文章编号:1004-0609(2011)03-0560-10

近液相线铸造Al-Si合金浆料非枝晶组织的形成与演变

弭光宝1, 2, 李培杰1, 2, 王 晶1, 2, 何良菊1

(1. 清华大学 新材料国际研发中心,北京 100084;

2. 清华大学 机械工程系先进成形制造教育部重点实验室,北京 100084)

摘 要:通过对比实验的方法,利用多次抛光原位观察和金相分析对近液相线铸造Al-Si合金浆料非枝晶组织的形成及演变规律进行研究,进而从熔体结构角度探讨非枝晶组织形成和稳定存在的机制。结果表明:对于Al-7.97Si工业用铝合金,在390~400 ℃的热环境中,常规近液相线铸造半固态浆料的转移及流变成形时间约为15 s;而在液相线以上不高温度区间对熔体施加旋转磁场作用,可延长浆料转移及流变成形的时间,其主要原因是旋转磁场对过热熔体产生的扰动作用一直影响到凝固过程的形核与长大,一方面使熔体中原子集团的尺寸、形状及分布发生改变,为提高形核率创造了条件,另一方面使固-液界面前沿的溶质浓度梯度减小,抑制成分过冷,同时增大了晶核稳态球形长大的临界半径。

关键词:Al-Si合金;过热熔体;旋转磁场处理;非枝晶组织;演变;稳定性;熔体结构

中图分类号:TG146.2+1;TG111.4 文献标志码:A

Formation and evolution of non-dendrite microstructure of Al-Si alloy slurry fabricated by near liquidus casting

MI Guang-bao1,2, LI Pei-jie1,2, WANG Jing1,2, HE Liang-ju1

(1. National Center of Novel Materials for International Research, Tsinghua University, Beijing 100084,China;

2. Key Laboratory for Advanced Materials Processing Technology, Ministry of Education,

Department of Mechanical Engineering, Tsinghua University, Beijing 100084,China)

Abstract: By comparing different experimental schemes and using multiple polishing in situ observation and metallographic analysis, the evolution law of non-dendrite microstructure of Al-Si alloy slurry fabricated by near liquidus casting was researched. Further, from the perspective of melt structure, the formation mechanism and stable existence of non-dendrite microstructure was discussed. The results show that, for Al-7.97Si, at 390-400 ℃, the process of transfer and rheoforming of semi-solid slurry will cost 15s by conventional near liquidus casting. However, in the temperature range not high above liquidus, because of the effect of applied rotating magnetic filed, the time of transfer and slurry rheoforming is elongated. The main reason is that the disturbance caused by rotating magnetic filed for overheating melt always influences the nucleation and growth during solidification. On one hand, the disturbance changes the sizes, shapes and distribution of atomic clusters, which provides the conditions for increasing nucleation rate; on the other hand, it also decreases the solute concentration gradients of solid-liquid interface, which restrains composition overcooling and increases the critical radius of globular growth for crystal nucleus in stable state.

Key words: Al-Si alloy; superheat melt; rotating magnetic filed treatment; non-dendrite microstructure; evolution; stability; melt structure

自1971年美国MIT的SPENCER等[1-2]开始研究半固态组织以来,国内外开发了多种半固态材料制备技术[3-8],至今方兴未艾。其中,仅浆料制备方法就有十余种,如机械或电磁搅拌法、近液相线铸造等,这些工艺方法各有优缺点,目前这方面研究主要集中在工艺优化、新工艺开发及后续流变成形和凝固组织控制机制等方面。然而,随着浆料制备基础理论及短流程流变成形技术研究的不断深入,制约其进一步发展和应用的瓶颈问题仍然是半固态浆料存储和转移过程中组织的枝晶化,为此研究浆料的非枝晶组织形成与演变规律具有重要意义。

近液相线铸造法(Near liquidus casting)由东北大学与墨尔本大学合作提出,是铸态组织非枝晶化的有效方式之一,主要通过控制合金熔体的浇注温度、保温时间及凝固条件等因素获得理想的非枝晶组织,具有适用合金范围广、生产效率高、投资少等优点。2000年,FLEMINGS教授等将机械搅拌与近液相线铸造相结合开发了新MIT法[9],半固态浆料制备开始呈现出复合化发展趋势[10],即一种或几种方法与近液相线铸造相结合制备半固态浆料,如短时弱电磁搅拌与低过热度浇注法[11-12]、近液相线铸造与应变诱导半固态等温处理[13]、剪切低过热度浇注[14]等,使半固态浆料的质量更加优异。因此,本文作者在研究Al-Si合金近液相线保温过程中枝晶组织演变[15]和近液相线铸造浆料非枝晶组织形成基础上,将液相线以上不高温度区间熔体的旋转磁场处理与近液相线铸造相结合,通过对比实验法探讨熔体旋转磁场处理对近液相线铸造浆料组织形成的影响,以期揭示出非枝晶组织近球形或球形长大的依时行为及其稳定性,并从熔体结构角度进一步讨论近液相线铸造非枝晶组织的形成机制。

