文章编号:1004-0609(2008)08-1458-08

热处理工艺对A356/SiCp性能及干滑动摩擦磨损特性的影响

金云学1,LEE Jung-moo2,KANG Suk-bong 2

(1. 江苏科技大学 先进焊接技术省级重点实验室,镇江 212003;

2. Advanced Materials Division, Korea Institute of Machinery and Materials, Changwon 641-010, Korea)

摘 要:研究分析热处理工艺对A356/SiCp复合材料的硬度、导电率及微观组织的影响,在此基础上研究复合材料的干滑动摩擦磨损特性。结果表明:固溶和T6热处理可显著提高复合材料的硬度,但降低导电率,而低温退火却比较显著地提高导电率;导电率高的低温退火态磨损特性基本与铸态一致,固溶处理及时效处理虽可有效提高硬度,但不提高耐磨性能,这表明T6热处理是否作为制动盘材料时的最佳热处理工艺,有待进一步研究;复合材料的磨损率随载荷的增加而增加,但低载荷时增加缓慢,高载荷时增加迅速;摩擦因数随着热处理工艺而变化,但对载荷变化不敏感,都在较小的范围内波动,基本是稳定的。

关键词:Al/SiCp;复合材料;干摩擦;热处理;摩擦磨损特性

中图分类号:TH 117.3; TF 1 文献标识码:A

Influence of heat treatment on properties and dry sliding frictional wear characteristics of A356/SiCp composite

JIN Yun-xue1, LEE Jung-moo2, KANG Suk-bong 2

(1.Provincial Key Laboratory of Advanced Welding Technology, Jiangsu University of Science and Technology; Zhenjiang 212003, China;

2. Advanced Materials Division, Korea Institute of Machinery and Materials, Changwon 641-010, Korea)

Abstract: The effects of different heat treatments on hardness, electric conductivity and microstructure of A356/SiCp composite were investigated. In addition, the dry sliding frictional wear characteristics were also studied. The composite’s hardness increases markedly after solid solution and T6 treatment while the conductivity reduces, and the conductivity increases markedly after the low temperature annealing. The wear experiment results show that the wear characteristic of casting composite is in good agreement with the low temperature annealing composite. The hardness increases effectively after solid solution and aging treatment while the wear resistant performance reduces. The wear rate of A356/SiCp composite increases with the increase of the applied load, under the lower load, and the wear rate increases slowly with load increasing, while under the higher load the wear rate increases quickly; the friction coefficient varies with heat treatment process and has no sensitivity to load, which varies in little range and appears stability.

Key words: Al/SiCp; composite; dry friction; heat treatment; friction and wear characteristic

随着高速列车的快速发展,对列车加速及制动性能提出了更高的要求。制动盘是高速列车簧下质量最大的零件,对列车的加速及制动性能有着重要的影响。作为高速列车的制动盘,要求具有优良的耐磨性和大而稳定的摩擦因数,要求摩擦因数随温度、载荷、速度、湿度等的变化要小,还要求优良的耐热性,大的热传导系数及小的密度等等[1]。目前,铁路列车的制动盘中广泛使用的铁基合金,因为密度大摩擦因数较小等原因,已难以满足高速列车制动盘的性能要求,因此新一代制动盘材料的研制已成为必然趋势。目前普遍认为,高速列车制动盘轻量化和性能提高的主要方法之一,就是采用低密度,并具有优良耐磨性及良好的力学和物理性能的铝基复合材料作为制动盘材 料[1?2]。

SiC颗粒增强铝基复合材料比起传统的铸铁材料,更适合制作高速列车制动盘,也具有很大的实用化的前景,使用铝基复合材料代替铸铁材料,可减少制动盘质量30%~40%,同时具有更大的导热系数和稳定的摩擦因数及优良的耐磨性。因此近年来受到广泛关注,其耐磨性能研究也成为铝基复合材料的研究热点之一[2?6]。

