DOI: 10.11817/j.ysxb.1004.0609.2021-39794

P元素添加对Cu-15Ni-8Sn合金干摩擦磨损性能的影响

郭诚君1,陈金水1,汪 航1,肖翔鹏1, 2,黄 浩1, 2,杨 斌1

(1. 江西理工大学 材料冶金与化学学部,赣州 341000;

2. 江西先进铜产业研究院,鹰潭 335000)

摘 要:研究Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金在400 ℃下时效不同时间以及在不同法向载荷下的磨损行为,采用扫描电镜(SEM)和三维表面轮廓仪观察磨痕和磨屑颗粒的形貌及成分分布。结果表明:相对于Cu-15Ni-8Sn而言,Cu-15Ni-8Sn-0.2P合金具有更高的峰值硬度、抗过时效能力及耐摩擦磨损性能。时效后的Cu-15Ni-8Sn-0.2P合金在往复干摩擦过程中的磨损方式主要以磨粒磨损为主,但在400 ℃时效15 h时,Cu-15Ni-8Sn合金黏着磨损量增加,这与合金硬度的降低有关。两种合金磨损量的大小与合金的硬度成反比,与法向载荷成正比。此外,相对于Cu-15Ni-8Sn合金而言,Cu-15Ni-8Sn-0.2P合金具有更好的耐高载荷摩擦磨损性能。随着法向载荷增加,两种合金发生疲劳磨损的概率增加。

关键词:Cu-15Ni-8Sn-0.2P合金;干摩擦;磨损行为;硬度

文章编号:1004-0609(2021)-05-1156-12 中图分类号:TG146.1 文献标志码:A

引文格式:郭诚君, 陈金水, 汪 航, 等. P元素添加对Cu-15Ni-8Sn合金干摩擦磨损性能的影响[J]. 中国有色金属学报, 2021, 31(5): 1156-1167. DOI: 10.11817/j.ysxb.1004.0609.2021-39794

GUO Cheng-jun, CHEN Jin-shui, WANG Hang, et al. Effect of P addition on dry sliding wear properties of Cu-15Ni-8Sn alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(5): 1156-1167. DOI: 10.11817/j.ysxb.1004.0609.2021-39794

Cu-15Ni-8Sn合金因其具有高的强度和硬度[1],良好的耐磨性[2]和抗应力松弛性能[3],且制备过程安全无毒,被认为是Cu-Be合金最有希望的替代材料之一[4]。Cu-15Ni-8Sn合金除了被用来制作电位器、继电器接触件、开关触片等弹性材料以外[5-6]。近年来,因其在重载轴承领域表现出优良的性能,被广泛应用于制造耐磨轴承、轴瓦、轴套以及牙轮钻头[7-8]。

Cu-Ni-Sn合金是一种典型的时效强化型铜合金,在润滑和干滑动条件下均显示出优异的耐摩擦磨损性能。张少宗等[2]在研究Cu-15Ni-8Sn合金干滑动条件下摩擦磨损行为时发现,合金硬度的大小对摩擦因数影响很小,但与磨损率成反比,当胞状沉淀的体积分数为10%时,合金的磨损率最低。成金娟等[7]研究Cu-15Ni-8Sn合金在油润滑条件下的摩擦磨损行为时发现,合金的磨损率随着法向载荷的增加而增加,随着滑动速度的增加而降低,根据磨损程度的不同,其磨损机制也不同。油和合金发生化学反应,生成相应的硫化物会加剧合金的分层磨损。此外,成金娟等还着重研究了Cu-15Ni-8Sn- 0.2Y合金[9]在去离子水和海水中以及Cu-15Ni-8Sn- 0.2Nb合金[10]在油摩擦条件下的摩擦磨损行为。然而,上述研究缺乏对微合金化处理前后合金的耐摩擦磨损性能比较分析,且对微合金化处理后合金在干滑动条件的摩擦磨损行为研究较少。

根据ZHAO和NOTIS等[11-12]的研究可知,Cu-Ni-Sn合金时效析出相的转化序列为:调幅组织→DO22有序相/L12有序相→γ-DO3相(胞状沉淀)。胞状沉淀的大面积产生,会导致合金力学性能和耐磨擦磨损性能急剧下降[1, 13-14],为了制备出性能优异的Cu-15Ni-8Sn合金,在提高合金性能的同时,采取必要的手段抑制其胞状沉淀的形成十分必要。微合金化作为抑制Cu-15Ni-8Sn合金胞状沉淀形成的有效方法之一,得到了广泛的研究。MIKI等[15]采用定量金相法研究了Cr、Al、Fe、In和Mn等元素的添加对Cu-10Ni-8Sn合金胞状沉淀的影响,结果表明,这些元素的加入均可抑制胞状沉淀的形成和长大。此外,Ti[16]、Si[17-19]、Co[20]、Nb[21-23]、V[24-25]和Fe[26]等元素的添加也可有效地抑制胞状沉淀的形成和长大。

然而,目前为止,大部分微合金化的研究主要集中于对胞状沉淀的抑制及其对力学性能的提升,对微合金化后Cu-Ni-Sn合金的耐摩擦磨损性能研究极少,同时对于其摩擦磨损行为及机理研究更是匮乏。磨损是材料失效的主要形式之一。轴承、轴瓦、轴套等零部件在使用过程中会因为磨损产生材料表面的损耗,导致零部件的尺寸发生改变,从而影响其使用寿命。为了满足各行业对高摩擦磨损性能材料的需求,有必要对微合金化后Cu-Ni-Sn合金的摩擦磨损行为进行深入的研究,该项工作的开展对于工业生产具有重要的指导作用。