1 实验

1.1 实验材料

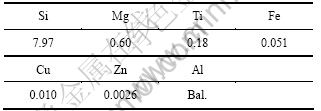

实验用铝合金铸锭的化学成分如表1所列,采用差热分析方法测得该合金液相线温度为616.9 ℃,共晶温度为577.2 ℃。

表1 铝合金的化学成分

Table 1 Chemical composition of aluminum alloy (mass fraction, %)

1.2 实验方法

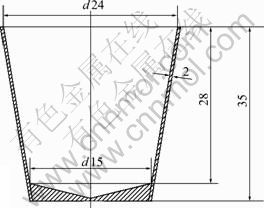

合金在40 kg的石墨坩埚电阻炉中进行熔炼,电阻炉功率为18 kW,熔炼温度为720 ℃,精炼完毕后经适当保温静置,然后开炉浇注,将熔体浇入预热温度为390~400 ℃的不锈钢铸型中(见图1),装满熔体的铸型在390~400 ℃的热环境中分别保温0、1、2、3、6、10、15和20s后直接放入10%盐浴中激冷。合金熔体浇注时的实测温度为618 ℃,采用镍铬-镍硅热电偶测温。

图1 激冷铸型示意图

Fig.1 Schematic diagram of chilled cast (unit: mm)

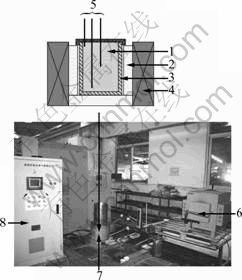

熔体处理实验在自制的旋转磁场产生装置中进行,该装置主要由本体磁场发生器、水循环冷却系统、搅拌器控制柜、热交换器和搅拌坩埚等组成,如图2所示。开启控制柜后,本体搅拌器产生旋转磁场,通过调节励磁电流和频率的大小来改变旋转磁场强度,励磁电流和频率分别在0~100 A、5~50 Hz范围内无级可调。搅拌坩埚采用不锈钢制成,尺寸为d 105 mm×100 mm。为防止坩埚内的熔体氧化、卷气或外溢,搅拌时加盖密封。磁场作用于熔体的时间为50 s,获取试样的方式同上。

1.3 组织检测

将水淬试样沿轴线剖开,取试样上相同位置的区域进行粗磨、精磨、抛光,然后用0.5%(体积分数)HF水溶液进行化学腐蚀。用Neophot-32光学显微镜观察试样中初生α(Al)相形貌。对获得的显微组织在金相分析软件系统中进行定量分析,即分别测出每块区域组织中初生α(Al)相晶粒的等积圆直径和形状系数,取平均值后得出该工艺条件下制得试样的平均等积圆直径(d)和平均形状系数(μ)。其中,等积圆直径通过测量穿

图2 实验设备和本体磁场发生器示意图

Fig.2 Schematic diagram of experimental equipment and ontologies magnetic generator: 1—Aluminum alloy melt; 2—Temperature control system; 3—Stainless steel crucible; 4—Ontologies magnetic field generator; 5—Thermocouple; 6—Holding furnace; 7—Whole magnetic field generator; 8—Control cabinet of magnetic field generator

过形心的两条长轴和两条短轴获得,初生α(Al)相的形状系数由下面公式计算后取平均值得到。

(1)

(1)

式中:S和P分别为α(Al)相晶粒的截面积和截面周长;μc介于0~1之间,μc越趋近1,表明α(Al)相枝晶退化效果越显著[16]。

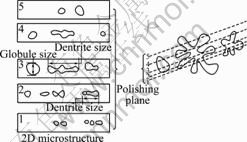

金相分析过程的难点是二维显微组织中非枝晶和树枝晶的区分问题。光学显微镜得到的是二维金相图片,只能显示出晶粒在所观察截面内的分布情况,组织中初生α(Al)相形状复杂,金相显示为独立的晶粒在抛光截面下面很可能是和其他晶粒相连接的,即它们其实是同一个树枝晶,只是被抛光截面切割成类似于几个独立的晶粒。为此,本研究在金相分析中采用多次抛光原位观察的方法,可以获得一定厚度范围内多个抛光截面中的晶粒尺寸和分布信息,进而推出晶粒在抛光截面法向的形貌和分布,最终辨别出该厚度层内的树枝晶和非枝晶组织。图3所示为采用多次抛光原位观察法区别树枝晶和非枝晶并对其尺寸进行测量的示意图。

