DOI: 10.11817/j.issn.1672-7207.2016.12.014

相近刃缘条件下不同铲板结构的切削阻力研究

贺雨田1, 2,吕彭民1

(1. 长安大学 道路施工技术与装备教育部重点实验室,陕西 西安,710064;

2. 西安特种设备检验检测院,陕西 西安,710065)

摘 要:

板切削倾角和加装水平铲刀2种方式,对平面铲板结构进行改进,并将2种方式得到的铲板分别视为简单铲板和复杂铲板。引入不同铲板结构刃缘相近的概念,使设计的3组简单铲板和复杂铲板具有相近刃缘前移距离,且平均前移距离分别为56.8,114.6和187.8 mm。以级配土为切削对象,采用自行设计的切削装置对3组铲板分别在30,60和90 mm这3种不同切削深度下进行土壤切削阻力对比试验。研究结果表明:有4组试验的简单铲板结构切削阻力小于复杂铲板结构的切削阻力,另有4组试验的2种铲板结构切削阻力基本接近,仅有1组试验的简单铲板结构切削阻力相对偏大。因此,在铲板切削刃缘相近的条件下,对于只考虑切削阻力的土壤切削过程,采用简单铲板结构代替复杂铲板结构是工程实际中有效可行的办法。

关键词:

中图分类号:TU411 文献标志码:A 文章编号:1672-7207(2016)12-4056-06

Study on cutting resistance of different blade structures in condition of similar blade-edge

HE Yutian1, 2, LU Pengmin1

(1. Key Laboratory of Road Construction & Equipment of MOE, Chang’an University, Xi’an 710064, China;

2. Xi’an Special Equipment Inspection Institution, Xi’an 710065, China)

Abstract: The structures of flat blades were improved considering two ways of reducing the rake angle of the flat blade and adding horizontal plate, and the blades improved by the two ways were regarded as simple blade and complex blade, respectively. The concept of edge similarity among different blade structures was introduced, and three groups of simple blades and complex blades with average values of 56.8, 114.6 and 187.8 mm were designed. Based on self-designed testing apparatus, contrast tests under three different cutting depths of 30, 60 and 90 mm on grading soil were carried out to compare the cutting resistance. The results show that four groups of test’s cutting resistances of the simple blades are less than those of the complex blades, and other four groups of tests present a similar cutting resistance, and only one group of test’s cutting resistance of simple blade is higher than that of the complex blade. Therefore, it is an effective and feasible method that complex blades structure is replaced by simple ones in condition of different blades’ structures with similar blade-edge with only considering cutting resistance.

Key words: flat blade; dead zone; blade-edge; soil cutting; cutting resistance; horizontal plate

在平面铲板对土壤的切削过程中,铲板前端的土壤在推挤作用下会形成一个不流动区域,该区域只在切削倾角较大时存在,称为边界楔形,或者叫“死区”。HETTIARATCHI等[1]对边界楔形的形成和其对铲板应力分布情况的影响进行了研究;MIEDEMA[2]指出边界楔形并非静态的,其侧面的土壤仍会以低速向外流动; WILLMAN等[3]指出铲板结构对切削阻力起决定性作用;郭志军等[4]对推土板触土曲面进行了设计改进,探索土壤切削减阻的最佳结构;COETZEE等[5-6]采用3种不同方法对谷物颗粒在铲板中的流动规律进行了研究,铲板内的谷粒存在1个V形特征的流动区域;REN等[7]将仿生粗糙铲板的切削特性与光滑铲板进行对比,探索土壤切削减阻的方法;陈波[8]讨论了土壤的切削机理,并对土壤动态切削条件下的土壤比阻与刀具切削速度之间的关系进行了研究;张锐等[9]对推土板作用下干土壤动态行为进行了离散单元模型和试验对比分析;ONO[10]采用离散单元模型,选择6种不同单元形状,对窄平面铲板切削阻力的影响进行了研究;此外,一些复杂几何结构铲板的土壤切削研究采用有限元方法[11-12]。平面铲板的切削倾角对切削阻力有显著影响[13],切削倾角减小,本质上是平面铲板刃缘的切削位置前移,为此,本文作者就铲板刃缘对土壤的切削位置相同或相近时切削阻力的变化进行研究。

