文章编号:1004-0609(2010)07-1316-05

温压-熔融渗硅法制备C/C-SiC摩擦材料及其摩擦磨损性能

韩团辉,肖 鹏,李 专

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以短切炭纤维、石墨粉、硅粉、树脂为原料,采用新开发的温压-熔融渗硅(WC-RMI)法制备C/C-SiC摩擦材料,对不同制动速度下材料的摩擦磨损性能进行研究,并对温压-熔融渗硅法的制备工艺过程进行理论分析。结果表明:C/C-SiC材料的密度可达1.78 g/cm3,残留单质Si的含量为0.3%,摩擦因数为0.36~0.43,体积磨损量低至0.6×10-2 cm3/MJ,且随着制动速度的增大,其磨损量迅速下降并趋于平稳;C/C-SiC材料在摩擦过程中能够形成光亮、平整、连续的摩擦膜,有效降低C/C-SiC材料的磨损量。

关键词:C/C-SiC摩擦材料;温压;熔融渗硅;摩擦磨损

中图分类号:TB332 文献标志码:A

Preparation and tribological properties of C/C-SiC composites by warm compacted-reactive melt infiltration process

HAN Tuan-hui, XIAO Peng, LI Zhuan

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The C/C-SiC composites were prepared by a new method of warm compaction-reactive melt infiltration (WC-RMI) process with short carbon fibers, graphite powders, Si powders and resins as raw materials. The friction and wear behaviors of C/C-SiC composites at different braking speeds were investigated. And the studies on WC-RMI method in theory were carried out. The results show that the density of C/C-SiC composites is 1.78 g/cm3, residual Si content is 0.3%, the friction coefficients are 0.36-0.43 and the wear loss decreases to 0.6×10-2 cm3/MJ. And the wear loss declines sharply at first and then keeps stable as the speed increases. The bright and smooth friction film in the course of friction forms on the C/C-SiC composites, which can decrease the wear loss obviously.

Key words: C/C-SiC composites; warm compaction; reactive melt infiltration; friction and wear

20世纪90年代中期,C/C-SiC复合材料(炭纤维增强炭和碳化硅双基体材料)开始应用于摩擦领域。C/C-SiC摩擦材料具有密度低、耐磨性好、摩擦因数高、制动平稳、抗腐蚀、抗氧化、耐高温、环境适应性强、寿命长和成本低廉等优点,成为最新一代高性能摩擦材料而引起研究者的广泛关注[1-3]。C/C-SiC摩擦材料的制备方法主要有化学气相渗透法(CVI),先驱体转化法(PIP),熔融渗硅法(RMI)和温压-原位反应法(WCISR )。化学气相渗透法能在低压、低温下进行,纤维受损小,但生产周期长,制造成本高[4-5];先驱体转化法能制备出形状复杂、近尺寸的复合材料部件,但需多次浸渗裂解,周期长[6-7];熔融渗硅法可在常压下短时间完成,周期短、成形性好,但其制造成本较高[8];温压-原位反应法工艺简单、成本低,是制备C/C-SiC摩擦材料的新工艺[3, 9-10]。肖鹏等[3, 10]和王林山[11]采用温压-原位反应法和熔融渗硅法开展C/C-SiC摩擦材料的研究。温压-原位反应法工艺简单、过程易于控制、周期短、成本低,是一种具有市场竞争力的工业化生产技术。已成功探索出以整体毡为预制体的熔融渗硅法制备C/C-SiC摩擦材料的工艺。这两种工艺均存在温压-原位反应法制备的材料致密度较低、力学性能较低、韧性较差的不足[9-10,12]。RMI法中,整体毡预制体和CVI沉积热解炭增密制备C/C多孔体成本较高。因此,本文作者在前期研究的基础上,提出温压与熔融渗硅相结合的方法制备C/C-SiC摩擦材料,即采用温压/炭化工艺制备C/C或C/C-Si多孔体,再通过RMI得到SiC基体;并从理论上分析温压-熔融渗硅法(WC-RMI)的工艺过程,研究在不同制动速度下C/C-SiC摩擦材料的摩擦磨损性能。

