混合方式对受控扩散凝固过共晶Al-Si合金初生硅相的影响

来源期刊:中国有色金属学报2011年第12期

论文作者:李夏 李元东 马颖 陈体军 郝远

文章页码:3033 - 3041

关键词:过共晶Al-Si合金;受控扩散凝固(CDS);初生硅

Key words:hypereutectic Al-Si alloy; controlled diffusion solidification; primary silicon

摘 要:

采用受控扩散凝固技术(CDS)制备Al-15%Si(质量分数)合金,研究混合方式对受控扩散凝固Al-15%Si合金初生硅相尺寸、形貌和分布的影响。结果表明:受控扩散凝固可以明显细化初生硅相,改善初生硅相形貌和在组织中的分布。其中,液?液混合细化效果比固?液混合细化效果好,特别是通过液态纯铝与液态Al-25%Si合金的液?液混合受控扩散凝固制备得到的凝固组织,其初生硅相平均尺寸仅为14 μm,且在组织中分布均匀。

Abstract:

The controlled diffusion solidification (CDS) was used to prepare hypereutectic Al-15%Si alloy, and the effects of mixing ways during CDS process on the size, morphology and distribution of primary silicon were studied. The results show that CDS can refine the size of primary silicon obviously. Meanwhile, the morphology and distribution of primary silicon can also be improved. The effect of liquid-liquid mixing is better than that of solid-liquid mixing. Especially, the microstructure of liquid pure Al mixing with liquid Al-25%Si alloy is the best. The particle size of primary silicon reaches up 14 μm and the primary silicon distributes uniformly in the matrix.

文章编号:1004-0609(2011)12-3033-09

李 夏1,李元东1, 2,马 颖1, 2,陈体军1, 2,郝 远1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金省部共建教育部重点实验室,兰州 730050)

摘 要:采用受控扩散凝固技术(CDS)制备Al-15%Si(质量分数)合金,研究混合方式对受控扩散凝固Al-15%Si合金初生硅相尺寸、形貌和分布的影响。结果表明:受控扩散凝固可以明显细化初生硅相,改善初生硅相形貌和在组织中的分布。其中,液-液混合细化效果比固-液混合细化效果好,特别是通过液态纯铝与液态Al-25%Si合金的液-液混合受控扩散凝固制备得到的凝固组织,其初生硅相平均尺寸仅为14 μm,且在组织中分布均匀。

关键词:过共晶Al-Si合金;受控扩散凝固(CDS);初生硅

中图分类号:TG249;TG146.2 文献标志码:A

LI Xia1, LI Yuan-dong1, 2, MA Ying1, 2, CHEN Ti-jun1, 2, HAO Yuan1

(1. State Key Laboraty of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology,

Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys, Ministry of Education, Lanzhou University of Technology,

Lanzhou 730050, China)

Abstract: The controlled diffusion solidification (CDS) was used to prepare hypereutectic Al-15%Si alloy, and the effects of mixing ways during CDS process on the size, morphology and distribution of primary silicon were studied. The results show that CDS can refine the size of primary silicon obviously. Meanwhile, the morphology and distribution of primary silicon can also be improved. The effect of liquid-liquid mixing is better than that of solid-liquid mixing. Especially, the microstructure of liquid pure Al mixing with liquid Al-25%Si alloy is the best. The particle size of primary silicon reaches up 14 μm and the primary silicon distributes uniformly in the matrix.

Key words: hypereutectic Al-Si alloy; controlled diffusion solidification; primary silicon

目前,石油资源短缺、环境污染严重,汽车使用量却越来越大,所以,提高内燃机效率、最大程度减少燃油损耗和减少尾气排放成为人们日益关注的问题。提高内燃机的效率必须从改善其使用材料着手,而活塞是内燃机最关键的部件之一。通常使用的活塞材料主要为钢、铸铁和铝合金等,但以铝合金材料为主。目前使用的铝合金活塞为铝硅类合金,铝硅合金有3类(亚共晶型、共晶型和过共晶型),应用最多的为共晶型铝硅合金。现阶段正由共晶型铝硅合金活塞向过共晶型铝硅合金活塞转变,主要是因为过共晶铝硅合金具有更优异的特点。过共晶铝硅合金具有硬度高、线膨胀系数低、耐磨性好、密度低等优点,是理想的汽车用活塞材料[1]。铝硅合金的平衡组织为初生Si、α(Al)固溶体和共晶体(Si+α(Al))。过共晶铝硅合金组织中存在大量的初生硅和共晶硅,在传统铸造过程中初生硅相极易长成粗大的板块状或长条状,严重割裂铝基体,导致铸件力学性能大大下降,且切削性能变差[2-6],限制了其大量的工业应用。所以,减小铸件组织中初生硅相尺寸、改善初生硅相形貌和分布,进而改善力学性能和加工性能,使其能够得到广泛的应用是近年来人们研究的重点[7-8]。目前,减小初生硅相尺寸、改善初生硅相形貌和分布的方法很多,主要分为两大类:一类是变质细化法,主要是通过添加P和稀土等[9-13];另一类是改进铸造方法,如快速凝固[14]、挤压铸造[15]、高压压铸[16]、熔体处理[17-20]、喷射沉 积[1, 21-22]、半固态铸造[23-24]和固液混合铸造[25]等。

