文章编号:1004-0609(2012)05-1421-09

无铅磷钙黄铜的组织与性能

朱权利1,张先满1,罗良颂2,李 微1,陈维平1,汪桂龙2,李 晨2

(1. 华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640;

2. 广东华金合金材料实业有限公司,广州 511356)

摘 要:通过熔铸方法,于中频感应炉中制备无铅磷钙黄铜铸锭,利用扫描电镜、电子能谱仪、电子万能试验机及卧式车床等手段,研究磷钙黄铜合金的显微组织和力学、切削及耐脱锌腐蚀性能,并结合切屑的形貌观察,分析金属间化合物对切削性能的改善作用。结果表明:磷、钙显著改变了黄铜的组织与性能,使得磷钙黄铜的组织由α相、β相和分布在晶界上及晶粒内的金属间化合物颗粒组成;无铅磷钙黄铜合金的主要成分(质量分数)为57%~60% Cu、40% Zn、0.7% P、0.5% Ca时,合金显示出优良的综合性能,其抗拉强度为362.7 MPa,伸长率为15.0%,布氏硬度为105.0HB,耐脱锌腐蚀深度为321.9 μm,切削性能与铅黄铜HPb59-1相当。

关键词:无铅;磷钙黄铜;显微组织;金属间化合物;性能

中图分类号:TG146.1; TG113.12 文献标志码:A

Microstructure and properties of lead-free P-Ca brasses

ZHU Quan-li1, ZHANG Xian-man1, LUO Liang-song2, LI Wei1,

CHEN Wei-ping1, WANG Gui-long2, LI Chen2

(1. National Engineering Research Center of Near-Net-Shape Forming for Metallic Materials,

South China University of Technology, Guangzhou 510640, China;

2. Guangdong Hua Jin Advanced Alloys Industrial Company Limited, Guangzhou 511356, China)

Abstract: The ingots of P-Ca brass were prepared in a medium frequency induction furnace through scientific casting process. The microstructure and mechanical, cutting and dezincification corrosion-resistance properties of P-Ca brass were studied by scanning electron microscopy (SEM), energy dispersive spectrometer(EDS), electron universal test machine and lathe, the effect of the intermetallics on the cutting performance was also studied through the observation of chips. The results show that, P and Ca change the microstructure and properties of brass alloys significantly, making the microstructure of P-Ca brass composed of α, β and intermetallic compounds dispersed on grain boundaries and in grains. The reasonable contents (mass fraction) of main elements are 57%-60% Cu, 40% Zn, 0.7% P and 0.5% Ca. The brass alloy containing this component has good performances as follows: tensile-strength of 362.7 MPa, elongation of 15.0%, Brinell hardness of 105.0HB, dezincification depth of 321.9 μm, and the cutting property is as well as that of HPb59-1.

Key words: lead-free; P-Ca brass; microstructure; intermetallics; property

铅黄铜由于具有一系列优良的特性,已被广泛应用于各个领域[1]。但这类材料中的铅容易以固态或气态的形式析出,进入环境后又不易被除去,并能不断富集,对环境和人体健康造成威胁,世界各国均很重视铅造成的污染和引起的危害,已限制和禁止铅黄铜的使用[2-4]。环保型易切削黄铜的研究已成为世界有色金属研究的热点,研究开发出无铅易切削黄铜将会产生巨大的社会效益和经济效益[5-7]。