高速列车用铝基复合材料制动盘,尚没有实现实用化的主要原因之一就是,其基础性能研究尚有很多不足之处。制动盘材料的性能要求中,摩擦磨损特性无疑是非常重要的性能要求之一。因此对铝基复合材料的耐磨性进行了较多的研究。已有的研究发现,几乎所有的研究都是在铝合金最佳热处理工艺,即T6状态下[4?5, 7?9],采用硬度较高的工具钢为对偶材料进行磨损实验的。众所周知,铝基复合材料的T6热处理是为了提高材料的力学性能而进行的热处理工艺,其结果虽能获得最佳的强度和韧性,不一定是获得最佳摩擦磨损特性。另外,也知道热处理时所选择的加热温度和保温时间的不同,材料的力学性能和导热性等物理特性会发生变化,但这些热处理工艺的变化对复合材料耐磨性的影响的研究报道很少,而这些规律和性能对列车制动盘等以耐磨性为主要性能要求的场合,对其热处理工艺的选择应具有指导意义。为给A356/SiC复合材料制动盘的热处理提供依据,在实验中对复合材料进行不同的固溶处理和随后的时效处理以及退火处理,本文作者探讨了复合材料的热处理对材料的力学性能(硬度)及物理性能(导电率)的影响规律,实验研究和分析了热处理工艺相应材料的干滑动摩擦磨损特性及磨损机制。

1 实验

1.1 试样的制备及热处理工艺

本实验所用复合材料为MC21公司提供的Al/SiC铸锭,该复合材料用于制备高速列车制动盘样件(直径为635 mm)。增强相为SiC,其平均尺寸为20 μm,加入量为20%,基体合金为A356,化学成分为: 6.58% Si,0.44% Mg,0.39% Fe,0.01% Cu,0.01% Zn,0.11% Ti。

A356/SiC复合材料的常用T6热处理工艺为:在538 ℃保温8 h进行固溶处理,然后在155 ℃时效5 h。铝合金的固溶过程可以改变共晶硅的形态和尺寸,同时改变导热系数等物理性能,而时效处理中由于弥散析出Mg2Si,又能同时改变力学性能和物理性能。为此采用多样化的热处理工艺,以观察材料硬度和导热系数对耐磨性的影响规律,热处理工艺方法及试样的编号如表1所列。

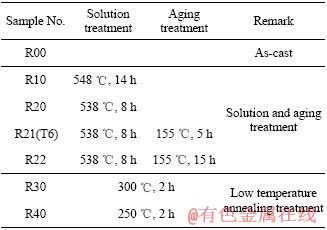

表1 热处理工艺

Table 1 Heat treatment process

1.2 显微组织观察

实验时采用Nikon光学显微镜和JEOL5800 扫描电子显微镜观察复合材料微观组织,复合材料试样采用10%HF-30% HCl-20%HNO3溶液腐蚀。材料的显微硬度,使用日本Akashi公司的HV?112型维氏硬度计和显微硬度计进行测试,测试时每个试样测试15次,取平均值。关于复合材料的导热性能,由于导热系数的测试相对比较复杂,而导电率的测定远比导热系数的测定简单迅速,且多数金属材料的导热性能和导电性能是呈正比关系,因此,本研究中采用SMP?10导电性测定仪,测定导电率,基于导电率最好的状态也是导热能力最好的状态这样的假设,选用导电率来代表导热性能。