1 实验

1.1 试样的制备

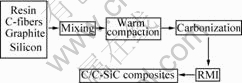

采用国产的长度为10 mm的短切炭纤维为增强相,基体成分来源于鳞片石墨、硼改性酚醛树脂(残炭率大于60%)、工业硅粉(粒度不大于47 μm,纯度为99.3%)。首先,将短炭纤维、硅粉、石墨粉、树脂按15?15?20?30的体积比均匀混合,然后温压(t≤200 ℃,p≤8 MPa)成坯体,坯体炭化(t≤900 ℃,氮气保护)后得到C/C-Si多孔体,最后在1 700 ℃时用埋粉法真空浸渗液体硅2 h制得C/C-SiC摩擦材料,试样制备流程图如图1所示。

图1 试样制备工艺流程图

Fig.1 Flow chart for manufacturing C/C-SiC composites

1.2 性能测试

采用排水法测定C/C-SiC摩擦材料的体积密度和开孔率;采用XRD分析材料的物相;利用SEM分析材料的断口形貌和摩擦膜形貌观察;摩擦磨损性能在QDM150可调速调压干式摩擦材料性能试验机上测试。摩擦性能测试时采用盘—块滑动对磨形式,对偶盘为30CrMoSiVA合金钢,试样尺寸为25 mm×25 mm×10 mm,以25 mm×25 mm面作为摩擦面,在试样上均匀取5点的厚度平均值来计算磨损量;实验条件:圆盘转动线速度分别为8、12、16、20、24 s,压紧力为1 MPa,滑行距离为1 884 m。

2 结果与讨论

2.1 工艺过程

2.1.1 C/C-Si多孔体的制备

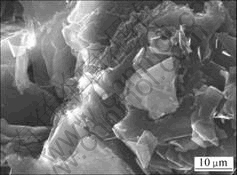

温压阶段各原料由酚醛树脂粘结,在压力作用下形成块状C/C-Si素坯。C/C-Si素坯经炭化处理,其中的树脂裂解转变成树脂炭,从而得到C/C-Si多孔体。炭化过程中树脂炭产生体积收缩导致C/C-Si多孔体内出现微裂纹,这些微裂纹成为后续熔硅浸渗过程中熔硅的渗入通道。由树脂在5 ℃/min的升温速率下的失 重—差热分析曲线(TG—DSC)[12]可知,树脂质量损失主要发生在室温到200 ℃和500到700 ℃的两个阶段,以H2O、H2、CO、CH4等热解产物的挥发为主要形式。在这两个温度阶段,酚醛树脂的炭化进程比较缓慢,升温不能过快。如果升温太快,反应剧烈,短时间内会产生大量气体,气态产物的迅速释放及气体通道受到固体树脂的阻碍,容易引起材料的分层和裂纹。炭化结束后,树脂裂解生成的树脂炭和原料中石墨共同构成试样中的基体炭,为后续硅碳反应提供碳源。图2所示为树脂炭的SEM像。

图2 树脂炭的SEM像

Fig.2 SEM image of resin-based carbon

2.1.2 原位硅碳反应

在1 150~1 414 ℃的温度阶段,即试样外部硅粉熔化前,原位硅粉便已开始与周围可接触到的碳反应生成碳化硅,此时的硅碳反应式如下:

Si(s)+C(s)→SiC(s) (1)

Si、C(包括石墨C、树脂C)、SiC的摩尔体积分别为12.0、6.1、12.5 cm3/mol, Si与基体C反应后生成SiC,体积约缩小为的原体积的69.1%,相当于增大C/C多孔体的孔隙率,从而更有利于试样外部液体Si的渗入。

Si-C相图[13]显示,热力学上,1 000 ℃以上固态硅碳可以反应生成碳化硅,而由于动力学的影响,只有高于1 150 ℃时,固态硅碳才能发生化学反应[14]。固相物质间化学反应发生的必要条件是反应物必须紧密接触。研究表明,即使在2 100 ℃的高温下,C原子和Si原子的自扩散系数也仅为1.5×0-13 cm2/s[15],而SiC中Si原子的扩散系数在1 600 ℃时为4.2×10-10 cm2/s、在1 800 ℃为9.5×10-10 cm2/s,C原子的扩散系数在1 600 ℃时为8.86×10-9 cm2/s、在1 800 ℃时为2.90×10-7 cm2/s [16],因此,原位硅碳反应速率较低,硅粉很难反应完全,剩余的硅则在熔融渗硅阶段以液体的形态参与硅碳反应。加快或者减慢升温速度,可以控制此阶段硅碳反应进行的程度。

