网络首发时间: 2019-05-24 07:00

TiB2增强Ti2AlNb基复合材料的放电等离子烧结制备及其摩擦学性能研究

西安建筑科技大学冶金工程学院

摘 要:

采用放电等离子烧结(SPS)法在1200℃制备含有不同质量分数TiB2的Ti2AlNb基复合材料,使用显微硬度仪研究不同TiB2含量的复合材料显微硬度变化规律,通过摩擦磨损试验机测试复合材料的摩擦系数,采用三维白光轮廓仪扫描磨痕形貌并计算复合材料的磨损体积和磨损率。结果表明:通过球磨和SPS制备的复合材料组织均匀,烧结过程中TiB2与Ti2AlNb原位反应生成TiB,过量的TiB二次反应原位生成TiB2相。本实验中,随TiB2含量的增加,材料的显微硬度随之增加,且在TiB2添加量为20%(质量分数)时材料的显微硬度达到最高值HV1446.3。复合材料的摩擦系数和磨损率均随TiB2添加量的增加先减小后增大,摩擦磨损时原位生成的TiB相起到减摩作用,原位生成的TiB2相起耐磨骨架作用。在TiB2含量为10%时复合材料的摩擦磨损性能最优,此时摩擦系数为0.554,磨损率为3.363×10-4mm3·N-1·m-1。复合材料的磨损机制为磨粒磨损和轻微黏着磨损共同作用。

关键词:

放电等离子烧结(SPS);Ti2AlNb基复合材料;增强相;显微硬度;摩擦磨损;

中图分类号: TB33

作者简介:王伟(1985-),男,陕西韩城人,博士,副教授,研究方向:钛基复合材料,金属材料加工润滑技术,电话:13609264618,E-mail:gackmol@163.com;

收稿日期:2019-04-18

基金:国家自然科学基金青年基金项目(51605249);凝固技术国家重点实验室(西北工业大学)开放课题(SKLSP201828)资助;

Preparation and Tribological Properties of TiB2 Reinforced Ti2AlNb Matrix Composites by Spark Plasma Sintering

Wang Wei Han Ziru Wang Qingjuan Zhou Haixiong Gao Yuan Wang Kuaishe

College of Metallurgy Engineering,Xi'an University of Architecture and Technology

Abstract:

Ti2AlNb-based composites with different mass fractions of TiB2 were prepared by spark plasma sintering(SPS)method at 1200 ℃.The microhardness of the composites with different TiB2 contents was studied by microhardness tester.The coefficient of friction of the composites was investigated by friction and wear tester.The wear trace morphology was scanned by three-dimensional white light scanner and the wear volume and wear rate of the composites were calculated.The results showed that the microstructure of composites prepared by ball milling and SPS was uniform.In the sintering process,TiB2 and Ti2AlNb reacted in situ to generate TiB,and excessive TiB reacted in situ to generate TiB2 phase.In this experiment,the microhardness of the material increased with the increase of TiB2 content,and the microhardness of the material reached the highest value of HV 1446.3 when the addition amount of TiB2 was 20%(mass fraction).The friction coefficient and wear rate of composite materials first decreased and then increased with the increase of the addition amount of TiB2.The TiB phase generated in situ played a role of antifriction,while the TiB2 phase generated in situ played a role of wear skeleton.When the content of TiB2 was 10%,the friction and wear performance of the composite was the best.At this time,the friction coefficient was 0.554 and the wear rate was 3.363×10-4mm3·N-1·m-1.The wear mechanism of composites was the combination of abrasive wear and slight adhesive wear.

Keyword:

spark plasma sintering(SPS); Ti2AlNb based composite; enhanced phase; microhardness; friction and wear;

Received: 2019-04-18

Ti2AlNb合金具有比强度高、热稳定性好、抗腐蚀性高、韧性和延展性优良等优点,是目前航空材料领域研究的热点

现有研究中,采用粉末冶金方法制备的Ti2AlNb基合金大多数是通过真空热压烧结、热等静压烧结而成。然而,这些方法烧结后的Ti2AlNb基合金晶粒粗大且大小不均,导致其综合性能较差。放电等离子烧结(SPS)具有更高的加热温度和更快的冷却速度、更短的保持时间和更高的压力等特点,可以制造出性能良好的金属基复合材料