图3 多次抛光原位观察法示意图

Fig.3 Schematic diagram of in-situ observation by repeated polishing

2 结果与分析

2.1 非枝晶组织的形成

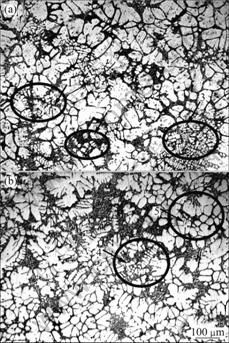

图4(a)和(b)所示分别为合金熔体在液相线以下(611 ℃)浇注到550~560 ℃预热铸型和液相线以上(618 ℃)浇注到390~400 ℃预热铸型的显微组织。从图4(a)中可以看出,所形成的初生α(Al)相非枝晶比较粗大、不圆整且分布不均匀,树枝晶生长在所形成非枝晶的外侧。这说明激冷过程中,坩埚中先期结晶核心在铸型内发生树枝状晶长大,如图4(a)中区域1所示;而熔体中剩余的其它液相中,一部分形成细小的非枝晶(区域2),另一部分形成细小的树枝晶(区域3);

图4 近液相线铸造Al-Si合金浆料的组织形成

Fig.4 Microstructure formation of Al-Si alloy slurry by near liquidus casting: (a) Pouring temperature of 611 ℃; (b) Pouring temperature of 618 ℃

从图4(b)中可以看出,熔体中剩余液相同样有一小部分形成细小的树枝晶(区域4),但大部分剩余液相在铸型中形成蔷薇状或近球形非枝晶(区域5)。这说明在液相线以下浇注制浆时,非枝晶组织的结晶核心大部分产生于坩埚壁或液面,由于激冷条件下,热环境不均匀,剩余液相中大部分直接呈枝晶化生长;当液相线以上浇注制浆时,非枝晶组织的结晶核心形成于预热铸型,一般为内生形核;当铸型预热温度较高时,浆料组织由于激冷作用会形成细小的树枝晶,减少了非枝晶的比率,所以,从浆料非枝晶组织形成看,铸型的预热温度为390~400 ℃比较合理。下面将在相同的铸型预热温度条件下分析浆料非枝晶组织的演变及其稳定性。

2.2 非枝晶组织的演变

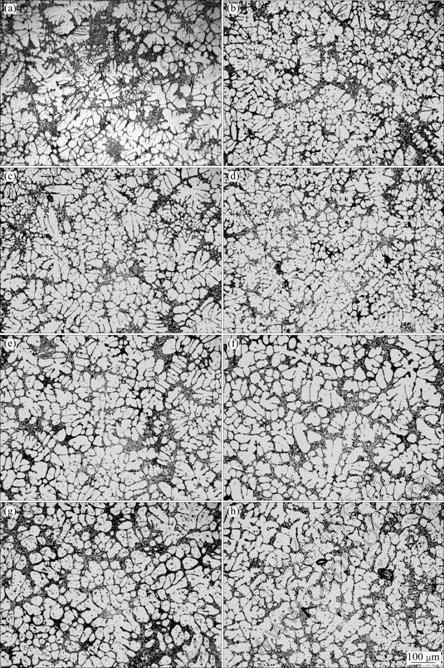

图5所示为预热铸型中浆料在不同保温时间下的

图5 浇注温度618 ℃下Al-Si合金浆料的非枝晶组织演变

Fig.5 Non-dendritic microstructure evolutions of Al-Si alloy slurry at pouring temperature of 618 ℃: (a) Holding time of 0 s; (b) Holding time of 1 s; (c) Holding time of 2 s; (d) Holding time of 3 s; (e) Holding time of 6 s; (f) Holding time of 10 s; (g) Holding time of 15 s; (h) Holding time of 20 s

显微组织(浇注温度为618 ℃)。从图5中可以看出,浆料不经保温处理而直接水淬得到的显微组织会出现细小的树枝晶,随着铸型中浆料保温时间的延长,过冷熔体中剩余的液相不断减少,且较为均匀地分布于初生α(Al)相周围,当快速冷却时,所形成的共晶组织也相对比较均匀,保温时间超过6 s后尤为明显,此时浆料中的非枝晶组织显著增大,当保温时间为20 s时,非枝晶组织中大部分呈蔷薇状,很多初生α(Al)相已经相互接触,并开始呈枝晶化趋势生长。

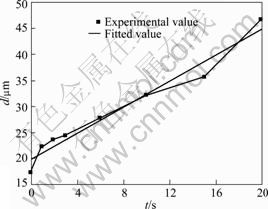

图6所示为浇注温度618 ℃下Al-Si合金浆料组织中初生相平均尺寸d与保温时间t之间的关系曲线。从图6中可以看出,浆料在铸型中保温10 s范围内,初生α(Al)相的平均尺寸与保温时间基本呈线性关系;当保温时间在10~15 s时,初生α(Al)相的长大速度开始变得比较平缓;超过15 s时,又开始快速长大;当保温时间约18 s时,初生α(Al)相的平均尺寸与保温时间不再呈线性关系;随着保温时间的继续延长,非枝晶组织将进一步粗化和枝晶化,此时大部分初生α(Al)相的球形长大已经发生失稳。所以,从初生α(Al)相平均尺寸指标看,浆料非枝晶组织在390~400 ℃的热环境中可以近球形或球形长大18 s,这也是在该热环境下浆料转移和流变成形所持续的时间。随着保温时间的进一步延长,浆料组织中的初生α(Al)相将会相互接触,非枝晶组织不断恶化。