近年来,国内外对无铅易切削黄铜进行了大量的研究,并已经取得了一定成果,主要是以铋[8-10]、 硅[11-12]、镁[13-15]、锑[16-18]及石墨[19-20]替代铅。铋黄铜容易发生铋以薄膜状在晶界偏聚,严重影响了铋黄铜的力学性能,但通过添加微量元素(如锡、磷、稀土等)可改变铋的偏析行为。美国已开发出8种无铅(或低铅)的易切削铋铜合金,日本近年来也申请了多项易切削铋铜合金专利,并开发出NB系列,部分已实现商品化,但由于铋资源有限,使得其价格昂贵,故铋黄铜难以推广应用。我国在无铅黄铜研究方面起步较晚,对铋黄铜缺少系统性的研究;硅黄铜的切削性能只有铅黄铜性能的70%~80%,同时刀具磨损较大,其切削性能还有待进一步提高,并且其铜含量高,其价格比一般黄铜高出很多。肖来荣等[15]通过熔铸、挤压的方法制备出镁黄铜棒材,其切削性能达到铅黄铜性能的78.5%,但镁黄铜在熔炼过程中容易发生氧化、吸气等,使得其无铅黄铜的熔炼工艺复杂,并且关于镁黄铜中化合物的种类、形态、分布的控制技术以及这些化合物的物理、化学性质等基础性问题仍需进一步研究;他们还进行了以锑代铅的研究[18],并取得了一定的成果,但近年来对于锑是否对人体有害也存在不同看法。关于石墨黄铜的开发,则由于石墨的强度低、密度小、容易上浮,同时其熔点高(3850℃),很难采用普通熔铸方法使其熔入黄铜基体中,需要采用离心、搅拌等先进的铸造技术,这使得生产工艺复杂,导致生产成本大幅增加。整体来说,国内外对于无铅黄铜的研究还处于探索阶段,在无铅黄铜的推广应用中还存在许多急需解决的难题,降低成本和提高切削性能并兼顾其导热、导电等综合使用性能,是无铅黄铜面临的重大问题。

考虑到替代铅的生产成本及对环境的影响,本文作者采用价格低廉且对环境和人体无毒的磷和钙替代铅,利用磷、钙与铜、锌等生成脆而不硬的金属间化合物来改善切削性能,并且同时加钙,利用钙和磷的相互作用,还可消除磷对黄铜脆性及导电等性能的不利影响。通过熔铸方法,制备了磷钙黄铜,并对其显微组织和力学、切削及耐脱锌腐蚀性能进行研究,为进一步提高磷钙黄铜合金的综合性能提供一定的理论参考。

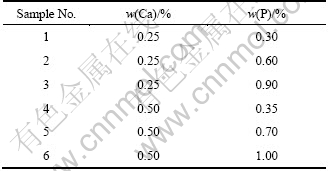

1 实验

试验原料如下:电解铜,工业纯锌锭,磷含量为14%(质量分数,下同)的P-Cu中间合金,工业纯锌锭和块状纯钙,铜稀土(含RE10%),纯锡。磷钙黄铜合金中磷、钙的含量如表1所列,而锡含量为0.5%,锌含量为40%,RE含量为0.15%,余量为铜。

表1 各试样的磷、钙含量

Table 1 Contents of P and Ca of samples

通过合理的熔铸工艺,将配料于中频感应炉中进行熔炼,浇注前须进行炉前检查,确保合金液合格后才能浇注,并严格控制熔炼温度和浇注温度。本试验成功制备无铅磷钙黄铜铸锭,并对制备出的磷钙黄铜合金进行力学性能实验、电镜扫描、能谱分析及切削和耐脱锌腐蚀试验分析。

主要设备如下:250 kg中频感应炉,微机控制电子万能试验机(型号为CMT5105),Nova Nano 430扫描电镜,INCA X-act能谱仪,国产C6132A1普通卧式车床,自行研制的恒温水槽,LeicaDMI 5000M金相显微镜。

2 结果和分析

2.1 磷钙黄铜的力学性能

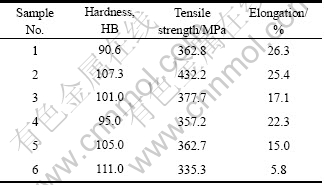

各试样的力学性能如表2所列。由表2可看出,各试样都呈现较好的力学性能,随着磷含量的增加,材料的硬度逐渐增大,而塑性则逐渐降低。尤其是试样6,当磷含量达到1.0%时,其表现出一定的脆性,但机加工时,并未表现出严重磨损刀具的现象。