鉴于上述情况,本文采用放电等离子烧结法(SPS)在1200℃,50 MPa下制备不同TiB2含量的Ti2AlNb基复合材料,研究该复合材料的显微硬度和摩擦学性能,为TiB2增强Ti2AlNb基复合材料的应用提供理论依据。

1实验

本实验采用Ti2AlNb球形预合金粉为基体,平均晶粒尺寸为53~180?m,纯度高于95%,TiB2为增强体,其平均晶粒尺寸为4~8?m,纯度为98%(质量分数)。Ti2AlNb预合金粉购于西安欧中材料科技有限公司。复合材料的制备过程如图1所示,分别将1%,3%,5%,10%,15%和20%(质量分数)的TiB2与Ti2AlNb合金粉在氩气保护下置于QM-3SP2型行星球磨机中以300 r·min-1进行高能球磨,球磨时间16 h,球料比为10∶1。球磨罐和磨球均为氧化锆材质。球磨后将复合粉末进行SPS烧结,烧结温度为1200℃,保温时间为15 min,烧结时间60 min,烧结压力为50 MPa。烧结出块体分别用TB01-TB06表示(表1)。

采用扫描电子显微镜(SEM)分析原始粉末和烧结后块体的显微组织。通过D/MAX-RB型X射线衍射仪(XRD)对原始粉末和烧结后块体进行物相分析。XRD检测条件为:电压40 kV,电流40 mA,使用Cu Kα射线,扫描角度2θ为20°~90°,扫描速度4(°)·min-1。

使用HVS-1000Z型数显显微硬度计(维氏硬度测量仪)测量各复合材料的显微硬度。硬度测试仪针头压载载荷为3 N,保压10 s。同时考虑误差的影响,每个试样测量6次,取平均值作为实际测量值。

图1 TiB2/Ti2AlNb复合材料的制备过程

Fig.1 Preparation process of TiB2/Ti2AlNb matrix composite

表1 复合材料标号与TiB2含量 下载原图

Table 1 Composite material labels and TiB2content(%,mass fraction)

通过德国BRUKER UMT-3型通用微摩擦试验机,测试复合材料在干摩擦条件下的摩擦学性能。图2为摩擦磨损实验示意图。摩擦副为Φ4 mm的Si3N4小球,施加载荷3 N,滑动时间为30 min。采用公式:W=V/(P×S)计算复合材料的磨损率,其中,V为磨损体积,P为施加载荷,S为总滑动距离。复合材料的磨损体积是通过三维白光轮廓仪扫描摩擦后的磨痕计算得到,使用0.1?m的垂直分辨率测量磨痕深度,0.8?m横向分辨率测量磨痕宽度。

2结果与讨论

2.1微观组织与物相分析

图3(a)是Ti2AlNb粉末球磨前的SEM图片,可以看出,Ti2AlNb粉体颗粒呈球形,颗粒的表面光滑,平均粒度在80~95?m,颗粒大小均匀,这是由于旋转电极制粉法制取的粉末颗粒形状为近球形,表面光洁流动性好,能保持约65%理论密度的稳定装填密度

