DOI:10.19476/j.ysxb.1004.0609.2018.03.06

旋转磁场作用下A356-La合金径向凝固组织形貌及稀土元素分布

陈 涛1,刘 政2,陈志平2,胡咏梅3

(1. 江西理工大学 材料科学与工程学院,赣州 341000;

2. 江西理工大学 机电工程学院,赣州 341000;

3. 江西理工大学 工程研究院,赣州 341000)

摘 要:利用OM、SEM分析低过热度浇注、双向低频电磁搅拌和稀土元素细化处理复合技术制备的A356-La铝合金铸锭,考察电磁场作用时间恒定时,磁场频率对合金铸锭径向显微组织和稀土元素分布规律的影响,并在最佳工艺参数上探讨熔体搅拌方式对径向组织演化及均匀性的影响。结果表明:磁场频率增加,晶粒球化程度显著,生长方式由枝晶向球晶转变,径向组织以及稀土元素点状弥散分布均匀性增强,磁场频率25 Hz、0.7R时达到最佳,平均等积圆直径和形状因子分别为36.2 μm和0.82;合金径向3个采集点晶粒直径和形状因子的平均值达到41.6 μm和0.76。双向连续搅拌作用于熔体时,组织形貌和均匀性优于单向连续搅拌、双向间歇搅拌。此搅拌方式加快熔体内部质量传输、热量传递进程,一定程度上避免集肤效应对组织均匀性的不利影响。

关键词:旋转磁场;A356-La合金;稀土元素分布;搅拌方式;凝固组织均匀性

文章编号:1004-0609(2018)-03-0483-09 中图分类号:TG146;TG244 文献标志码:A

树枝晶是合金凝固后常见的显微组织形貌,这种复杂的组织形貌对合金材料的性能有着重要影响[1]。因此,有效地控制合金凝固过程中枝晶的生长行为,使其破碎演变为球形晶粒,对于获得优质半固态合金浆料十分必要。半固态成形技术作为一种新型细晶浆料制备技术,在低熔点的铝、镁合金和高温合金中应用日趋成熟[2-5],为制备晶粒细小、圆整的优质合金浆料提供了技术选择。

另外,从金属凝固理论可知合金浆料组织细化的主要途径是:激发熔体内部原子团簇大量形核,形成数目可观的自由晶继而控制晶粒长大过程使其尺寸稳定[6]。赵倩等[7]指出半固态电磁搅拌技术以磁力密度梯度大、磁能利用率高和穿透性强为特征,是调控半固态铝合金浆料晶粒尺寸的有效途径。当铝熔体处于液固两相温度区间时,引入交变磁场,磁场与熔体间交互作用形成电磁搅拌力,引起熔体的三维强制流动,促使熔体内部的质量传输、热量传递处于快速混合状态,从而加快液相强制流动。还有研究表明[8-10],强制对流环境下合金浆料中初生α相、共晶相、二次相的晶粒尺寸得以细化,其形态规整和分布均匀性得到提升;合金元素的偏析现象得到改善。然而,由于合金是多种元素组分构成的体系,影响获得完整球形且分布均匀的晶粒的因素较多(如热力学与动力学条件;磁场集肤效应等)。另外,在合金熔体中添加适量稀土元素进行细化处理是优化合金凝固组织的有效方式[11-14]。尽管笔者前期对恒定转向磁场作用下熔体的流动特性[15],加入稀土元素在电磁场调控下的扩散路径、存在形式与分布状态也已基本熟知[16],但在双向电磁搅拌处理下,熔体的流动方向、对流强度和电磁力的大小发生周期性变化时,可能导致稀土元素在合金中的传输、分布呈现新规律。这将对浆料晶粒组织演化产生重要的影响,为此需探明其中蕴含的工艺信息。

综上所述可知,目前关于铝熔体中稀土元素在工频范围内双向搅拌处理下的流动特性研究尚较少,双向搅拌处理下稀土元素的扩散形式、分布状态以及凝固组织演化机理有待探讨。因此,本文作者对A356合金熔体施加双向搅拌和稀土元素细化处理复合作用,研究不同电磁搅拌条件下合金径向凝固组织的均匀性、初生相的演化规律和铸锭径向稀土元素的分布规律。以期通过利用稀土元素细化效应及低频电磁场的电磁效应为合金材料的细化和强化提供试验依据。

1 实验

1.1 合金熔炼、细化变质和电磁场处理

试验所用电磁搅拌装置由三相异步电动机改制而成,通过电磁调频控制器调节作用于液态合金熔体的磁场频率来调控合金液流的流动速率、电磁力的大小和搅拌强度。在电磁场下,采用低过热浇注和等温保温热处理复合工艺制备合金浆料。试验炉料为A356铝合金,经DTA(Differential thermal analysis)测试合金的液相线温度为615.3 ℃。铝锭预热后其熔炼实验在SG2-5-12电阻坩埚炉内进行,熔炼温度为720 ℃。在合金充分熔化静置数分钟后加入覆盖剂,防止熔体在加热过程中被氧化,保温10 min后进行2~3次除气除渣精炼。Al-La中间合金中La含量为20%(质量分数),在炉温780 ℃时将Al-La中间合金加入熔体中,以最终合金中含0.6 %La为基准控制其加入量,对熔体进行变质处理。待熔体温度降至630 ℃时浇入预热至 350 ℃的不锈钢铸型中,铸型尺寸为d 55 mm×100 mm。电磁搅拌频率设置为5 、15 、25和35 Hz,双向连续搅拌20 s(正-反向各搅拌10 s)。即时通电启动旋转磁场,搅拌终了后将铸型置于600 ℃的箱式电阻炉内保温10 min。保温结束后对熔体进行快速水淬处理以保存高温时合金浆料的组织形态。

