文章编号:1004-0609(2011)09-2084-07

WSP流变铸造与球化处理对

Al-18%Si-5%Fe合金组织和性能的影响

管仁国, 曹富荣, 赵占勇, 黄红乾, 张秋生, 王 超

(东北大学 材料与冶金学院,沈阳 110004)

摘 要:提出了波浪形倾斜板流变铸造(WSP)装置制备过共晶Al-Si-Fe合金的方法,对Al-18%Si-5%Fe合金流变铸造与球化处理进行研究。结果表明,WSP流变铸造可以明显改善合金中初晶硅、Al18Si10Fe5和Al8Si2Fe相的形貌。随着浇注温度降低,各相趋于细化和球化。WSP流变铸造过程中合金组织的形成源于3种机制:结晶雨带来的晶核增殖,斜板强冷却作用下晶体抑制生长和流动剪切作用下晶体破碎。WSP流变铸造与球化处理进一步改善Al-18%Si-5%Fe合金组织,合金维氏硬度达到87.5。在干摩擦条件下Al-18%Si-5%Fe合金的磨损率达到5.4 mg/h。

关键词:过共晶Al-Si合金;波浪形倾斜板;流变铸造;球化

中图分类号:TG 111.4;TG 244.1 文献标志码:A

Effects of wavelike sloping plate rheocasting and spheroidisation on microstructures and properties of Al-18%Si-5%Fe alloy

GUAN Ren-guo, CAO Fu-rong, ZHAO Zhan-yong, HUANG Hong-qian, ZHANG Qiu-sheng, WANG Chao

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: A novel method of preparing hypereutectic Al-Si-Fe alloy was proposed by wavelike sloping plate (WSP) rheocasting device, and the rheocasting and spheroidisation treatment of Al-18%Si-5%Fe alloy were investigated. The results reveal that the morphologies of primary crystal Si, Al18Si10Fe5 and Al8Si2Fe phase in this alloy can be improved obviously by WSP rheocasting. With the decrease of pouring temperature, various phases tend to be refined and spheroidised. The formation of microstructures in this alloy originates from three mechanisms such as crystal nucleus multiplication brought by crystallization rain, crystal restraining growth under strong cooling of sloping plate and crystal break-up under flow shear. The WSP rheocasting and spheroidisation treatment further improve the microstructure of Al-18%Si-5%Fe alloy. The Vickers hardness of the alloy is 87.5. The wear rate of Al-18%Si-5%Fe alloy under dry friction is 5.4 mg/h.

Key words: hypereutectic Al-Si alloy; wavelike sloping plate; rheocasting; spheroidisation

随着能源短缺、石油价格暴涨和环境污染的加剧,节能环保和提高汽车性能成为国际高度重视的课题。汽车活塞是汽车的关键部件,降低活塞材料的密度、提高其使用性能和降低成本对汽车工业节能、提高车辆寿命和降低运行成本具有重要的现实意义[1-3]。

过共晶Al-Si合金材料密度低,约为铸铁的1/3,具有良好的耐磨性能与较低的热膨胀系数,可替代铁质材料制造汽车活塞,因此,近年来研究人员广泛重视这种材料,并开展了大量研究工作[4-6]。在传统铸造工艺生产的过共晶Al-Si合金中,硅相在凝固生长过程中一般以小平面状长大,凝固后的尺寸较大,一般呈板片状、五角形或多角形,这种组织使合金的机械加工性能与力学性能降低。因此,如何控制初晶硅的形貌和大小成为研究的热点问题。另外,传统的观点认为,铝合金中的铁元素为杂质元素,因为铁在铝合金中会形成针状脆硬相,这种相会割裂铝基体,形成微裂纹,降低了材料的力学性能。但是如果能够有效地控制其形貌,在铝基体中形成的弥散、细小的铁相会起到自生弥散颗粒增强作用,大幅度提高复合材料的力学性能,同时会提高Al-Si合金的热稳定性。因此,如何制备含有弥散、细小的初晶硅和铁相组织的过共晶Al-Si-Fe合金是国际上高度重视的问题。