扩散凝固(Diffusion solidification)是由LANGFORD和ROBERT[26]在1978年首次提出的,最初应用在铸钢上。后来经发展,LANGFORD和APELIAN[27]又提出受控扩散凝固(Controlled diffusion solidification, CDS)的概念。CDS技术是将两种不同成分、不同温度的合金熔体混合,最终凝固成同一成分目标合金的过程。自从扩散凝固概念提出之后,SAHA等[28]一直致力此方面的研究,研究内容主要是针对变形铝合金铸造化,力求解决变形铝合金在铸造过程中的热裂问题。KHALAF等[29]还对CDS技术制备亚共晶铝合金过程中,组织中非枝晶初生铝相的形成机理进行比较详细的研究,并提出相关理论假设。

本文作者采用受控扩散凝固技术(CDS)制备了过共晶Al-15%Si(质量分数)合金,以求达到减小初生硅相尺寸,改善初生硅相形貌和分布,并对受控扩散凝固混合方式进行了较为详细的研究。

1 实验

实验材料分别为:Al-25%Si过共晶型铝硅合金,液相线温度为753 ℃;ZL102合金,共晶温度为 577 ℃;纯铝,纯度为99.999%,熔点为660 ℃。所制备的目标合金为Al-15%Si合金,液相线温度为 640 ℃。

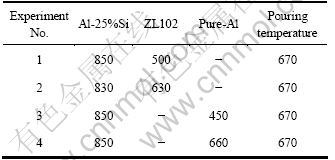

首先,根据实验材料及目标合金中硅含量(15%Si)要求进行计算、配料,然后进行实验,实验设计如表1所列。实验主要分为两类:固-液混合受控扩散凝固和液-液混合受控扩散凝固,具体实验方案如图1 所示。

表1 各材料预处理温度

Table 1 Treatment temperatures of materials (℃)

图1 受控扩散凝固混合方式示意图

Fig.1 Schematic diagram of mixing ways of controlled diffusion solidification

1) 固-液混合受控扩散凝固。将预热到预定温度的固态ZL102合金或纯铝分别加入到经熔化、精炼、除气、除渣后冷却到预定温度的液态Al-25%Si合金 熔体中。同时,将测温仪上的热电偶插入熔体内部收集温度数据,待固态材料完全熔化后停置一段时间。观察测温仪上的温度数据变化情况,待目标合金熔体各处温度均匀一致,达到预定浇注温度时浇注到金属型中成形得到d 15 mm×150 mm圆柱形锭料。

2) 液-液混合受控扩散凝固。将Al-25%Si合金经熔化、精炼、除气、除渣处理达到预定温度,与此同时,将ZL102合金或纯铝处理达到预定温度,之后将Al-25%Si合金熔体倒入ZL102合金熔体或纯铝熔体中。之后的操作与实验方案(1)相同。

最后,将制得的铸锭切割取样得到d 15 mm×15 mm的小块。经粗磨、细磨、精磨、抛光后,用体积分数为0.5%的HF水溶液腐蚀。在MEF-3金相显微镜下观察、拍照,用Image Pro Plus软件测量晶粒 尺寸。

