DOI:10.19476/j.ysxb.1004.0609.2019.12.04

无铅环保硅黄铜的耐蚀性能

杨 超1,陶鲭驰1,卢海洲1,杨玉川1,丁 智1,丁言飞2,张卫文1,朱权利1

(1. 华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640;

2. 广东华艺卫浴实业有限公司,江门 529321)

摘 要:通过添加Si和Al代替HPb59-1铅黄铜的Pb,采用锌含量法调控相组成,结合XRD、SEM和XPS等分析方法研究合金元素及其决定的相组成对无铅环保硅黄铜耐蚀性能的影响。结果表明:随着Zn含量增加,合金相组成由α+β、β转变到β+γ,基于脱锌层厚度可得这三类合金的抗脱锌能力由大到小依次为β、α+β、β+γ。在α+β和β+γ型黄铜腐蚀过程中,β相作为阳极优先被腐蚀,随后为α相和γ相。添加Si、Al、B和RE等元素后,所有合金的脱锌层厚度均在200 μm以下,其中Zn含量为46.2%的合金脱锌层厚度仅为92.4 μm,远优于HPb59-1铅黄铜的。无铅硅黄铜的脱锌腐蚀表层氧化膜主要由Cu2O、CuO、SiO2和Al2O3组成,Al和Si元素的添加提高了无铅硅黄铜的耐脱锌腐蚀能力。

关键词:无铅硅黄铜;Zn含量;相组成;耐蚀性能

文章编号:1004-0609(2019)-12-2717-12 中图分类号:TG178 文献标志码:A

铅黄铜具有优良的力学性能、易切削加工性、优异的耐腐蚀性和成形性能,广泛应用于卫生、电气、设备制造等众多行业[1]。然而,铅黄铜中的Pb对环境和人类健康危害极大[2-4]。当铅黄铜用于水环境中时,其中的Pb元素容易从基体中析出[5],从而威胁人类的健康。人们对环境和健康问题日益关注促进了各行各业对无铅黄铜的需求[2, 5],研制环保的无铅黄铜用来代替铅黄铜已成为必然趋势。在前期工作中,本课题组采用基于Zn含量规则的设计方法制备的无铅环保硅黄铜[6],抗拉强度、伸长率均优于传统HPb59-1铅黄铜的,切削性能也与HPb59-1铅黄铜的相近。而黄铜在特定的环境下容易发生脱锌腐蚀,从而导致工件失效,因此,要使无铅硅黄铜得到推广应用,其耐腐蚀性能也是一个需要考虑的重要指标。

目前,国内外公布了许多制备无铅黄铜合金的专利[7-10],通过添加Sn、Bi、Al、As、P、Mg和Si等合金元素代替有毒的Pb元素,制备了切削性能和耐腐蚀性能均较好的无铅黄铜。此前,EL-SHERIF等[11-12]研究了Zn和Pb含量对铅黄铜合金在NaCl溶液和无氯中性硫酸盐溶液中电化学行为的影响。CLAESSON等[13]对As、Sb和P 3个合金元素对单相α铅黄铜抗脱锌性能的影响进行了系统研究。近期,ST?LNACKE等[5]研究了低Pb含量铝铁砷黄铜的耐蚀性能与材料成分及热处理的关系,发现热处理促使AlAs金属间化合物颗粒沿晶界、孪晶和铅颗粒上的析出,以及沿晶界形成β相,降低了合金的耐蚀性。然而,以上文献均是基于单相α铅黄铜进行的,对多相的无铅黄铜的耐蚀性能的研究仍比较有限。

在无铅黄铜的耐蚀性能研究方面,黄劲松等[14-15]使用电化学方法研究了无铅易切削镁黄铜的耐蚀性能,发现Mg易在腐蚀介质中产生疏松多孔的氧化膜,这种疏松多孔的氧化膜不能对基体产生很好的保护作用,使其耐蚀性略有降低。闫静等[16]研究了不同的加工工艺对无铅易切削铋黄铜的耐脱锌腐蚀性能的影响。结果表明:冷拔态的铋黄铜,由于β相沿着冷加工方向分布,同时位错密度和残余应力的增加,导致了其耐脱锌腐蚀性能比热轧态的黄铜和铸造态的黄铜差。热轧态的黄铜,由于在热加工过程中发生了回复和再结晶,使得其耐腐蚀性能和铸造态的相当。朱权利等[17]研究了镁锑黄铜的脱锌腐蚀性能和添加少量Sn、Al元素对其耐腐蚀性能的影响。研究表明,镁锑黄铜的脱锌腐蚀首先发生在β相,当β相脱Zn完全后,α相才开始脱Zn;Mg由于在熔炼时起到脱氧作用而提高了合金的耐蚀性能;Sn可强化晶界并和Cu、O等元素构成致密保护膜(如Sb2O3),有效地提高镁锑黄铜的抗腐蚀性能。文中虽提到Al在表面形成的致密Al2O3薄膜对合金的抗脱锌腐蚀性能的提高有利,但没有相关的试验依据和进一步的研究。孙慧等[18]通过向Cu-Zn二元合金中添加高Zn含量的Al、Mg和Si等元素制备了以β相为基体的无铅黄铜,考察了所制备合金在热处理前后的腐蚀行为。结果表明,热处理态的无铅黄铜腐蚀电流密度与脱锌腐蚀速率均较铸态小,热处理后合金的脱锌腐蚀层厚度为118 μm,耐腐蚀性能得到提高。

由于各无铅黄铜是基于不同Pb替代元素而设计的,其耐蚀性能研究也大多是基于合金元素的作用而进行。本文研究了α+β、β和β+γ三类无铅硅黄铜合金的抗脱锌能力关系,并结合XRD、SEM和XPS等分析方法对表层氧化膜的组成和合金元素Si、Al等的作用机理进行了研究。