1.3 摩擦磨损实验

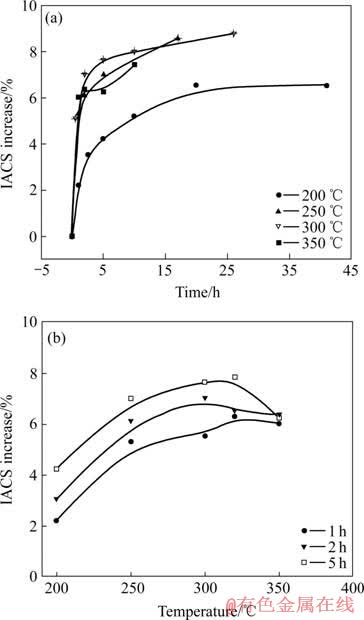

采用英国Plint and Partners公司的TE/92型销-盘式的摩擦实验装置进行干滑动摩擦磨损实验。实验机运行时,为了使销试样的受力和磨损均匀,把两个销试样同时对称装夹,实验结果取2个试样的平均值。实验时把复合材料加工成直径8 mm、长15 mm的销试样。实验时每个销试样的磨损面都用金相砂纸研磨到1000号,使它们具有相同的表面粗糙度,实验后,将销试样浸入丙酮超声清洗,用感度为0.1 mg的分析天平检测磨损质量损失,测定每个试样密度,用于计算体积磨损率,磨损率m用下式计算:

磨损对偶材料(Disc),选用AISI D2工具钢(1.5% C,11.5% Cr,0.8% V,0.75% Mo),实验前先把工具钢进行淬火加回火处理,使其硬度控制在HV730,然后加工成直径105 mm、厚度10 mm的盘状,作为盘试样,表面用磨床进行研磨以确保实验条件的一致性。

本实验中滑动速度固定为1 m/s,附加载荷在50~450 N之间变化,磨损距离确定为1 500 m,但当附加载荷超过300 N时,因为磨损严重,磨损距离缩短为750 m。

2 结果与分析

2.1 热处理工艺对材料性能的影响

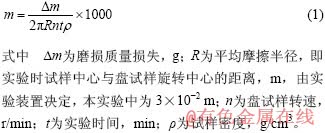

A356为铝硅合金,其中的共晶硅形态和尺寸会在一定程度上影响材料的力学性能及耐磨性能,因此有必要研究共晶硅的形态尺寸对耐磨性的影响规律。为了改变共晶硅的尺寸和形态,在不出现过烧现象的前提下,需要在较高的温度下进行固溶处理,以便最大限度地改变共晶硅的形态和尺寸。为了确定适当的固溶温度,首先进行了如图1所示的DSC实验。由DSC结果可知,复合材料加热过程中551 ℃开始到590 ℃有一个大的吸热峰,对应材料的熔解及融化潜热的吸收;冷却过程中在约574 ℃和536 ℃存在放热峰,该峰对应于冷却过程中初生α(Al)析出及共晶反应时结晶潜热的释放。再根据以往研究A356合金的热处理研究经验,选择了(548±2) ℃保温14 h的工艺,以求共晶硅形态的较大变化,选择的时效时间为14 h,处于过时效状态,目的是使弥散析出相聚集长大。另外,铝合金的固溶处理导致合金元素的大量固溶,使得材料的导热系数降低,也不利于复合材料作为高速列车制动盘材料的应用,但退火状态下,第二相的充分析出会使导电率提高,为此有必要实验研究退火处理工艺对导电率的影响规律实验。