2 结果与分析

2.1 受控扩散凝固中合金的热力学计算

受控扩散凝固技术最关键的两个过程为热量扩散和质量扩散。其中,前者所需时间较短,其扩散速度是后者的3倍[24],特别是在液-液混合时,热量扩散过程几乎是在一瞬间完成的。混合时,一个温度骤然下降,而另一个温度则迅速上升。在此过程中涉及到熔体由于过冷而产生的爆发形核、部分晶核熔化变小、原子团簇变小或长大等一系列复杂的变化过程。受控扩散凝固技术的一部分细化作用就是通过热量扩散时发生的形核过程,使熔体中形成尽可能多的晶核或形核质点,从而使目标合金凝固组织得到细化。质量扩散时,由于两种合金(高硅和低硅合金混合)在成分上的差异都与目标合金成分不同,为了达到目标合金成分,两种合金混合后只能通过扩散才能形成浓度场均匀的目标合金熔体,也即浓度差导致的质量扩散。然而,这两个过程并不是相互独立的。因为原子的扩散能力随温度的变化而变化,所以溶质原子的扩散速度、扩散均匀程度与熔体温度有着紧密联系。热量扩散直接影响质量扩散过程,进而决定最终的凝固组织。所以,探明由于热量扩散导致熔体内部发生的一系列复杂变化是非常必要的。这些复杂变化的宏观表征主要是表现在温度变化上,随着熔体温度的降低,原子团簇尺寸逐渐变大;而随着熔体温度的升高,则原子团簇尺寸减小。固态材料熔化成液态,晶粒变为原子或原子团,结构发生彻底的改变。总体来讲,受控扩散凝固过程中两种合金的温度变化带来了材料结构上的变化。

受控扩散凝固过程中两种被预处理的合金在混合之前是两个独立的个体,两者成分、存在状态各不相同,分别处于不同的热力学状态下。混合之后两者合二为一,通过热量扩散和质量扩散达到与它们成分不同的目标合金熔体,也即从两种热力学状态变化为单一热力学状态。混合后高温合金释放出热量温度降低,低温合金则吸收热量温度上升,所以,目标合金熔体的温度介于两种合金预处理温度之间。这两者热量的释放和吸收之间的关系直接决定着目标合金熔体的存在状态、热力学状态以及熔体结构,其关系可用热比系数k表示。

![]() (1)

(1)

式中:k为热比系数,即高温合金放出的热量与低温合金吸收的热量之比;Mh为高温合金的物质的量;Ml为低温合金的物质的量;?Th、?Tl为温度变化量;![]() 、

、![]() 为两种合金的比热容;Lh为单位物质的量高温合金熔体释放出的热量;Ll为单位物质的量低温固态材料熔化吸收的热量;Tp为浇注温度;T h、Tl为两种合金的预处理温度。

为两种合金的比热容;Lh为单位物质的量高温合金熔体释放出的热量;Ll为单位物质的量低温固态材料熔化吸收的热量;Tp为浇注温度;T h、Tl为两种合金的预处理温度。

![]() (2)

(2)

![]() (3)

(3)

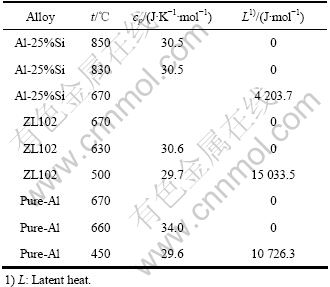

计算过程中所需数据均由Pandat软件计算获得,所需数据如表2所列,Mh/Ml值如表3所列。将式(2)和(3)以及表2和3中所需数据代入式(1)中计算,计算结果如表4所列。

k值的大小表示两种预处理合金热力学状态之间的关系,同时也影响着两种预处理合金混合后所得目标合金熔体的存在状态、内部结构和热力学状态。当k>1时,混合后高温合金释放的热量多于低温合金所吸收的热量,使目标合金熔体温度高于浇注温度。这样,熔体温度较高,原子扩散能力较强,在下降至浇注温度的一段时间内,溶质原子可以充分扩散。两种合金混合过程中形成的形核质点,即原子团簇,在熔体内部充分游离,且不会由于局部区域过冷而迅速长大。当k<1时,混合后高温合金释放的热量少于低温合金吸收的热量,使得目标合金熔体温度低于预定浇注温度。这种情况下,混合时高温合金被迅速过冷且过冷程度较深,熔体中局部区域深过冷,从而使混合时形成的初生相形核质点迅速长大。同时,混合后熔体温度较低,原子扩散能力弱,致使溶质扩散不均匀可能出现团聚现象。