1.2 试样制取与测试分析

从不同工艺条件下合金铸锭横截面的中心部(0R)、径向0.7R处和边部(1R),在轴向距底部10 mm处截取一个圆片并从中切取一个过圆心的扇形圆片作为金相试样。试样经预磨、机械抛光后并利用0.5% HF (体积分数)水溶液进行腐蚀处理。随后,采用ZEISS AXIOSKOP2型光学显微镜(OM)拍摄金像图并进行组织分析。研究双向电磁搅拌作用下稀土La在铸锭径向分布规律时,应用XL30W/TMP扫描电镜(SEM)对不同磁场频率下获得的合金试样径向(0R、0.7R和1R)拍取背散射电子像。为了探讨搅拌方式对径向凝固组织均匀性的影响,在前述研究电磁频率参数和稀土分布位置较佳的工艺基础上,对熔体施加不同搅拌方式(单向连续搅拌、双向间歇搅拌(间歇时间4s)和双向连续搅拌),来研究搅拌方式对凝固组织形貌和均匀性的影响。另外,为了表征电磁搅拌下径向凝固组织形貌圆整度和晶粒尺寸细化程度,利用Image-pro-plus和Excel测量计算各频率下合金中初生α相的形貌特征参数:平均等积圆直径、平均形状因子。平均等积圆直径和平均形状因子计算公式分别为:D=2(A/π)1/2;F=4πA/P2。式中:P为合金中初生相的平均周长;A为初生相的平均面积。若F的数值越大或者越趋近于1,则表明浆料中初生α相形貌圆整,此时,合金中的晶粒细化以及均匀化程度最大,组织性能最优。