图6 铸型中浆料保温时间对初生α(Al)相平均尺寸的影响

Fig.6 Effect of holding time of slurry in mold on average size of primary α(Al) phase

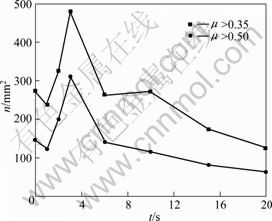

图7所示为浆料组织中平均形状系数(μ)分别大于0.35和0.5的初生α(Al)相数密度n(单位面积内初生α(Al)相非枝晶的数量)与保温时间t之间的关系曲线。从图7中可以看出,铸型中浆料保温大约3 s时,存在一个形成非枝晶的高峰;当保温时间超过3 s时,随着保温时间的延长,初生α(Al)相的数密度逐渐减小;当保温18 s时,μ大于0.35和0.50的初生α(Al)相的数量分别减少到125和65个;当保温时间在3 s以下时,由于铸型中剩余熔体比较多,如前非枝晶形成,此时组织中更多的是树枝晶或柱状非枝晶,从而使平均形状系数0.35~0.5范围内初生α(Al)相的数密度大大减小。

图7 铸型中浆料的保温时间对不同圆整度初生α(Al)相数密度的影响

Fig.7 Effect of holding time of slurry in mold on number density of primary α(Al) phase with different roundness

综合初生α(Al)相平均尺寸和形状系数两指标,合金浆料在390~400 ℃预热铸型中保温3~15 s时,初生α(Al)相呈近球形或球形长大,并能够相对稳定地存在,即在这样的热环境下为半固态浆料的转移和流变成形提供大约15 s的时间。

2.3 熔体旋转磁场处理的影响

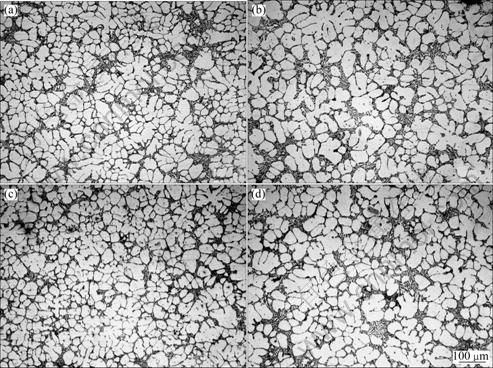

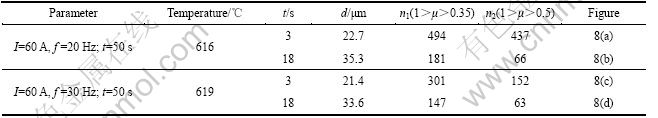

图8所示为液相线不高温度区间内对Al-Si合金熔体进行旋转磁场处理后近液相线铸造得到的显微组织,工艺参数及显微组织定量描述如表2所列。从图8和表2中可以看出,与常规近液相线铸造相比,经磁场处理后的浆料组织中初生α(Al)相更加细小、圆整,且分布均匀;预热铸型中浆料保温3 s时,浆料组织中近球形或球形初生α(Al)相的数密度同样很大,凝固过程中有更多的初生α(Al)相保持近球形或球形长大,当保温18 s时,非枝晶组织的尺寸明显增大,部分区域开始出现蔷薇状非枝晶,初生α(Al)相的球形长大尚未发生强烈失稳,此时浆料组织仍能很好地满足半固态加工成形要求,这说明熔体的磁场处理作用一直影响到合金的凝固过程,与未经磁场处理相比,不仅改善了近液相线铸造的形核过程,增加了结晶核

图8 熔体磁场处理后近液相线铸造Al-Si合金浆料的显微组织

Fig.8 Microstructures of Al-Si alloy slurry by near liquidus casting after magnetic field treatment: (a) Holding time of 3 s; (b) Holding time of 18 s; (c) Holding time of 3 s; (d) Holding time of 18 s

表2 不同旋转磁场工艺参数下近液相线铸造Al-Si合金浆料的显微组织参数

Table 2 Microstructure parameters of Al-Si alloy slurry by near liquidus casting under different processing parameters of rotation magnetic field

心数量,还提高了非枝晶近球形或球形长大的稳定性,最终使半固态浆料转移和流变成形时间延长;在处理时间相同的条件下,磁场处理温度区间越低,平均形状系数大于0.5的非枝晶数量越多,即初生α(Al)相球化程度越高。由于磁场处理完全是在液相线以上不高温度区间进行的,所以可以推断旋转磁场处理对合金熔体的结构与状态产生了作用。