本课题组前期研究表明[27],在Cu-15Ni-8Sn合金中添加P元素可以析出Ni10SnP3相,有效抑制胞状沉淀的形核和长大。为了更全面地了解P元素对Cu-15Ni-8Sn合金综合性能的影响,本文结合前期的研究结果,对比研究不同时效状态下Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金的摩擦磨损行为,并对不同载荷条件下合金的摩擦磨损行为和组织演变进行了观察。

1 实验

Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金选用纯铜杆、纯锡粒、纯镍块和纯钴片,在Ar2气氛保护下,采用真空感应熔炼设备熔炼浇铸而成,浇铸模具的尺寸为d 45 mm×110 mm。铸锭经过(850 ℃, 15 h)的退火处理后,迅速水冷,而后经过多道次轧制使其总变形量为70%。采用电火花线切割设备将轧制后的板材切割成20 mm×20 mm×3 mm的样品后,分别在400 ℃时效处理30 min~15 h。时效后的样品经过600~2000目的SiC砂纸多道次研磨并抛光后,在空气中于HSR-2M型高速往复摩擦磨损实验仪(兰州中科凯华科技开发有限公司生产)进行球-盘往复式滑动摩擦。对偶摩擦副材质为直径3.5 mm的Si3N4球,往复长度为10 mm,加载时间为20 min,电机转速为300 r/min(摩擦往复频率 5 Hz),载荷分别为20 N、50 N、80 N、100 N和120 N。摩擦磨损实验后,采用NonaMap 500LS 型表面轮廓仪对磨痕的二维和三维轮廓进行表征(扫描距离1 mm,扫描速率100 μm/s),最后使用式(1)计算平均体积磨损率[28]。

(1)

(1)

式中:S为磨痕截面轮廓面积,m2;l为磨痕长度,m;F为法向载荷,N;L为摩擦行程,m;t为摩擦时间,s;f为摩擦往复频率,Hz。

利用扫描电子显微镜(SEM, Tescan-Orsay Mira3, LMH)观察试样的显微组织和形貌,利用透射电子显微镜(TEM,FEI-Tecnai-G20)观察样品的形貌和结构,TEM样品的制备采用电解双喷+离子减薄的方法,电解液为35%硝酸+65%甲醇(体积分数),温度为-30 ℃。样品的硬度采用显微维氏硬度计(华银200HVS-5)在4.9 N载荷下测定。

2 结果与讨论

2.1 显微组织和力学性能

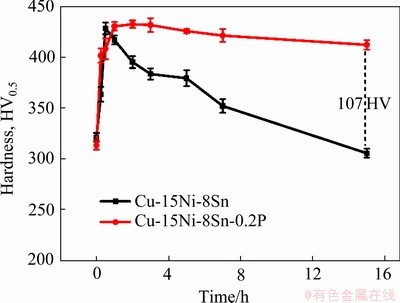

图1所示为70 %冷轧后Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金在400 ℃时效不同时间的硬化曲线。由图1可知,两组合金的硬度随时效时间的增加先增大后减小,P元素的添加可提高Cu-15Ni-8Sn合金的峰值硬度,同时可明显改善Cu-15Ni-8Sn合金的抗过时效能力。Cu-15Ni-8Sn合金的峰值硬度为428 HV0.5(30 min),而Cu-15Ni- 8Sn-0.2P合金的峰值硬度为432 HV0.5(3 h)。当时效时间延长至15 h时,Cu-15Ni-8Sn合金的硬度为305 HV0.5,Cu-15Ni-8Sn-0.2P合金的硬度为412 HV0.5;相对于Cu-15Ni-8Sn合金而言,Cu-15Ni- 8Sn-0.2P合金的硬度高出107 HV0.5。

图1 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金400 ℃时效不同时间的硬度曲线

Fig. 1 Hardness curves of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys aged at 400 ℃ for different time

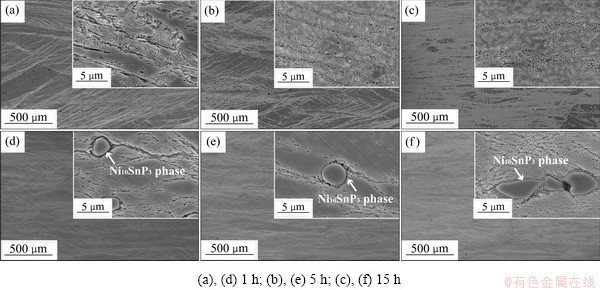

图2所示分别为70%冷轧后Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金在400 ℃下时效1 h、5 h和15 h的二次电子图。由图2可观察到明显的变形态组织,晶粒呈纤维状沿着轧制方向拉长变形。时效1 h时(见图2(a)和(d)),在Cu-15Ni-8Sn合金中可观察到胞状沉淀的形成,其沿着晶界析出并向晶粒内部延伸,呈片层状分布(见图2(a))。随着时效时间的增加,胞状沉淀的体积分数增加,在时效15 h时,Cu-15Ni-8Sn合金的基体几乎被胞状沉淀覆盖(见图2(c)),而此时,在Cu-15Ni-8Sn-0.2P合金中仅观察到少量的胞状沉淀从晶界析出(见图2(f))。这主要与Ni10SnP3相的形成有关,P元素的添加在凝固和时效过程中会形成Ni10SnP3相,主要沿着晶界分布,在时效过程中可占据胞状沉淀的形核位置,从而有效抑制胞状沉淀的形核和长大。