2.2 磷钙黄铜合金的显微组织

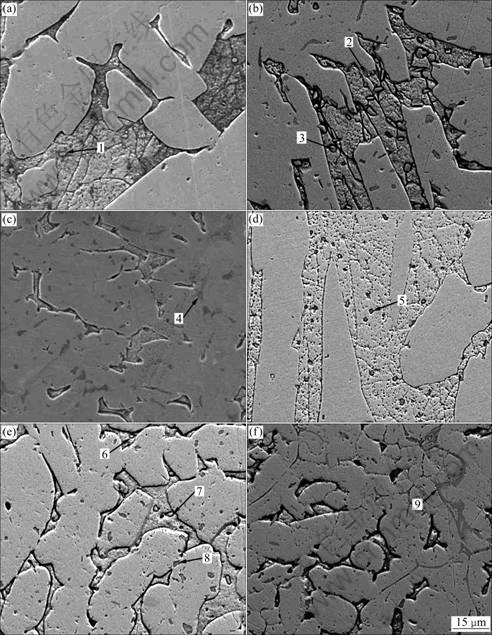

各试样的SEM像如图1所示。由图1可见,组织中的α、β相清晰可辨。对比试样1~3,发现随着磷含量的增加,α相增多,而β相则逐渐减少,且试样2含有的第二相颗粒较多;试样4~6也有相同的规律,试样5含第二相颗粒较多,但与之不同的是,随着磷、钙含量的增加,试样6组织中在α相内出现细密的连续网状的Cu-P等中间合金的共晶组织。金属-非金属共晶的形貌,与金属-金属共晶的层片或棒状结构不同,而是相互连接在一起的排列非常紊乱的分枝。

表2 各试样的力学性能

Table 2 Mechanical properties of samples

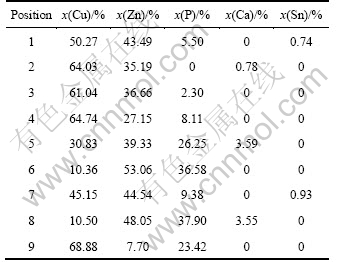

分别对图1中的各标记处的第二相颗粒进行能谱分析,结果如表3所列。从表3可知,在磷钙黄铜合金中,存在多种由铜、锌、磷、钙等组成的复杂结构的金属间化合物。其中,9处颗粒中铜、磷摩尔比接近3:1,可初步判断为Cu3P,而其他各处的化合物有待进一步研究。

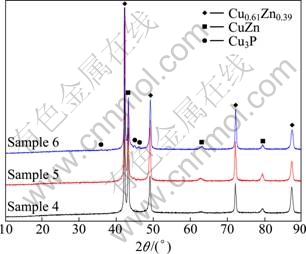

2.3 物相分析

考虑到试样4~6中添加的磷、钙较多,可能生成的合金相种类也较多,故对其进行X射线衍射分析,结果如图2所示。由图2可知,磷钙黄铜合金主要由α相(Cu0.61Zn0.39)和β相(CuZn)组成,试样4中,仍无明显的新相产生,但随着磷含量的增多,试样5的衍射谱中逐渐出现新的衍射峰,并且在试样6中,其峰值更为明显,这些衍射峰位置与文献[21]中的Cu3P主衍射峰位置相同,再结合表3中试样6的能谱分析结果,可推测出合金中存在Cu3P相。但并没有检测到文献[22]报道的由铜、锌、磷、钙组成的结构复杂的金属间化合物如Ca3Cu2Zn2P4、Ca2CuZn2P3、Ca4Cu3Zn2P5的存在,这可能是由于其体积分数不多,实验设备检测不到等原因引起的。

图1 各试样SEM像及能谱位置

Fig. 1 SEM images of as cast P-Ca brass samples and positions of EDS: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4; (e) Sample 5; (f) Sample 6

表3 图1中各第二相的EDS分析结果

Table 3 EDS results of second phases marked in Fig. 1

图2 试样4~6的XRD谱

Fig. 2 XRD patterns of samples 4~6

2.4 切削性能

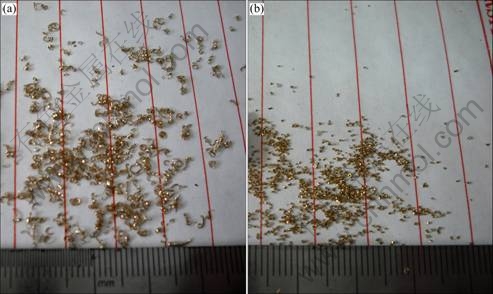

各试样的切削性能的好坏以是否断屑来判断[23]。根据车削结果可看出,各切屑表面都光亮,断屑良好,其中试样5的切屑大致成“C”形,切屑短小,在形态和尺寸上,与含铅黄铜HPb59-1的切屑相似,其切屑如图3所示。故相比之下,磷钙黄铜中的试样5的切削性能最好,接近HPb59-1的。