3 讨 论

根据金属熔化机制及X射线衍射试验数据可知,金属熔体微观结构的不均匀性存在于液相线以上一定温区,原子集团是产生这些微观结构不均匀性的主要方面[17-18]。熔化后的金属熔体由带低能量粒子的类晶体原子集团和含高能量激活原子的无序区域组成,其中原子集团的平均尺寸为2~5 nm,存在的时间为10-7~10-8 s,这两个区域的相互作用处于动力学平衡中,且经常交换原子[19]。由于每一种合金都存在一个或多个原子集团失稳的温度Ti(液态金属的物性发生异常变化或滞后现象)[20-22],即熔体在向气态转变过程中将发生一次或多次结构转变,如在升温过程中,Al熔体粘度曲线在800 ℃左右发生异常变化,因此,结合工程上的实际熔炼条件,熔体处理一般在原子集团第一次发生失稳的温度以下进行。在该温度区间内,原子集团的平均尺寸是温度的连续函数,即原子集团尺寸与温度之间存在一一对应关系[23]。POUND等[24]对在该温度区间内原子集团如何演变以及对凝固过程有何影响进行了研究。

Pound等[24]认为,给定液相中原子集团的大小、数量及分布是过冷度的函数,也就是说原子集团的性质和状态对熔体的凝固行为有重要影响。因此,基于金属熔体结构的微观不均匀性理论[17-18],可以给出液相线以上不高温度区间原子集团的演变规律[23]:

, T0≤T≤TC (2)

, T0≤T≤TC (2)

式中:R(T )为T温度下原子集团的平均半径;α为几何形状因子,0<α≤1;Z1为金属熔化前的配位数;r为原子集团中原子之间的距离;Q为激活能;k为玻尔兹曼常数;C0为熔点处被激活原子的相对浓度;Tm为熔点;T0为过冷熔体中临界形核温度;TC为熔体从液态到气态转变过程中发生第一次结构转变(原子集团失稳)的温度。

从式(2)中可知,随着温度的升高,原子集团的尺寸逐渐减小,当在较高温度进行铸造时,原子集团随着温度的快速降低而迅速长大至临界形核尺寸,熔体在不均匀的相起伏中形成晶胚,在这个过程中,原子集团在不均匀的温度场和浓度场中长大,其长大行为具有明显的方向性(温度场不均匀程度比较大),故原子集团尺寸和分布不均匀、形状不规则,这种条件下为凝固提供的有效结晶核心数量少,导致大部分初生相沿着不均匀的热流方向呈树枝状晶生长;而在液相线附近,原子集团的尺寸相对较大,原子集团的大小、数量与分布都较为均匀和稳定,宏观上表现为熔体中温度场和浓度场都比较均匀,在一定过冷度下,熔体的相起伏状态相对稳定,当原子集团的尺寸达到临界形核尺寸时,大量均匀分布、形状规则的原子集团就会部分瞬时长大为稳定的结晶核心,此时熔体中的热环境相对比较均匀,晶胚周围的扩散边界层厚度差别不大,从而促进初生相呈近球形或球形长大,这与实验结果相一致,如图6和7所示,铸型中初生α(Al)相近球形或球形长大时间为3~15 s。

近液相线铸造前对熔体进行旋转磁场处理,一方面改善了熔体中原子集团的大小、形状和分布,为先期形核率的提高创造有利条件,另一方面使晶胚稳态近球形或球形长大的概率大大提高。

随着熔体温度的降低,原子集团的尺寸不断增大,当旋转磁场作用于熔体时,加快了原子集团的游动速率(扩散速率增大),增加相互碰撞与结合次数,使原子集团形状和分布更加均匀,宏观上使熔体温度场和浓度场更加均匀,且随着温度的进一步降低,这些原子集团在相起伏下很容易达到临界形核半径,形成稳定存在的晶胚。在这个过程中,旋转磁场使熔体产生定向运动,同时,熔体中伴随着原子集团之间的原子交换而发生能量交换。由式(2)可知,激活能的变化使得原子集团的尺寸减小,于是提高了形核前和形核初期熔体中原子集团的数量,相起伏将使原子集团在更低的温度下达到临界形核半径,即在较大的过冷度下开始结晶,这是结晶核心数量增加、形核率提高的重要原因。可见,磁场作用增大了形核初期熔体中有效结晶核心的数量,为形核率的提高创造了条件。

在近液相线铸造之前,熔体已经从旋转磁场中移出,磁场并没有直接作用于晶核的长大过程,而由前述实验结果可知,熔体处理后初生α(Al)相近球形或球形长大的时间延长了。那么液相线以上的磁场是如何影响晶核长大过程的?下面将对这个问题给出解释。

晶核球形稳态生长的动力学判据[25]:

G≥ (3)

(3)

式中:G为固-液前沿温度梯度;R为固-液界面生长速度;D为液相扩散系数;K为溶质平衡分配系数;ΔT0为成分为C0的合金固-液相线温度差;Γ为Gibbs-Thomson系数(Γ=σ/ΔSf),ΔSf为单位体积熔化熵,σ为固-液界面能。