改善共晶硅与初晶硅相组织的方法有两种途径,一是通过添加变质剂,二是改进加工技术。目前添加变质剂的研究较多,变质剂主要有钠、锶、钡和稀土等,它们是改善共晶硅的有效元素,而磷与稀土可以有效地改善初晶硅组织,常见的变质剂有P-S、P-Ba、P-Sr和P-RE等,变质剂逐渐由单一变质向二元、三元、多元变质发展[7-9]。变质技术在一定程度上可改善共晶硅与初晶硅组织,但是同时存在一定问题,如工艺复杂,难于控制;其次,不同元素之间存在“中毒”现象;另外,容易带来杂质元素与气孔夹杂等缺陷。采用先进的生产工艺改善过共晶Al-Si-Fe合金中的硅相和铁相组织也广受重视,目前采用的方法主要有喷射沉积、超声波振动、机械搅拌和电磁搅拌等[10-14],其中电磁搅拌与喷射沉积技术的研究比较成功,已经用来制备过共晶Al-Si合金材料,但喷射沉积技术容易产生气孔夹杂、收得率较低。其他技术的研究尚不十分成熟。半固体加工与快速冷却技术也是制备过共晶Al-Si合金材料的重要方法,倾斜板技术是通过对熔体的快速冷却制备半固体材料,可以充分细化和球化合金组织。本文作者提出采用波浪形倾斜板流变铸造(WSP-Wavelike sloping plate rheocasting)与球化热处理相结合来制备过共晶Al-Si-Fe合金,目的是开发高效、低成本的过共晶Al-Si-Fe合金的制备技术。

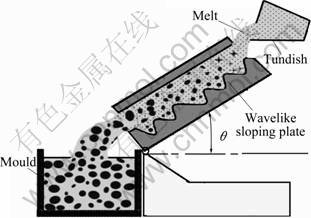

1 实验

采用自行设计的波浪形倾斜板实验装置进行流变铸造实验,波浪形倾斜板的工作原理如图1所示,将液态合金浇注到与水平方向成一定角度θ的波浪形倾斜板上,合金液流经斜板时受到斜板的急剧冷却作用,产生大量晶核并不断结晶凝固。在凝固过程中熔体发生波浪形流动,熔体内部形成较强的剪切力,使合金的凝固组织得到细化和球化,从而获得具有细小固相和部分液相组成的半固态金属浆料,最后浆料直接浇注到铸模中进行流变铸造成形,铸成的锭坯可供给后续加工使用。

图1 波浪形倾斜板流变铸造的基本原理示意图

Fig.1 Schematic diagram of wavelike sloping plate process for rheocasting

实验材料为自行配制的Al-18%Si-5%Fe(质量分数)合金。合金熔炼时,首先将商业Al-20%Si合金加热到740 ℃熔化并保温,将预热干燥后的工业纯铝加入到熔化的合金液中反应,并将熔体继续加热到800 ℃后保温10 min,向熔化的合金液中加入活性铁粉,并进行搅拌,待其反应完全后加入适量六氯乙烷精炼,静置扒渣后保温20 min。将倾斜板的倾角θ调整为45°,倾斜板长度调整为600 mm,在650~720 ℃之间进行浇注,铸模采用水冷铜模,铸锭尺寸为30 mm×100 mm×200 mm。为进行对比研究,同时对Al-18%Si合金和Al-18%Si-5%Fe合金进行常规铸造,浇注温度为710 ℃,采用相同的铸造铜模。

将流变铸造和常规铸造得到合金锭坯在中心位置取样,机械抛光后用0.5%HF+99.5%H2O溶液进行腐蚀,酒精擦拭并吹干后在Olympus PMG51数码金相显微镜下观察合金组织。用SSX-500扫描电镜分析Al-18%Si-5%Fe合金铸锭试样的成分及合金的相组成。采用450SVD型维氏光学硬度计分别对不同试样进行硬度测试,质量载荷为3 kg,加载时间为10 s,对比研究不同合金的硬度差别。采用万能摩擦试验机对比研究流变铸造与球化处理得到的Al-18%Si-5%Fe合金铸锭与常规铸造得到的Al-18%Si合金铸锭的耐磨性能,试样尺寸为d 3 mm×20 mm,采用45号钢作为摩擦副,如图2所示,在干摩擦条件下加载10 N压力,加载20 min进行磨损实验,实验完毕后称量摩损量并计算磨损率,对比材料的耐磨性能。