2 结果与分析

2.1 磁场频率对合金铸锭径向凝固组织的影响

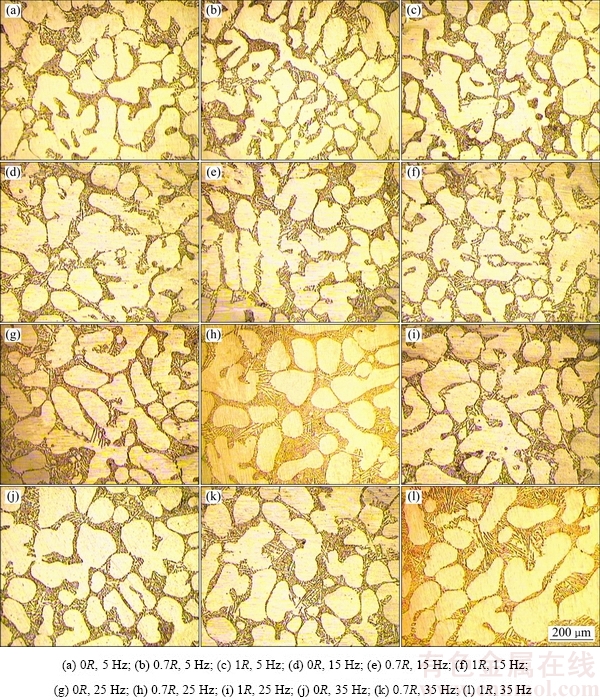

图1所示为不同磁场频率下半固态A356-La合金铸锭径向初生α相的形貌。从图1可见,合金铸锭中心部、0.7R和边部初生晶粒尺寸得到了不同程度细化。磁场频率5 Hz作用于熔体时,电磁力驱动合金液流的流动速率和搅拌强度较弱,枝晶破碎、剪切程度有限。凝固组织形貌保留枝晶特征,晶界轮廓清晰可见。中心部的晶粒组织有明显二次枝晶臂断裂迹象和分支形态,0.7R和边部的初生相由细长条枝晶和蔷薇状晶粒构成,相较于中心部组织形貌有所优化,但整体组织形态较差,初生相的形貌还不能满足流变成形的要求(见图1(a)~(c))。Image-pro-plus测量显示铸锭0.7R处初生相的平均等积圆直径为62.6 μm、形状因子0.55,若定义合金浆料径向3个采集点初生相晶粒尺寸的均值作为合金径向平均晶粒尺寸,则5 Hz磁场频率处理下合金径向平均晶粒直径为69.1 μm、形状因子0.53。图1(d)~(f)是合金熔体施加15 Hz电磁搅拌时初生α相的组织特征。频率增加使电磁力对熔体的搅拌作用和枝晶破碎强度增强,改善了初生相形貌。铸锭中心部发达枝晶的数目减少,边缘蔷薇晶向球晶演化;0.7R处细长的枝晶向棒状晶转变;边部蔷薇晶的数量继续增加,但依旧含有少量枝晶。合金0.7R处晶粒平均直径减小至53.7 μm、形状因子增加到0.67;径向平均晶粒直径为64.8 μm、形状因子为0.59。磁场频率增至25 Hz时的晶粒组织形貌见图1(g)~(i),合金中枝晶组织已基本消失殆尽。中心部晶粒为椭圆形和类球形;在电磁力诱发的熔体强制对流冲刷下,棒状晶粒逐步演化为如0.7R处所示的细小球晶;铸锭边部合金液流受到铸型和熔体间温差所形成的激冷效应作用,使得浆料中出现了少量枝晶。此时,合金径向0.7R处初生α相的平均等积圆直径进一步细化至36.2 μm,形状因子增至0.82;平均晶粒直径进一步降至41.6 μm,形状因子增至0.76,合金径向平均晶粒尺寸呈现相似的增长关系。当磁场频率35 Hz时,中心部、0.7R和边部的部分球状初生相合并生长的趋势增强,组织中出现了尺寸较大的枝晶(见图1(j)~(l))。原因是由于磁场频率增大,则熔体热量散失速率增大,从而导致冷却速率亦增大。为初生相向树枝晶生长提供了动力学条件。因此合金铸锭0.7R处和径向初生α相的平均等积圆直径分别增至44.2 μm和46.6 μm;形状因子减小为0.73和0.70。

图1 不同磁场频率作用下半固态A356-La合金铸锭径向初生α相的形貌

Fig. 1 Morphologies of primary α phase in semisolid A356-La alloy ingot radial under different magnetic field frequencies

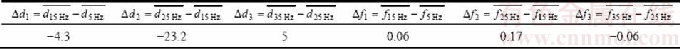