1 实验

在Cu-Zn二元合金体系中,Si和Al的加入可导致β相区的大幅左移和γ相的形成[19]。相应的,Si和Al对Cu-Zn二元相图的影响可近似等价成Zn含量的变化。同时,Si和Al固溶于基体晶格中,可起到固溶强化的作用,有助于提高合金强度和显微硬度。Si还可形成致密的SiO2氧化膜,从而提高合金的耐腐蚀性[20]。Al在合金熔体表面形成Al2O3薄膜,可防止熔炼过程中Zn的挥发。因此,可基于Zn含量规则[21]设计高强度和耐腐蚀的无铅硅黄铜,Zn含量规则即基于虚拟Zn含量(X)确定黄铜合金的相组成,其计算方法如下[21]:

式中:wZn和wCu分别是黄铜合金中实际的Zn和Cu质量分数; 为其他合金元素的质量分数wi和虚拟Zn含量系数Ki的乘积之和。Si和Al元素的Ki分别为10和6[21]。另外,在所有黄铜合金中加入0.005% B、0.05% Ti和0.05% RE(质量分数)作为复合变质剂。

为其他合金元素的质量分数wi和虚拟Zn含量系数Ki的乘积之和。Si和Al元素的Ki分别为10和6[21]。另外,在所有黄铜合金中加入0.005% B、0.05% Ti和0.05% RE(质量分数)作为复合变质剂。

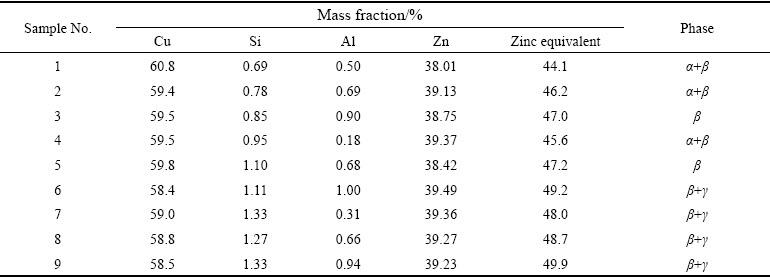

无铅高强度硅黄铜通过中频感应电炉熔炼,试验原料为电解铜、分析纯锌粒、纯铝粒、纯硅、铜钛(22% Ti)、铝硼(3% B)中间合金和复合稀土。将试验原料加入石墨坩埚中熔炼,溶液在1100 ℃保温40 min后浇注到预热至250 ℃的石墨模具中。制备的无铅硅黄铜铸锭通过ARL 4460金属分析仪进行光谱分析,其化学成分如表1所示。由于变质元素RE、Ti、B加入量较少而未能检测出来,故不列于表中。使用X射线衍射(XRD)鉴定相组成,并用扫描电子显微镜(SEM)和能谱仪(EDS)对铸件进行显微组织与元素分布、含量分析。

腐蚀试验按国家标准GB/T 10119—2008《黄铜耐脱锌腐蚀性能的测定》进行。先通过线切割获得10 mm×10 mm×10 mm的合金块体,用环氧树脂镶样,用500#砂纸打磨,试样暴露面积为100 mm2,将试样放入(75±2) ℃的CuCl2溶液(10 g/L)中腐蚀24 h。腐蚀过程结束后,在扫描电镜下测定脱锌层的厚度,观察腐蚀形貌。采用X射线光电子能谱仪(XPS,仪器型号:Axis Ultra DLD)分析脱锌腐蚀试验后样品表面氧化膜的元素组成及其化学价态。使用单色Al Kα射线作为X光源,分析室真空度约为6.58×10-7 Pa,以表面污染C1s(284.6 eV)为标准进行能量校正。

表1 无铅硅黄铜光谱分析表

Table 1 Spectral analysis of lead-free silicon brass

2 结果与讨论

2.1 铸锭的显微组织

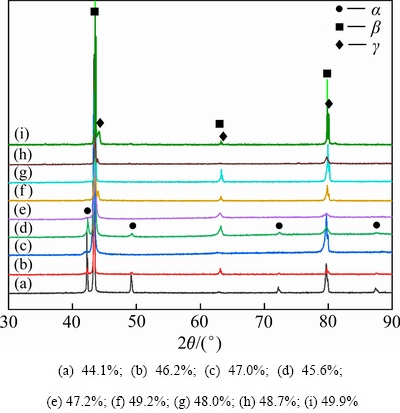

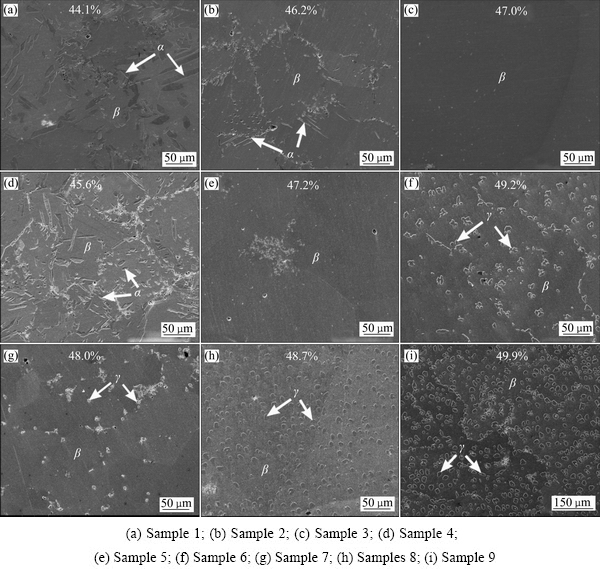

图1所示为不同Zn含量无铅黄铜的XRD谱。由图1可知,当合金的Zn含量为44.1%、46.2%和45.6%时,合金组织为α+β双相;当Zn含量为47.0%和47.2%时,合金组织为β单相,当Zn含量为49.2%、48.0%、48.7%和49.9%时,合金组织为β+γ双相。其中,β相的衍射峰强度大于α相和γ相的,所以合金基体相为β相。各合金对应的显微组织如图2所示,SEM像与XRD结果基本一致,此外部分合金组织中还有少量的金属间化合物。在Cu-Zn二元相图中,β相体积分数主要受Zn含量和热处理的控制。由于合金的Zn含量随Si和Al含量的增加而增加,β相体积分数也因此增加。当合金的Zn含量大于47.0%时,合金的组织由α+β双相转变为β单相;当Zn含量大于48.0%时,合金组织转变为β+γ双相。所以黄铜合金的相组成可以通过Zn含量规则来控制。