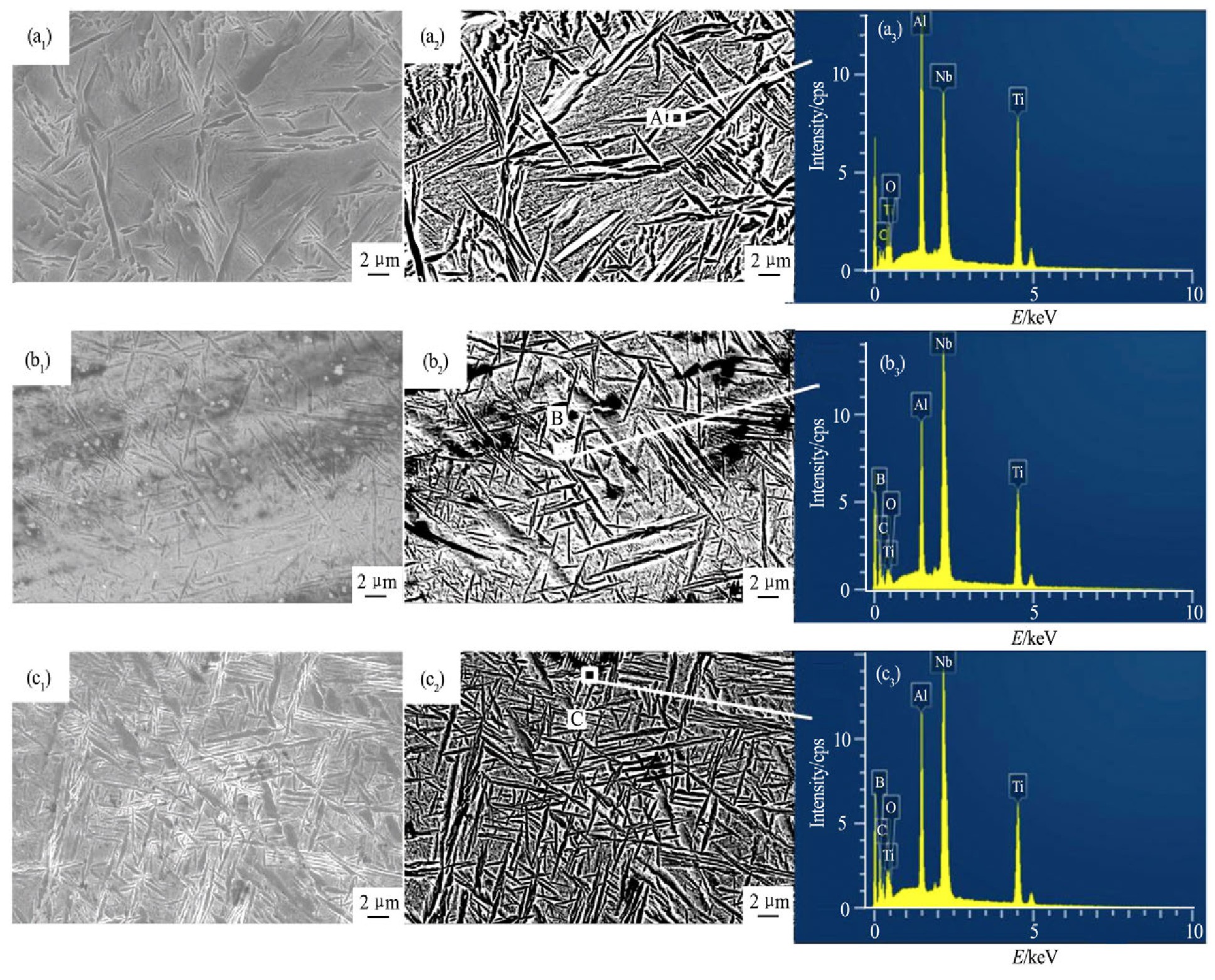

图4为TB01,TB03和TB04复合材料SPS后的SEM图片及能谱(EDS)分析。由材料的扫描组织可以看出:复合材料界面结合紧密无孔隙;基体中均存在针状析出相,且随着TiB2含量增加,针状组织长度变短,在TB04中可以看出针状相形成了均匀分布的网篮组织。

表2为图4中能谱分析得出的各组分元素含量。由各组分原子比可知:烧结后基体呈B2相,析出针状组织为O相且随着TiB2含量增加,析出的O相含量增加,这主要是由于加入TiB2与基体发生反应消耗了Ti元素,使得原先的Ti2AlNb元素比例失配。由图4(b3)和表2中b3的原子比,可知此时在O相边界处的亮色组织为TiB相;由图4(c3)与其对应原子比发现基体中存在富TiB2区。

图2 摩擦磨损实验示意图

Fig.2 Sketch map of friction and wear test

图3 Ti2AlNb粉末与TiB2粉末球磨前的SEM图像

Fig.3 SEM images of Ti2AlNb powder(a)and TiB2powder(b)before ball milling

图5为不同含量TiB2/Ti2AlNb基复合材料XRD图,从图中可以看出:添加少量TiB2的Ti2AlNb基复合材料如TB01和TB02中没有出现TiB2的衍射峰,至TiB2添加5%时出现微弱TiB2衍射峰,继续添加TiB2,TiB2的衍射峰强度提升,在含20%TiB2时达到最大,推测此时在36.5°出现的TiB2是二次原位反应生成的TiB2(100)。TiB的衍射峰强度随着TiB2含量的增加而变强,故推测加入的TiB2与基体反应被消耗生成了TiB且在10%TiB2时TiB含量最多。随着TiB2继续增加,TiB的衍峰变弱直至消失,且在28°出现未完全与基体反应剩余的TiB2(200)的衍射峰(TB05和TB06)。Namini和Azadbeh