2.1.3 熔融渗硅

随着温度的升高,C/C-Si多孔体外部的硅粉熔化,液体Si在毛细管力的驱动下顺着微孔和微裂纹渗入到多孔体内部,与接触到的C(包括炭纤维和基体炭)发生硅碳反应生成SiC基体,液体Si的渗入和硅碳反应同时进行,此时的硅碳反应式如下:

Si(l)+C(s)→SiC(s) (2)

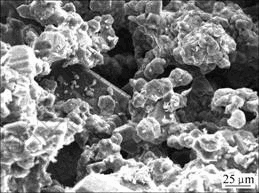

Si、C(包括石墨、树脂C)、SiC的摩尔体积分别为11.1、6.1、12.5 cm3/mol,渗入的液体Si与基体C反应生成SiC,相当于基体中C的体积增大到原体积的2.05倍,试样的致密度也提高了。同时,毛细管的半径由于SiC的生长而逐渐减小,如果毛细管入口被生成的SiC堵死,Si的渗入中止,则会在材料内形成闭孔。预制体中孔的形状、大小和分布复杂,它们在三维方向呈网状分布,孔的大小和形状随位置不同而改变。因此,在不同的孔中液Si的渗入速率和填满孔所需要的时间是不同的。孔径较大的地方需要渗入Si的体积大,其毛细管作用力却较小,因此渗入速率也较低,需要渗入的时间较长。对于半径较小的孔,它被迅速填满,同时由于SiC的生成,小孔容易被堵塞,成为继续渗入的“瓶颈” [17]。因此,改善坯体中孔的结构,对熔融渗硅法制备C/C-SiC摩擦材料有重要的影响。图3所示为SiC的SEM像。由图3可看出,SiC颗粒呈现多面体形貌。

图3 SiC的SEM像

Fig.3 SEM image of SiC

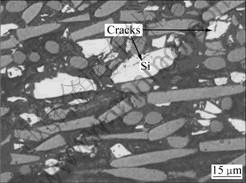

目前普遍认为碳颗粒部分熔解于液体硅中,形成一层SiC包覆在碳颗粒表面,碳与硅通过再扩散到达Si-SiC和C-SiC界面进行反应。液态Si与固体态C反应生成SiC的过程是一个快速、放热的过程,材料内部来不及反应完全的熔融Si残留在材料中并被SiC基体包围。残留硅的来源有两部分:未完全反应的原位硅和渗入的液体硅。图4所示为C/C-SiC摩擦材料的金相照片。其中明亮的白色物质即为残留Si,被黑色的SiC基体包围,呈圆形或者丝状的物质为短切炭纤维,其余的灰色物质则为基体C。在残留的Si中明显有微小裂纹产生,其原因是当温度降到Si的熔点时,液体Si开始凝固,其体积膨胀约8%;体积膨胀导致应力产生;降温速度越快,应力越大,当应力大到一定程度并来不及释放时必然会导致微小裂纹的产生。

图4 C/C-SiC摩擦材料的金相照片

Fig.4 Optical micrograph of C/C-SiC composites

2.2 物相、组分及基体形貌

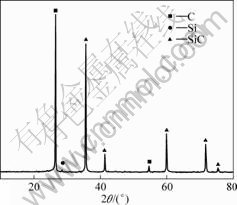

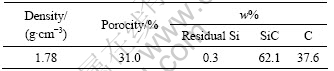

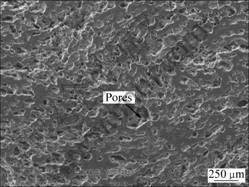

图5所示为试样基体成分的XRD谱。试样各组分含量由XRD物相分析得到(见表1)。试样中残留Si含量为0.3%,SiC含量较高。图6所示为试样的SEM 像。由图6可看出,试样的结构较为疏松,材料中仍有许多小孔洞或气孔存在。其原因之一为在熔融渗硅过程中,试样内形成了一定量的闭孔;原位硅碳反应的发生为另一影响因素。