图1 不同Zn含量无铅硅黄铜的XRD谱

Fig. 1 XRD patterns of lead-free silicon brass with different Zn contents

图2 不同Zn含量无铅硅黄铜的SEM像

Fig. 2 SEM images of lead-free silicon brass with different Zn contents

2.2 脱锌层厚度

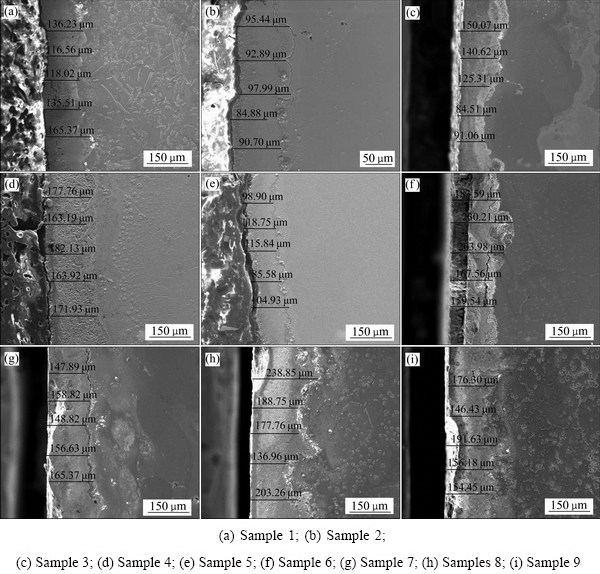

图3所示为不同Zn含量合金脱锌腐蚀后腐蚀横截面的SEM像。从图3可以看出,试样1~9的脱锌层均为层状脱锌。其中,试样6~9的脱锌层表面出现了腐蚀产物脱落的现象。这是由于Zn在脱锌腐蚀时选择性溶解,留下了疏松的铜结构层,当受到磨样、抛光等带来的外部拉应力时,铜层就会开裂而脱落。

在每个试样上等距离选取5个点测量脱锌深度,取算术平均值作为试样的平均脱锌层厚度。其中,试样1~9的平均脱锌层厚度分别为134.3、92.4、118.3、171.8、105.1、189.0、155.5、184.9和164.8 μm。所有无铅硅黄铜合金的平均脱锌层厚度都在200 μm以下,远远小于HPb59-1铅黄铜的361.9 μm[22]。可见,所研制的无铅硅黄铜的耐脱锌腐蚀性能均优于铅黄铜,该结果与曹标等[23]的研究结论一致。此前,张璐怀等[24]研制的Cu-Zn-Sb-Ce-Ti无铅黄铜合金,其平均脱锌层厚度约为255.05 μm;闫静等[16]研制的无铅铋黄铜平均脱锌腐蚀深度为200~300 μm。可见,本文制备的无铅硅黄铜合金的耐脱锌腐蚀性能更好。9种无铅硅黄铜合金中,试样1、2、4都是α+β两相组织,通过Image pro软件计算这3种合金中α相的体积分数分别为30.76%、1.14%、20.75%,因此,在腐蚀过程中,可将试样2看成为单一的β相组织。试样3和5为单一β相组织,试样6~9为β+γ组织。通过比较合金的平均脱锌层厚度来评估α+β、β和β+γ 3类合金的抗脱锌能力大小,由大到小依次为β、α+β、β+γ。

2.3 脱锌层的腐蚀形貌及成分检测

图3 不同Zn含量无铅硅黄铜的脱锌层形貌

Fig. 3 Morphologies of dezincification layers for lead-free silicon brass with different Zn contents

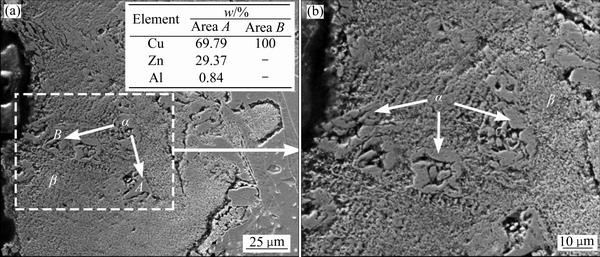

图4 试样1脱锌层形貌和EDS结果

Fig. 4 Morphologies and EDS results of dezincification layer of sample 1

图4所示为试样1脱锌层的形貌。从图4(b)可以看出,α+β双相无铅硅黄铜经过脱锌腐蚀过后,在α与β相的相界出现了缝隙和孔洞,α相尺寸增大,而基体β相则为疏松多孔结构。对图4(a)中不同区域的α相进行能谱分析可知,在靠近合金腐蚀表面的α相脱锌完全,而在远离合金表面的α相则含有大量的Zn元素。由此可知,当α+β双相黄铜被腐蚀时,暴露在基体表面的β相会首先发生Zn溶解,当包围α相的β相脱锌完全后,α相成为脱锌区的“孤岛”,随后也会发生脱锌腐蚀。

图5所示为试样1脱锌层横截面的形貌和能谱分析结果。如图5所示,试样1腐蚀层中的腐蚀产物元素有Cu、O、Cl、Al、Si、Zn。试样中Cu含量在腐蚀层分布比较均匀,远远高于基体含量水平。Zn含量在脱锌层含量较低,明显低于基体含量水平。脱锌层上还存在并未脱锌完全的α相(含新生成的α相),该相含有较高的Zn含量。这表明脱锌层中β相脱锌完全,而部分α相还没有脱锌。在图5中,试样1腐蚀表面的O、Cl、Al、Si含量明显高于合金内部的含量,这说明在腐蚀的过程中,Al、Si元素会从内部扩散到合金表面[22],从而在合金表面与氧结合生成Al、Si的氧化物,阻止Zn的溶解,提高合金的耐腐蚀性能。