综合不同磁场频率下合金铸锭径向凝固组织形貌、初生相的平均等积圆直径和平均形状因子的数值可知,在25 Hz、0.7R处的晶粒相较于中心部和边部更加细小圆整。另外,为了进一步直观表明合金径向凝固组织的细化和均匀程度时,定义各相邻磁场频率间合金径向3个采集点初生α相平均等积圆直径和形状因子均值间的差值分别记为Δdi和Δfi(如Δd1为5 Hz与15 Hz间合金径向平均等积圆直径的差值;Δf1为平均形状因子的差值)。表1所列为表征合金径向晶粒组织细化和圆整程度Δdi和Δfi的数值。由表1可知,晶粒的细化和球化过程主要发生在15~25 Hz,频率继续增加时,合金组织反而出现了恶化。在双向连续电磁搅拌作用下,合金径向显微组织均匀性增强,晶粒尺寸波动幅度平缓。各频率下半固态合金铸锭0.7R处初生相的平均等积圆直径和形状因子变化趋势如图2所示。由图2可以看出,合金径向最佳的试样采集点位于0.7R处,且25 Hz是获取球晶的适宜频率。

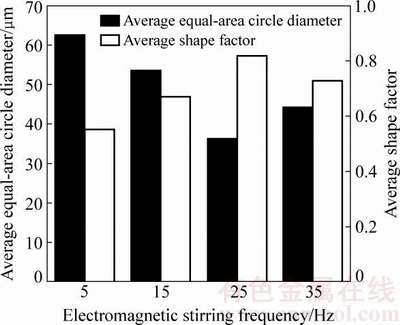

2.2 磁场频率对合金铸锭径向稀土元素分布和形态的影响

文献[17]中的结果表明,处于此磁场下熔体流动速率的最大值位于凝固界面前沿即在合金径向0.7R左右,流场速率与磁感应强度的分布特性和稀土元素在合金径向的分布规律存在一定的关联性。合金熔体凝固时对磁感应强度大小和磁感应线的分布规律数值模拟表明,熔体中的磁感应强度由铸型中心向边缘单调递增变化,在边缘附近磁感应强度处于峰值[18]。磁感应线的分布呈现类似规律,由中心稀疏到边缘密集。为此,试验选取0R、0.7R、1R这3个径向采集点分析稀土元素分布规律。图3所示为 25 Hz时半固态A356-La铝合金铸锭径向稀土元素分布SEM-BE像。从图3中可看出,亮白物主要分布于初生α相的晶界和相界,依据Al-La二元合金相图推断亮白物为铝镧化合物,但稀土元素La在合金径向分布均匀性和稀土化合物的形态却存在差异。图3(a)所示为稀土元素La在合金心部分布状态。从图中可看出,稀土化合相在晶界上错乱分布,形态呈针状,弥散均匀分布程度较弱,合金中存在稀土元素分布富集(贫化)现象。其原因是:合金中稀土La的原子半径远大于Al及其他元素的原子半径,不固溶于Al基体中,只偏聚在晶界和相界;并且由于电磁场的分布特性使得电磁力对合金中心熔体的搅拌作用和合金液流的冲刷剪切效应对稀土化合相形态的控制作用几乎趋近于零。由图3(b)可看出,合金径向0.7R处稀土化合相的形态已由心部的针状转变为细点状,弥散均匀分布,合金中没有出现稀土元素富集(贫化)区域。其原理是电磁搅拌使熔体形成强制对流,熔体中的稀土元素在电磁力和离心力的复合驱动作用下,趋向沿着合金铸锭的径向由心部向边部迁移,稀土元素在迁移过程中受到熔体粘滞力阻滞在合金凝固界面前沿驻留,合金液流在电磁力的搅动下强力冲刷凝固界面前沿驻留的稀土化合物,促进其形态向细点状演化,均匀分布于合金浆料中。合金边部(1R)稀土元素分布如图3(c)所示,针状的稀土化合物再现,分布均匀程度较0.7R处发生了明显的衰减。解析导致边部稀土化合物形态和分布出现此现象的机理是,试验时铸型中的凝固壳层在熔体浇注完毕后短时内形成,稀土元素在沿径向迁移过程中被凝固壳层捕获,此外凝固界面由型壁向熔体中心推进与沿径向迁移的稀土元素碰撞使其停驻于型壁附近,凝固壳层的存在也使得电磁力对稀土化合物的搅拌效果衰减,从而导致了稀土化合物呈针状在边部富集(或贫化)。