表2 热力学计算所需数据

Table 2 Data used in thermodynamic calculation

表3 高温合金与低温合金的物质的量之比

Table 3 Ratio of Mh and Ml

表4 各实验热力学计算结果

Table 4 Thermodynamic calculation results of experiments

2.2 受控扩散凝固中温度随时间的变化曲线

图2所示为各受控扩散凝固实验混合过程中温度随时间的变化曲线,其中图2(a)和(c)所示为固-液混合,即实验1和3;图2(b)和(d)为液-液混合,即实验2和4。如图2(a)和(c)所示,高温Al-25%Si合金熔体由于低温固态ZL102合金或纯Al的加入,温度迅速降低,同时,低温固态ZL102合金或纯Al也逐渐被熔化成液态。且随着时间的延长,熔体温度趋于稳定。此过程中,从混合开始到目标合金熔体温度趋于稳定所需时间较长,约为20 s。根据表4计算结果可知,k值分别为0.14和0.84,高温Al-25%Si合金熔体释放的热量少于低温固态ZL102合金或纯Al熔化所吸收的热量。由于此时坩埚仍然置于加热炉内,高温的液态Al-25%Si合金所不能提供的热量可以由炉膛内热量加以补充,从而充分熔化固态材料,使最终熔体温度趋于稳定达到预定浇注温度。

如图2(b)和(d)所示,当高温Al-25%Si合金熔体加入到低温ZL102合金熔体或纯Al熔体中时,低温熔体温度瞬时升高,高温熔体温度瞬间降低,随后目标合金熔体温度开始下降直至达到预定浇注温度。在表4的热力学计算结果中,实验2和4的k值分别为2.15和42.7,计算结果与所测温度曲线相对应。实验2中高温熔体释放的热量多于低温熔体吸收的热量,但相差不大,所以,曲线上显示的混合后目标合金熔体的最高温度只是稍高于预定浇注温度;而实验4中的k值很大,曲线上显示的目标合金熔体的最高温度比预定浇注温度高很多。且随着时间的延长,熔体温度逐渐降低,并逐渐达到预定浇注温度。

图2 混合过程中Al-25%Si合金的温度—时间曲线

Fig.2 Temperature—time curves of Al-25%Si alloy during mixing: (a) Experiment 1; (b) Experiment 2; (c) Experiment 3; (d) Experiment 4

2.3 受控扩散凝固组织

图3所示为传统铸造方式下Al-15%Si合金的微观组织。由图3可以看出,组织中初生硅相呈现不规则的粗大板块状,平均尺寸为105 μm,有些板片最大长度达200 μm,且团聚现象明显。共晶硅则呈现针片状,紧密排布在一起且非常发达,针片长度为80~120 μm。

图3 传统铸造下Al-15%Si合金的微观组织

Fig.3 Microstructure of Al-15%Si alloy during traditional casting

图4所示为受控扩散凝固技术制备的合金的凝固组织。图4(a)所示为预热到500 ℃固态ZL102合金与850 ℃液态Al-25%Si合金混合后浇注得到的微观组织,即实验1。从图4(a)中可以看出,初生硅相明显细化,平均尺寸为42 μm。虽然初生硅相形貌仍为块状,但块体尺寸明显减小,有一定程度团聚,共晶硅相针片长度明显变短,平均长度为50~60 μm。图4(b)所示为630 ℃液态ZL102合金与830 ℃液态Al-25%Si合金混合后浇注得到的微观组织,也即实验2。同样可以发现,初生硅相明显细化,平均尺寸为30 μm,初生硅形貌主要为小块状和少量细长板片状,也存在一定程度的团聚,但较图4(a)有所减弱,共晶硅仍然是针片状,针片长度变短。图4(c)所示为预热到450 ℃固态纯铝与850 ℃液态Al-25%Si合金固-液混合后浇注得到的微观组织,即实验3。可以看到初生硅相细化,与图4(a)和(b)相比,尺寸有所增大,且团聚现象明显,但形貌较规整,大多为近似正方形或长方形块状,平均尺寸为37 μm,同样,针片状的是共晶硅相。图4(d)所示为660 ℃液态纯铝与850 ℃液态Al-25%Si合金液-液混合后浇注得到的微观组织,即实验4。此组织中初生硅相细化效果非常明显,初生硅相尺寸细小,平均尺寸仅为14 μm,形貌也较为规则,呈近球形,而且分布均匀。共晶硅相也得到很大程度的细化,同时从图片中可以看到初生α(Al)相大部分呈近球形。

图4 不同混合方式下合金的凝固组织

Fig.4 Microstructures of alloys during different mixing ways: (a) Solid ZL102 mixing with liquid Al-25%Si; (b) Liquid ZL102 mixing with liquid Al-25%Si; (c) Solid pure Al mixing with liquid Al-25%Si; (d) Liquid pure Al mixing with liquid Al-25%Si