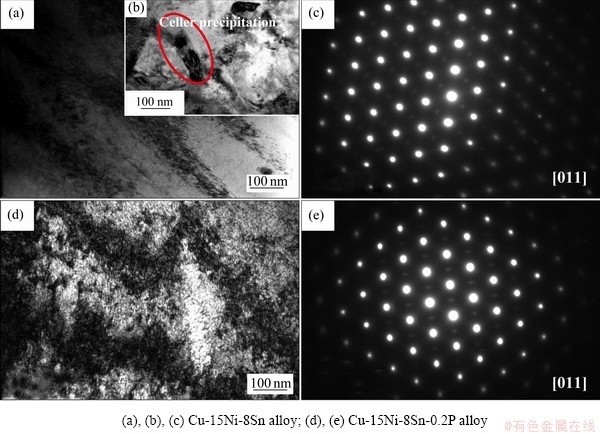

图3所示为Cu-15Ni-8Sn合金和Cu-15Ni-8Sn- 0.2P合金在400 ℃时效1 h的TEM像及对应的选区电子衍射谱(SADP)。由图3(a)和(d)所示,Cu-15Ni-8Sn合金具有优异的冷加工硬化特性,高密度位错缠结在一起并形成位错壁。由于高密度位错对衍衬像的干扰,难以观察到明显的调幅组织。此外,时效1 h时,Cu-15Ni-8Sn合金中可观察到胞状沉淀的形成,这与图2(a)的结果一致。图3(c)和(e)所示为Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金沿着[011]Cu晶带轴的SADP图,从图中可观察到超点阵斑点的存在,说明合金此时已经发生了有序化,这是合金时效强化的主要原因[1]。

2.2 时效不同时间合金的摩擦磨损行为

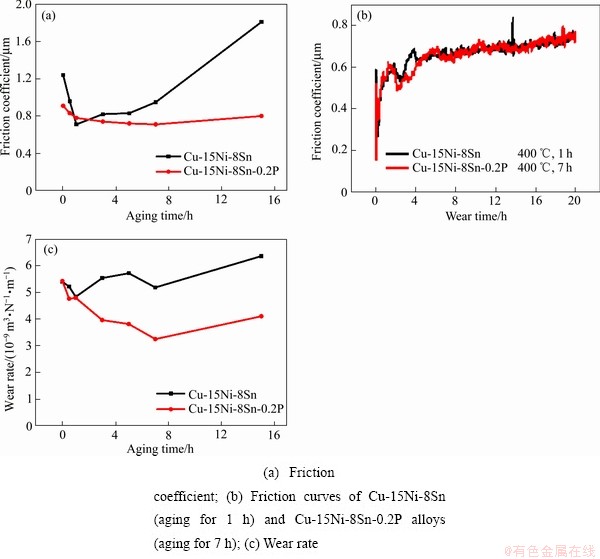

图4所示为Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金在载荷为50 N时的平均摩擦因数和磨损率随时效时间的变化曲线。由图4(a)可知,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的摩擦因数随着时效时间的延长先降低后增加,两组合金分别在400 ℃时效1 h和7 h时具有最小的摩擦因数。此外,在时效3 h之后(包括3 h),Cu-15Ni-8Sn和Cu-15Ni-8Sn- 0.2P合金之间摩擦因数的差值越来越大。图4(b)所示为Cu-15Ni-8Sn(400℃时效1 h)和Cu-15Ni-8Sn-0.2P合金(400 ℃时效7 h)摩擦因数随摩擦时间的变化曲线,两组合金均在摩擦初期出现摩擦因数陡然增高而后降低,最后随时间延长趋于平稳状态的现象,这说明合金在摩擦过程中经历了磨合和稳定磨损阶段。磨损开始之前,磨球和合金接触面光滑,随着摩擦的进行,接触面积迅速扩大而发生破坏,表面黏着和塑性变形等作用导致摩擦因数迅速增加。随着摩擦时间的延长,磨屑在摩擦过程中发生变形、氧化,不断地形成和排出,达到动态平衡状态,因此,摩擦因数变化缓慢进入稳定磨损阶段。

图2 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金400 ℃时效不同时间的二次电子图

Fig. 2 Secondary electronic diagrams of Cu-15Ni-8Sn alloy((a)-(c)) and Cu-15Ni-8Sn-0.2P alloy((d)-(f)) aged at 400 ℃ for different time

图3 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金400 ℃时效1 h的TEM像及其对应的选区电子衍射图

Fig. 3 TEM images of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys aged at 400 ℃ for 1 h and corresponding selected area electron diffraction patterns

图4 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金摩擦因数和磨损率随时效时间及摩擦时间的变化曲线

Fig. 4 Curves of friction coefficient and wear rate of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys with aging time and wear time

图4(c)所示为两组合金磨损率随时效时间的变化曲线,其变化趋势与摩擦因数一致。随着时效时间的增加,两组合金磨损率先降低后增加,且同一时效状态下,Cu-15Ni-8Sn-0.2P合金具有更低的磨损率。Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的最低磨损率分别为4.83×10-9和3.25×10-9 m3/(N·m)。这说明Cu-15Ni-8Sn-0.2P合金具有更好的耐摩擦磨损性能。