1 切削理论

针对土壤切削的理论模型较多,各模型均有一定的适用范围。由于土壤作业环境的不确定因素较多,很难建立1个普遍适用的模型[11]。各土壤模型的建立大多是在对试验观察和总结的基础上得到的,为了简化试验过程和理论分析,通常采用易于比较的铲板结构。平面铲板作为最简单的结构,在土壤切削的二维和三维模型建立和试验研究中较常见[12-14]。

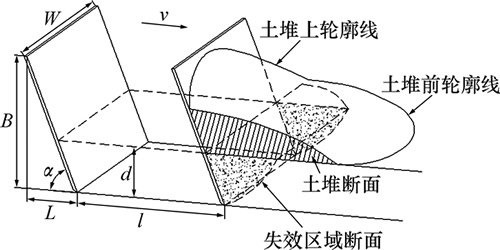

图1所示为平面铲板的三维土壤切削模型。图1中:W为铲板宽度;B为铲板沿切削方向投影的高度;L为刃缘前移距离;α为切削倾角;d为切削深度;l为切削位移;v为切削速度。土壤切削过程会经历2个阶段:切削阻力持续增加阶段和切削阻力相对稳定阶段。在前一阶段土壤不断堆积,在后一阶段土壤堆积达到稳定[19]。图1还给出了土壤堆积稳定的轮廓线,从轮廓线的边缘看,上轮廓线和前轮廓线均近似呈抛物线。在切削过程中,由于铲板对土壤挤压作用,被切削土壤始终存在1个失效面。为了更直观地表达切削过程,图1还给出了沿侧翼的断面图,其中,斜线阴影部分为土堆断面,点状阴影部分为失效区域断面。两个断面在铲板对土壤的切削中不断前移,且土壤堆积过程是失效土壤向上流动形成的。

从图1可以看出:以垂直平面为参考对象,铲板刃缘位置与切削倾角一一对应,两者关系式为

L=B·cotα (1)

由式(1)可知:假设平面铲板刃缘前移距离确定,则平面铲板的切削倾角也是确定的。在确定的切削深度下,铲板刃缘前移距离越大,切削倾角越小;当切削倾角增加时,刃缘前移距离会减小,此时,通过加装水平铲板可以获得相近的刃缘条件。对如图1所示平面铲板,将铲板改变成高为B、水平方向长度为L的直角铲板,则直角铲板与平面铲板的刃缘前移距离相同,但铲板结构发生了改变。

图1 土壤切削模型

Fig. 1 Soil cutting model

2 试验过程

2.1 铲板结构

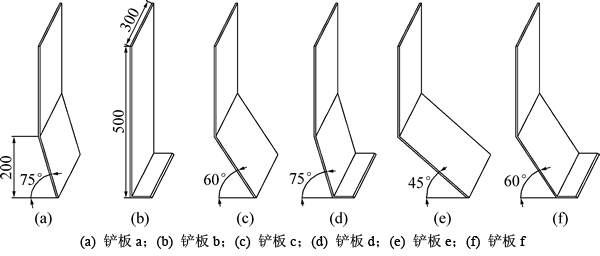

对铲板设计了6种结构形式,如图2所示。这6种铲板结构在切削方向上的投影相同,高为500 mm,宽为300 mm。除铲板b以外,其余5种铲板均在距刃缘切削平面高200 mm处进行折弯;且铲板b与切削平面的夹角为90°,铲板a和d与切削平面的夹角均为75°,铲板c和f与切削平面的夹角均为60°,铲板e与切削平面的夹角为45°;平面铲板折弯75°后得到铲板a,垂直铲板加装水平铲刀后得到铲板b,铲板a加装水平铲刀得到铲板d,铲板c加装水平铲刀得到铲板f。6个铲板的切削刃缘与垂直铲板相比均向前延伸,为了使铲板a与b、铲板c和d以及铲板e和f的刃缘有相近的前移距离,需对所加装水平铲板进行设计。