图5 C/C-SiC材料的XRD谱

Fig.5 XRD pattern of C/C-SiC composites

表1 试样的基本物理性能及组分

Table 1 Basic physical properties and composition of sample

图6 C/C-SiC材料的SEM像

Fig.6 SEM image of C/C-SiC composites

2.3 摩擦磨损性能

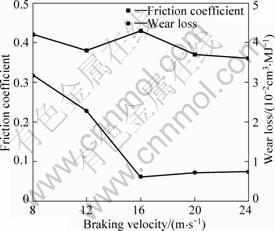

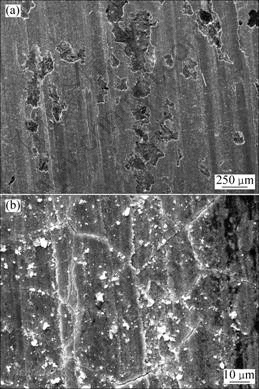

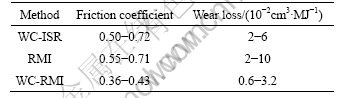

图7所示为试样的摩擦因数及磨损量与制动速度的关系。由图7可看出,摩擦因数在0.36~0.43时,对速度和能量不敏感;磨损量在(0.6~3.2)×10-2 cm3/MJ时,随着制动速度的增大,磨损量迅速下降并趋于平稳。这些都与在摩擦磨损过程中试样表面形成了一层十分光亮、平整、连续的膜结构有密切关系。当试样和对偶盘之间开始摩擦时,微观上是两种材料的表面微凸体相互接触、嵌入,所以产生较大的摩擦力。微凸体变形过程中产生的一部分碎屑在载荷的作用下压实、涂覆,在摩擦表面或者填充在表面的孔隙中,形成一层碎屑膜,即摩擦膜,磨屑中硬质粒子(如SiC和Si等)便对摩擦表面产生“犁沟”作用。摩擦膜的形成减小摩擦表面微凸体之间的直接接触,对摩擦起润滑作用,导致材料的摩擦因数减小并趋于稳定,同时显著降低材料的磨损量。图8所示为试样的摩擦膜的SEM像。由图8可以看出,摩擦膜上存在大量的微小颗粒、裂纹和明显的叠加痕迹;在一定的压力和温度条件下,摩擦膜在循环的“生成—破坏、部分消失—再生成”过程中必然会出现大量的裂纹。试样磨损的主要形式为磨粒磨损和粘着磨损。采用温压-原位反应法、熔融渗硅法和温压-熔融渗硅法3种方法所制备的C/C-SiC摩擦材料的摩擦磨损性能如表2所列。由表2可知,采用温压-熔融渗硅法所制备的材料的摩擦因数和磨损量均低于另外两种方法所制备的材料的。这与采用本方法所制备的C/C-SiC摩擦材料在摩擦磨损过程中,可以在试样表面形成结构良好的摩擦膜有密切关系。

图7 试样的摩擦因数及磨损量与制动速度的关系

Fig.7 Curves of friction coefficient and wear loss vs braking velocity of sample

图8 试样摩擦膜的SEM像

Fig.8 SEM images of friction film on sample: (a) Lower magnification; (b) Higher magnification

表2 不同方法制备的C/C-SiC材料的摩擦磨损性能比较

Table 2 Comparison of friction and wear behaviors of C/C-SiC composites by different methods

3 结论

1) 采用温压-熔融渗硅法制备的C/C-SiC摩擦材料密度可达1.78 g/cm3,残留单质Si含量为0.3%,摩擦系数在0.4左右,体积磨损量低至0.6×10-2cm3/MJ。

2) 在摩擦磨损过程中,C/C-SiC摩擦材料表面形成一层十分光亮、平整、连续的摩擦膜,使材料对摩擦速度和能量不敏感。

REFERENCES

[1] 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术, 2003 (1): 24-32.

ZHANG Li-tong, CHENG Lai-fei, XU Yong-dong. Progress in research work of new CMC-SiC[J]. Aeronautical Manufacturing Technology, 2003(1): 24-32.

[2] KRENKEL W, HENKE T. Design of high performance CMC brake discs[J]. Key Engineering Materials, 1999, 164/165(2): 421-424.

[3] 肖 鹏, 熊 翔, 张红波, 黄伯云. C/C-SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学报,2005, 15(5): 667-674.

XIAO Peng, XIONG Xiang, ZHANG Hong-bo, HUANG Bai-yun. Progress and application of C/C-SiC ceramic braking materials[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667-674.

[4] SANOKAWA Y, IDO Y, SOHDA Y, NAKAZAWA N, KAYA H. Application of continuous fiber reinforced silicon carbide matrix composites to a ceramic gas turbine model for automobiles[J]. Ceram Eng Sci Proc, 1997, 18(4): 221-228.