图4 不同含量TiB2/Ti2AlNb复合材料的表面形貌(SEM)及EDS分析

Fig.4 SEM images and EDS result of TiB2/Ti2AlNb composites with different TiB2contents

(a)TB01;(b)TB03;(c)TB04

表2 各组分元素含量 下载原图

Table 2 Element contents of each component at positions in Fig.4(%,atom fraction)

Namini和Azadbeh

根据不同含量TiB2/Ti2AlNb基复合材料的28°~48°XRD放大图(图5(b)),可知其衍射峰最高峰对应着基体Ti2AlNb,但其有所偏移,Shu等

2.2 TiB2添加量对硬度的影响

TiB2的添加量对复合材料显微硬度的影响如图7所示,随TiB2添加量的增加,复合材料的显微硬度整体呈上升趋势。添加1%TiB2的Ti2AlNb基复合材料显微硬度为HV 482.38,相比于未经强化的Ti2AlNb显微硬度HV 301.2,显微硬度明显增大:少量添加TiB2即可使复合材料硬度提升60%以上。添加3%到5%TiB2时,显微硬度变化不明显,这是由于加入的TiB2和基体反应被消耗且低硬度的O相随TiB2的加入而增多,此时复合材料较之纯Ti2AlNb的硬度小幅度提升主要依赖于二次生成的TiB2的增强效果。TiB2添加量大于10%开始复合材料显微硬度大幅增加,加入20%TiB2时,材料显微硬度为HV 1446.3,相比于Ti2AlNb提高了380.2%,对应复合材料XRD图谱可知,此时复合材料显微硬度的大幅提升主要依赖于未完全反应的TiB2:TiB2为硬质增强相有超高的强度微硬度,故未完全反应的TiB2聚集使复合材料显微硬度大幅提升。

图5 不同含量TiB2/Ti2AlNb复合材料的XRD图谱和28°~48°放大图

Fig.5 XRD patterns of TiB2/Ti2AlNb matrix composites with different TiB2contents(a)and enlarged images of 28°~48°(b)