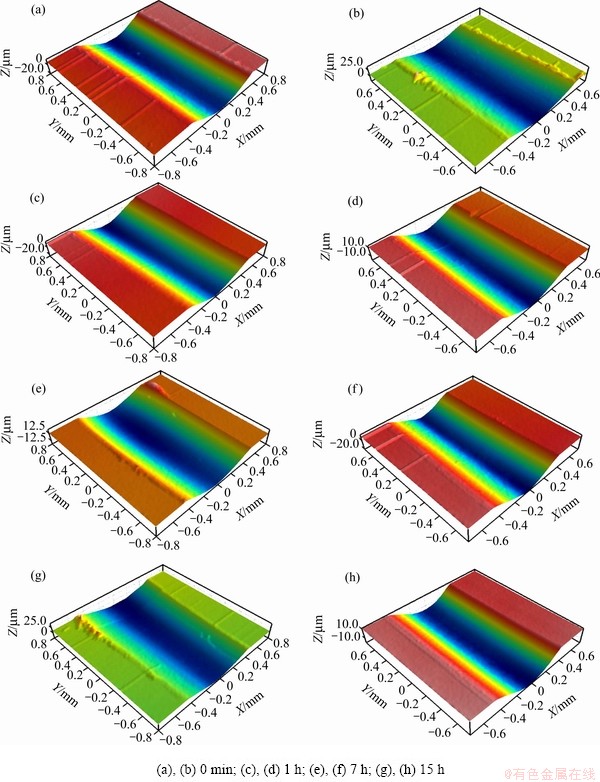

图5所示为400 ℃时效0 h、1 h、7 h和15 h的Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金磨痕的三维轮廓模拟图。合金磨痕为椭圆形凹坑,最大深度在磨痕中心位置,该区域受到的接触应力最为集中,塑性变形最为严重。合金磨痕的三维形貌变化趋势与图4(b)磨损率的变化趋势一致。

图5 时效不同时间的Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金磨痕的三维形貌

Fig. 5 Three dimensional morphologies of wear marks of Cu-15Ni-8Sn((a), (c), (e), (g)) and Cu-15Ni-8Sn-0.2P((b), (d), (f), (h)) alloys aged at different time

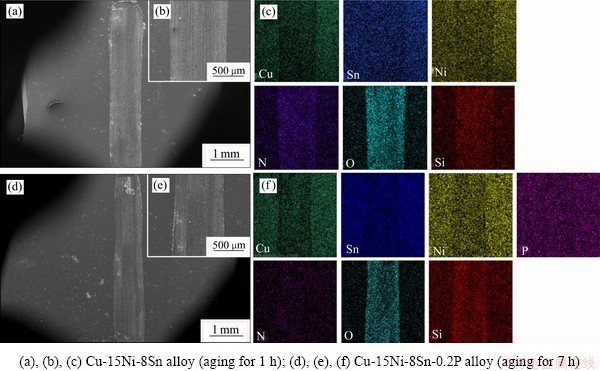

图6 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金磨痕的SEM像及其能谱面扫描分析结果

Fig. 6 SEM images and corresponding EDS mapping analysis results of wear marks of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys

图6所示为400 ℃时效1 h的Cu-15Ni-8Sn合金和400 ℃时效7 h的Cu-15Ni-8Sn-0.2P合金磨痕的SEM像及其能谱(EDS)面扫图。由图6(a)、(b)、(d)、(e)可知,Cu-15Ni-8Sn-0.2P合金(757 μm)的磨痕宽度明显小于Cu-15Ni-8Sn合金(918 μm),这也说明Cu-15Ni-8Sn-0.2P合金具有更好的耐摩擦磨损性能。同时,对磨痕形貌进行EDS面扫,其结果如图6(c)和(f)所示。在两组合金的磨痕处均可观察到O元素的富集,这说明在高速往复摩擦过程中基体与O2结合生成了氧化物,氧化磨损是合金发生磨损的一个重要原因。此外,还可以在两组合金的磨痕形貌中发现Si元素的富集,这说明在摩擦的过程中磨球与基体发生了材料的迁移,Si元素因为黏着磨损转移到基体表面,使得合金磨痕的化学成分发生了改变,该区域发生了黏着磨损。

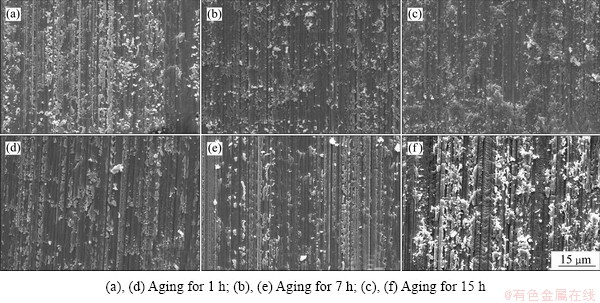

图7所示分别为时效1 h、7 h和15 h的Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金磨痕的SEM像。时效1 h时,两组合金试样均发生了严重的塑性变形,合金磨损表面均存在很多深浅不一的犁沟和划痕,且磨损表面附着大量被压扁的块状或颗粒状磨屑,呈现出典型的磨粒磨损特征。往复摩擦过程中,由于磨球Si3N4的硬度远大于Cu-15Ni-8Sn合金的硬度,磨球与基体表面接触后微凸体之间相互咬合剪切,导致脱落的磨屑中含有一些硬质颗粒;这些硬质颗粒在磨球的作用下压入合金,通过往复式摩擦作用,产生磨粒磨损的犁沟。随着摩擦的进行,大部分磨屑在磨球应力的作用下,沿运动方向被推出摩擦区域,但也存在部分磨损碎片和氧化物颗粒不易被排出,从而填入微凹坑中。此外,还可观察到少量的黏着坑,表明两组合金也发生了黏着磨损,但此时还是以磨粒磨损为主。随着时效时间的延长,在时效15 h时,在Cu-15Ni-8Sn合金中观察到大量的黏着坑(见图7(c)),此时Cu-15Ni-8Sn合金以黏着磨损为主;而Cu-15Ni-8Sn- 0.2P合金磨痕主要由深而宽的犁沟组成,并未观察到大量的黏着坑(见图7(d)),还是以磨粒磨损为主。

2.3 不同载荷下的摩擦磨损行为

图7 时效不同时间的Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金磨痕的SEM像

Fig. 7 SEM images of wear marks of Cu-15Ni-8Sn((a), (b), (c)) and Cu-15Ni-8Sn-0.2P((d), (e), (f)) alloys aged for different time