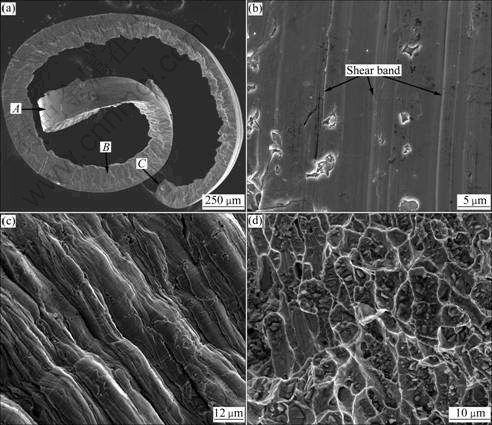

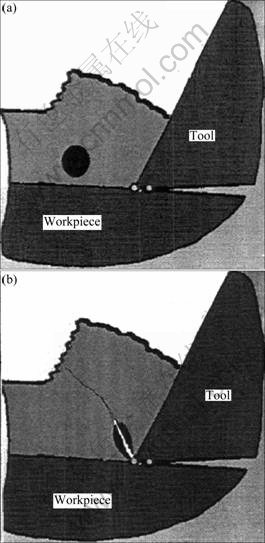

对试样5的切屑进行SEM分析,结果如图4所示。图4(a)所示为呈“6”字形的细小的切屑,宏观上看起来,切屑靠刀刃侧表面很光亮,但沿图4(a)中箭头“A”方向经更高倍数放大后(见图4(b)),发现其表面存在近似垂直于切削方向的周期性的剪切带,可认为变形是沿着剪切面发生间断的滑移,而且有大量空洞,疑似金属间化合物在切削过程中脱落或熔化时留下的;图4(c)所示为切屑的自由表面(图4(a)中箭头“B”所指方向),呈现周期性的凹凸状的层片结构,并且在一次剪切带之间,有二次剪切带,可判断出这种层片结构源于刀刃-工件接触面(见图4(b))产生的周期性的剪切带向切屑自由表面的扩展[24],故切屑形成过程可简单地当作是各层片结构间在剪切力作用下通过位错实现的相互滑移过程。一般金属晶体内的缺陷间隔是微米数量级的,故滑移间隔也是微米数量级,但图中切屑的自由面却具有更大的一些间隔凹凸,其原因是由于切削多晶体金属时,其内部晶粒的强度或结晶方向不同或者振动等造成的。图4(d)所示为切屑断面(图 4(a)中箭头“C”所指,即剪切面),可看到大量的韧窝,且韧窝内大多包含着第二相颗粒,剪切断口从这些类似夹杂物的颗粒开始,而在裂纹及变形硬化达到最大程度后形成。同时,各晶粒被剪切拉长成椭球形。

图3 试样的切屑照片

Fig. 3 Chips of samples: (a) Sample 5; (b) HPb59-1

图4 磷钙黄铜切屑的SEM像

Fig. 4 SEM images of chips of P-Ca brass: (a) Macroscopic full-view of chip; (b) Tool-contact surface of chip marked by “A” in (a); (c) Free surface of chip marked by “B” in (a); (d) Fracture of chip marked by “C” in (a)