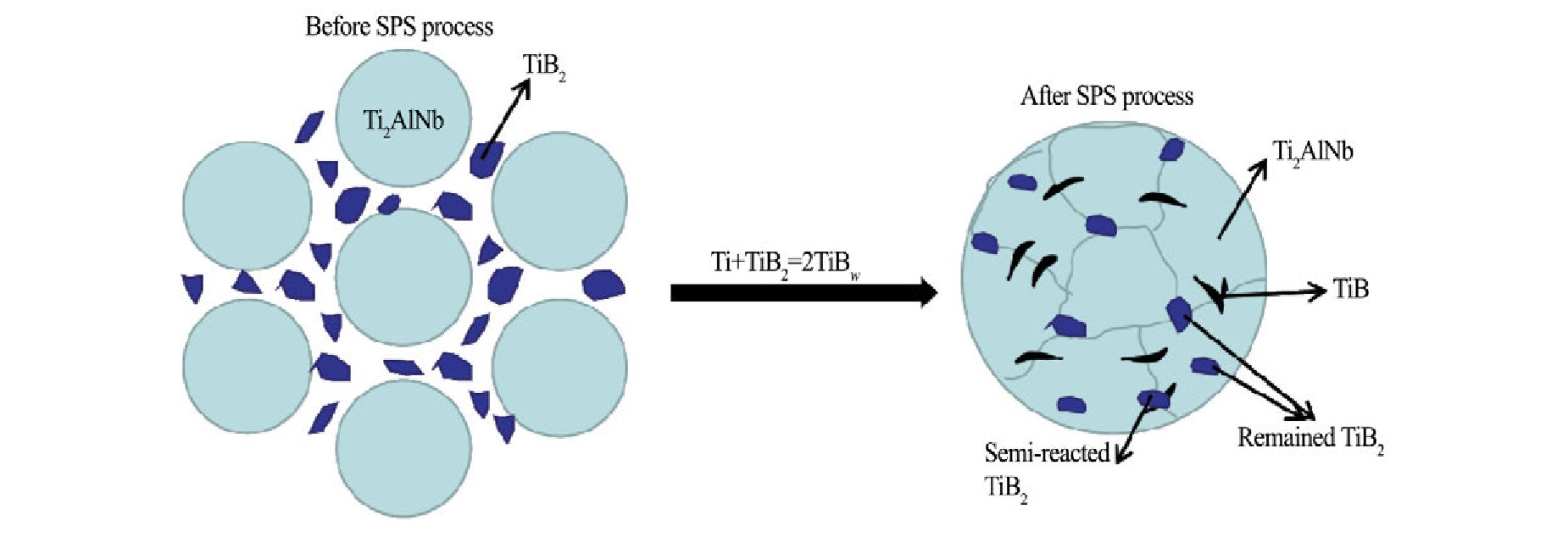

图6 TiB2/Ti2AlNb复合材料放电等离子烧结过程中相变的示意图

Fig.6 Schematic diagram of phase transformation in discharge plasma sintering process of TiB2/Ti2AlNb composite material

图7 不同含量TiB2/Ti2AlNb复合材料的平均显微硬度

Fig.7 Average microhardness of TiB2/Ti2AlNb matrix compos-ites with different TiB2contents

此外,TiB2增强相的加入在基体中起钉扎作用可以细化基体晶粒,达到细晶强化的效果

2.3摩擦磨损性能

图8(a~f)为不同含量TiB2/Ti2AlNb复合材料的摩擦系数—时间曲线图,对比可以看出不同含量TiB2/Ti2AlNb复合材料的摩擦系数均随时间推移趋于一个稳定范围。图8(b)中材料的摩擦系数在1000 s之后略有上升后再次趋于稳定,这是由于摩擦层不稳定造成的

图8 不同含量TiB2/Ti2AlNb复合材料的摩擦系数

Fig.8 Friction coefficient of TiB2/Ti2AlNb composite with different TiB2contents

(a)TB01;(b)TB02;(c)TB03;(d)TB04;(e)TB05;(f)TB06

图9(a)为不同含量TiB2/Ti2AlNb复合材料的平均摩擦系数变化图,图9(b)为不同含量TiB2/Ti2AlNb复合材料的磨损率对比图,将图9(a,b)做横向对比可以发现,随TiB2含量增加,TiB2/Ti2AlNb复合材料的平均摩擦系数与磨损率均出现先降低后升高的趋势:当TiB2含量小于10%时,复合材料摩擦系数和磨损率随TiB2添加量的增加而减小,说明此时TiB2的加入可以改善复合材料的耐磨性,根据复合材料XRD图谱可知,此时随TiB2添加量的增加,反应生成的TiB含量增加,此时基体的摩擦系数和磨损率的减小是TiB对基体的优化效果;当TiB2添加量达到10%时,由图5中TB04的28°~48°放大图可知,此时基体中存在二次反应生成的TiB2相,由于其为TiB的原位生成物,分布非常均匀不存在聚集现象,可以在摩擦中起到很好的耐磨骨架的作用。基体中TiB此时也达到最大,TiB在摩擦中起到减摩作用。此时复合材料平均摩擦系数达到最低为0.554,磨损率达最低3.363×10-4mm3·N-1·m-1。

当增强相TiB2添加量大于10%时,复合材料的摩擦系数和磨损率反而上升。摩擦系数的降低和升高可以用材料的硬度以及添加相的聚集进行解释。随着TiB2的添加,复合材料的显微硬度上升,材料强度与硬度呈正相关关系,此时按照强度越高摩擦系数应当减小,在TiB2添加量小于等于10%时依旧遵循此规律。但当TiB2添加量超过10%时,由材料XRD图谱和SEM图可知,此时未完全反应TiB2出现聚集,TiB2呈脆硬性,增强相的聚集导致摩擦磨损时硬质颗粒剥落,故而摩擦系数变大。Kumar等

图9 不同TiB2含量复合材料平均摩擦系数和磨损率

Fig.9 Average friction coefficient(a)and wear rate(b)of the composites with different TiB2contents