图5所示为受控扩散凝固对初生硅相尺寸的影响。整体上看,通过受控扩散凝固技术得到的凝固组织中,初生硅相与传统铸造相比得到很大程度的细化。初生硅相尺寸从传统铸造的105 μm减小到40 μm,甚至更小,最小的平均尺寸仅为14 μm。这说明受控扩散凝固技术对细化过共晶Al-Si合金初生硅相有非常明显的效果。从受控扩散凝固技术混合方式来看, 液-液混合扩散对初生硅相的细化效果较固-液混合扩散细化效果好。

图5 受控扩散凝固对初生硅相尺寸的影响

Fig.5 Effect of CDS on size of primary silicon

3 讨论

受控扩散凝固是一个熔体温度场均匀化和浓度场均匀化过程。固-液混合扩散或液-液混合扩散时,将预热到一定温度的固态合金加入到高温液态合金中或者将高温液态合金加入到低温合金中,低温固态合金或熔体温度迅速上升,高温合金熔体温度迅速降低,其中温度—时间变化如图2所示。混合后,除两者之间产生大量热量交换之外,质量交换也同时进行。随着时间的延长,两者通过一系列的质量、热量交换,形成温度场、浓度场均一的目标合金组织。与受控扩散凝固相比,传统铸造过程中只有单一成分的合金熔体、单一的温度参数。不存在温度的骤变以及浓度场均匀化过程,在浇注成形时,熔体内部形成的晶核数目较少,所以,最终凝固组织中初生相尺寸较大。然而,受控扩散凝固时,熔体内部结构变化较传统铸造过程复杂得多。液态熔体被过热到很高的温度,成为一个内部成分、温度、结构均匀的组织。当加入另一种低温组织时,高温熔体温度会迅速降低,低温组织吸收高温熔体的热量温度迅速升高,最终混合后的目标合金熔体温度值介于两者温度之间。在这个过程中,熔体结构会发生一系列变化。

金属熔体的结构会随熔体温度以及成分的差异而产生变化,熔体温度较低时, 熔体中含有许多短程有序的类固相原子集团,也称为原子团簇[17, 30]。王冰 等[31]认为,金属熔体是由具有一定幻数的原子团簇和金属原子共同组成。该原子团簇能够保持一定尺寸和结构的稳定性,且与温度相关。一定温度下,某一幻数的团簇数量较多,且温度升高,团簇向小尺度团簇数量占优的方向变化,温度降低团簇则向大尺度团簇数量占优的方向发展。这些熔体中稳定存在的原子团簇是金属凝固时临界晶核的“准晶胚”。大尺度的原子团簇越多,相同凝固条件下临界晶核的“准晶胚”越多,凝固组织越细小;相反,则凝固组织粗化。受控扩散凝固混合过程中,高温熔体由于被迅速冷却,熔体内部原有的平衡状态被打破,温度降低会使熔体中原子团簇的数目迅速增多且尺寸增大。反之,低温熔体或固态合金由于吸收热量温度升高,低温熔体中原有的大尺寸原子团簇会因温度升高分散为数量更多、尺寸更小的原子团簇;低温固态合金会由固态转变为液态,结构发生彻底变化,固态组织中晶体结构变成具有大量近程有序的原子团簇结构或者原子。

固-液混合受控扩散凝固时,固态组织会被熔化成液态,形成大量的原子团簇,尺寸变小;高温熔体中原子团簇数目增多,尺寸变大。随着时间的延长,熔体内部温度梯度逐渐减小,熔体中原子团簇尺寸逐渐均匀,并随着温度的降低尺寸增大,逐渐达到临界晶核尺寸形成“准晶胚”,作为形核质点。液-液混合受控扩散凝固时,高温熔体被迅速冷却,形成大量原子团簇,低温熔体中原本存在的大尺寸原子团簇尺寸减小,并分散为数目更多的小尺寸原子团簇。当整个熔体温度场均匀后,随着温度的降低,所有原子团簇尺寸增大,逐渐达到临界晶核尺寸形成“准晶胚”,从而作为形核质点。熔体中形核质点(“准晶胚”)的大量增殖有利于最终凝固组织细化。无论是固-液混合扩散还是液-液混合扩散,都能够明显细化初生硅相,其细化效果如图4中凝固组织金相照片以及图5中初生硅相尺寸柱状图所示。