令刃缘与垂直铲板相比向前延伸距离分别为La,Lb,Lc,Ld,Le和Lf。铲板a,c和e经垂直铲板折弯后,其刃缘前移距离由式(1)可得:La≈53.6 mm,Lc≈115.5 mm,Le=200 mm。根据铲板结构特点,为方便开展试验,将铲板b,d和e加装的水平铲板的长度均设计为60 mm,则铲板b,d和e的刃缘前移值分别为:Lb=60.0 mm,Ld≈113.6 mm,Lf≈175.5 mm。此时,铲板a和b切削刃缘前移距离的绝对差值约为6.4 mm,铲板c和b切削刃缘前移距离的绝对差值小于2.0 mm,铲板e和f切削刃缘前移距离的绝对差值稍大,约为24.5 mm,3组铲板切削刃缘前移距离平均值分别为56.8,114.6和187.8 mm。以铲板切削刃缘前移距离平均值为参考对象,铲板a和b、铲板c和d以及铲板e和f这3组铲板的前移距离实际值与参考值的误差分别为5.6%,0.08%和6.5%,从工程应用角度看满足试验对比的要求,因此,采用上述3组切削刃缘前移距离相近的铲板进行对比试验研究,并将铲板a,c和e视为简单结构,铲板b,d和f视为复杂结构。

图2 铲板结构

Fig. 2 Blades structures

2.2 土壤物理特性

切削土壤是由50%河砂、20%旱砂和30%黄土构成的级配土,含水量为5.5%左右,密度为1.5~1.7 g/cm3。

2.3 试验过程

对比试验在自行研制的引拽式土壤切削装置上进行。切削速度设置为0.12 m/s,选择3种不同切削深度,分别为30,60和90 mm。

3 试验结果

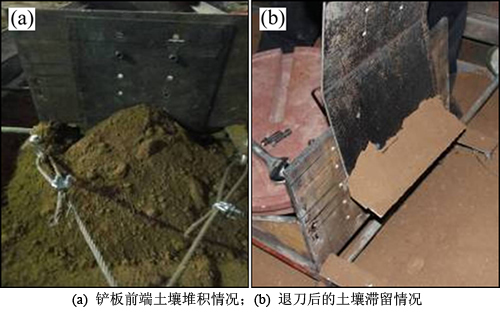

图3所示为试验的土壤切削过程,铲板前土壤堆积比较稳定且具有一定规律(见图3(a))。切削完成后,将铲板退出,有水平铲刀的铲板存在土壤滞留现象。这是由于铲板在大切削角下对土壤切削时会存在1个“死区”[1]。试验用铲板由于水平铲刀存在,人为制造了1个不流动区域,该区域的土壤滞留仍为楔形块的形式(见图3(b))。