式(3)中,右侧第一项为成分过冷影响项,第二项为曲率影响项,第一项增大不利于满足不等关系,易使界面生长失去稳定性;第二项增大有利于满足不等关系,易使界面生长保持稳定。由此可见,近球形或球形长大存在一个稳定长大的临界半径RΓ,HUANG和GHCKSMANN[26]经过研究后认为,晶粒保持球形长大的临界半径RΓ为

(4)

(4)

式中:R*为临界形核半径;λS为固相热导率;λL为液相热导率。

从式(4)中可看出,当球形生长半径达到RΓ时,生长即会失稳,当球形生长半径小于RΓ时,仍呈球形长大。因此,欲获得理想非枝晶组织,可通过条件改变达到以下两种情况:一是晶粒长大相互抵触时,其半径仍然未达到RΓ;二是晶粒生长至相互未抵触时,半径已达到RΓ,球形生长发生失稳,呈枝晶长大,需要使其转变为近球晶或等轴非枝晶。

由于实际中近液相线铸造过程是在磁场停止作用后立即进行的,根据液固态结构相关性研究[27-28],熔体中原子集团的性质和状态仍然会继续保持着磁场作用的效果,如原子集团的形状、尺寸及分布等近似不变,所以凝固过程中磁场作用是以间接扰动(磁场扰动)方式存在的。当磁场扰动作用存在时,凝固界面前沿温度梯度和浓度梯度均有所减小,界面前沿的扩散得到增强,即扩散系数变大,由成分过冷判据[29]很难判断磁场对成分过冷的影响是增强还是减弱,然而,实际熔体中界面前沿温度边界层的厚度远大于浓度边界层(扩散边界层)的厚度[30],且磁场扰动的存在使温度和浓度边界层的厚度进一步减小,所以,成分过冷的影响大大减小,从式(3)界面稳定性的动力学条件看,液相线以上磁场扰动可有效抑制成分过冷,使界面张力在晶核长大过程中起主导作用,因而球形长大趋于稳定。此外,近液相线铸造时,熔体中液相与固相的温度相接近(熔体中固相温度略低于液相温度[31]),故固相热导率略大于液相热导率,将经典临界形核半径公式代入式(4)有

(5)

(5)

式中:ΔT为过冷度。

根据式(5),晶粒保持球形长大的临界半径RΓ与过冷度ΔT成反比,即ΔT减小,保持球形长大的临界半径增大。这并不与前述形核初期ΔT增大矛盾。磁场扰动的存在,减小了原子集团的尺寸,使形核初期的过冷度增大,大大提高了有效结晶核心的数量;而在形核过程中和形核后期,磁场扰动作用同样使凝固过程的温度场比较均匀,尤其在开始产生晶胚时,由于潜热的存在,剩余熔体形核的ΔT快速减小,使RΓ迅速增大,即增大了晶核稳态球形长大的概率。但是,这种情况下并没有影响实际形核的难度,一方面近液相线铸造形核的主要方式是内生异质形核[32],另一方面磁场扰动作用使原子集团的尺寸减小,数量增大,当熔体温度进一步降低时,原子集团很容易产生合并长大或相互堆积,即熔体中除单个原子占据晶格点阵空位生长外,还会有取向一致的原子集团进入空位与生长的晶体相连接,如图9所示[33]。

综合上述两个方面,在磁场扰动作用下,晶核球形稳定生长的临界半径RΓ变大了,使一部分球晶在长大抵触之前仍未达到其球形稳态生长的临界半径,生长未发生失稳而将球形长大的晶粒形态保留下来。当然,在实际熔体中,一部分晶核球形长大过程中很有可能发生失稳而长成枝晶,磁场扰动作用是否对已达到RΓ的失稳晶核产生作用,尚有待于讨论。

总之,熔体中的原子集团是近液相线铸造非枝晶组织的主要结晶核心来源,原子集团的大小、形状及分布等是影响理想非枝晶组织形成的微观本质因素;旋转磁场产生的扰动作用贯穿于近液相线铸造的形核和长大过程,并最终减弱趋于消失,改善了晶粒球形长大的稳定性,有效地促进了理想非枝晶组织的形成。

图9 原子集团附着到类固相原子集团粗糙表面示意图[33]

Fig.9 Schematic diagram of atomic groups attached to rough surface of solid-like atomic groups[33]

4 结论

1) 在均匀的热环境中,近液相线铸造Al-Si合金浆料的非枝晶球形长大对时间比较敏感,随着浆料保温时间的延长,非枝晶的球形长大开始失稳,当超过15 s时,非枝晶长大方式开始转变为枝晶长大;而浇注后立即激冷,熔体中剩余液相容易呈枝晶方式长大。