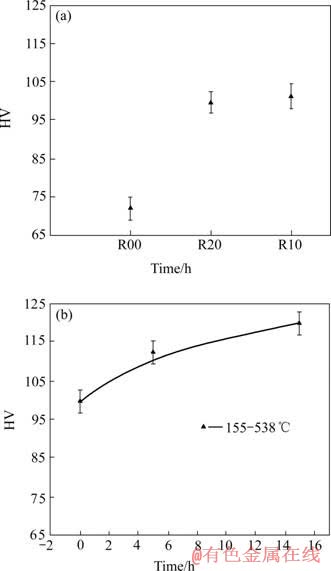

图1 复合材料的DSC结果

Fig.1 DSC analysis of composite

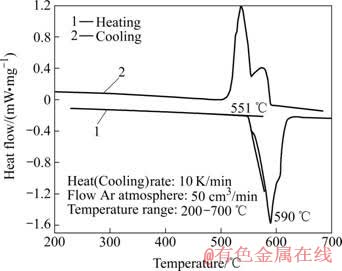

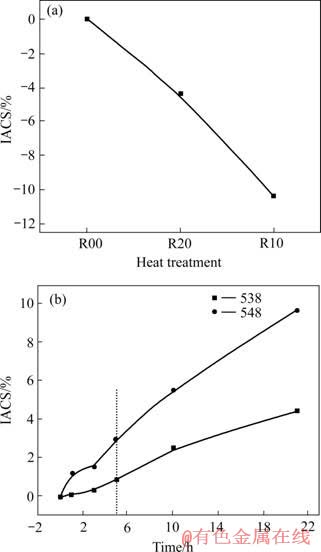

图2所示为低温退火温度对复合材料导电率的影响。可见在250 ℃和300 ℃处理时,导电率高且随保温时间加长,据此实验结果选择了250 ℃和300 ℃保温2 h的热处理工艺,此时导电率分别约增加了6.11%和7.02%。图3和图4所示为复合材料进行固溶处理和时效处理时,复合材料基体的显微硬度值变化和导电率的变化。由图可见,固溶处理本身可以提高基体材料的显微硬度(图3(a)),时效处理可进一步提高基体材料的硬度(图3(b))。基体的显微硬度值从铸态的HV0.172左右,固溶处理可增加到约HV0.1100,时效处理后进一步增加到约HV0.1120,固溶和时效处理可提高复合材料的强度,主要是基体合金在热处理过程中得到强化带来的[10]。同时复合材料的导电率,则在固溶过程中显著下降(图4(a)),其主要原因是,因为合金元素的固溶,增加了生子振动的阻力,高导电铜合金等固溶处理也会发生导电率的下降[11]。时效处理过程中,虽然由于Mg2Si等相的沉淀析出和基体中过饱和度的减小,导致导电率的提高,但正常的时效时间内(峰时效)提高幅度非常有限,恢复到铸态的导电率水平还需要20 h以上的长时间时效(图4(b))。

图2 复合材料导电率增量随低温退火时间和温度的变化

Fig.2 Variations of increment of electrical conductivity with low temperature annealing time (a) and temperature (b)

图3 固溶及时效处理与基体显微硬度的关系

Fig.3 Relations of solution (a) and aging treatment (b) to micro-hardness of matrix

图4 固溶及时效处理与导电率的变化

Fig.4 Variations of electric conductivity with solid solution (a) and aging treatment (b)

2.2 热处理后的微观组织

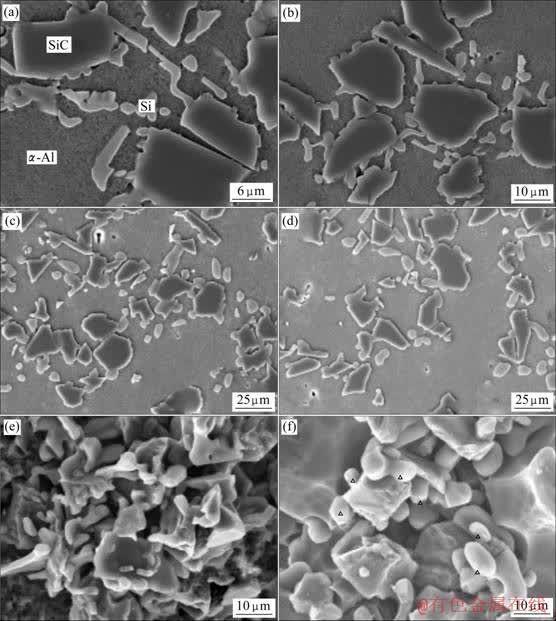

复合材料经上述热处理后的微观组织如图5所示。可见,A356/SiCp复合材料由SiC粒子,共晶硅粒子及基体金属组成,共晶硅粒子和SiC颗粒基本分布在初生α(Al)枝晶周围和枝晶之间。铸态下共晶硅以长条状相互连接(图5(a), (e)),低温退火处理时,由于脱溶使得导电率上升,但微观组织,尤其是共晶硅的形态几乎没有变化(图5(b)),固溶处理后的试样中,由于高温下共晶硅被溶解和熔断,成了短棒状或者接近球形的形态存在于基体之中(图5(c)),且当固溶温度和时间增加时,共晶硅的熔断及球状化更明显(图5(d))。固溶处理后复合材料微观组织的这些变化与文献[12?13]的研究结果基本一致。

