上降低了磨损, 但最终由于过多的Cu而导致磨损加剧, 图3(e)和(f)分别为其在摩擦中期塑性变形(s〈750m)和后期粘着(s>750m)的磨损形貌。

3 结论

1) Fe3Al-Cu基刹车材料相比Fe基材料密度小, 有较高的硬度和强度, 随着Cu含量的增加, 材料的密度提高, 硬度和强度降低。

2) Fe3Al-Cu基刹车材料的平均摩擦系数和磨损率都随着Cu含量的增加而升高。 Cu含量为12%~18%的刹车材料摩擦系数较高且稳定, 耐磨性好, 具有良好的综合性能。

3) Fe3Al-Cu基刹车材料在不同摩擦阶段的摩擦磨损机制不同。 摩擦初期以磨粒磨损为主, 表现为表面凹坑和犁沟; 在摩擦中期磨损表现为塑性变形、 裂纹扩展和片层脱落, 磨损加快; 摩擦后期由于摩擦表面的瞬时高温以氧化磨损为主, Al2O3、 Fe2O3等氧化膜的交替形成和剥落有利于摩擦系数稳定和磨损率降低, 但Cu含量过高时局部发生粘着磨损, 导致摩擦系数波动以及磨损严重。

图3 试样磨损表面的SEM照片

Fig.3 SEM micrographs of wear surface of different samples

REFERENCES

[1]徐润泽. 粉末冶金结构材料学[M]. 长沙: 中南工业大学出版社, 2002. 291-295.

XU Run-ze. Powder Metallurgy Structural Materials[M]. Changsha: Central South University of Technology Press, 2002. 291-295.

[2]Locker K D. Friction materials overview[J]. Powder Metallurgy, 1992, 35(4): 253-254.

[3]姚萍屏, 熊翔, 黄伯云. 粉末冶金航空刹车材料的应用现状与发展[J]. 粉末冶金工业, 2000, 10(6): 35-38.

YAO Ping-ping, XIONG Xiang, HUANG Bai-yun. Present situation and development of powder metallurgy airplane brake materials[J]. Powder Metallurgy Industry, 2000, 10(6): 35-38.

[4]杨永连. 烧结金属摩擦材料[J]. 机械工程材料, 1995, 19(6): 18-21.

YANG Yong-lian. Sintered metal friction materials[J]. Materials for Mechanical Engineering, 1995, 19(6): 18-21.

[5]Garbar I I. The effect of load on the structure and wear of friction pair materials[J]. Wear, 1997, 205: 240-245.

[6]姚萍屏, 熊翔, 袁国洲, 等. 铜对粉末冶金航空刹车材料物理力学性能的影响[J]. 中国有色金属学报, 2000, 10(S1): 81-83.

YAO Ping-ping, XIONG Xiang, YUAN Guo-zhou, et al. Effect of copper on physical and mechanical properties of powder metallurgy airplane brake materials[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(S1): 81-83.

[7]刘伯威, 樊毅, 张金生, 等. SiO2和SiC对Cu-Fe基烧结摩擦材料性能的影响[J]. 中国有色金属学报, 2001, 11(1): 110-113.

LIU Bai-wei, FAN Yi, ZHANG Jin-sheng, et al. The effects of SiO2 and SiC on the properties of Cu-Fe base sintered friction material[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 110-113.

[8]樊毅, 张金生, 高游, 等. 铁含量对铁-铜基摩擦材料性能的影响[J]. 摩擦学学报, 1999, 19(3): 204-208.

FAN Yi, ZHANG Jin-sheng, GAO You, et al. The effects of Fe content on the properties of Fe-Cu base friction materials[J]. Tribology, 1999, 19(3): 204-208.

[9]尹衍升. 铁铝金属间化合物[M]. 上海: 上海交通大学出版社, 1996. 29-34.

YIN Yan-sheng. Iron Aluminium Intermetallics[M]. Shanghai: Shanghai Jiaotong University Press, 1996. 29-34.

[10]Stoloff N S. Iron aluminides: present status and future prospects[J]. Materials Science and Engineering A, 1998, 258: 1-14.

[11]ZHU S M, Tamura M, Sakamoto K. Characterization of Fe3Al-base intermetallic alloys fabricated by mechanical alloying and HIP consolidation[J]. Materials Science and Engineering A, 2000, 292: 83-89.

[12]范润华, 孙康宁, 尹衍升. Fe3Al金属间化合物的机械合金化[J]. 机械工程学报, 2000, 36(8): 55-60.

FAN Run-hua, SUN Kang-ning, YIN Yan-sheng. Mechanical alloying of Fe3Al intermetallics[J]. Chinese Journal of Mechanical Engineering, 2000, 36(8): 55-60.

[13]尹衍升, 张景德, 李嘉, 等. Fe3Al/Al2O3复合材料梯度涂层德摩擦磨损行为[J]. 摩擦学学报, 2003, 23(5): 376-379.

YIN Yan-sheng, ZHANG Jing-de, LI Jia, et al. Friction and wear properties of Fe3Al/Al2O3 composite graded coatings[J]. Tribology, 2003, 23(5): 376-379.

[14]Kim Y S, Kim Y H. Sliding wear behavior of Fe3Al-based alloys[J]. Materials Science and Engineering A, 1998, 258: 319-324.

[15]Alman D E, Hawk J A, Tylczak J H, et al. Wear of iron-aluminide intermetallic-based alloys and composites by hard particles[J]. Wear, 2001, 251: 875-884.

基金项目: 教育部博士点基金资助项目(20020422001); 山东省重点基金资助项目(Z2002F02)

收稿日期: 2004-07-20; 修订日期: 2004-10-25

作者简介: 刘英才(1969-), 男, 副教授, 博士.

通讯作者: 尹衍升, 教授; 电话: 0532-8628415; E-mail: yys2003@ouc.edu.cn

(编辑袁赛前)