表1 相邻磁场频率间半固态A356-La合金3个采集点初生α(Al)相平均等积圆直径与形状因子均值间的差值Δdi与Δfi

Table 1 Difference of average equal area circle diameter (Δdi) and shape factor (Δfi) of primary α(Al) phase in three collection point of semi-solid A356-La alloy under adjacent magnetic field frequencies

图2 不同磁场频率作用下半固态A356-La合金铸锭径向0.7R处初生相的平均等积圆直径与形状因子

Fig. 2 Average equal-area circle diameter and average shape factor of primary α phase 0.7R of semisolid A356-La alloy ingot under different electromagnetic stirring frequencies

图3 25 Hz时半固态A356-La铝合金铸锭径向稀土元素分布SEM-BE像

Fig. 3 SEM-BE images of semisolid A356-La Al alloy ingot in radial distribution of rare earth elements at 25 Hz

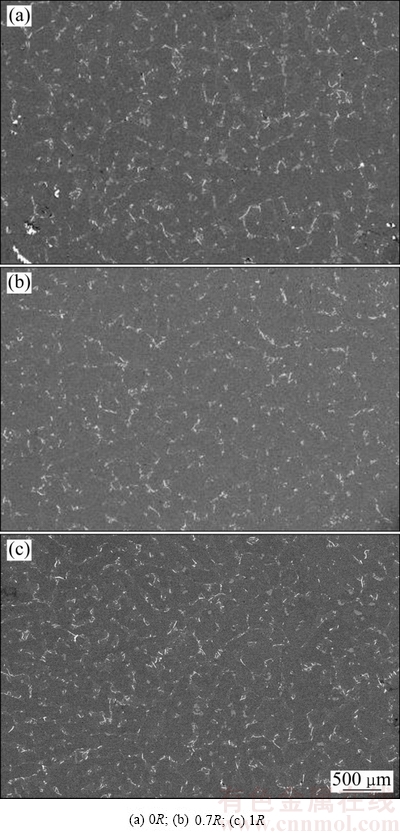

2.3 熔体搅拌方式对合金铸锭径向0.7R处凝固组织及均匀性的影响

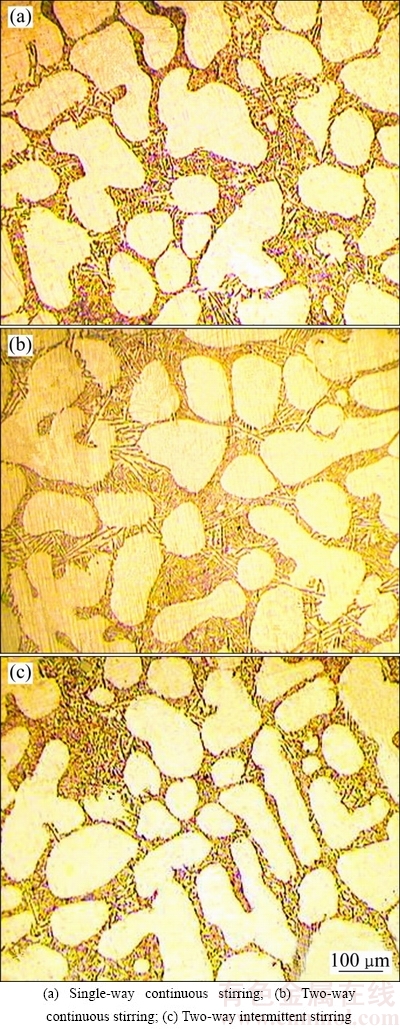

图4所示为磁场频率25 Hz且作用时间20 s的条件下不同搅拌方式时合金径向0.7R处初生α相的形貌及均匀程度。由图4可知,合金熔体搅拌方式变化是导致初生相的演化和尺寸发生改变的重要因素。图4(a)所示为液态合金单向连续搅拌时的显微组织,初生相由枝晶碎块和类球晶构成,晶粒间的尺寸和圆整度相差较大,分布均匀性也较差。主要原因是:单向连续搅拌时,合金液流与磁场协同转动;熔体的流场保持恒定的流向;流场状态平稳、液相流速涨幅变化较小;熔体中初生晶粒受到液流冲刷强度较弱以及铸型内高温熔体热量散失速率较小。此时初生α相的平均等积圆直径为45.3 μm、形状因子为0.72。晶粒的尺寸和形态均匀程度有待进一步优化。当熔体施加双向连续搅拌时,晶粒尺寸细小,凝固组织以球晶为主。双向电磁搅拌力的大小和方向周期性变化驱动合金熔体强制对流,导致结晶器内的固液两相金属液流混合折叠程度加强,固相颗粒与液态金属间热量交换速率增大,溶质处于快速传输状态促进了凝固系统温度场和溶质场的均匀化,为晶粒形核和抑制其生长过程提供了热力学和动力学条件,促使晶粒在凝固整个进程中保持向球晶演化趋势。此时初生晶粒的平均等积圆直径减小至36.2 μm、形状因子增至0.82(见图4(b))。另外,电磁搅拌过程中短时间歇所制备的合金浆料凝固组织见图4(c),初生相为狭长枝晶和大尺寸的椭球晶。浆料中初生固相晶粒较单向搅拌、双向连续搅拌向枝晶转变趋势增强。此时初生相α相的平均等积圆直径反增至47.6 μm、形状因子降至0.68。

图4 25 Hz时不同熔体搅拌方式下半固态A356-La合金铸锭径向0.7R处初生α相的形貌

Fig. 4 Morphologies of primary α phase at 0.7R of semisolid A356-La alloy ingot under different melt mixing methods and 25 Hz

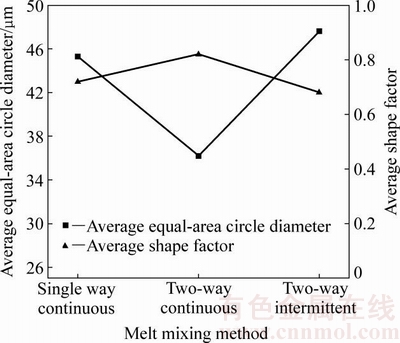

图5所示为磁场频率25 Hz不同熔体搅拌方式下半固态合金铸锭径向0.7R处初生相平均等积圆直径和形状因子的曲线图。为从数学上定性反映不同熔体搅拌方式间半固态合金铸锭径向0.7R处初生相的细化和均匀化程度,定义ΔD1表示双向间歇搅拌和双向连续搅拌下初生晶粒平均等积圆直径的差值;ΔF1表示双向间歇搅拌和双向连续搅拌下初生晶粒平均形状因子的差值。ΔD2表示双向间歇搅拌和单向连续搅拌下初生晶粒平均等积圆直径的差值;ΔF2表示双向间歇搅拌和单向连续搅拌下初生晶粒平均形状因子的差值。ΔD1、ΔF1、ΔD2、ΔF2的数值分别为-11.4、0.14、-2.3、0.04,ΔD1<ΔD2<0;ΔF1>ΔF2>0。定性结果亦显示出与图5合金凝固组织形貌演化规律相一致的结论:双向连续搅拌较其他两种搅拌方式处理下初生相的细化和均匀化程度更高,此搅拌方式更有利于细晶浆料的制备。

图5 磁场频率25 Hz不同熔体搅拌方式作用下半固态A356-La合金径向0.7R处初生相的平均等积圆直径和形状因子

Fig. 5 Average equal-area circle diameter and average shape factor of primary α phase at 0.7R of semisolid A356-La alloy under different melt mixing methods and 25 Hz magnetic field