图5 不同热处理条件下的显微组织

Fig.5 Microstructures under different heat treatments: (a) As-cast; (b) Annealing at 300 ℃; (c) Solution at 538 ℃; (d) Solution at 548℃; (e) As-cast (deep corrosion); (f) Solution at 538 ℃ (deep corrosion)

为了确认共晶硅立体形态的变化,配制特殊腐蚀剂,进行深腐蚀,并通过SEM像可观察到,铸态下相互连接的长棒状的共晶硅(图5(e)),同时也可以观察到共晶硅是在SiC粒子表面形核并长大的。固溶后的短棒状及球形共晶硅也可以通过深腐蚀试样观察到(图5(f))。通过上述实验可知固溶处理可显著改变复合材料微观组织,但提高导电率的低温退火对微观组织从SEM像中看几乎没有变化。

2.3 摩擦磨损特性

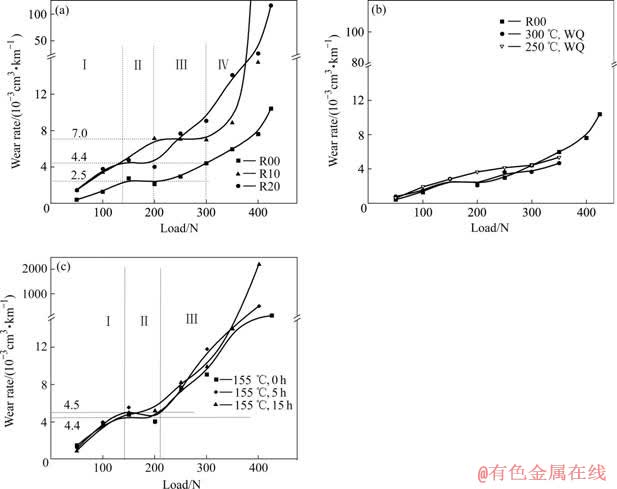

经上述热处理后的试样在相同条件下进行干滑动摩擦磨损实验,求出磨损率(单位磨损距离,单位面积的磨损体积)如图6所示。复合材料的磨损率随附加载荷的变化大体上可分为4个区域(图6(a)),把这4个区域在磨损图中分别用Ⅰ、Ⅱ、Ⅲ和Ⅳ表示(以图6(a)中的R20试样为例)。其中I区域为磨损率随载荷缓慢增加的区域,主要发生氧化磨损;Ⅱ区域为磨损率不随载荷变化,保持稳定的区域,该区域的磨损过程中存在氧化磨损,剥离磨损及粘着磨损等磨损机制,载荷进一步增加则磨损率又开始增加;进入Ⅲ区域,这时以剥离磨损为主,同时存在粘着磨损和氧化磨损。当载荷达到Ⅳ区域时,磨损率开始急剧增加,磨损以粘着磨损为主。在4个区域中,Ⅰ、Ⅱ和Ⅲ区域相当于轻微磨损,而Ⅳ区域相当于激烈磨损。

图6 摩擦磨损特性

Fig.6 Frictional wear characteristics: (a) As- cast and solid solution; (b) As-cast and low temperature annealing; (c) Aging treatment after solution

随着复合材料热处理工艺的不同,滑动摩擦中区域Ⅱ的起始载荷大小及稳定的磨损率也略有不同。铸态复合材料的稳定磨损率约为2.5×10?3 cm3/km,而538 ℃固溶时约为4.4×10?3 cm3/km,而更高的温度548 ℃固溶时约为7.0×10?3 cm3/km。但不同温度固溶的两个磨损曲线,相互缠结,差别不大,因此可以认

为固溶温度对复合材料滑动摩擦磨损特性几乎没有影响。实验中T6热处理,虽然有效提高材料的硬度,但耐磨性能却不如铸态材料和低温退火材料,其中原因已在文献[14]中进行了详细的分析和研究,这里不再叙述。