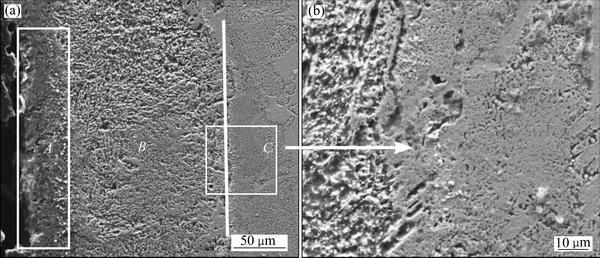

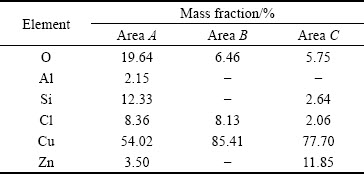

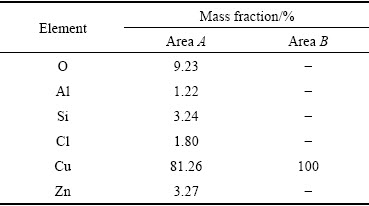

图6所示为试样4(α+β相)脱锌层的形貌。在图6(a)中,可以观察到试样4脱锌层出现了A、B、C 3个不同区域。A区域颜色较深,组织致密,厚度达到20~30 μm左右;B区域组织为疏松多孔结构。图6(b)为C区域的放大图,可以发现C区域和试样1脱锌层腐蚀形貌比较相似,相比B区域组织较致密,同时,还可以看到一些未脱锌的“孤岛”区域。对A、B、C 3个区域分别进行能谱分析,结果如表2所列。A区域中,O、Al、Si的质量分数分别为19.64%、2.15%、12.33%。Al、Si含量远高于基体的名义成分,表明A区域形成了一层含Cu、Al和Si的致密氧化膜。B区域中Cu、Cl、O的质量分数分别为85.41%、8.13%、6.46%,此区域已经完全脱锌,其腐蚀产物主要为铜的氯化物和氧化物。C区域中Zn的质量分数为11.85%,此区域并未完全脱锌,若继续脱锌腐蚀较长时间,C区域将会形成B区域相似的形貌。对比A、B两个区域的Zn含量可以发现,A区域中还存在少量Zn,B区域中则完全没有。这可能是由于A区域形成的氧化膜对Zn向溶液中扩散过程存在阻滞作用,大量的Zn将聚集于基体表面,形成Zn富集。

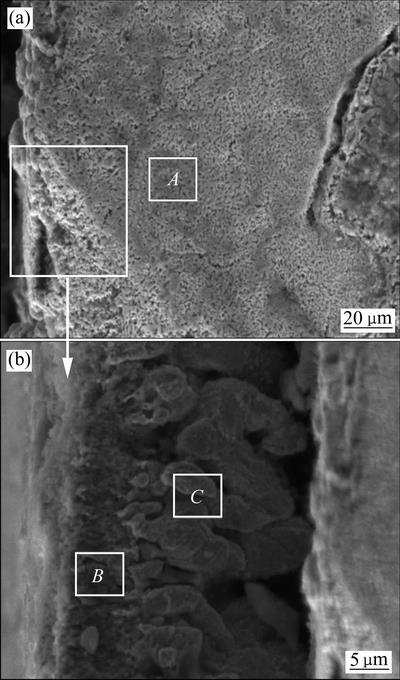

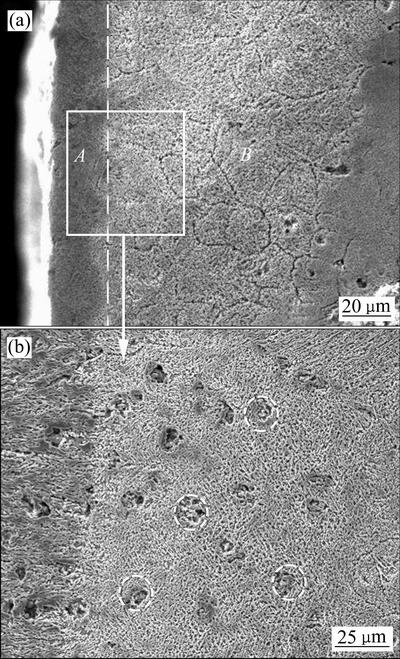

图7所示为试样3脱锌层的形貌。试样3组织为单一β相,在腐蚀过程中,其晶界处优先被腐蚀,紧接着β相发生脱锌腐蚀[17],如图7(a)所示。合金经过脱锌腐蚀后留下了疏松多孔的铜结构,合金脱锌层也出现了A、B、C 3个不同区域。由于强度降低,合金腐蚀表面出现了脱落的现象,如图7(b)所示。图中B、C两个区域存在着很大的差异,B区域结构致密,C区域结构呈现疏松状态。对A、B、C 3个区域进行能谱分析,其结果列于表3。在试样3表层O、Al、Si元素的质量分数分别达到了19.98%、3.16%、14.84%。此结果表明合金表面形成了一层含Al、Si的氧化膜,阻止了Zn的溶解,有效低抑制了无铅硅黄铜的脱锌;而在合金内部的A区和C区则脱锌完全。

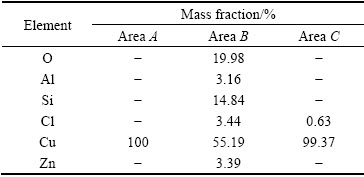

图8所示为试样8脱锌层的形貌。试样8组织为β+γ双相组织。从图8(a)可以发现,合金基体在脱锌腐蚀后出现了疏松的铜结构,同时也出现了严重的晶间腐蚀。在白线两侧出现了不一样的形貌和颜色。β+γ双相硅黄铜合金在腐蚀介质中还发生了组织的选择性腐蚀,即先是β相发生脱锌腐蚀,当β相脱锌完全后才扩展到γ相[20]。而在图8(b)中的白色圆圈部分出现了很大的腐蚀坑,其形状和大小与γ相一样,这是由于γ相在脱锌后,与基体的结合强度降低,在机械抛光的过程中脱落而形成了凹坑。