图2 摩擦副实物图

Fig.2 Practicality diagram of friction set

2 结果与分析

2.1 Al-18%Si与Al-18%Si-5%Fe合金常规铸造组织

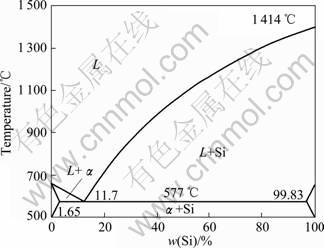

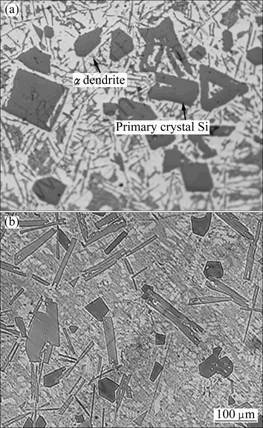

Al-Si相图如图3所示,Al-18%Si合金的液相线温度约为690 ℃,固相线温度约为577 ℃,其半固态区间约为113 ℃。过共晶Al-Si合金的平衡态凝固组织由α(Al)基体、初生硅相和(α+Si)共晶体组成。当冷却速度增大到10 K/s时,凝固组织中出现枝晶状α相。如图4(a)所示,由于铜模冷却能力较强,Al-18%Si合金组织中出现了少量不发达的枝晶α相,α相枝晶是冷却速度较快时出现的一种非平衡凝固组织。在710 ℃浇注时,由于浇注温度较高,硅原子充分扩散与生长,形成了多角状不规则初晶硅和细长的共晶硅。

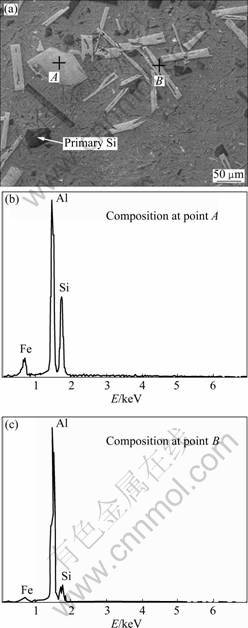

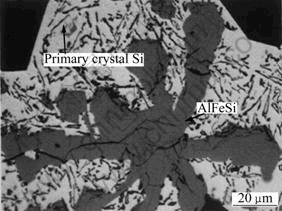

图4(b)所示为Al-18%Si-5%Fe合金常规铸造组织。由图4(b)可以发现,添加5%的铁元素后,合金中出现粗大的针状或片状相,其颜色比初晶硅的浅,而初晶硅受到这些新相的穿插和分割发生了一定程度的细化。图5所示为对Al-18%Si-5%Fe合金中针状和片状相的成分分析,根据原子组成比可知,点A处片状相为Al18Si10Fe5,点B处针状相为Al8Si2Fe。因此,通过本工艺铸造的Al-18%Si-5%Fe合金组织由α铝基体、初晶硅、共晶硅、Al18Si10Fe5和Al8Si2Fe三元相组成。一般认为,铁在Al-Si合金中容易形成α-Al8Si2Fe和β-Al5FeSi,α-Al8Si2Fe呈汉字或骨骼状,对基体性能有益,而β-Al5FeSi呈针状,对基体有害[11]。通过本实验得到的合金中未发现β-Al5FeSi相。初晶硅、共晶硅、Al18Si10Fe5和Al8Si2Fe三元相是强化相,如何充分细化和球化初晶硅、Al18Si10Fe5和Al8Si2Fe三元相是本研究的主要目标。

图3 Al-Si合金二元相图

Fig.3 Binary phase diagram of Al-Si alloy

图4 Al-Si合金和Al-18%Si-5%Fe合金常规铸造组织

Fig.4 Microstructures of normal castings of Al-Si and Al-18%Si-5%Fe alloys: (a) Al-Si alloy, 710 ℃ pouring; (b) Al-18%Si-5%Fe alloy, 710 ℃ pouring