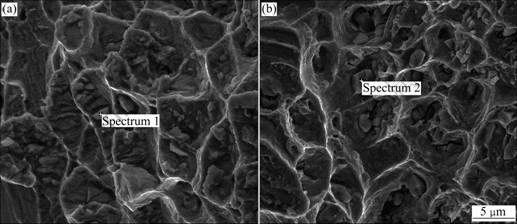

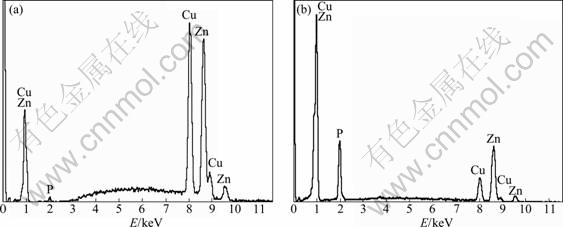

对图4(d)中第二相颗粒进行能谱分析,位置见图5,同时可看出,这些颗粒大多在2 μm左右,能谱分析结果如图6和表4所示。其中,在能谱1的位置,第二相颗粒中铜、锌、磷的摩尔比约为9:27:14,而在能谱2的位置,第二相颗粒中铜、锌、磷的摩尔比为25:22:3,其铜含量明显高于能谱1处的第二相颗粒,其锌、磷的含量则相对较少,故可推断出存在两种不同的第二相。但与前面观察SEM组织时的能谱分析不同,此时没有检测到钙的存在,可能是由于含钙的化合物在切削加工产生的剧烈的热效应中,熔化或者脱落,起到类似铅的改善切削性能的作用。并且这些低熔点化合物的熔化或者脱落,与图4(b)中剪切面上残留的大量空洞相映衬。这些颗粒偏聚在晶界上,会降低α/α和α/β晶界能,进而引发沿晶断裂[25]。

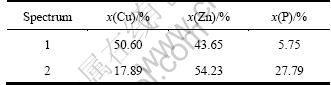

金属间化合物改善切削性能的高低,主要取决于其是否能弥散分布在基体中[25]。而这种化合物能否进入基体晶粒内部,与二者表面张力密不可分。如图7所示,此时系统自由能的变化量

ΔG=[σLIS1+σICS2]-[σLI(S1+S2)+σLCS2]<0 (1)

即应满足

σIC<σLI+σLC (2)

式中:σIC为化合物颗粒与晶体间的界面张力;σLI为金属液体与化合物颗粒间的界面张力;σLC为金属液体与晶体间的界面张力,S1为化合物颗粒与金属液体的粘附面积;S2为化合物颗粒与晶体的接触面积。

图5 切屑断口处的能谱位置

Fig. 5 Positions of second phase on fracture of chip measured by EDS: (a) Spectrum 1; (b) Spectrum 2

图6 图5中各第二相的EDS谱

Fig. 6 EDS spectra of second phases marked in Fig. 5: (a) Spectrum 1; (b) Spectrum 2

表4 图5中各第二相的EDS分析结果

Table 4 EDS results of second phases marked in Fig. 5

只有满足了式(2)时,化合物才有可能被晶体粘附而卷入晶体内,否则,化合物颗粒就会与晶粒分开而偏聚在晶界上。目前,本研究主要是在不明显降低加

工使用性能的前提下,通过合理的熔铸工艺实现这一目的,进而改善黄铜合金的切削性能。

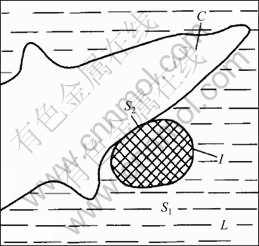

这些第二相颗粒的存在割断了基体的连续性,其断屑模型如图8所示。由图8可见,切削加工时,剪切面上的晶粒在剪切力的作用下,沿着滑移面通过位错运动进行滑移,原本近似球形的晶粒被剪切拉长成椭球形,而含铜、锌、磷等元素的复杂金属间化合物颗粒,弥散分布在晶界上,割断了基体组织的连续性,其与刀具接触,相当于减小了刀具与基体的接触面积,进而减小了切削力,起到改善切削性能的作用;同时,这些脆而不硬的第二相颗粒的存在,促使剪切角增大,使得通过位错运动的滑移变得容易,其在剪切力作用下发生变形后断裂或者脱落,甚至在切削热的作用下部分熔化,引发其周围的金属基体产生应力集中,位错萌生、增殖、长大、复合,萌发裂纹并致使其扩展,使切削很快断裂而不会连续长大,从而改善切削性能。

图7 金属间化合物附着晶体示意图[26]

Fig. 7 Sketch maps of intermetallics attached to crystals[26]

图8 切屑形成过程模型[27]

Fig. 8 Model of chips forming process[27]