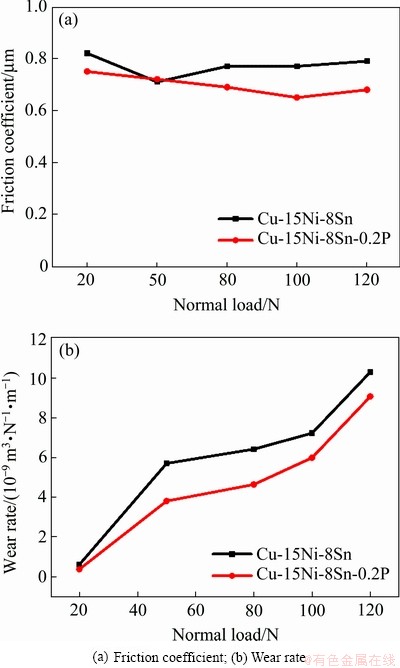

载荷是影响合金磨损量的一个关键因素,比摩擦因数对磨损量的影响更为显著。根据前面的研究结果可知,400 ℃时效1 h的Cu-15Ni-8Sn合金和400 ℃时效7 h的Cu-15Ni-8Sn-0.2P合金具有最好的耐摩擦磨损性能,因此本小节研究这两组合金在不同载荷下的摩擦磨损行为。图8(a)和(b)所示分别为这两组合金的摩擦因数和磨损率随载荷变化的曲线,由图8(a)可知,两组合金的摩擦因数均随着载荷的增加先减小后增大,且在同一载荷下,Cu-15Ni-8Sn-0.2P合金具有更低的摩擦因数。Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金分别在载荷为50 N和100 N时具有最小的摩擦因数,其值分别为0.71和0.65。由图8(b)可知,两组合金的磨损率随着载荷的增加不断增加,同样的,在同一载荷下,Cu-15Ni-8Sn-0.2P合金具有更低的磨损率。综上可知,Cu-15Ni-8Sn-0.2P合金具有更好的耐摩擦磨损性能。

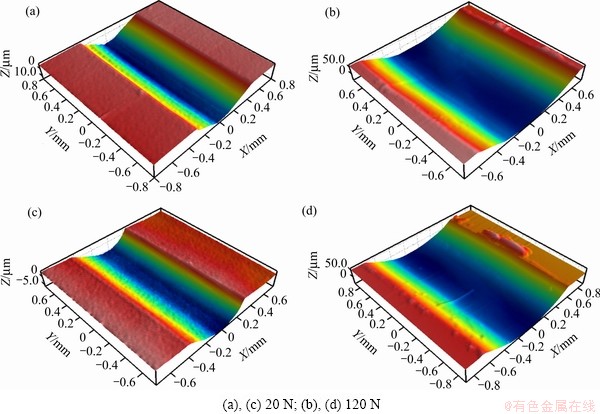

图9所示为Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金分别在20 N和120 N载荷下磨痕的三维形貌图。随着法向载荷的增大,两组合金磨痕宽度逐渐增大。当法向载荷为20 N时,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的磨痕宽度分别为774和646 μm;当法向载荷增大到120 N时,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的磨痕宽度分别增加至1272和1215 μm。相对Cu-15Ni-8Sn合金而言,同一载荷下,Cu-15Ni-8Sn-0.2P合金具有更小磨痕宽度,因此其磨损体积也更小。

图8 Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金摩擦因数和磨损率随载荷的变化曲线

Fig. 8 Curves of friction coefficient and wear rate of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys with load

图9 Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金在不同载荷下磨痕的三维形貌图

Fig. 9 Three dimensional morphologies of wear marks of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys under different loads

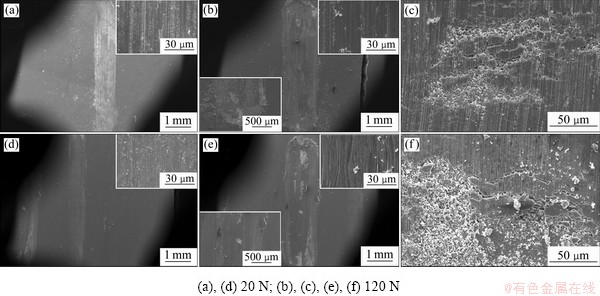

图10所示为Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金分别在20 N载荷和120 N载荷下磨痕的SEM像。由图10(a)和(d)可知,当法向载荷为20 N时,由于载荷较小,此时部分磨损碎片和氧化物颗粒不易被排出,而被填入微凹坑中,夹在磨球与合金基体之间,对基体表面进行磨粒磨损。因此,在两组合金的磨痕表面存在轻微划痕区,由一条条犁沟组成,此时磨损方式主要为磨粒磨损。当法向载荷增加到120 N时,由图10(b)和(e)可知,两组合金的磨痕形貌主要由平整区和局部疲劳剥落坑组成;相对于载荷20 N而言,犁沟深度和密度明显减少,但疲劳剥落坑增多,且凹坑处可观察到明显的裂纹和颗粒状材料(见图10 (c)和(f))。此时,两组合金的磨损机制主要是磨粒磨损和疲劳剥落磨损。