图5 试样1脱锌层的线扫描能谱图

Fig. 5 Line EDS results of dezincification layer of sample 1

对试样8脱锌层进行成分分析,其结果列于表6中。由表6可知,脱锌层表面Si、Al的含量大幅提高,是原始含量的两倍,同时在表层还含有大量的氧。此结果表明在脱锌层表面形成了Si、Al的氧化膜,这些膜的形成有效地将无铅硅黄铜合金表面的基体金属和腐蚀介质隔离,阻碍了Cu和Zn被腐蚀的过程,减少了Cu和Cl-的接触机会,从而有效的阻止了腐蚀反应的发生,改善了无铅硅黄铜的耐蚀性能。

图6 试样4脱锌层的形貌

Fig. 6 Morphologies of dezincification layer of sample 4

图7 试样3脱锌层的形貌

Fig. 7 Morphologies of dezincification layer of sample 3

表2 试样4脱锌层各区域能谱分析结果

Table 2 EDS results of different regions in dezincification layer of sample 4

图8 试样8脱锌层的形貌

Fig. 8 Morphologies of dezincification layer of sample 8

表3 试样3脱锌层各区域能谱分析结果

Table 3 EDS results of different regions in dezincification layer of sample 3

表4 试样8脱锌层各区域能谱分析结果

Table 4 EDS results of different regions in dezincification layer of sample 8

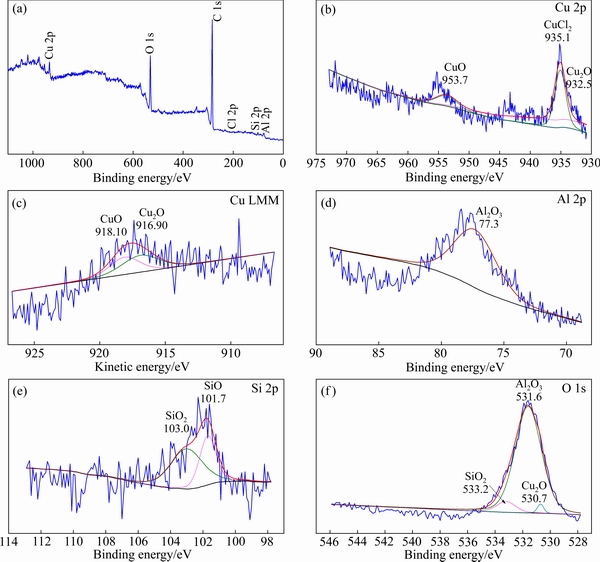

2.4 脱锌腐蚀表层氧化膜XPS分析

利用X射线光电子能谱仪测试脱锌腐蚀试验后样品表层氧化膜的元素组成及其化学价态,并利用XPS Peak对获得的试验数据进行拟合和分析。由于各试样的成分相近,表层氧化膜的组成也基本一致,故在此只列出试样3的表层氧化膜分析结果,如图9所示。合金表面元素的XPS全谱如图9(a)所示,其谱峰主要由Cu 2p、O 1s、C1s、Cl 2p、Si 2p和Al 2p组成[25-26]。图9(b)为Cu 2p的谱线图,其谱峰主要由3个单峰组成,分别是932.5 eV的Cu2O峰、935.1 eV的CuCl2峰和953.7 eV的CuO峰[27]。其中,CuCl2来自于脱锌腐蚀的腐蚀液;Cu2O是铜合金在腐蚀过程中形成的一层致密、均匀的表层氧化膜[25],Cu2O可进一步氧化为CuO,其反应式为Cu2O+1/2O2→2CuO。由于CuO和Cu2O的结合能差距不大,通过Cu的俄歇峰Cu L3M4, 5M4, 5可进一步确定两种化合物的存在[28],如图9(c)所示。图9(d)为Al 2p的谱线图,其谱峰由一个单峰组成,即位于77.3 eV的Al2O3峰[29]。Si 2p的谱峰(见图9(e))则由结合能为101.7 eV和103.0 eV的两个单峰组成,分别对应SiO2和SiO[30-31]。O 1s的谱峰(见图9(f))可分成3个单峰,分别是530.7 eV的Cu2O峰、531.6 eV的Al2O3峰和533.2 eV的SiO2峰[30, 32-33],进一步印证了合金脱锌腐蚀表层氧化膜的主要由Cu2O、SiO2和Al2O3构成。

图9 试样3表层氧化膜的XPS分析

Fig. 9 XPS analysis of surface oxide film of sample 3

2.5 脱锌腐蚀机理

根据优先溶解机制,Zn的标准电极电位比Cu负很多,所以无铅硅黄铜非常容易发生成分选择性腐蚀,Zn被优先腐蚀,而电势较高的Cu则被留下来,形成疏松多孔的Cu和氧化铜层[34-35]。同时在脱锌过程中会发生β→α相转变,所以在图4(a)中可以看到α相尺寸有增大的现象。

在α+β双相无铅硅黄铜中,β相是以电子化合物CuZn为基体的固溶体,相比α相其电位较负,所以在腐蚀过程中作为阳极而先发生脱锌腐蚀。α相和β相之间的电位差在一定程度上加快了β相的腐蚀速率,所以α+β双相无铅硅黄铜的抗脱锌能力低于单一β相无铅硅黄铜。而单一β相黄铜被腐蚀时,其晶界优先被腐蚀,紧接着β相发生脱锌腐蚀。这是由于合金晶粒内部与晶界存在腐蚀电位差,在晶界形成腐蚀原电池,使晶界先被腐蚀。β+γ双相硅黄铜的腐蚀机理和α+β的双相硅黄铜类似,由于β相与γ相存在腐蚀电位差,先在晶界发生脱锌腐蚀。而相比γ相,β相的电位较负,故先作为阳极脱锌,当β相脱锌完全后,γ相才开始脱锌[20]。所以,β+γ双相无铅硅黄铜的抗脱锌能力低于单一β相无铅硅黄铜。