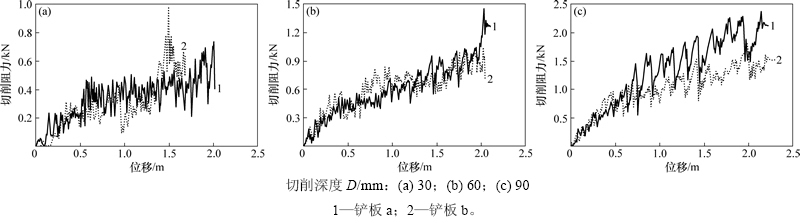

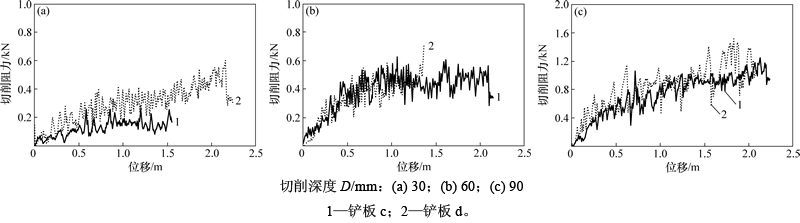

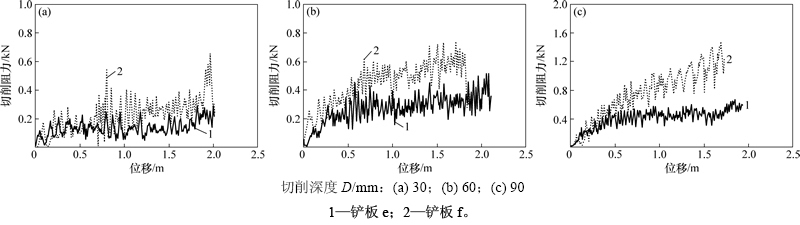

6种铲板(铲板a和b,c和d,e和f)分别在3种不同切削深度下,共进行18组土壤切削试验。3组铲板在不同切削深度下的切削阻力变化曲线分别如图4~6所示。

图3 土壤切削过程

Fig. 3 Soil cutting processes

4 对比分析

从图4~6可看出:切削阻力经历了从逐步增加到基本稳定这2个阶段;切削阻力在切削位移达700 mm后基本稳定。因此,在对比分析中,切削阻力为切削位移大于700 mm时的平均值。

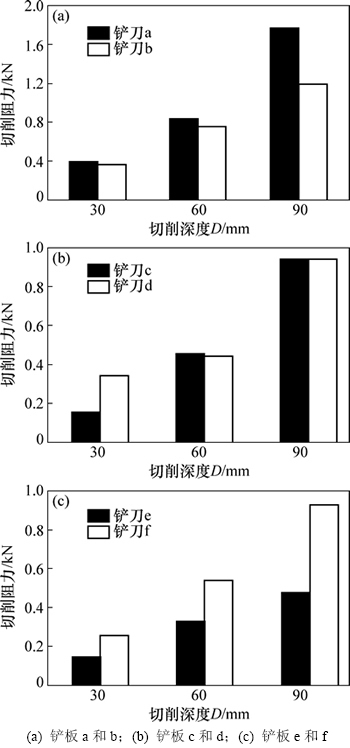

3组铲板在不同切削深度下的平均切削阻力对比见图7。从图7(a)可见:当切削深度为30 mm时,铲板a和b的切削阻力分别为0.404 kN和0.365 kN,铲板b的切削阻力是铲板a的90.4%;当切削深度为60 mm时,铲板a和b的切削阻力分别为0.828 kN和0.757 kN,铲板b的切削阻力是铲板a的91.4%;当切削深度为90 mm时,铲板a和b的切削阻力分别为1.766 kN和1.182 kN,铲板b的切削阻力是铲板a的67.0%。从铲板a和铲板b的切削阻力对比可以看出:铲板b的切削阻力均比铲板a的小,但切削阻力在切削深度为30 mm和60 mm时较接近;当切削深度达到90 mm时,铲板b的切削阻力明显比铲板a的小。

图4 铲板a和b的切削阻力变化曲线

Fig. 4 Curves of cutting resistance for blades a and b

图5 铲板c和d的切削阻力变化曲线

Fig. 5 Curves of cutting resistance for blades c and d

图6 铲板e和f的切削阻力变化曲线

Fig. 6 Curves of cutting resistance for blades e and f

从图7(b)可见:当切削深度为30 mm时,铲板c和d的切削阻力分别为0.152 kN和0.344 kN,铲板c的切削阻力约为铲板d的44.0%,二者的切削阻力存在较大差异;当切削深度为60 mm时,铲板c和d的切削阻力分别为0.453 kN和0.437 kN,基本接近;当切削深度为90 mm时,铲板c和d的切削阻力分别为0.943 kN和0.942 kN,基本相当。对比铲板c和铲板d的切削阻力,二者的大小无一致性,但在切削深度为60 mm和90 mm时,切削阻力可以认为是完全一致的。