受控扩散凝固混合方式不同,其细化效果也不同。图4(a)和(c)中属固-液混合扩散,图4(b)和(d)中属液-液混合扩散。通过对比发现,液-液混合扩散细化效果较好。固-液混合扩散过程中,由于固态材料是以块状加入,因此,在固态材料被完全熔化以前,熔体内部温度梯度较大,局部过冷度大。且溶质扩散和温度变化缓慢,温度变化如图2(a)和(c)所示。随着时间的延长,混合时所形成的形核质点会因为温度梯度的存在逐渐长大,导致初生相粗大、团聚。且由于块体材料尺寸较大,在加入高温熔体中时导致局部过冷度较大。深过冷区域由于温度较低,溶质扩散能力变差,可能产生团聚。这些因素不利于最终凝固组织中初生相的细化和均匀分布。而液-液混合扩散时,整个熔体内部对流作用较强,原子扩散能力强,温度场和浓度场均一化时间较短,可以从图2(b)和(d)得以验证。正因如此,混合过程中熔体内部形成的形核质点较多而且尺寸均匀。除此之外,混合时形成的大量形核质点在对流作用下均匀分布于熔体内部并保存下来。这些因素非常有利于最终凝固组织中初生相的细化和均匀分布。

4 结论

1) 采用受控扩散凝固技术(CDS)制备过共晶Al-15%Si合金,可以明显地细化初生硅相,并改善初生硅相形貌及其在组织中的分布。

2) 热力学计算所得热比系数k值与实验过程中实际所测温度—时间变化曲线吻合。当k>1时,混合时高温合金释放的热量多于低温合金所吸收的热量,混合后目标合金熔体的温度高于预定浇注温度;k<1时,则恰好相反。

3) 与传统铸造相比,采用受控扩散凝固技术(CDS)制备共晶Al-15%Si合金所得到的凝固组织,初生硅相不仅尺寸细小,而且其形貌和在组织中分布也得到明显的改善。尤其是通过660 ℃液态纯铝与 850 ℃液态Al-25%Si合金液-液混合受控扩散凝固制备得到的凝固组织,其初生硅相平均尺寸仅为14 μm,且非常均匀地分布在组织中。

4) 受控扩散凝固混合方式不同,细化效果不同,液-液混合扩散细化效果较固-液混合扩散效果好。 固-液混合扩散时,熔体内部温度梯度较大,局部过冷度大,且溶质扩散较为缓慢,混合时所形成的形核质点会因为温度梯度的存在而逐渐长大,导致初生相粗大和团聚;液-液混合扩散时,整个熔体内部对流作用较强,温度场、浓度场均一化时间较短,原子扩散能力强,混合过程中熔体内形成的形核质点较多,有利于最终凝固组织中初生相细化和在组织中均匀分布。

REFERENCES

[1] HOU Long-gang, CAI Yuan-hua, CUI Hua, ZHANG Ji-shan. Microstructure evolution and phase transformation of traditional cast and spray-formed hypereutectic aluminium-silicon alloys induced by heat treatment[J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(3): 297-306.

[2] KAPRANOS P, KIRKWOOD D H, ATKINSON H V, RHEINLANDER J T, BENTZEN J J, TOFT P T, DEBEL C P, LASLAZ G, MAENNER L, BLAIS S, RORDRIGUEZ-IBABE J M, LASA L, GIORDANO P, CHIARMETTA G, GIESE A. Thixoforming of an automotive part in A390 hypereutectic Al-Si alloy[J]. Journal of Materials Processing Technology, 2003, 135: 271-277.

[3] 全燕鸣, 周泽华, 张发英. 过共晶铝硅合金组织对切削加工性能的影响[J]. 机械工程学报, 1998, 34(1): 1-6.

QUAN Yan-ming, ZHOU Ze-hua, ZHANG Fa-ying. Effect of structure of hypereutectic Al-Si alloy on machinability[J]. Chinese Journal of Mechanical Engineering, 1998, 34(1): 1-6.

[4] YE Hai-zhi. An overview of the development of Al-Si-alloy based material for engine applications[J]. Journal of Materials Engineering and Performance, 2003, 12(3): 288-297.

[5] 葛良琦, 颜银标, 蒋 良, 杨 军. 高硅铝合金中初晶硅形态控制研究进展[J]. 材料导报, 2007, 21(3): 70-73.

GE Liang-qi, YAN Yin-biao, JIANG Liang, YANG Jun. The approaches to ameliorate morphologies of primary silicon in hypereutectic Al-Si alloys[J]. Materials Review, 2007, 21(3): 70-73.