2.2 波浪形倾斜板流变铸造对Al-18%Si-5%Fe合金组织的影响

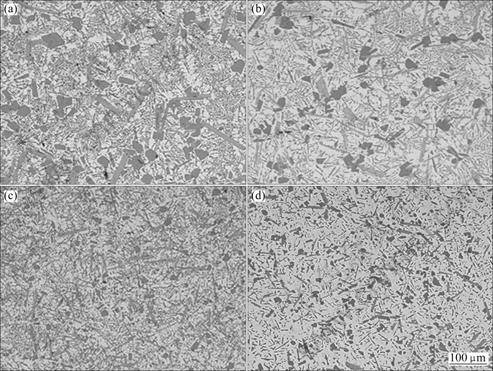

图6所示为不同浇注温度条件下WSP流变铸造得到的Al-18%Si-5%Fe合金组织。由图6可以看出,随着浇注温度降低,合金中的初晶硅、共晶硅、Al18Si10Fe5和Al8Si2Fe三元相均发生细化,尤其是初晶硅、共晶硅最为明显,而含铁的三元相发生细化的同时,其针状形貌变化不大,但当浇注温度降低到670 ℃时,含铁的三元相才明显变短。因此, 670 ℃浇注可以得到组织优良的合金锭坯。

图5 Al-18%Si-5%Fe合金中组成相成分分析

Fig.5 Composition analysis of constituent phases of Al-18%Si-5%Fe alloy: (a) SEM image; (b) Composition of point A; (c) Composition of point B

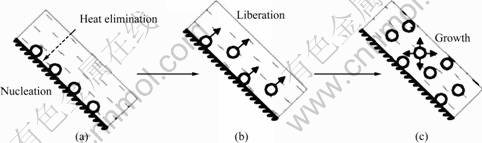

WSP流变铸造过程是熔体动态快速凝固过程,浇注温度较低时,熔体在斜板表面会受三个方面的作用:一是熔体接触倾斜板时受到倾斜板表面的强冷却作用,熔体会发生快速凝固,使熔体中的硅、铁原子得不到充分扩散和聚集长大就发生了结晶,因此,抑制了初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相的长大;二是熔体接触倾斜板后大量形核,晶核在流动作用下不断地脱离斜板表面,进入熔体内部,即形成了“结晶雨”现象,如图7所示,这种结晶雨使熔体中形成了大量晶核,最终为细小合金组织,形成提供了有利条件;三是熔体在波浪形斜板表面流动过程中内部形成较强的剪切作用,使熔体在凝固过程中保持均匀的成分场,在一定程度上减缓了熔体在凝固过程中粗大初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相的形成。众所周知,熔体中铝、硅、铁元素的分布对成形组织至关重要,如果某一区域出现铝元素的贫化,往往会伴随着初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相的形成。熔体的波浪形流动会降低合金成分偏析,使合金凝固过程中成分场趋于均匀,为形成细小均匀的合金组织提供了条件,通过WSP流变铸造的Al-18%Si-5%Fe合金的组织比常规铸造的合金组织更加细小。对比图4 和6可以看出,在上述三个方面的作用机制下,WSP流变铸造可以明显改善常规铸造时产生的粗大不规则的初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相合金组织。随着浇注温度的降低,这种作用更加明显。

熔体在传统凝固过程中,液相溶质中的扩散层比液相中的热量扩散层小约3个数量级,因此,在溶质扩散层内热过冷度可以近似忽略。如果同时忽略结晶潜热的作用,那么就只考虑引发枝晶生长的单一因素,即成分过冷。CHEN等[10]在假设固相中无扩散的条件下,给出了单个枝晶生长时成分过冷与固相生长距离间的关系:

(1)

(1)

式中:c0 为初始溶质浓度;cs为固相溶质浓度;ml为液相线斜率;k0为溶质分配系数;v为固液界面的凝固速率;Dl为溶质扩散系数;x为固相生长距离。

如果晶粒生长达到xn时,产生了新的临近晶粒形成所需要的过冷度,那么此时的xn即为凝固合金的晶粒尺寸,根据这种理论,得出了相关晶粒尺寸xn的表达式:

(2)

(2)

在Al合金中,形成的初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相纵横交错,阻断了硅原子和铁原子的有序充分扩散,降低了液相中的扩散系数Dl,因此会使合金组织细小。

图6 不同浇注温度条件下WSP流变铸造得到的Al-18%Si-5%Fe合金组织

Fig.6 Microstructures of Al-18%Si-5%Fe alloy billets prepared by WSP rheocasting under different pouring temperatures: (a) 710 ℃; (b) 690 ℃; (c) 680 ℃; (d) 670 ℃

图7 结晶雨现象示意图

Fig.7 Schematic diagram of crystallization rain: (a) Nucleation; (b) Nuclei moving freely and dispersing into melt-nucleus moving; (c) Grain growth

另外,在WSP流变铸造Al-18%Si-5%Fe合金过程中,由于倾斜板的冷却作用和熔体的流动作用,会降低熔体中溶质扩散层的大小,且熔体中温度梯度比传统铸造过程大得多,此时的?Tn是影响熔体中固相晶粒大小的主要因素,?Tn越大,晶粒越细小,这也是WSP流变铸造制备Al-18%Si-5%Fe合金时浇注温度越低,合金组织越细小的原因。

毛卫民等[12]在研究电磁搅拌制备过共晶Al-Si合金时发现电磁搅拌也会细化初晶硅组织,认为在电磁搅拌下,过共晶铝硅合金中的初晶硅并不是理想的单晶,在初晶硅中存在很多缺陷,表现在初晶硅板片上存在许多孔洞及薄弱的结合处,还有可能存在孪晶、位错、亚晶界等缺陷,虽然电磁搅拌对初晶硅产生的剪切力很难使单晶硅破碎,但由于存在上述缺陷,初晶硅会发生机械折断。实验发现,随电磁搅拌功率增加,熔体内部的紊流加剧,这使初晶硅破碎的几率增加,从而导致初生硅尺寸的减小。这种解释已在相关研究中得到验证,秦克[15]发现了过共晶Al-Si合金中AlSiFe相表面的裂纹,如图8所示,其研究结果表明,电磁搅拌能够细化和球化过共晶Al-20%Si-3%Fe合金组织。而采用波浪形倾斜板进行WSP流变铸造时同样存在剧烈的紊流流动,也会使具有缺陷的初晶硅或含Fe相组织发生断裂和细化。

综上所述,WSP流变铸造过程中合金组织的形成源于3种机制的作用:结晶雨带来的晶核增殖,斜板强冷却作用下晶体抑制生长和流动剪切作用下晶体 破碎。

图8 电磁搅拌制备Al-20%Si-3%Fe合金过程中发现的AlSiFe相表面裂纹[15]

Fig.8 Surface cracks of AlFeSi phases in Al-20%Si-3%Fe alloy prepared by electromagnetic stirring[15]

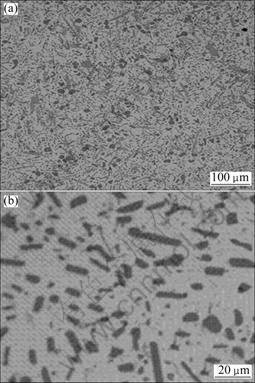

2.3 球化处理对Al-18%Si-5%Fe合金流变铸造组织的影响

图9所示为通过WSP流变铸造制备的Al-18%Si-5%Fe合金铸锭在540 ℃温度下保温球化处理12 h后的组织。可见,合金组织得到进一步改善,初晶硅和Al18Si10Fe5和Al8Si2Fe相分布趋于均匀、细小和圆整,尤其是片状和条状初晶硅会发生明显的断裂,成为点链状分布,如图9(b)所示。这种过程可以用熟化机理来解释,初晶硅以及Al18Si10Fe5和Al8Si2Fe三元相表面的曲率不一样,这些固相与液相界面处所对应的平衡溶质元素的浓度也不一样,在界面曲率大的地方所对应的液相的平衡溶质浓度较高,而界面曲率小的地方所对应的液相的平衡溶质浓度较低。根据凝固理论,溶质将由曲率大的地方向曲率小的地方扩散,使初生相尖角发生钝化,以便降低界面能和系统总能量,这是一个能量降低的自发过程。而有些片条状相的细颈区或带有缺陷的区域在界面能的作用下会发生断裂,促进了片条状组织的细化和球化。在加热保温的过程中溶质原子可以充分扩散,促进了初生相的熟化过程,也就促进了细化和球化过程。