从图7(c)可见:当切削深度为30 mm时,铲板e和f的切削阻力分别为0.149 kN和0.255 kN,铲板e的切削阻力约为铲板f的58.7%;当切削深度为60 mm时,铲板e和f的切削阻力分别为0.330 kN和0.540 kN,铲板e的切削阻力约为铲板f的61.0%;当切削深度为90 mm时,铲板e和f的切削阻力分别为0.478 kN和0.928 kN,铲板e的切削阻力约为铲板f的51.6%。在这3种情况下,铲板e的切削阻力均比铲板f的小。这是因为铲板f在切削过程中,由于水平铲刀的存在会人为导致在铲板前端形成不动的土壤“死区”,对“死区”所堆积土壤的推送显著增加切削阻力。

图7 3组铲板在不同切削深度下的平均切削阻力对比

Fig. 7 Comparison of average cutting resistance for three groups of blade under different cutting depths

5 结论

设计了3组几何外形结构存在一定差异的铲板,其共同特征是铲板刃缘的前移距离基本相近;对3组铲板中所包含的6种不同结构进行土壤切削试验。试验结果表明:

1) 对铲板a和铲板b,在切削深度为30 mm和60 mm时,切削阻力差异不大,但在切削深度为90 mm时,铲板a的切削阻力比铲板b的大;对铲板c和铲板d,在切削深度为30 mm时,铲板c的切削阻力比铲板d的小,在其余2种切削深度下,切削阻力平均值基本相近;对铲板e和铲板f,在3种切削深度下,铲板e的切削阻力均显著比铲板f的小。

2) 综合比较3组铲板的结构,在刃缘前移值相近的条件下,将铲板a,c和e的结构分别与铲板b,d和f的结构进行比较,铲板a,c和e的结构相对简单。在所有9组对比试验中,只有1组试验简单结构的切削阻力明显比复杂结构的大,4组试验的切削阻力基本接近,其余4组简单结构的切削阻力明显比复杂结构的小。因此,在进行土壤切削机械的铲板结构设计时,当铲板结构在刃缘尺寸确定的条件下,选择结构相对简单的铲板,在一定条件下可显著减小切削阻力;当刃缘相近且切削阻力基本相近时,也可以使用简单铲板结构,不仅减少加工制造的成本,而且可满足工程实际需要。

参考文献:

[1] HETTIARATCHI D R P, REECE A R. Boundary wedges in two dimensional passive soil failure[J]. Geotechnique, 1975, 25(2): 197-220.

[2] MIEDEMA S A. The cutting mechanisms of water saturated sand at small and large cutting angles[C]//International Conference on Coastal Infrastructure Development-Challenges in the 21st Century. Hong Kong, China, 2004: 1-14.

[3] WILLMAN B M, BOLES W W. Soil-tool interaction theories as they apply to lunar soil stimulant[J]. J Aerosp Eng, 1995, 8(2): 88-99.

[4] 郭志军, 杜干, 李忠利, 等. 触土曲面形式对推土板减阻性能影响的正交试验[J]. 农业机械学报, 2015, 46(7): 372-378.

GUO Zhijun, DU Gan, LI Zhongli, et al. Orthogonal experiment on resistance reduction by soil-engaging surfaces of bulldozer blade[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 372-378.

[5] COETZEE C J, BASSON A H, VERMEER P A. Discrete and continuum modelling of excavator bucket filling[J]. Journal of Terramechanics, 2007, 44(4): 177-186.

[6] COETZEE C J, ELS D N J. The numerical modelling of excavator bucket filling using DEM[J]. Journal of Terramechanics, 2009, 46(5): 217-227.

[7] REN L Q, HAN Z W, LI J Q, et al. Experimental investigation of bionic rough curved soil cutting blade surface to reduce soil adhesion and friction[J]. Soil & Tillage Research, 2006, 85(4): 1-12.

[8] 陈波. 土壤动态切削的试验研究[J]. 筑路机械与施工机械化, 2000, 17(2): 11-13.

CHEN Bo. Experimental study of soil dynamic cutting[J]. Road Machinery & Construction Mechanization, 2000, 17(2): 11-13.

[9] 张锐, 李建桥, 许述财, 等. 推土板切土角对干土壤动态行为影响的离散元模拟[J]. 吉林大学学报(工学版), 2007, 37(4): 822-827.