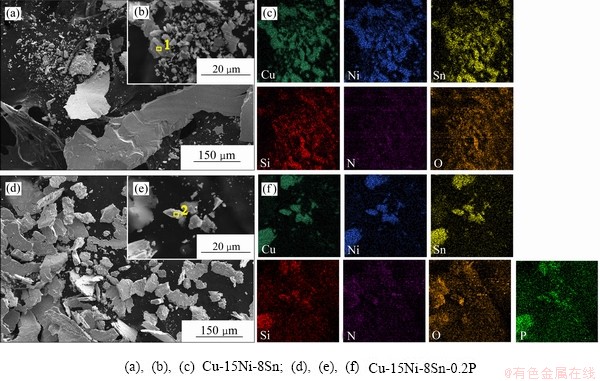

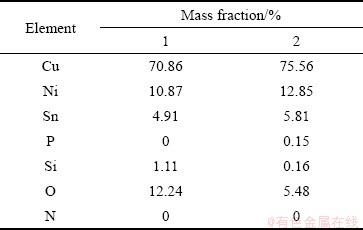

图11所示为Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金磨屑碎片的SEM像及其对应的EDS面扫描图。由图11(a)和(d)可知,两组合金的磨屑主要由大的扁平片状磨屑和细小的颗粒状磨屑组成。由图11(c)和(f)可知,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的磨屑主要由Cu、Ni、Sn、O、Si元素组成,此外,在Cu-15Ni-8Sn-0.2P合金的磨屑中还发现了P元素的富集。表1所列为图11(b)和(e)中“1”和“2”位置对应的EDS点扫描结果,该结果与EDS面扫描结果一致。Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金磨屑的O含量分别为12.24%和5.48%(质量分数)。两组合金在往复摩擦过程中,磨球与合金基体之间发生了材料的迁移。磨屑的产生来自于往复摩擦过程中磨球和合金基体之间材料的剥落,同时,由于塑性变形导致两接触面之间产生高温,剥落的磨屑发生氧化。

3 讨论

综合上述的研究结果可知,在Cu-15Ni-8Sn合金中添加P元素可提高合金的峰值硬度和抗过时效能力,同时可提高合金的耐摩擦磨损性能。在时效过程中,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的磨损方式主要由磨粒磨损、氧化磨损和黏着磨损组成。其中,在时效初期,两组合金主要以磨粒磨损为主;当时效至15 h以后,Cu-15Ni-8Sn合金的磨损方式主要以黏着磨损为主,同时还伴随着磨粒磨损,而此时Cu-15Ni-8Sn-0.2P合金的磨损方式还是以磨粒磨损为主。

图10 不同载荷下Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金磨痕的SEM像

Fig. 10 SEM images of wear marks of Cu-15Ni-8Sn((a), (b), (c)) and Cu-15Ni-8Sn-0.2P((d), (e), (f)) alloys under different loads

图11 磨屑碎片的SEM图及其对应的EDS面扫描图

Fig. 11 SEM images and corresponding EDS mapping of debris of samples

根据ARCHARD提出的黏着磨损量的计算公式[29]可知:

(2)

(2)

式中:K为磨屑形成率;β为相对表面膜缺陷系数;L为总滑动距离,m;W为法向载荷,N;H为材料的布氏硬度,HB。由式(2)可知,黏着磨损量与材料的硬度呈反比,这意味着硬度越低黏着磨损量越大。由图1可知,时效15 h时,Cu-15Ni-8Sn合金的硬度大幅度下降,故该状态下合金的黏着磨损量增加。Cu-15Ni-8Sn合金硬度大幅度下降与胞状沉淀的形成和长大有关(见图2)。P元素的添加可形成Ni10SnP3相颗粒,该颗粒相在晶界处富集,可以有效抑制胞状沉淀的形成和长大,提高合金的抗过时效能力。故时效15 h时,Cu-15Ni-8Sn-0.2P合金的磨损方式主要以磨粒磨损为主。此外,P元素的添加可提高Cu-15Ni-8Sn合金的峰值硬度,这也是Cu-15Ni-8Sn-0.2P合金具有更好的耐摩擦磨损性能的原因之一。

表1 图11(b)和(e)对应位置EDX点扫结果

Table.1 EDX results of corresponding positions in Fig. 11(b) and (c)

磨粒磨损机制主要分为三类:微观切削、挤压剥落和疲劳破坏等,其中显微切削机制主导的磨损量可根据RABINOWICZ提出的公式计算[29]:

(3)

(3)

式中:Ka为磨损系数;Hm为材料的硬度,HB;L为总滑动距离,m;W为法向载荷,N。由式(3)可知,材料的磨粒磨损量与载荷成正比,与硬度呈反比。结合图1和图4可知,在干摩擦过程中,提高Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的硬度能够显著降低其磨损率,但合金的最低磨损率并不对应合金的最高硬度,胞状沉淀也对合金摩擦行为产生影响。根据张少宗等[2, 30]的研究结果可知,胞状组织为10%时Cu-15Ni-8Sn合金具有最佳的磨损率。

载荷是影响合金磨损体积的一个重要参数,它决定了摩擦磨损过程中摩擦副与合金表面的实际接触面积、应力、磨痕深度等大小。由图8(a)可知,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的摩擦因数随着法向载荷的增加,先降低后增加,而磨损量则一直增加。由式(1)和式(2)可知,合金的磨损量与载荷成正比,当法向载荷较小时,合金产生轻微的磨损,磨损量小;增大法向载荷,磨球与合金的实际接触面积增加,塑性变形和剥落现象加剧,出现疲劳剥落坑,磨损量也增大(见图10(c)和(f))。此外,载荷增加导致接触表面应力增加,一方面使得摩擦界面温度升高,加速滑动表面氧化膜的形成;另一方面,增加了合金表面发生脆性剥落的概率,有利于促进磨粒更快形成。这两者的共同作用使得夹杂在磨球与合金表面之间的磨粒从滑动摩擦转变为滚动摩擦[31]。相对于滑动摩擦而言,滚动摩擦具有更小的摩擦阻力,这也是随着载荷增加,Cu-15Ni-8Sn和Cu-15Ni-8Sn-0.2P合金的摩擦因数先降低的主要原因。但是,当载荷过大时,磨球和合金表面形成的氧化物薄膜易破裂,使得磨球与合金表面密切接触,导致合金的摩擦因数增大。