9种合金抗脱锌能力的提升,与添加的Al、Si、B和RE 4种元素有很大的关系。在黄铜脱锌腐蚀过程中,Zn原子可以通过双空位进行扩散,而B元素能占据并进入双空位,导致Zn原子双空位的迁移速度减缓,黄铜的抗脱锌能力得到提高[36-37]。RE的加入能消除合金溶液中的杂质,这样在腐蚀过程中原电池数目得以减少,提高了合金的抗脱锌能力[17, 36]。Al元素对提高黄铜的耐蚀性作用十分明显,由于Al的标准电位比Zn低,具有更大的离子化趋向,这使得Al能更快的与腐蚀介质中的O结合生成氧化物,形成一层致密的Al2O3膜附着在黄铜表面[17],不同于黄劲松等[14]制备的镁黄铜形成的疏松多孔的氧化膜,该氧化膜有效地将无铅硅黄铜合金表面的基体金属和腐蚀介质隔离,阻碍了Cu和Zn被腐蚀的过程,减少了Cu和Cl-的接触机会,从而有效地阻止了腐蚀反应的发生,提高了无铅硅黄铜的耐腐蚀性能。但Al的添加有一定的限度,由试样4、5、6可知,当Si含量保持基本不变时,随着Al含量的增加,黄铜的组织由α+β相转变为β相,此时黄铜的耐脱锌腐蚀能力提高;若进一步增加Al含量,使黄铜组织由β相转变为β+γ相,黄铜的耐脱锌腐蚀能力下降。添加的Si元素一方面能降低液相线温度,使得铸件变得紧密,一定程度上降低了Zn原子的扩散速率;另一方面,Si能与腐蚀介质中的O结合形成一层致密的SiO2膜附着在黄铜表面,该氧化膜能阻止Zn原子的进一步扩散[20]。由试样2、5、8可知,当Al含量保持基本不变时,随着Si含量的增加,黄铜的组织也会发生类似于Si含量增加的相转变;当Si含量较高时,黄铜组织由β相转变为β+γ相,其耐脱锌腐蚀能力也会随之降低。结合XPS结果可知,Al、Si元素在腐蚀的过程中从内部扩散到合金表面与氧结合生成Al2O3和SiO2薄膜,填补了Cu2O薄膜的缺陷,使黄表面的Cu2O膜更加均匀致密,从而进一步提高了无铅硅黄铜的耐脱锌腐蚀能力。

3 结论

1) 当无铅硅黄铜的Zn含量大于47.0%时,合金的组织由α+β双相转变为β单相;当Zn含量大于48.0%时,合金组织转变为β+γ双相。

2) 基于合金脱锌层厚度可得,α+β、β、β+γ 3类合金的抗脱锌能力由大到小依次为β、α+β、β+γ。在α+β和β+γ型黄铜腐蚀过程中,电位较负的β相作为阳极优先被腐蚀,随后α相或γ相也会发生脱锌腐蚀。

3) 添加Si、Al、B和RE等元素后,9种合金的脱锌层厚度均在200 μm以下,其中Zn含量为46.2%的合金脱锌层厚度仅为92.4 μm,远优于HPb59-1铅黄铜的。

4) 无铅硅黄铜的脱锌腐蚀表层氧化膜主要由Cu2O、CuO、SiO2和Al2O3构成,Al和Si元素在合金表面与氧结合生成Al2O3和SiO2膜,提高了无铅硅黄铜的耐脱锌腐蚀能力。

REFERENCES

[1] 王碧文. 环保铜合金的开发及应用[J]. 世界有色金属, 2012, 28(9): 56-57.

WANG Bi-wen. Development and application of environmentally friendly copper alloy[J]. World Nonferrous Metal, 2012, 28(9): 56-57.

[2] SCHULTHEISS F, JOHANSSON D, BUSHLYA V, ZHOU Jin-ming, NILSSON K, ST?HL J E. Comparative study on the machinability of lead-free brass[J]. Journal of Cleaner Production, 2017, 149: 366-377.

[3] 朱权利, 张先满, 罗良颂, 李 微, 陈维平, 汪桂龙, 李 晨. 无铅磷钙黄铜的组织与性能[J]. 中国有色金属学报, 2012, 22(5): 1421-1429.

ZHU Quan-li, ZHANG Xian-man, LUO Liang-song, LI Wei, CHEN Wei-ping, WANG Gui-long, LI Chen. Microstructure and properties of lead-free P-Ca brasses[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1421-1429.

[4] TOULFATZIS A, PANTAZOPOULOS G, DAVID C, SAGRIS D, PAIPETIS A. Final heat treatment as a possible solution for the improvement of machinability of Pb-free brass alloys[J]. Metals, 2018, 8(8): 575.

[5] ST?LNACKE E, CLAESSON E, OBITZ C, LILJA M, ODQVIST J, HAGSTR?M J, ROD O. Corrosion- microstructure interrelations in new low-lead and lead-free brass alloys[J]. Materials Science and Technology, 2018, 34: 1-8.

[6] YANG C, DING Z, TAO Q C, LIANG L, DING Y F, ZHANG W W, ZHU Q L. High-strength and free-cutting silicon brasses designed via the zinc equivalent rule[J]. Materials Science and Engineering A, 2018, 723: 296-305.

[7] 杨桂香, 杨景周, 杨景浩. 一种无铅黄铜合金: 中国, CN 103725919 A[P]. 2014-04-16.

YANG Gui-xiang, YANG Jing-zhou, YANG Jing-hao. Lead-free brass alloy: China, CN 103725919 A[P]. 2014-04-16.

[8] LI Jia-de. Lead-free bismuth-free silicon-free brass: European, EP2913415A1[P]. 2015-09-02.

[9] 柳瑞清, 蔡 薇, 邱光斌, 王 刚, 肖翔鹏, 柳 羏, 邓予生, 李双龙. 一种无铅黄铜合金及其制备方法: 中国, CN 102925744 A[P]. 2013-02-13.