2.5磷钙黄铜脱锌腐蚀

无铅磷钙黄铜的脱锌腐蚀实验按照GB10119—88《黄铜耐脱锌腐蚀性能的测定》进行。各试样在腐蚀试验前用酚醛树脂镶样,使其暴露面积为100 mm2,经过金相砂纸磨平后,用蒸馏水洗净、烘干。再浸入1% CuCl2水溶液中进行腐蚀,腐蚀时间为24 h,溶液温度为(75±2)℃。取出后沿纵向切开,抛光剖面后,用金相显微镜测量其腐蚀深度。

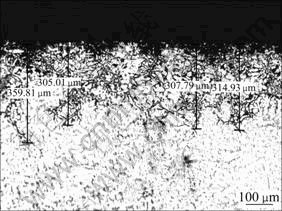

对6个试样进行脱锌腐蚀试验,并用金相显微镜测量其腐蚀深度。观测结果为:试样1的平均腐蚀深度为360.00 μm,试样2的为357.62 μm,试样3的为428.22 μm,试样4的为305.01 μm,试样5的为321.89 μm,试样6的为274.13 μm。其中,试样5的脱锌腐蚀深度如图9所示,有清晰的腐蚀通道。而HPb59-1的平均脱锌层厚度为361.9 μm[28],可见,本实验研制的磷钙黄铜各试样脱锌腐蚀性能均优于HPb59-1的。

图9 试样5脱锌腐蚀深度

Fig. 9 Dezincification depth of sample 5

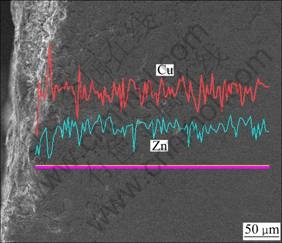

对试样5进行扫描电镜分析,结果如图10所示。并沿图中的横线进行能谱线扫描,其中铜、锌的含量如图中标识所示。由图10可看出,靠近腐蚀面的边界上,铜含量远大于锌含量,故表层为脱锌后留下的铜,并且当线扫描的横线经过通道时,锌急剧减少,而铜含量则增加,故可判断这些通道为脱锌后留下的。但表层区域的脱锌不完全,并未出现由β相完全脱锌后留下疏松多孔的铜和残留的α相。正是由于没有出现这类疏松多孔的结构,使得磷钙黄铜的耐脱锌腐蚀性能优良。这与磷钙黄铜中加入的合金元素有关。

黄铜的组织结构和成分对脱锌腐蚀的影响很大。磷钙黄铜合金的基体为α+β相,脱锌腐蚀首先开始于晶界等高能量的地方,进而是基体表面的β相,最后是含铜量较高的α相。锡可在相界和α相晶界富集,能抑制锌的迁移,磷的添加则可改变相的分布,并提高β相的稳定性[29],而稀土的加入,可大大细化晶粒[30],从而增大了晶界面积,为锌的扩散增加了阻力;同时稀土与黄铜中杂质等反应,净化了合金晶界,在一定程度上降低了合金的腐蚀速率,从而提高了合金的耐脱锌腐蚀性能。

图10 试样5脱锌腐蚀深度的SEM像能谱线扫描

Fig. 10 SEM image and line scan analysis of dezincification layer of sample 5

3 结论

1) 采用普通熔铸方法,成功制备出无铅磷钙黄铜铸锭,其合金组织主要由α、β相和含铜、锌、磷、钙的金属间化合物组成,这些金属间化合物弥散分布在晶界和晶粒内。

2) 磷、钙显著改变了黄铜合金的组织和性能,优化的无铅易切削磷钙黄铜合金的主要成分如下:57%~ 60% Cu,40% Zn,0.7% P,0.5% Ca。此时,合金显示出优良的综合性能:抗拉强度为362.7 MPa,伸长率为15.0%,布氏硬度为105.0HB,脱锌腐蚀深度为321.9 μm。

3) 磷钙黄铜合金中存在的脆而不硬的金属间化合物,在剪切力的作用下,发生变形后断裂或者脱落,甚至有部分发生熔化,产生应力集中,萌生裂纹并扩展,使切屑断裂,从而显著改善了其切削性能。

REFERENCES

[1] PETERS D M. Lead-free brass alloys seek new markets [J]. Foundry Management & Technology, 2002, 130(7): 8-9.