[5] 徐永东, 张立同, 成来飞, 朱文超. CVI法制备三维碳纤维增韧碳化硅陶瓷基复合材料[J]. 硅酸盐学报, 1996, 24(10): 485-489.

XU Yong-dong, ZHANG Li-tong, CHENG Lai-fei, ZHU Wen-chao. Three dimensional carbon fiber reinforced silicon carbide composites prepared by chemical vapor infiltration[J]. J Chin Ceram Soc, 1996, 24(10): 485-489.

[6] DURAN A, APARICIO M, REBSTOCK K, VOGEL W D. Rein filtration processes for polymer derived fiber reinforced ceramics [J]. Key Engineering Materials, 1997, 127/131(1): 287-294.

[7] ORTONA A. SiC-SiCf CMC manufacturing by hybrid CVI-PIP techniques: Process optimization[J]. Fusion Engineering and Design, 2000, 51/52: 159-163.

[8] HARNISCH B, KUNKEL B, DEYERLER M, BAUEREISEN S, PAPENBURG U. Ultra-light weight C/SiC mirrors and structures[J]. ESA Bulletin 95, 1998(8): 148-152.

[9] 杨 阳. 温压-原位反应法制备C/C-SiC制动材料的摩擦磨损性能[D].长沙: 中南大学, 2007.

YANG Yang. Friction and wear properties of C/C-SiC composites by WC-ISR[D]. Changsha: Central South University, 2007.

[10] 李 专, 肖 鹏, 熊 翔, 杨 阳, 旷文敏. 温压-原位反应法制备C/C-SiC材料过程中裂纹的形成机制[J].中南大学学报: 自然科学版, 2008, 39(3): 506-511.

LI Zhuan, XIAO Peng, XIONG Xiang, YANG Yang, KUANG Wen-min. Form mechanism of cracks in fabricated process of C/C-SiC frictional composites through warm compacted-in situ reacted process[J]. Journal of Central South University: Science and Technology, 2008, 39(3): 506-511.

[11] 王林山. RMI法制备C/C-SiC复合材料及其性能的研究[D]. 长沙: 中南大学, 2003.

WANG Lin-shan. Preparation and study on performance of C/C-SiC composites by RMI[D]. Changsha: Central South University, 2003.

[12] 秦明升. 炭纤维及树脂对C/C-SiC摩擦材料性能的影响[D].长沙: 中南大学, 2009.

QIN Ming-sheng. Effects of carbon fibres and resins on the performance of C/C-SiC composites[D]. Changsha: Central South University, 2009.

[13] 张 宁, 茹红强, 才庆魁. SiC粉体制备及陶瓷材料液相烧 结[M]. 沈阳: 东北大学出版社, 2008: 3.

ZHANG Ning, RU Hong-qiang, CAI Qing-kui. Preparation of SiC powder and liquid phase sintering of ceramic materials[M]. Shenyang: Northeastern University Press, 2008: 3.

[14] HAUTTMANN S, KUNZE T, MUELLER J. SiC formation and influence on the morphology of polycrystalline silicon thin films on graphite substrates produced by zone melting recrystallization [J]. Thin solid films, 1999, 338(1/2): 320-324.

[15] LESSING P A, ERICKSON A W, KUNERTH D C. Thermal cycling of siliconized-SiC at high temperature[J]. Journal of Materials Science, 2001, 36(6): 1389-1394.

[16] HON M H. DAVIS R F. Self-diffusion of 14C in polycrystalline β-SiC[J]. Journal of Materials Science, 1979, 14(10): 2411-2421.

[17] 王继平, 金志浩, 钱军民, 乔冠军. 反应熔渗法制备C/C-SiC复合材料及其反应机理和动力学的研究进展[J]. 硅酸盐学报, 2005, 33(9): 1120-1126.

WANG Ji-ping, JIN Zhi-hao, QIAN Jun-min, QIAO Guan-jun. Research progress on mechanism and kinetics of C/C-SiC composites prepared by reactive melt infiltration[J]. J Chin Ceram Soc, 2005, 33(9): 1120-1126.

(编辑 杨 华)

基金项目:湖南省科技重大专项资助项目(2009FJ1011-3)

收稿日期:2009-09-11;修订日期:2009-11-25

通信作者:肖鹏,教授,博士;电话:0731-88830131;E-mail: xiaopeng@mail.csu.edu.cn