ZHANG Rui, LI Jianqiao, XU Shucai, et al. Simulation on dynamic behavior of dry soil ahead of the bulldozing plate with different cutting angles by DEM[J]. Journal of Jilin University (Engineering and Technology Edition), 2007, 37(4): 822-827.

[10] ONO I, NAKASHIMA H, SHIMIZU H, et al. Investigation of elemental shape for 3D DEM modeling of interaction between soil and a narrow cutting tool[J]. Journal of Terramechanics, 2013, 50(4): 265-276.

[11] ARMIN A, FOTOUHI R, SZYSZKOWSKI W. On the FE modeling of soil-blade interaction in tillage operations[J]. Finite Elements in Analysis and Design, 2014, 92(24): 1-11.

[12] IBRAHMI A, BENTAHE H, HBAIEB M, et al. Study the effect of tool geometry and operational conditions on mouldboard plough forces and energy requirement: Part 1. Finite element simulation[J]. Computers and Electronics in Agriculture, 2015, 117(9): 258-267.

[13] KOBAYASHI T, OCHIAI H, FUKAGAWA R, et al. A proposal for estimating strength parameters of lunar surface from soil cutting resistances[C]//10th Biennial ASCE International Conference on Engineering, Construction, and Operations In Challenging Environments (Earth and Space 2006). Houston, 2006: 1-8.

[14] JAYASURIYA H P W, SALOKHE V M. A review of soil tine models for a range of soil conditions[J]. J Agric Engng Res, 2001, 79(1): 1-13.

[15] ALUKO1 O B, CHANDLER H W. Characterisation and modelling of brittle fracture in two-dimensional soil cutting[J]. Biosystems Engineering, 2004, 88(3): 369-381.

[16] MALAGUTI F. Soil machine interaction in digging and earthmoving automation[C]//Proceedings of the 11th International Symposium on Automation and Robotics in Construction. Brighton, 1994: 187-192.

[17] 陆怀民. 切土部件与土壤相互作用的粘弹塑性有限元分析[J]. 土木工程学报, 2002, 35(6): 17-81.

LU Huaimin. Finite element analysis for the interaction of soil cutting part and soil[J]. China Civil Engineering Journal, 2002, 35(6): 17-81.

[18] OBERMAYR M, VRETTOS C, EBERHARD P, et al. A discrete element model and its experimental validation for the prediction of draft forces in cohesive soil[J]. Journal of Terramechanics, 2014, 53(4): 93-104.

[19] YANG Qinsen, SUN Shuren. A soil-tool interaction model for bulldozer glades[J]. Journal of Terramechanics, 1994, 31(2): 55-65.

(编辑 陈灿华)

收稿日期:2016-01-10;修回日期:2016-03-22

基金项目(Foundation item):国家科技支撑计划项目(2015BAF07B02)(Project(2015BAF07B02) supported by the National Key Technology R&D Program of the Ministry of Science and Technology of China)

通信作者:吕彭民,博士生导师,教授,从事机械动态仿真与优化设计及结构抗疲强度与可靠性研究;E-mail:lpmin@chd.edu.cn

摘要:针对减小平面铲板切削倾角和加装水平铲刀2种方式,对平面铲板结构进行改进,并将2种方式得到的铲板分别视为简单铲板和复杂铲板。引入不同铲板结构刃缘相近的概念,使设计的3组简单铲板和复杂铲板具有相近刃缘前移距离,且平均前移距离分别为56.8,114.6和187.8 mm。以级配土为切削对象,采用自行设计的切削装置对3组铲板分别在30,60和90 mm这3种不同切削深度下进行土壤切削阻力对比试验。研究结果表明:有4组试验的简单铲板结构切削阻力小于复杂铲板结构的切削阻力,另有4组试验的2种铲板结构切削阻力基本接近,仅有1组试验的简单铲板结构切削阻力相对偏大。因此,在铲板切削刃缘相近的条件下,对于只考虑切削阻力的土壤切削过程,采用简单铲板结构代替复杂铲板结构是工程实际中有效可行的办法。