[2] PETERS D T. New bismuth/selenium red brass alloys solve lead concerns [J]. Modern Casting, 1997, 87(2): 57-59.

[3] SANDVIG A M, SIMONI T, EDWARDS M, DAVID H, BOYD G, KIRMEYER G. Nonleaded brass—A summary of performance and costs [J]. Journal AWWA, 2009, 101(7): 83-94.

[4] YOSHIAKI T, MOTOAKI K, KIYOSHI I. Lead-free free cutting brass alloy and its manufacturing method: JP, 2008214760A [P]. 2008-05-22.

[5] JANG Y H, KIM S S, KIM I S. Effect of alloying elements on elevated temperature tensile ductility of Bi added, Pb-free brass [J]. Journal of the Korean Institute of Metals and Materials, 2004, 42(7): 537-542.

[6] YOU S J, CHOI Y S, Kim J G. Stress corrosion cracking properties of environmentally friendly unleaded brasses containing bismuth in Mattsson’s solution [J]. Materials Science and Engineering A, 2003, 345(122): 207-214.

[7] NAKANO A, HIGASHIIRIKI K, ROCHMAN N T, YAMADA K, HAMAISHI K, SUEYOSHI H. Removal of lead from brass scrap by compound-separation method [J]. Journal of the Japan Institute of Metals, 2005, 69(2): 198-201.

[8] LA FONTAINE A, KEAST V J. Compositional distributions in classical and lead-free brasses [J]. Materials Characterization, 2006, 57(4/5): 424-429.

[9] JANG Y, KIM S, HAN S. Effect of misch on elevated temperature tensile ductility of the Cu-Zn-Bi alloy [J]. Metallurgical and Materials Transactions A, 2005, 36A: 1060-1065.

[10] 肖来荣, 舒学鹏, 易丹青, 张路怀, 覃静丽, 胡加瑞. 无铅易切削铋锑黄铜的组织与性能[J]. 中南大学学报: 自然科学版, 2009, 40(1): 117-122.

XIAO Lai-rong, SHU Xue-peng, YI Dan-qing, ZHANG Lu-huai, QIN Jing-li, HU Jia-rui. Microstructure and properties of unleaded free-cutting brass containing bismuth and stibium [J]. Journal of Central South University: Science and Technology, 2009, 40(1): 117-122.

[11] HIDEKI Y, KO H, KATSUYUKI N, TOMOKI I, NORIAKI F. Lead-free free-cutting copper alloy, and lead-free free-cutting copper alloy for continuous casting: JP, 2009007657A [P]. 2007-06-29.

[12] 庞晋山, 肖寅昕. 无铅易切削黄铜的研究[J]. 广东工业大学学报, 2001, 18(3): 63-66.

PANG Jin-shan, XIAO Yin-xin. Study of nonleaded easy-cutting brass [J]. Journal of Guangdong University of Technology, 2001, 18(3): 63-66.

[13] HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun, MA Chang-song. Microstructure and properties of cutting magnesium-brass containing no lead [J]. Transactions of Nonferrous Metals Society of China, 2005, 15(6): 1242-1247.

[14] 黄劲松, 彭超群, 章四琪, 黄伯云, 马长松. 无铅易切削镁黄铜的组织与性能[J]. 材料科学与工程学报, 2006, 24(6): 854-858.

HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun, MA Chang-song. Microstructure and properties of cutting lead-free brass containing magnesium [J]. Journal of Materials Science & Engineering, 2006, 24(6): 854-858.

[15] 肖来荣, 张路怀, 刘 彦, 张喜民, 胡加瑞. 镁黄铜的组织与性能研究[J]. 材料工程, 2010, 9: 10-14.

XIAO Lai-rong, ZHANG Lu-huai, LIU Yan, ZHANG Xi-min, HU Jia-rui. Microstructure and property of magnesium brass [J]. Materials Engineering, 2010, 9: 10-14.

[16] XIAO Lai-rong, SHU Xue-peng, YI Dan-qing, ZHANG Xi-min, QIN Jing-li, HU Jia-rui. Microstructure and properties of unleaded free-cutting brass containing stibium [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(s1): 1055- 1059.