2.4 流变铸造与球化处理的Al-18%Si-5%Fe合金材料的性能

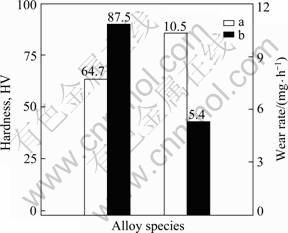

传统铝合金铸造时,Fe被认为是Al-Si合金中的有害元素,会形成含Fe的复杂相,Fe相晶体结构分为六角晶型(立方晶型)和单斜晶型,以针状或片状存在的铁相对合金的力学性能有害,Al-Si-Fe三元金属间化合物的硬度比较高,而细化和球化的铁相会起到弥散强化的作用,同时铁的加入使初晶硅分布更加均匀,提高了耐磨性,同时能够提高过共晶Al-Si合金高温力学性能和稳定性。图10所示为常规铸造Al-18%Si合金与WSP流变铸造与球化处理Al-18%Si- 5%Fe合金的硬度与耐磨性能对比。由图10可以看出,通过添加铁元素,采用WSP流变铸造和球化处理可以明显提高过共晶Al-Si合金材料硬度,Al-18%Si-5%Fe合金的维氏硬度为87.5,比Al-18%Si合金的维氏硬度(64.7)提高了35%,而Al-18%Si-5%Fe合金的磨损率为5.4 mg/h,比Al-18%Si合金的磨损率(10.5 mg/h)降低了48%。因此,该合金具有较高的硬度和优良的耐磨性能,通过挤压或锻造加工后可以制备高性能的活塞。

图9 WSP流变铸造的Al-18%Si-5%Fe合金坯料在540 ℃保温12 h后的合金组织

Fig.9 Microstructures of Al-18%Si-5%Fe alloy WSP rheocasting billet after holding at 540 ℃ for 12 h

图10 流变铸造和球化处理的Al-18%Si-5%Fe合金硬度及磨损率与Al-18%Si合金的对比

Fig.10 Comparison of Vickers-hardness and wear rate of Al-18%Si-5%Fe alloy processed by WSP rheocasting and spheroidisation treatment with those of Al-18%Si alloy: (a) Al-18%Si; (b) Al-18%Si-5%Fe

3 结论

1) 采用WSP流变铸造可以明显地改善Al-18%Si-5%Fe合金中初晶硅、Al18Si10Fe5和Al8Si2Fe相的形貌,随着浇注温度降低,各相趋于细化和球化。

2) WSP流变铸造过程中Al-18%Si-5%Fe合金组织的形成源于3种机制的作用:结晶雨带来的晶核增殖,斜板强冷却作用下晶体抑制生长和流动剪切作用下晶体破碎。

3) 通过WSP流变铸造制备的Al-18%Si-5%Fe合金铸锭在540 ℃温度下保温球化处理12 h,合金组织得到进一步改善。

4) 经WSP流变铸造和球化处理后的Al-18%Si- 5%Fe合金维氏硬度比Al-18%Si合金硬度提高了35%,达到87.5;在干摩擦条件下,制备的Al-18%Si- 5%Fe合金的磨损率比常规铸造Al-18Si合金的降低了48%,仅为5.4 mg/h。采用WSP流变铸造与球化处理可以制备组织性能优良的Al-18%Si-5%Fe合金材料。

REFERENCES

[1] 罗守靖, 田文彤, 谢水生, 毛卫民. 半固态加工技术及应用[J]. 中国有色金属学报, 2000, 10(6): 765-773.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng, MAO Wei-min. Semisolid process and application[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-773.