LIU Rui-qing, CAI Wei, QIU Guang-bin, WANG Gang, XIAO Xiang-peng, LIU Yang, DENG Yu-sheng, LI Shuang-long. Lead-free brass alloy and preparation method thereof: China, CN 102925744 A[P]. 2013-02-13.

[10] YANG C, DING Z, DING Y F, FENG S Z. Lead-free easy-cutting high-strength corrosion-resistant silicon-brass alloy and the preparation method and use thereof: United States Patent, Publication Number: US 2018/0148813 A1[P]. 2018-05-31.

[11] EL-SHERIF R M, ISMAIL K M, BADAWY W A. Effect of Zn and Pb as alloying elements on the electrochemical behavior of brass in NaCl solutions[J]. Electrochimica Acta, 2004, 49(28): 5139-5150.

[12] ISMAIL K M, ELSHERIF R M, BADAWY W A. Effect of Zn and Pb contents on the electrochemical behavior of brass alloys in chloride-free neutral sulfate solutions[J]. Electrochimica Acta, 2004, 49(28): 5151-5160.

[13] CLAESSON E, ROD O. The effect of alloying elements on the corrosion resistance of brass[J]. Materials Science and Technology, 2016, 32(17): 1794-1803.

[14] 黄劲松, 彭超群, 章四琪, 黄伯云, 马长松. 无铅易切削镁黄铜的组织与性能[J]. 材料科学与工程学报, 2006, 24(6): 854-857.

HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun, MA Chang-song. Microstructure and properties of cutting lead-free brass containing magnesium[J]. Journal of Materials Science and Technology, 2006, 24(6): 854-857.

[15] HUANG Jin-song, PENG Chao-qun, ZHANG Si-qi, HUANG Bai-yun, MA Chang-song. Microstructure and properties of cutting magnesium-brass containing no lead[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(6): 1242-1247.

[16] 闫 静, 唐生渝, 王 均, 陶明大, 赵 桢, 何章亮, 沈保罗. 加工工艺对无铅黄铜耐腐蚀性能的影响[J]. 特种铸造及有色合金, 2006, 26(11): 733-735.

YAN Jing, TANG Sheng-yu, WANG Jun, TAO Ming-da, ZHAO Zhen, HE Zhang-liang, SHEN Bao-luo. Effects of processing techniques on corrosion resistant of Pb-free brass[J]. Special Casting & Nonferrous Alloys, 2006, 26(11): 733-735.

[17] 朱权利, 刘楷周, 吴维冬, 刘太权, 陈维平. 新型无铅黄铜的耐蚀性能研究[J]. 新技术新工艺, 2009, 38(6): 84-86.

ZHU Quan-li, LIU Kai-zhou, WU Wei-dong, LIU Tai-quan, CHEN Wei-ping. Study on corrosion resistance of new unleaded brass[J]. New Technology & New Process, 2009, 38(6): 84-86.

[18] 孙 慧, 董晟全, 梁艳峰, 李高宏. 热处理工艺对无铅黄铜腐蚀行为的影响[J]. 热加工工艺, 2012, 41(4): 153-155.

SUN Hui, DONG Sheng-quan, LIANG Yan-feng, LI Gao-hong. Effect of heat treatment on corrosion behavior of lead-free brass[J]. Hot Working Technology, 2012, 41(4): 153-155.

[19] SUKSONGKARM D, ROJANANAN S, ROJANANAN S. Microstructure and hardness of Cu-Zn-Si-Al-Sn brasses with antimony addition[J]. Advanced Materials Research, 2013, 802: 179-183.

[20] 赵作福, 齐锦刚, 王建中, 刘兴江, 王家毅. 电脉冲处理对硅黄铜耐蚀性能的影响[J]. 华南理工大学学报 (自然科学版), 2015, 43(7): 28-32.

ZHAO Zuo-fu, QI Jin-gang, WANG Jian-zhong, LIU Xing-jiang, WANG Jia-yi. Effects of electric pulse treatment on corrosion resistance of silicon brass[J]. Journal of South China University of Technology (Natural Science Edition), 2015, 43(7): 28-32.

[21] 路俊攀, 李湘海. 加工铜及铜合金金相图谱[M]. 长沙: 中南大学出版社, 2010: 97-98.

LU Jun-pan, LI Xiang-hai. Metallographic atlas of processed copper and copper alloy[M]. Changsha: Central South University Press, 2010: 97-98.

[22] 陈丙璇, 宋 婧, 钟建华. 易切削黄铜耐磨耐腐蚀性能的研究[J]. 铸造, 2006, 55(5): 516-518.

CHEN Bing-xuan, SONG Jing, ZHONG Jian-hua. Research of the corrosion-resistant and cear-resisting performance and environmental brass[J]. Foundry, 2006, 55(5): 516-518.

[23] 曹 标, 庞晋山, 陈 明. 环境友好无铅硅黄铜的耐腐蚀性能研究[J]. 检验检疫学刊, 2014, 24(2): 1-3.

CAO Biao, PANG Jin-shan, CHEN Ming. Corrosion resistance research of environmental lead-free brass with silicon[J]. Journal of Inspection & Quarantine, 2014, 24(2): 1-3.

[24] 张路怀, 肖来荣, 舒学鹏, 温燕宁, 张喜民. 正交试验法在无铅黄铜成分设计中的应用[J]. 北京工业大学学报, 2009, 35(9): 1241-1247.

ZHANG Lu-huai, XIAO Lai-rong, SHU Xue-peng, WEN Yan-ning, ZHANG Xi-min. The application of orthogonal experiment to the composition design of lead-free brass[J]. Journal of Beijing University of Technology, 2009, 35(9): 1241-1247.

[25] 罗宗强, 张卫文, 辛保亮, 李元元. Cu-17Ni-3Al-X合金在中性盐雾中的腐蚀行为[J]. 中国有色金属学报, 2012, 22(1): 106-113.