[17] ZHU Quan-li, WU Wei-dong, LIU Kai-zhou, CHEN Geng-chun, CHEN Wei-ping. Study on microstructure and properties of brass containing Sb and Mg [J]. Science in China Series E: Technological Sciences, 2009, 52(8): 2172-2174.

[18] 肖来荣, 张路怀, 舒学鹏, 柳公器, 胡嘉瑞. 无铅锑黄铜轧制工艺的研究[J]. 材料工程, 2009(S1): 288-292.

XIAO Lai-rong, ZHANG Lu-huai, SHU Xue-peng, LIU Gong-qi, HU Jia-rui. Research of rolling technique of unleaded brass containing stibium [J]. Materials Engineering, 2009(S1): 288- 292.

[19] NATH D, GUPTA A K, ROHATGI P K. Extrusion of lead-free cast copper alloy-graphite particle composite [J]. Journal of Materials Science Letters, 1997, 16: 1595-1596.

[20] KESTURSATYA M, KIM J K, ROHATGI P K. Friction and wear behavior of a centrifugally cast lead-free copper alloy containing graphite particles [J]. Metallurgical and Materials Transactions A, 2001, 32A: 2115-2125.

[21] MAUVERNAY B, DOUBLET M L, MONCONDUIT L. Redox mechanism in the binary transition metal phosphide Cu3P [J]. Journal of Physics and Chemistry of Solids, 2006, 67: 1252-1257.

[22] FRIK L, MEWIS A. Stacking variants of SrPtSb and CaAl2Si2 analogous units [J]. Z Anorg Allg Chem, 1999, 625: 126-130.

[23] 李 勇, 许 方. 无铅易切削黄铜的研究现状及其展望[J]. 广东有色金属学报, 2006, 16(4): 267-270.

LI Yong, XU Fang. Research situation and outlook of free-cutting nonleaded brass [J]. Journal of Guangdong Nonferrous Metals, 2006, 16(4): 267-270.

[24] JIANG M Q, DAI L H. Formation mechanism of lamellar chips during machining of bulk metallic glass [J]. Acta Materialia, 2009, 57: 2730-2738.

[25] WOLLEY D J, FOX A G. The embrittlement of leaded and unleaded α+β (60-40) brass in the temperature range 300 to 500 ℃ [J]. Journal of Materials Science Letters, 1988, 7: 763-765.

[26] 黄劲松, 彭超群, 章四琪, 黄伯云. 无铅易切削铜合金[J]. 中国有色金属学报, 2006, 16(9): 1486-1493.

HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun. Lead free cutting copper alloys [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1486-1493.

[27] 张路怀. 60Cu-Zn-xMg合金组织与性能研究[D]. 长沙: 中南大学, 2009: 1-82.

ZHANG Lu-huai. Research on the microstructures and properties of 60Cu-Zn-xMg alloys [D]. Changsha: Central South University, 2009: 1-82.

[28] 陈丙璇, 宋 婧, 钟建华. 易切削黄铜耐磨耐腐蚀性能的研究[J]. 铸造, 2006, 55(5): 516-518.

CHEN Bing-xuan, SONG Jing, ZHONG Jian-hua. Research of the corrosion-resistant and wear-resisting performance of environmental brass [J]. Foundry, 2006, 55(5): 516-518.

[29] KARPAGAVALLI R, BALASUBRAMANIAM R. Influence of arsenic, antimony and phosphorous on the microstructure and corrosion behavior of brass [J]. Journal of Materials Science, 2007, 42: 5954-5958.

[30] 许传凯, 胡振青, 章四琪. 无铅易切削磷黄铜合金及其制造方法: 中国, 200810110819.8 [P]. 2008-06-11.

XU Chuan-kai, HU Zhen-qing, ZHANG Si-qi. Lead-free free-cutting phosphorous brass alloy and its manufacturing method: CN, 200810110819.8 [P]. 2008-06-11.

(编辑 何学锋)

收稿日期:2011-04-25;修订日期:2011-11-03

通信作者:朱权利,副教授,硕士;电话:020-62324601;E-mail: qlzhu@scut.edu.cn