4 结论

1) 在Cu-15Ni-8Sn合金中添加P元素有利于提高合金的峰值硬度、抗过时效能力和耐摩擦磨损性能。在400 ℃时效15 h时,Cu-15Ni-8Sn合金和Cu-15Ni-8Sn-0.2P合金的硬度分别约为305 HV0.5和412 HV0.5,相对于Cu-15Ni-8Sn合金而言,Cu-15Ni-8Sn-0.2P合金的硬度高出了107 HV0.5。

2) 经过时效处理后,Cu-15Ni-8Sn-0.2P合金在往复干摩擦过程中的磨损方式主要以磨粒磨损为主;在400 ℃时效15 h后的Cu-15Ni-8Sn合金黏着磨损量增加,这与合金硬度的降低有关。两组合金磨损量的大小与合金的硬度成反比,与法向载荷成正比。

3) 相对于Cu-15Ni-8Sn合金而言,Cu-15Ni- 8Sn-0.2P合金具有更好的耐高载荷摩擦磨损性能,法向载荷为100 N时其摩擦因数最小为0.65。当载荷过大时(120 N),两种合金均发生疲劳剥落磨损。

REFERENCES

[1] SPOONER S, LEFEVRE B G. The effect of prior deformation on spinodal age hardening in Cu-15Ni-8Sn alloy[J]. Metallurgical Transactions A, 1980, 11(7): 1085-1093.

[2] ZHANG Shao-zong, JIANG Bo-hong, DING Wen-jiang. Dry sliding wear of Cu-15Ni-8Sn alloy[J]. Tribology International, 2010, 43(1/2): 64-68.

[3] VIRTANEN P, TIAINEN T. Stress relaxation behaviour in bending of high strength copper alloys in the Cu-Ni-Sn system[J]. Materials Science and Engineering A, 1997, 238(2): 407-410.

[4] 潘 震. 铍铜替代用高性能铜基弹性合金的开发现状[J]. 材料开发与应用, 2014(2): 99-104.

PAN Zhen. Recent advances in copper base elastic alloys for replacing beryllium copper alloy[J]. Material development and Application, 2014(2): 99-104.

[5] CRIBB W R, RATKA J O. Copper spinodal alloys: new technology enables production of larger copper parts with the high-strength spinodal structure[J]. Advance Materials & Processes, 2002, 160(11): 27-30.

[6] SCOREY C R, CHIN S, WHITE M J, et al. Spinodal Cu-Ni-Sn alloys for electronic applications[J]. Journal of Metals, 1984, 36(11): 52-54.

[7] CHENG Jin-juan, ZHANG Shi-zhong, GAN Xue-ping, et al. Wear map for sliding wear behavior of Cu-15Ni-8Sn alloy against bearing steel under oil-lubricated condition[J]. Journal of Central South University, 2020, 27(2): 311-324.

[8] CRIBB W R, GRENSING F C. Spinodal copper alloy C72900-new high strength antifriction alloy system[J]. Canadian Metallurgical Quarterly, 2011, 50(3): 232-239.

[9] CHENG Jin-juan, GAN Xue-ping, LEI Qian, et al. Tribological behaviors of an ultrahigh strength Cu-15Ni-8Sn-0.2Y alloy sliding against TC6 titanium alloy in deionized water and seawater[J]. Tribology Letters, 2020, 68(21): 1-18.

[10] CHENG Jin-juan, ZHANG Shi-zhong, GAN Xue-ping, et al. Wear regime and wear mechanism map for spark-plasma-sintered Cu-15Ni-8Sn-0.2Nb alloy under oil lubrication[J]. Journal of Materials Engineering and Performance, 2019, 28(7): 4187-4196.

[11] ZHAO J C, NOTIS M R. Spinodal decomposition, ordering transformation, and discontinuous precipitation in a Cu-15Ni-8Sn alloy[J]. Acta Materialia, 1998, 46(12): 4203-4218.

[12] ZHAO J C, NOTIS M R. Microstructure and precipitation kinetics in a Cu-7.5Ni-5Sn alloy[J]. Scripta Materialia, 1998, 39(11): 1509-1516.

[13] PLEWES J T. High-strength Cu-Ni-Sn alloys by thermomechanical processing[J]. Metallurgical Transactions A, 1975, 6(3): 537-544.

[14] 刘宇轩. 热处理工艺对Cu-15Ni-8Sn合金力学性能和摩擦磨损性能的影响[D]. 广州: 华南理工大学, 2015.

LIU Yu-xuan. Effects of heat treatment on mechanical properties and wear behavior of Cu-15Ni-8Sn alloy[D]. Guangzhou: South China University of Technology, 2015.

[15] MIKI M, OGINO Y. Effects of doped elements on the cellular precipitation in Cu-10Ni-8Sn alloy[J]. Materials Transactions, JIM, 1994, 35(5): 313-318.

[16] ZHAO Chao, ZHANG Wei-wen, WANG Zhi, et al. Improving the mechanical properties of Cu-15Ni-8Sn alloys by addition of titanium[J]. Materials, 2017, 10(9): 1038-1048.

[17] YU Q X, LI X N, WEI K R, et al. Cu-Ni-Sn-Si alloys designed by cluster-plus-glue-atom model[J]. Materials & Design, 2019, 167: 107641.

[18] ZHAO Chao, WANG Zhi, PAN De-qing, et al. Effect of Si and Ti on dynamic recrystallization of high-performance Cu-15Ni-8Sn alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(12): 2556-2565.

[19] MIKI M, OGINO Y. Effect of Si addition on the cellular precipitation in a Cu-10Ni-8Sn alloy[J]. Materials Transactions, JIM, 1990, 31(11): 968-974.