3 讨论

3.1 集肤效应对合金铸锭径向凝固组织的影响

磁场环境下铝熔体可视为一种具有高黏性的导电材质,在旋转磁场作用下合金熔体周期性的旋转运动切割磁感应线感生感应电流,感应电流与磁场间交互作用形成Lorentz力,对熔体产生强烈的搅拌作用。电磁场磁感应强度数值模拟表明[18],磁感应强度在电磁结晶器的径向从中心到型壁边缘磁感应强度大小单调递增梯度变化;磁力线由中心稀疏到边缘密集。依据洛伦兹力方程[19]:F=J×B。F为Lorentz力;J为电流密度;B为磁感应强度。可知Lorentz力在合金熔体径向的分布呈现与磁感应强度相似规律。因此,铸型径向位于不同位置的初生相受到电磁力的大小和方向、合金液流的冲刷强度、热量传导和质量传输方式以及晶粒间的碰撞剪切强度和概率都存在显著差异,从而导致初生α相在合金浆料径向的组织形态及均匀性呈非均衡状态。这种由于电磁场自身分布特性所诱导的合金浆料初生相径向演化方式、晶粒形态以及分布的差异称之为集肤效应。磁感应强度在合金熔体中的作用机理可用集肤深度进行表征,集肤深度的表达式为[20]:δ=[1/(σμπf)]1/2。式中:σ为铝合金电导率;f为旋转磁场电流频率;μ为铝合金熔体的磁导率。从表达式可以看出电流频率与熔体集肤效应呈反比关系,电磁搅拌过程中铝合金的电导率处于相对恒定时,当旋转频率减小,集肤深度增大。相反,旋转频率增大,集肤深度反而减小。低频搅拌(5 Hz)时,磁感应强度在熔体内部的作用距离较长,磁感应线贯穿整个熔体,使其整体处于电磁搅拌作用下。但由于磁场频率处于低位电磁搅拌,其搅拌强度较弱,电磁力对合金浆料中初生枝晶的剪切作用有限。此外,铸型中的高温金属熔体与已预热的铸型间仍存在较大的温差,型壁处的晶粒沿热流反方向以枝晶形态向熔体心部生长。因此,在铸锭边部及心部、0.7R处初生相都形成了粗大的枝晶(见图1(a)~(c))。当磁场频率适当提升(15 Hz、25 Hz),此时虽然电磁感应强度在熔体中的作用距离有所减小,但电磁力的增大使熔体形成强烈的混合对流,加快熔体内部质量传输、热量传递,使晶粒的形核处于一个相对稳定的凝固体系中,自由晶的数量大大增加,晶核四周长大环境总体保持一致。合金铸锭的中心部(0R)、0.7R和边部(1R)处的晶粒组织较低频搅拌得到了显著优化,此时初生相基本呈现球形(见图1(d)~(i)),0.7R处初生α相的形貌达到最佳。其原因为:一方面,合适的电磁频率搅拌避免了熔体心部高温对晶粒的熔蚀,能够获得大量的自由晶核,保证了晶粒向球晶演化所需要的高晶核密度;另一方面,抑制了型壁激冷效应所诱导的枝晶生长趋势。此外,磁场频率25 Hz与熔体惯性响应频率接近,对克服自然对流、减小晶粒凝固前沿温度和浓度梯度的作用更加明显,抑制了枝晶生长。当磁场频率35 Hz时,熔体形成大的集肤效应,电磁体积力仅作用于合金浆料的表面,对液态合金的搅拌作用有限,使得结晶器中心的合金熔体几乎不具有搅拌效果,合金中心部(0R)、0.7R和边部晶粒的形态都有所恶化。因此,得到了形貌如图1(j)~(l)所示尺寸较大的短棒状和枝状晶。

3.2 双向电磁场作用下稀土元素迁移分布规律

合金熔体在电磁力的径向分量和轴向分量作用下主要发生了与磁场转动方向同向的周向流动和绕轴的轴向环流,且周向流动速率远大于轴向流率[21]。因此,铸型内合金液流的流动形式以周向为主导。电磁场环境下熔体中溶质原子随金属液流在电磁力径向分量的作用下,从熔体中心的高温区向铸型型壁附近的低温区迁移。在溶质原子迁移过程中,原子迁移速率与原子半径存在正相关性,即原子半径越大,迁移速率越大。在A356-La合金中,稀土La的原子半径远远大于其他合金元素的原子半径。因此,La原子向铸锭边部运动的趋势更大,并且随着离熔体中心距离的增加,原子运动的线速度增大,这种运动趋势也将更加明显。从而导致电磁力的搅拌效应对合金中心部的溶质原子扩散、迁移作用失效,形成了如图3(a)所示的针状且分布无序的稀土化合物。另外,处于固液相区的A356- La合金熔体具有较高的黏性,合金浆料中溶质原子沿径向扩散迁移时将受到熔体粘滞力的阻滞。但是溶质原子向铸锭边部的扩散还要受到铸型壁上已结晶的凝固层向熔体中心推进的固/液凝固界面的阻碍。随着熔体温度的降低,由型壁处形成的凝固层的固/液界面向铝合金熔体内部推进,并与向外迁移的溶质原子相遇,在其凝固前沿驻留、聚集[22]。因此,稀土元素在0.7R处没有出现边部的富集(或贫化)现象,在适宜的冲刷力作用下,稀土化合相均匀且呈点状分布。此外虽然合金边部溶质原子受到了最大电磁搅拌力的搅拌作用,但合金边部凝固环境更加复杂以及凝固界面对溶质原子的吸附作用,从而导致了如图3(c)所示的稀土化合相针状形态再现。

4 结论

1) 合金熔体在不同磁场频率搅拌处理下获得了初生相尺寸细小、形貌圆整的半固态合金铸锭,铸锭中心部和边部晶粒呈枝晶形态;0.7R处初生α(Al)形貌以类球晶或球晶为主。25 Hz磁场频率作用下,半固态合金铸锭径向0.7R处晶粒尺寸和均匀性最佳,平均等积圆直径为36.2 μm、形状因子为0.82,且在该工艺条件下,合金径向初生相的平均等积圆直径均值为41.6 μm,平均形状因子均值为0.76。