铝合金的时效处理虽然可以较显著的提高复合材料的显微硬度,但由图6(c)可见,不同硬度的试样(时效时间不同)磨损率曲线几乎重叠,表明复合材料基体时效过程中弥散析出硬质点,可以提高材料强度和硬度,但耐磨性几乎没有影响。低温退火处理的复合材料,导电率明显提高,但耐磨性曲线与铸态基本重叠,表明导热系数的增加,在销-盘式的磨损条件下,对复合材料耐磨性不产生影响(图6(b)),其原因可能与磨损实验设备的结构有关。

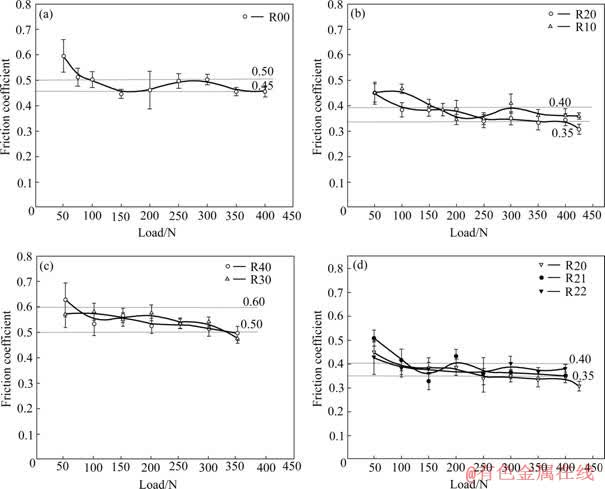

作为制动盘材料,不仅要有优良的耐磨性,同时因为迅速的制动,还要求具有对环境变化不敏感的摩擦因数。图7所示为摩擦因数随附加载荷的变化。可见不同热处理条件下,虽有着不同大小的摩擦因数值,但共同的特点是150 N以下的低载荷中,摩擦因数随载荷的增加而减少,但超过150 N的载荷范围内是稳定的,铸态材料稳定在0.45~0.50范围,固溶及时效的材料稳定在0.35~0.40,低温退火的材料则稳定在0.5~0.60。总体上看,不管热处理工艺如何,摩擦因数随着载荷增加而降低,这主要是因为当载荷较小时,复合材料和偶件材料表面的微凸点间接触面积小,粘着严重,表现出较大的摩擦因数,随载荷的增加,微凸点被压缩变形,粗糙度减少接触面积增大,宏观上摩擦因数值也降低。这与文献[15]的结果相一致。

图7 摩擦因数随载荷的变化

Fig.7 Variations of friction coefficients with load: (a) As-cast; (b) Solution treatment; (c) Low temperature annealing; (c) Aging treatment after solution

3 结论

1) 低温退火可使复合材料的导电率提高6%~ 8%,但固溶处理却使导电率降低约10%,时效只能有限地提高导电率。

2) 铸态材料和低温退火态复合材料的耐磨特性基本一致,固溶处理及时效处理虽可有效提高硬度,但不提高耐磨性能,因此T6热处理不一定要作为制动盘材料时的最佳热处理工艺。

3) 磨损率随载荷的增加而增加,但低载荷时增加缓慢,到高载荷时增加迅速。

4) 复合材料的摩擦因数,随着热处理工艺而变化,但对随载荷变化不敏感,都在较小的范围内波动,是稳定的。

REFERENCES

[1] 宋宝韫, 高 飞, 陈吉光, 于庆军, BERTHI Y. 高速列车制动盘材料的研究进展[J]. 中国铁道科学, 2004, 25(4): 11?18.

SONG Bao-yun, GAO Fei, CHEN Ji-guang, YU Qing-jun, BERTHI Y. Development of materials for high speed train brake discs[J]. China Railway Science, 2004, 25(4): 11?18.

[2] 黄 楠, 刘世楷. 我国高速列车制动摩擦材料的发展方向[J]. 铁道车辆, 1993(9): 29?31.

HUANG Nan, LIU Shi-kai. Development direction of braking friction materials for high-speed trains in China[J]. Rolling Stock, 1993(9): 29?31.