2) 对于Al-7.97Si工业用铝合金,在390~400 ℃的热环境中,常规近液相线铸造半固态浆料的转移和流变成形时间约为15 s;而在液相线以上的不高温度区间,对合金熔体施加旋转磁场处理延长了浆料的转移和流变成形时间,这将为半固态流变成形技术开发提供参考。

3) 液相线以上不高温度区间的磁场扰动作用一直影响到凝固过程的形核与长大,一方面使熔体形核之前和形核初期的原子集团尺寸、形状及分布发生改变,有效增加了结晶核心的数量,另一方面使固-液界面的溶质浓度梯度减小,抑制了成分过冷,同时增大了晶核稳态球形长大的临界半径。

REFERENCES

[1] SPENCER D B, MEHRABILA R, FLEMINGS M C. Rheological behaviour of Sn-15Pb in the crystallization range[J]. Metall Trans, 1972(3): 1925-1932.

[2] FLEMINGS M C. Behavior of metal alloys in the semi-solid state[J]. Metallurgical Transactions A, 1991, 22(5): 957-981.

[3] 罗守靖, 田文彤, 谢水生, 毛卫民.半固态加工技术及应用[J]. 中国有色金属学报, 2000, 10(6): 765-773.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng, MAO Wei-min. Technology and applications of semi-solid forming[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-773.

[4] 管仁国, 李建平, 陈礼清, 王 超. 波浪型倾斜板振动过程中合金组织的形成机理[J]. 材料研究学报, 2008, 22(4): 363-368.

GUAN Ren-guo, LI Jian-ping, CHEN Li-qing, WANG Chao. Mechanism of alloy microstructure formation during vibrating wavelike sloping plate process[J]. Chinese Journal of Materials Research, 2008, 22(4): 363-368.

[5] 崔建忠, 路贵民, 刘 丹, 董 杰. 半固态浆制备技术的新进展[J]. 哈尔滨工业大学学报, 2000, 32(4): 110-113.

CUI Jian-zhong, LU Gui-min, LIU Dan, DONG Jie. New headway in semi-solid slurry making technology[J]. Journal of Harbin Institute of Technology, 2000, 32(4): 110-113.

[6] FINDON M. Semi-solid slurry formation via liquid metal mixing[D]. Worcester, MA: Worcester Polytechnic Institute, 2003: 3-20.

[7] DOUTRE D, LANGLAIS J, ROY S. The SEED process for semi-solid forming[C]//Oroc of 8th International Conference on Semi-solid Processing of Alloys and Composites. Limmasol, Cyprus, 2004: 10.

[8] NAFISI S, GHOMASHCHI R. Effects of modification during conventional and semi-solid metal processing of A356 Al-Si alloy[J]. Materials Science and Engineering A, 2006,41(5): 273-285.

[9] YURKO J A, MARINEZAND R A, FLEMINGS M C. Development of the semi-solid rheocasting(SSM) process[C]// Proceeding of the 7th S2P, Japan, 2002: 659-664.

[10] 弭光宝, 薛克敏, 张早明, 李培杰.半固态坯料制备及其加工成形数值模拟最新进展[J]. 中国科技论文在线精品论文, 2008, 1(2): 44-53.

MI Guang-bao, XUE Ke-min, ZHANG Zao-ming, LI Pei-jie. The iatest research development of semi-solid billet making and numerical simulation[J]. Highlights of Science Paper Online, 2008, 1(2): 44-53.

[11] 汤国兴, 毛卫民, 刘永峰. 复合工艺对半固态A356铝合金浆料组织的影响[J]. 材料研究学报, 2008, 22(2): 167-170.

TANG Guo-xing, MAO Wei-min, LIU Yong-feng. Effect of compound process on semi-solid slurry of A356 aluminum alloys[J]. Chinese Journal of Materials Research, 2008, 22(2): 167-170.

[12] 樊 刚, 张家涛, 魏 昶. 低过热度浇注弱电磁搅拌下半固态Al-30Si合金凝固特性分析[J]. 特种铸造及有色合金, 2008, 28(4): 278-280.

FAN Gang, ZHANG Jia-tao, WEI Chang. Solidification characteristics of semi-solid Al-30Si alloy by weak electromagnetic stirring with low super-heating pouring[J]. Special Casting & Nonferrous Alloys, 2008, 28(4): 278-280.

[13] XUE K M, MI G B, WANG Q R. Study on compound fabrication technology of semi-solid billet of Al-Si alloy based on SIMA method[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(Sl): 1224-1231.

[14] GUO H M, YANG X J, HU B. Reocasting of aluminum alloy A356 by low superheat pouring with a shear field[J]. Aeta Metallurgic (Letters), 2006(5): 328-334.

[15] 弭光宝, 薛克敏, 张早明, 王清瑞. AlSi9Mg合金在近液相线区保温过程中枝晶组织的演变[J]. 特种铸造及有色合金, 2006, 26(5): 285-287.