[2] HA T K, PARK W J, AHN S, CHANG Y W. Fabrication of spray-formed hypereutectic Al-25Si alloy and its deformation behavior[J]. Journal of Materials Processing Technology, 2002, 130/131: 691-695.

[3] LI S S, ZHAO A M, MAO W M, ZHONG X Y. Mechanical properties of hypereutectic Al-Si alloy by semisolid processing[J]. Transactions of Nonferrous Metals Society of China, 2000, 10(4): 441-444.

[4] WANG F, YANG B, DUAN X J, XIONG B Q, ZHANG J S. The microstructure and mechanical properties of spray-deposited hypereutectic Al-Si-Fe alloy[J]. Journal of Materials Processing Technology, 2003, 137(1/3): 191-194.

[5] CHEN C M, YANG C C, CHAO C G. Thixocasting of hypereutectic A1-Si-2.5Cu-1Mg-0.5Mn alloys using densified powder compacts[J]. Materials Science and Engineering A, 2004, 366(1): 183-194.

[6] ESKIN D G. Effect of melt over heating on primary solidification in aluminum alloy[J]. Zur Metallkund, 1996, 87(4): 295-301.

[7] 袁晓光, 徐达鸣, 张淑英, 李庆春. 喷射沉积Al-Si-Fe-Cu-Mg合金的微观组织和力学行为[J]. 金属学报, 1997, 33(3): 248-252.

YUAN Xiao-guang, XU Da-ming, ZHANG Shu-ying, LI Qing-chun. Microstructure and mechanical properties of spray deposited Al-Si-Fe-Cu-Mg alloy[J]. Acta Metallurgica Sinica, 1997, 33(3): 248-252.

[8] ICHIKAWA K, ISHIZUKA S. Improvement of microstructure in hypereutectic Al-Si alloys by rheocasting[J]. Transactions of the Japan Institute of Metals, 1987, 28(5): 434-444.

[9] VIVES C. Elaboration of semisolid alloys by means of new electromagnetic rheocasting process[J]. Metallurgical Transactions B, 1992, 23(2): 189-206.

[10] CHEN Z W, HE Z, JIE W Q. Growth restriction effects during solidification of aluminum alloys[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 410-413.

[11] ZHOU J, DUSZCYK J, KOREVAAR B M. As-spray-deposited structure of an Al-20Si-5Fe Osprey perform and its development during subsequent processing[J]. Journal of Materials Science, 1991, 26(19): 5275-5291.

[12] 毛卫民, 李树索, 赵爱民, 崔成林, 王德仁, 钟雪友. 电磁搅拌Al-24%Si合金的显微组织[J]. 中国有色金属学报, 2001, 11(5): 819-822.

MAO Wei-min, LI Shu-suo, ZHAO Ai-min, CUI Cheng-lin, WANG De-ren, ZHONG Xue-you. Microstructures of hypereutectic Al-24%Si alloy stirred by electromagnetic field[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 819-822.

[13] ZHONG G, WU S S, JIANG H W, AN P. Effects of ultrasonic vibration on the iron-containing intermetallic compounds of high silicon aluminum alloy with 2% Fe[J]. Journal of Alloy and Compounds, 2010, 492(1/2): 482-487.

[14] SUKUMARAN K, PAI B C, CHAKRABORTY M. The effect of isothermal mechanical stirring on an Al-Si alloy in the semisolid condition[J]. Materials Science and Engineering A, 2004, 369(1/2): 275-283.

[15] 秦 克. 过共晶Al-Si合金电磁调质的研究[D]. 沈阳: 东北大学, 2007: 92-93.

QIN Ke. Study on the electromagnetic metamorphism of hypereutectic Al-Si alloy[D]. Shenyang: Northeastern University, 2007: 92-93.

(编辑 何学锋)

基金项目:国家自然科学基金重点和面上资助项目(51034002,50974038); 中央高校基本科研业务费资助项目(N090502003)

收稿日期:2010-09-03;修订日期:2010-12-27

通信作者:管仁国, 教授, 博士; 电话: 024-83686459; E-mail: guanrg@smm.neu.edu.cn