式中,V为磨损体积损耗,k为磨损系数,L为滑动距离,P为施加载荷,H为试样的硬度。本实验中,施加载荷和滑动距离恒定,由公式可知复合材料的磨损损耗与硬度成反比,所以磨损存在先减小的趋势;而当TiB2添加量超过10%时,未完全反应和二次生成TiB2的虽然能使材料硬度大幅度上升,但此时初始添加的TiB2的积聚形成了富TiB2区

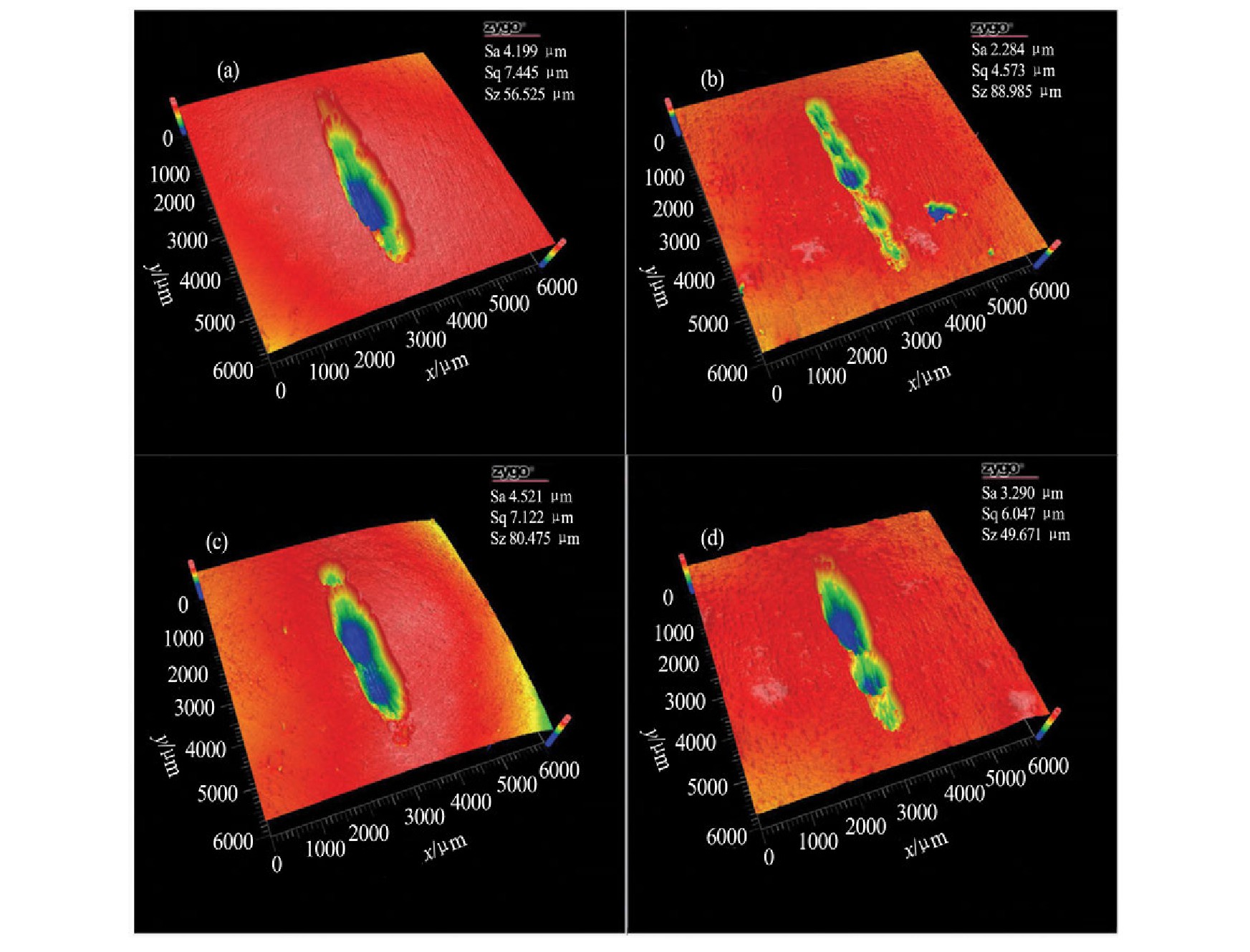