MI Guang-bao, XUE Ke-min, ZHANG Zao-ming, WANG Qing-rui. Microstructural evolution during holding of AlSi9Mg alloy above liquidus[J]. Special Casting & Nonferrous Alloys, 2006, 26(5): 285-287.

[16] 唐靖林, 殷雅俊, 范钦珊, 曾大本. 液固温区不同初生α相形态A356合金的流变行为[J]. 中国有色金属学报, 2002, 12(3): 430-435.

TANG Jing-lin, YIN Ya-jun, FAN QIN-shan, ZENG Da-ben. Rheological behavior of semi-solid A356 alloy with different morphology of primary a phases[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(3): 430-135.

[17] BAUM B A, HASSIN G A, TYAGUNOV G V. Liquid steel[M]. Moscow: Metallurgical industry press, 1984: 12-48. (in Russian)

[18] YERSHOV G S, BYCHNOV YU B. Regeneration of high strength aluminum alloy [M].Moscow: Metallurgy Press, 1979: 5-60. (in Russian)

[19] SKREBCOV A M. The temperature of completely destroy of atomic cluster in metal melt – What is its value[J]. Transaction of Higher Education-Ferrous Metallurgy(steel), 2009(2): 28-32. (in Russian)

[20] FILIPPOV E S. Structure, physics and chemistry of metallurgical melt [M]. Moscow: Metallurgical Industry Press, 1995: 50-158. (in Russian)

[21] SKREBCOV A M. Temperature destruction clusters metal melt academician VI arkharova or just a waste of hereditary properties of the charge? Effect А М Skrebtsova[J].Casting Process, 2008(5): 9-15. (in Russian)

[22] 张 雯, 刘彩池, 王海云, 徐岳生, 石义情.半导体硅熔体的有效(磁)黏度[J]. 物理学报, 2008, 57(6): 3875-3879.

ZHANG Wen, LIU Cai-chi, WANG Hai-yun, XU Yue-sheng, SHI Yi-qing. The effective viscosity of silicon melt in malnetic field[J]. Acta Phys Sin, 2008, 57(6): 3875-3879.

[23] MI G B, LI P J, HE L J. Calculation model of metal melt structural information Ⅱ[J]. Science in China: Physics, Mechanics & Astronomy, 2010. (in press)

[24] POUND G M. Perspectives on nucleation[J]. Metallurlical Transactions A, 1985, 16: 487-502.

[25] FLEMINGS M C. Solidification Processing[M]. New York: McGraw Hill Book Company, 1974: 42-78.

[26] HUANG S C, GHCKSMANN M E. Fundamentals of dendritic solidification: Ⅱ Development of sidebranch structure[J]. ACTA MET, 1981, 29: 717.

[27] NIKITIN V I. Heredity and technology of genetic engineering in cast alloys[J]. Foundry, 2002,10: 8-10. (in Russian)

[28] DUBROVSKII S A, SHIPELNIKOV A A, ROGOTOVSKII A N. The atom group characteristics hypothesis of charging structure hereditary in ferrous metals[J]. Transaction of Higher Education – Chernozem, 2008, 11 (1): 89-96. (in Russian)

[29] 刘全坤, 祖方遒. 材料成形原理[M]. 北京: 机械工业出版社, 2004: 83-85.

LIU Quan-kun, ZU Fang-qiu. Material forming basic principle[M]. Beijing: China Machine Press, 2004: 83-85.

[30] 黄 焰, 刘 山, 鲁德洋, 周尧和, 程功善, 张福生. 枝晶生长中的对流效应与形态选择[J]. 中国空间科学技术, 1989(1): 11.

HUANG Yan, LIU Shan, LU De-yang, ZHOU Yao-he, CHENG Gong-shan, ZHANG Fu-sheng. Fluid flow and pattern selection in dendritic growth[J]. Chinese Space Science and Technology. 1989(1): 11.

[31] 吴树森. 材料加工冶金传输原理[M]. 北京: 机械工业出版社, 2001: 232.

WU Shu-sen. Principle of metallurgy transmission for material processing[M]. Beijing: China Machine Press, 2001: 232.

[32] 董 杰, 路贵民, 任栖锋, 崔建忠. 液相线铸造法非枝晶半固态组织形成机理探讨[J]. 金属学报, 2002, 38(2): 203-207.

DONG Jie, LU Gui-min, REN Qi-feng, CUI Jian-zhong. Discussion on the formation mechanism of nondendritic semi-sold microstructures during liquidus casting[J]. Acta Metallrugica Sinica, 2002, 38(2): 203-207.

[33] KOPTSEV V V. Model of crystallization process[J]. Transaction of Higher Education—Metallurgy, Ferrous Metallurgy, 2005, (2): 25-27. (in Russian)

(编辑 何学锋)

基金项目:清华-力劲压铸高新技术研究中心资助课题

收稿日期:2010-02-05;修订日期:2010-05-11

通信作者:弭光宝,博士研究生;电话:010-62773639;E-mail: mgb07@mails.tsinghua.edu.cn