[20] GUO Cheng-jun, CHEN Jin-shui, XIAO Xiang-peng, et al. The effect of Co addition on the modulated structure coarsening and discontinuous precipitation growth kinetics of Cue15Nie8Sn alloy[J]. Journal of Alloys and Compounds, 2020, 835: 155275.

[21] GAO Min-qiang, CHEN Zong-ning, KANG Hui-jun, et al. Effects of Nb addition on the microstructures and mechanical properties of a precipitation hardening Cu-9Ni-6Sn alloy[J]. Materials Science and Engineering A, 2018, 715: 340-347.

[22] OUYANG Yi, GAN Xue-ping, ZHANG Shi-zhong, et al. Age-hardening behavior and microstructure of Cu-15Ni-8Sn-0.3Nb alloy prepared by powder metallurgy and hot extrusion[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(9): 1947-1955.

[23] OUYANG Yi, GAN Xue-ping, LI Zhou, et al. Microstructure evolution of a Cu-15Ni-8Sn-0.8Nb alloy during prior deformation and aging treatment[J]. Materials Science and Engineering A, 2017, 704: 128-137.

[24] GUO Zhong-kai, JIE Jin-chuan, LIU Shi-chao, et al. Effect of V addition on microstructures and mechanical properties of Cu-15Ni-8Sn alloy[J]. Materials Science and Engineering A, 2019, 748: 85-94.

[25] GUO Zhong-kai, JIE Jin-chuan, LIU Shi-chao, et al. Suppression of discontinuous precipitation in age-hardening Cu-15Ni-8Sn alloy by addition of V[J]. Journal of Alloys and Compounds, 2020, 813: 152229.

[26] GUO Cheng-jun, WAN Jia, CHEN Jin-shui, et al. Inhibition of discontinuous precipitation and enhanced properties of Cu-15Ni-8Sn alloy with Fe addition[J]. Materials Science and Engineering A, 2020, 795: 139917.

[27] GUO Cheng-jun, SHI Yu-fan, CHEN Jin-shui, et al. Effects of P addition on spinodal decomposition and discontinuous precipitation in Cu-15Ni-8Sn alloy[J]. Materials Characterization, 2020, 171: 110760.

[28] 张钦英. 多弧离子镀制备ZrAlN涂层及其摩擦学性能研究[D]. 赣州: 江西理工大学, 2018.

ZHANG Qing-ying. The tribological properties research on ZrAlN coating by multi-arc ion plating[D]. Ganzhou: Jiangxi University of Science and Technology, 2018.

[29] 刘正林. 摩擦学原理[M]. 北京: 高等教育出版社, 2009.

LIU Zheng-lin. Tribological principle[M]. Beijing: China Higher Education Press, 2009.

[30] ZHANG Shao-zong, JIANG Bo-hong, DING Wen-jiang. Wear of Cu-15Ni-8Sn spinodal alloy[J]. Wear, 2008, 264(3/4): 199-203.

[31] 韩文强. TiN、TiAlN摩擦磨损特性及其涂层刀具、齿轮的性能研究[D]. 重庆: 西南大学, 2014.

HAN Wen-qiang. Research on friction, wear characteristics and coated tool, gear performances of TiN and TiAlN[D]. Chongqing: Southwest University, 2014.

Effect of P addition on dry sliding wear properties of Cu-15Ni-8Sn alloy

GUO Cheng-jun1, CHEN Jin-shui1, WANG Hang1, XIAO Xiang-peng1, 2, HUANG Hao1, 2, YANG Bin1

(1. Faculty of Materials Metallurgy and Chemistry, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. Jiangxi Advanced Copper Industry Research Institute, Yingtan 335000, China.)

Abstract: The wear behaviors of Cu-15Ni-8Sn and Cu-15Ni-8Sn-0.2P alloys aged at 400 ℃ for different time and under different normal loads were studied. The morphology and composition distribution of wear marks and debris particles were observed by scanning electron microscopy (SEM) and three-dimensional surface profilometer. The results show that compared with Cu-15Ni-8Sn alloy, the Cu-15Ni-8Sn-0.2P alloy has higher peak hardness, over aging resistance and wear resistance. The wear modes of aged Cu-15Ni-8Sn-0.2P alloy during dry sliding wear are abrasive wear, oxidation wear and adhesive wear. However, the adhesion wear of Cu-15Ni-8Sn alloy increases after aged at 400 ℃ for 15 h, which is related to the decrease of hardness. The wear losses of both the alloys are inversely proportional to the hardness and proportional to the normal load. In addition, compared with Cu-15Ni-8Sn alloy, Cu-15Ni-8Sn-0.2P alloy has better wear resistance under high load, and the minimum friction coefficient is 0.65 when the normal load is 100 N. Further, the probability of fatigue wear increases with the increase of normal load.

Key words: Cu-15Ni-8Sn-0.2P alloy; dry sliding wear; wear behavior; hardness

Foundation item: Project(2016YFB0301400) supported by the National Key Research and Development Program of China; Projects(51561008, 51761013) supported by the National Natural Science Foundation of China; Project(GJJ160605) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2020-07-10; Accepted date: 2020-11-06

Corresponding author: YANG Bin; Tel: +86-13970798000; E-mail: yangbin@jxust.edu.cn

(编辑 王 超)

基金项目:国家重点研究计划资助项目(2016YFB0301400);国家自然科学基金资助项目(51561008,51761013);江西省自然科学基金资助项目(GJJ160605)

收稿日期:2020-07-10;修订日期:2020-11-06

通信作者:杨 斌,教授,博士;电话:13970798000;E-mail:yangbin@jxust.edu.cn