2) 不同磁场频率旋转磁场作用下合金径向稀土元素的分布均匀性以及存在形态表明,在磁场频率25 Hz、合金铸锭径向0.7R处,显微组织中稀土元素均匀弥散分布、形态呈细点状;稀土元素的富集(或贫化)现象以及稀土化合相的形态得到有效的控制。

3) 施加25 Hz磁场频率不同电磁搅拌方式下合金铸锭0.7R处晶粒组织形貌和均匀性表明,3种搅拌方式间初生晶粒的尺寸和形状因子的差值存在不等式关系:ΔD1<ΔD2<0、ΔF1>ΔF2>0。双向连续搅拌促进了凝固体系质量传输、热量传递。较单向连续搅拌、双向间歇搅拌获得了尺寸更加细小,形态规整的球晶组织。平均等积圆直径为36.2 μm、形状因子为0.82,组织的均匀性也大大提升,有效地减缓了磁场集肤效应对凝固组织均匀性的不利影响。

REFERENCES

[1] 郭春文, 李俊杰, 马 渊, 王锦程. 定向凝固过程中枝晶侧向分枝生长行为与强制调控规律[J]. 物理学报, 2015, 64(14): 333-340.

GUO Chun-wen, LI Jun-jie, MA Yuan, WANG Jin-chen. Growth behaviors and forced modulation characteristics of dendritic sidebranches in directional solidification[J]. Acta Physica Sinica, 2015, 64(14): 333-340.

[2] METAN V, EIGENFELD K. Controlling mechanical and physical properties of Al-Si alloys by controlling grain size through grain refinement and electromagnetic strring[J]. The European Physical Journal Special Topics, 2013, 220(1): 139-150.

[3] BOLOURI A, SHAHMIRI M, KANG C G. Coarsening of equiaxed microstructure in the semisolid state of aluminum 7075 alloy through SIMA processing[J]. Journal of Materials Science, 2012, 47(8): 3544-3553.

[4] DOBRZANSKI L A, KROL M, TANSKI T, MANIARA R. Effect of cooling rate on the solidification behavior of magnesium alloys[J]. Archives of Computational Materials Science and Surface Engineering, 2009, 1(1): 21-24.

[5] SAHOO R, MANTRY S, SAHOO T K, JHA B B. Influence of microstructure on high temperature solid particle erosion behaviour of Ti-6Al-4V alloy [J]. Transactions of the Indian Institute of Metals, 2014, 67(3): 299-304.

[6] 高义民. 金属凝固原理[M]. 西安: 西安交通大学出版社, 2010: 30.

GAO Yi-min. Metal solidification principle[M]. Xi’an: Xi’an Jiaotong University Press, 2010: 30.

[7] 赵 倩, 张兴国,张环月, 郭建设, 侯晓光, 房灿峰. 螺旋磁场电磁搅拌的数值模拟[J]. 中国有色金属学报, 2014, 24(4): 1041-1049.

ZHAO Qian, ZHANG Xing-guo, ZHANG Huan-yue, GUO Jian-she, HOU Xiao-guang, FANG Chuan-feng. Numerical simulation of spiral magnetic field of electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4): 1041-1049.

[8] SEO P K, LEE S M, KANG C G. A new process proposal for continuous fabrication of rheological material by rotational barrel with stirring screw and its microstructural evoluation[J]. Journal of Materials Processing Technology, 2009, 209(1): 171-180.

[9] JI S, FAN Z, BEVIS M J. Semi-solid processing of engineering alloys by a twin-screw rheomoulding process[J]. Materials Science and Engineering A, 2001, 299(1/4): 210-217.

[10] WANNASIN J, MARTINEZ R A, FLEMINGS M C. Grain refinement of an aluminum alloy by introducing gas bubbles during solidification [J]. Scripta Materialia, 2006, 55(2): 115- 118.

[11] LI J H, SUETSUGU S, TSUNEKAWA Y, SCHUMACHER P. Refinement of eutectic Si phase in Al-5Si alloys with Yb additions[J]. Metallyrgical and Materials Transactions A, 2013, 44(2): 669-681.

[12] KAUR P, DWIVEDI D K, PATHAK P M. Effect of electromagnetic stirring and rare earth compuounds on the microstructure and mechanical properties of hypereutectic Al-Si alloys[J]. The International Journal of Advanced Manufacturing Technology, 2012, 63(1/4): 415-420.

[13] 刘腾,滕新营,周国荣, 刘立艳. 微量Y、Er元素对AZ91镁合金微观组织及力学性能的影响[J]. 稀有金属材料与工程, 2012, 41(11): 1940-1944.

LIU Teng, TENG Xin-ying, ZHOU Guo-rong, LIU Li-yan. Effects of Y and Er addition on microstructure and mechanical properties of as-cast AZ91 alloy[J]. Rare Metal Materials and Engineering, 2012, 41(11): 1940-1944.

[14] TAN C, ZHANG K, TIAN X, CAI W. Effect of Gd addition on microstructure, martensitic transformation and mechanical properties of Ni50Mn36Sn14 ferromagnetic shape memory alloy[J]. Journal of Alloys and Compounds, 2017, 692: 288-293.