LUO Zong-qiang, ZHANG Wei-wen, XIN Bao-liang, LI Yuan-yuan. Corrosion behavior of Cu-17Ni-3Al-X alloy in neutral salt atmosphere[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(1): 106-113.

[26] KAZANSKY L P, PRONIN Y E, ARKHIPUSHKIN I A. XPS study of adsorption of 2-mercaptobenzothiazole on a brass surface[J]. Corrosion Science, 2014, 89: 21-29.

[27] MAROIE S, HAEMERS G, VERBIST J J. Surface oxidation of polycrystalline α(75%Cu/25%Zn) and β(53%Cu/47%Zn) brass as studied by XPS: Influence of oxygen pressure[J]. Applications of Surface Science, 1984, 17(4): 463-467.

[28] FIN?GAR M, KEK MERL D. An electrochemical, long-term immersion, and XPS study of 2-mercaptobenzothiazole as a copper corrosion inhibitor in chloride solution[J]. Corrosion Science, 2014, 83: 164-175.

[29] LINDSAY J R, ROSE H J, SWARTZ W E, WATTS P H, RAYBURN K A. X-ray photoelectron spectra of aluminum oxides: structural effects on the “Chemical shift”[J]. Applied Spectroscopy, 1973, 27(1): 1-5.

[30] NGUYEN T P, LEFRANT S. XPS study of SiO thin films and SiO-metal interfaces[J]. Journal of Physics: Condensed Matter, 1989, 1(31): 5197-5204.

[31] TRINH Q H, NGUYEN D B, HOSSAIN M M, MOK Y S. Deposition of superhydrophobic coatings on glass substrates from hexamethyldisiloxane using a kHz-powered plasma jet[J]. Surface and Coatings Technology, 2019, 361: 377-385.

[32] OTAMIRI J C, ANDERSSON S L T, ANDERSSON A. Ammoxidation of toluene by YBa2Cu3O6+x and copper oxides: Activity and XPS studies[J]. Applied Catalysis, 1990, 65(1): 159-174.

[33] TAN B J, KLABUNDE K J, SHERWOOD P M A. XPS studies of solvated metal atom dispersed (SMAD) catalysts. Evidence for layered cobalt-manganese particles on alumina and silica[J]. Journal of the American Chemical Society, 1991, 113(3): 855-861.

[34] HONG Lu, GAO Ke-wei, CHU Wu-yang. Determination of tensile stress induced by dezincification layer during corrosion for brass[J]. Corrosion Science, 1998, 40(10): 1663-1670.

[35] 李 勇. 黄铜脱锌腐蚀的研究进展[J]. 南方金属, 2005, 27(6): 15-18.

LI Yong. An overview on the dezincification of brass[J]. Southern Metals, 2005, 27(6): 15-18.

[36] 杨胜利, 吴 语. 黄铜脱锌腐蚀的研究进展[J]. 世界有色金属, 2011, 27(4): 50-53.

YANG Sheng-li, WU Yu. An overview on the dezincification of brass[J]. World Nonferrous Metals, 2011, 27(4): 50-53.

[37] 王吉会, 姜晓霞, 李诗卓. 硼砷抑制黄铜脱锌的协同作用机制[J]. 科学通报, 1997, 42(6): 669-672.

WANG Ji-hui, JIANG Xiao-xia, LI Shi-zhuo. Synergistic mechanism of boron and arsenic inhibiting dezincification of brass[J]. Chinese Science Bulletin, 1997, 42(6): 669-672.

Corrosion resistance of lead-free environment-friendly silicon brass

YANG Chao1, TAO Qing-chi1, LU Hai-zhou1, YANG Yu-chuan1, DING Zhi1, DING Yan-fei2, ZHANG Wei-wen1, ZHU Quan-li1

(1. National Engineering Research Center of Near-net-shape Forming for Metallic Materials, South China University of Technology, Guangzhou 510640, China;

2. Guangdong Huayi Plumbing Fittings Industry Co., Ltd., Jiangmen 529321, China)

Abstract: By adding Si and Al instead of Pb in HPb59-1 lead brass, the phase composition of lead-free environment- friendly silicon brass was controlled by zinc equivalent rule. The effects of alloying elements and phase composition on the corrosion resistance of the controlled alloys were analyzed by XRD, SEM and XPS methods. The results show that, with the increase of zinc equivalent, the phase composition of the controlled silicon brasses transforms from α+β and β into β+γ. Based on the thickness of dezincification layer, the anti-dezincification ability decreases successively as following of β, α+β, β+γ. During the corrosion process of α+β and β+γ brasses, the potential negative β phase is preferentially corroded as an anode, and then is α phase or γ phase. After adding Si, Al, B and RE, the thickness of the dezincification layer of all controlled alloys is below 200 μm. Especially, the corresponding thickness value for the alloy with the zinc equivalent of 46.2% is only 92.4 μm, which indicates that the corrosion resistance is improved significantly compared with HPb59-1 lead brass. The surface oxide film of the prepared silicon brass following dezincification corrosion is mainly composed of Cu2O, CuO, SiO2 and Al2O3, and additions of Al and Si elements improve the dezincification resistance of lead-free silicon brass.

Key words: lead-free silicon brass; zinc equivalent; phase composition; corrosion resistance

Foundation item: Project(2016B090931002) supported by the Guangdong Application-oriented Special Funds for Science and Technology Research and Development, China; Project(2014A010105020) supported by Guangdong Special Funds for Public Welfare Research and Capacity Building, China

Received date: 2018-11-06; Accepted date: 2019-06-24

Corresponding author: YANG Chao; Tel: +86-20-87111132; E-mail: cyang@scut.edu.cn

(编辑 李艳红)

基金项目:广东省应用型科技研发专项重大项目(2016B090931002);广东省公益研究与能力建设专项资金项目(2014A010105020)

收稿日期:2018-11-06;修订日期:2019-06-24

通信作者:杨 超,教授,博士;电话:020-87111132;E-mail:cyang@scut.edu.cn