[6] 王杰芳, 谢敬佩, 刘忠侠, 李继文, 翁永刚, 王明星. 国内外铝硅活塞合金的研究及应用述评[J]. 铸造, 2005, 54(1): 24-27.

WANG Jie-fang, XIE Jing-pei, LIU Zhong-xia, LI Ji-wen, WENG Yong-gang, WANG Ming-xing. Review on the research and application of Al-Si piston alloy at home and abroad[J]. Foundry, 2005, 54(1): 24-27.

[7] 杨伏良, 甘卫平, 陈招科. 高硅铝合金几种常见制备方法及其细化机理[J]. 材料导报, 2005, 19(5): 42-45.

YANG Fu-liang, GAN Wei-ping, CHEN Zhao-ke. A few preparation methods and their delication mechanism for high-silicon aluminum alloy[J]. Materials Review, 2005, 19(5): 42-45.

[8] 张洪峰, 田光辉, 熊运昌, 徐通生. 铝硅合金铸造新工艺的研究与应用[J]. 铸造, 2008, 57(9): 892-894.

ZHANG Hong-feng, TIAN Guang-hui, XIONG Yun-chang, XU Tong-sheng. Research and application of new casting technique for Al-Si alloy[J]. Foundry, 2008, 57(9): 892-894.

[9] 刘 萍. 稀土Pr对过共晶Al-18%Si-Mg合金组织与性能影响的研究[J]. 铸造, 2007, 56(1): 26-30.

LIU Ping. The influence on microstructure & mechanical properties of the hypereutectic Al-18%Si-Mg casting alloys with rare earth modification[J]. Foundry, 2007, 56(1): 26-30.

[10] HE Ke-zhun, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Effect of phosphorus modification on the microstructure and mechanical properties of DC cast Al-17.5Si-4.5Cu-1Zn-0.7Mg-0.5Ni alloy[J]. Transactions of the Indian Institute of Metals, 2009, 62: 4-5.

[11] 姚书芳, 毛卫民, 赵爱民, 钟雪友. 铸造铝硅合金细化变质处理的研究进展[J]. 铸造, 2000, 49(9): 512-515.

YAO Shu-fang, MAO Wei-min, ZHAO Ai-min, ZHONG Xue-you. The development of refining and modification of cast Al-Si alloy[J]. Foundry, 2000, 49(9): 512-515.

[12] DAI Hong-shang, LIU Xiang-fa. Effects of individual and combined additions of phosphorus, boron and cerium on primary and eutectic silicon in an Al-30Si alloy[J]. Rare Metals, 2009, 28(6): 651-655.

[13] 王泽华, 毛协民, 张金龙, 欧阳志英. Sr-PM复合变质过共晶铝硅合金[J]. 特种铸造及有色合金, 2005, 25(4): 241-243.

WANG Ze-hua, MAO Xie-min, ZHANG Jin-long, OUYANG Zhi-ying. Modification of Al-Si hypereutectic alloys by Sr-PM[J]. Special Casting & Nonferrous Alloys, 2005, 25(4): 241-243.

[14] 王爱琴, 谢敬佩, 刘忠侠, 李继文, 王文焱. 快速凝固Al-Si合金的组织形态及相结构[J]. 材料热处理学报, 2008, 29(2): 99-102.

WANG Ai-qin, XIE Jing-pei,LIU Zhong-xia, LI Ji-wen, WANG Wen-yan. Microstructure and phase structure of rapidly solidified Al-Si alloy[J]. Transactions of Materials and Heat Treatment, 2008, 29(2): 99-102.

[15] 万 里, 罗吉荣, 兰国栋, 梁琼华. 挤压铸造过共晶A390合金的组织与力学性能[J]. 华中科技大学学报: 自然科学版, 2008, 36(8): 92-95.

WAN Li, LUO Ji-rong, LAN Guo-dong, LIANG Qiong-hua. Mechanical properties and microstructures of squeezed and cast hypereutectic A390 alloy[J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2008, 36(8): 92-95.

[16] CHIANG Ko-ta, LIU Nun-ming, TSAI Te-chang. Modeling and analysis of the effects of processing parameters on the performance characteristics in the high pressure die casting process of Al-Si alloys[J]. International Journal of Advanced Manufacturing Technology, 2009, 41: 1076-1084.

[17] 何树先, 孙宝德, 王 俊, 周尧和. 熔体温度处理工艺对A319合金组织和性能的影响[J]. 中国有色金属学报, 2001, 11(5): 834-839.