[15] 刘 政, 张嘉艺, 余昭福. 电磁场作用下中铝合金熔体流动的混沌特征的仿真与分析[J]. 中国有色金属学报, 2015, 25(11): 3026-3032.

LIU Zheng, ZHANG Jia-yi, YU Zhao-fu. Simulation and analysis on chaotic characteristic of flow in Al alloy melt under electromagnetic field[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3026-3032.

[16] 刘 政,陈 涛,陈志平. 双向电磁搅拌对半固态A356铝合金凝固组织的影响[J] 中国有色金属学报, 2018, 28(1): 31-38.

LIU Zheng, CHEN Tao, CHEN Zhi-ping. Effects of two-way electromagnetic stirring on solidified microstructure of semisolid A356 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 31-38.

[17] 张伟强. 金属电磁凝固原理与技术[M]. 北京: 冶金工业出版社, 2004.

ZHANG Wei-qiang. Principles and techniques of electro- magnetic solidification of metals[M]. Beijing: Metallurgical Industry Press, 2004.

[18] 陈兴润, 张志峰, 徐 骏, 石力开. 电磁搅拌法制备半固态浆料过程电磁场、流场和温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-run, ZHANG Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in semi-solid slurry preparation by electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

[19] ZHANG Z F, CHEN X R, XU J, SHI L K. Numerical simulation on electromagnetic field, flow field and temperature field in semisolid slurry preparation by A-EMS[J]. Rare Metals, 2010, 29(6): 635-641.

[20] GOLAK S. Manufacture of locally reinforced composite discs by casting in the alternating electromagnetic field[J]. Advances in Materials Science and Engineering. 2015, 2015(1): 1-7.

[21] 张 琦, 金俊泽, 王同敏, 李廷举, 郭庆涛. 金属液在旋转电磁搅拌器作用下的流动分析[J]. 中国有色金属学报, 2007, 17(1): 98-104.

ZHANG Qi, JING Jun-zhe, WANG Tong-min, LI Ting-ju, GUO Qing-tao. Analysis of molten metal flow in rotating magnetic field[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 98-104.

[22] 刘 政, 刘小梅, 朱 涛, 谌庆春. 低频电磁搅拌对半固态铝合金中稀土分布的影响[J]. 金属学报, 2015, 51(3): 272-280

LIU Zheng, LIU Xiao-mei, ZHU Tao, CHEN Qing-chun. Effects of electromagnetic stirring with low current frequency on RE distribution in semisolid aluminum alloy[J]. Acta Metallugica Sinica, 2015, 51(3): 272-280.

Radial solidification microstructure and rare earth elements distribution of A356-La alloy under rotating magnetic field

CHEN Tao1, LIU Zheng2, CHEN Zhi-ping2, HU Yong-mei3

(1. School of Materials Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Mechanical and Electrical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

3. Institute of Engineering and Research, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: A356-La aluminum alloy ingot prepared by composite technology of low superheat pouring, two-way low-frequency electromagnetic stirring and rare earth element refinement were analyzed by OM and SEM, which contains the microstructure with fine size and round shape primary phase. The influence of magnetic field frequency on the radial microstructure and distribution of rare earth elements in alloy ingot was investigated, when the stirring time of electromagnetic field was constant. The results indicate that when the frequency of magnetic field increases, the degree of grain spheroidization becomes significantly better. The growth mode of grain changes from dendrite grain to globular grain, and the distribution of microstructure along the radial and rare earth element becomes uniform. When the magnetic field frequency is 25 Hz and the radius is 0.7R, the morphology of the primary phase can reach at optimum. The average equal-area circle diameter and shape factor of the primary phase are 36.2 μm and 0.82, respectively. The average primary phase diameter and shape factor from the three collecting points in the radial direction are 41.6 μm and 0.76, respectively. In addition, the influence of melt stirring ways on the evolution and uniformity of microstructure along the radial was discussed under the optimum technological parameters. It indicates that the morphology and uniformity of the microstructure obtained from the two way continuous stirring are better than the single way continuous stirring and two-way intermittent stirring. This stirring way accelerates the internal mass transfer and heat transfer process of the melt, and then, to a certain extent, the adverse effect of skin effect on uniformity of solidification structure can be avoided.

Key words: rotating magnetic field; A356-La alloy; distribution of rare earth elements; stirring method; solidification microstructure uniformity

Foundation item: Projects (51144009, 51361012) supported by the National Natural Science Foundation of China; Project(20142bab206012) supported by the Natural Science Foundation of Jiangxi Province, China; Project(GJJ14407) supported by the Science and technology of Jiangxi Provincial Education Department, China

Received date: 2016-12-08; Accepted date: 2017-04-17

Corresponding author: LIU Zheng; Tel:+86-797-8312137; E-mail:liukk66@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51144009,51361012);江西省自然科学基金资助项目(20142bab206012);江西省教育厅科技项目(GJJ14407)

收稿日期:2016-12-08;修订日期:2017-04-17

通信作者:刘 政,教授,博士;电话:0797-8312137;E-mail:liukk66@163.com