[3] BLAN P J, MCLAUGHLIN J C. Effects of water films and sliding speed on the frictional behavior of truck disc brake materials[J]. Tribology International, 2003, 36: 709?715.

[4] KIOURTSIDIS G E, SKOLIANOS S M. Wear behavior of artificially aged AA2024/40_m SiCp composites in comparison with conventionally wear resistant ferrous materials[J]. Wear, 2002, 253: 946?956.

[5] 戈晓岚, 许晓静, 蔡 兰, 陈康敏, 居志兰. SiCp含量和尺寸对Al基复合材料摩擦学特性的影响[J]. 中国有色金属学报, 2005, 15(3): 458?462.

GE Xiao-lan, XU Xiao-jing, CAI Lan, CHEN Kang-min, JU ZHi-lan. Effect of grain size and content of SiCp on tribology characterization of SiCp/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 458?462.

[6] MURATOGLU M, AKSOY M. Abrasive wear of 2124Al-SiC composites in the temperature range 20?200 ℃[J]. Journal of Materials Processing Technology, 2006, 174: 272?276.

[7] GUI Man-chang, KANG Suk-bong, LEE Jung-moo. Dry sliding wear behavior of spray deposited AlCuMn alloy and AlCumn/SiCp composite[J]. Journal of Materials Science, 2000, 35: 4749?4762.

[8] GUI Man-chang, KANG Suk-bong, LEE Jung-moo. Influence of porosity on dry sliding wear behavior in spray deposited Al- 6Cu-mn/SiCp composite[J]. Materials Science and Engineering A, 2000, 293: 146?156.

[9] NATARAJAN N, VIJAYARANGAN S, RAJENDRAN I. Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material[J]. Wear, 2006, 261, 812?821.

[10] 樊建中, 肖伯律, 左 涛, 桑吉梅, 张维玉, 徐 骏, 石力开. 热处理对SiCp/Al复合材料强度和塑性的影响[J]. 中国有色金属学报, 2006, 16(2): 228?234.

FAN Jian-zhong, XIAO Bo-lü, ZUO Tao, SANG Ji-mei, ZHANG Wei-yu, XU Jun, SHI Li-kai. Effect of heat treatment on strength and ductility of SiCp/Al composite[J]. The Chinese Journal of Nonferrous Metal, 2006, 16(2): 228?234.

[11] 王冀恒. 高强高导CuNiCrSi铜合金冶金质量及强化工艺研究[D]. 镇江: 江苏科技大学, 2005.

WANG Ji-heng. Metallurgical quality and strengthening technology of the CuNiCrSi alloy[D]. Zhenjiang: Science and Technology of Jiangsu University, 2005.

[12] SHIVKUMAR S, RICCI S, STEENHOFF B. An experimental study to optimize the heat treatment of A356 alloy[J]. AFS Transactions, 1989, 238: 791?810.

[13] SAMUEL F H, AMUEL A M. Effect of heat treatment on the microstructure tensile properties, and fracture behavior of permanent mold Al-10wt pct Si-0.6 wt pct Mg/SiC/10p composite castings[J]. Metallurgical and Materials Transactions A, 1994, 25A: 2247?2263.

[14] JIN Yun-xue, LEE Jung-moo, KANG Suk-bong. Dry sliding wear properties of A356/SiCp composites(II): Comparison of wear properties wity heat treatment[J]. J Kor Inst Met & Mater, 2007, 45(3): 179?185.

[15] 张永振, 邱 明, 上官宝, 铁喜顺, 马东辉. 高速干摩擦条件下铝基复合材料的摩擦磨损行为研究[J]. 摩擦学学报, 2005, 25(4): 343?347.

ZHANG Yong-zhen, QIU Ming, SHANG Guan-bao, TIE Xi-shun, MA Dong-hui. Friction and wear behavior of the materials under very high sliding velocity[J]. Tribology, 2005, 25(4): 343?347.

收稿日期:2007-11-21;修订日期:2008-02-24

通讯作者:金云学,教授,博士;电话:13775361375;E-mail: jinyunxue@126.com

(编辑 陈爱华)