HE Shu-xian, SUN Bao-de, WANG Jun, ZHOU Yao-he. Effect of melt temperature treatment on solidification structure of A319 alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 834-839.

[18] 叶春生, 宋俊杰, 张新平, 潘 冶. 不同成分铝硅合金熔体混合对初生硅相细化的研究[J]. 铸造, 2002, 51(3): 145-147.

YE Chun-sheng, SONG Jun-jie, ZHANG Xin-ping, PAN Ye. Investigation on refining granules of primary Si phase by melt mixing with different components of Al-Si alloys[J]. Foundry, 2002, 51(3): 145-147.

[19] 张 蓉. 熔体过热处理对Al-Si过共晶合金凝固组织及耐磨性的影响[D]. 西安: 西北工业大学, 2000: 36-48.

ZHANG Rong. The effect of melt overheating treatment on the microstructure and resistance of Al-Si hypereutectic alloys[D]. Xi’an: Northwestern Polytechnical University, 2000: 36-48.

[20] 桂满昌, 贾 均, 李庆春. 液态过热对高硅Al-Si合金组织和性能的影响[J]. 航空材料学报, 1996, 16(1): 26-31.

GUI Man-chang, JIA Jun, LI Qing-chun. Influences of liquid superheating treatment on the structure and mechanical properties of hypereutectic Al-Si alloys[J]. Journal of Aeronautical Materials, 1996, 16(1): 26-31.

[21] WANG F, YANG B, DUAN X J, XIONG B Q, ZHANG J S. The microstructure and mechanical properties of spray-deposited hypereutectic Al-Si-Fe alloy[J]. Journal of Materials Processing Technology, 2003, 137: 191-194.

[22] 甄子胜, 赵爱民, 毛卫民, 孙 峰, 钟雪友. 喷射沉积高硅铝合金显微组织及形成机理[J]. 中国有色金属学报, 2000, 10(6): 815-818.

ZHEN Zi-sheng, ZHAO Ai-min, MAO Wei-min, SUN Feng, ZHONG Xue-you. Microstructures and formation mechanism of spray deposited hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 815-818.

[23] HOGG S C, ATKINSON H V. Inhibited coarsening of a spray- formed and extruded hypereutectic aluminum-silicon alloy in the semisolid state[J]. Metallurgical and Materials Transactions A, 2005, 36: 149-159.

[24] PAN Q Y, APELIAN D, ALEXANDROU A N. Yield behavior of commercial Al-Si alloys in the semisolid state[J]. Metallurgical and Materials Transactions B, 2004, 35: 1187-1202.

[25] 陈振华. Al-Si合金固液混合铸造[J]. 中国有色金属学报, 2000, 10(3): 349-352.

CHEN Zhen-hua. Solid-liquid mixing casting of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 349-352.

[26] LANGFORD G, ROBERT E C. Steel casting by diffusion solidification[J]. Metallurgical Transactions B, 1978, 9: 5-19.

[27] LANGFORD G, APELIAN D. Diffusion solidification[J]. Journal of Metals, 1980, 32(9): 28-34.

[28] SAHA D, SHANKAR S, APELIAN D, MAKHLOUF M M. Casting of aluminum based wrought alloys using controlled diffusion solidification[J]. Metallurgical and Materials Transactions A, 2004, 35(7): 2174-2180.

[29] KHALAF A A, ASHTRAI P, SHANKAR S. Formation of nondendritic primary aluminum phase in hypoeutectic alloys in controlled diffusion solidification (CDS): A hypothesis[J]. Metallurgical and Materials Transactions B, 2009, 40: 843-849.

[30] 王广厚. 原子团簇科学[J]. 科技导报, 1994, 10: 9-11.

WANG Guang-hou. The science of atomic clusters[J]. Science & Technology Review, 1994, 10: 9-11.

[31] 王 冰, 王建中, 曹丽云, 齐锦刚, 苍大强. 过热度对电脉冲孕育处理Al-5%Cu合金凝固组织的影响[J]. 热加工工艺, 2007, 36(13): 61-63.

WANG Bing, WANG Jian-zhong, CAO Li-yun, QI Jin-gang, CANG Da-qiang. Influence of superheat degree on structure of Al-5%Cu alloy by electric pulse modification[J]. Hot Working Technology, 2007, 36(13): 61-63.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51064017)

收稿日期:2010-11-25;修订日期:2011-05-16

通信作者:李元东,教授,博士;电话:0931-2976795;E-mail: liyd_lut@163.com