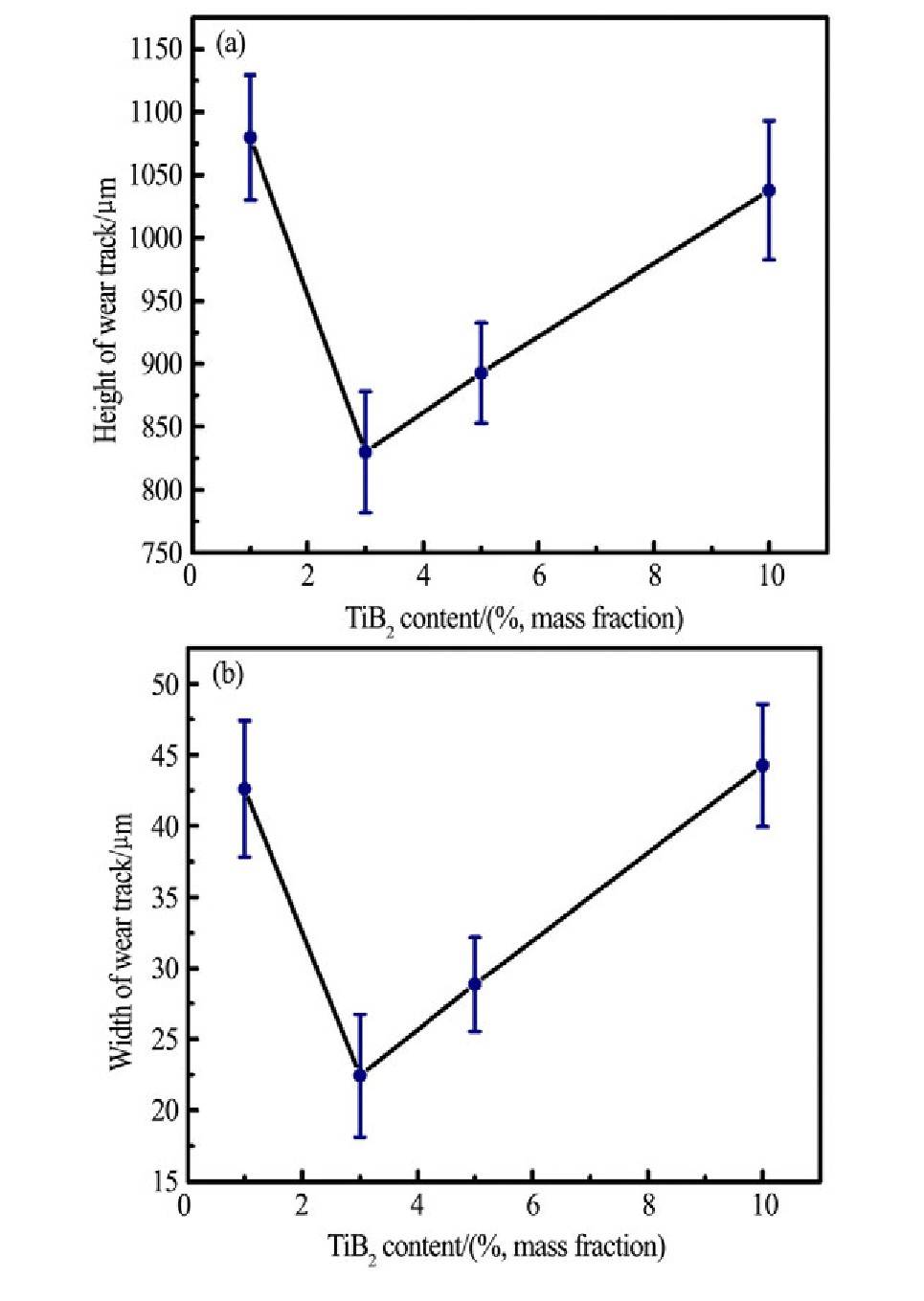

图10(a~d)为1%~10%TiB2/Ti2AlNb(TB01-TB04)复合材料摩擦磨损后的三维白光图。三维白光图可以直观清晰地看到不同含量TiB2/Ti2AlNb复合材料的磨损后的磨痕形貌和磨损体积的变化。直观发现磨痕的形貌沿摩擦相对运动方向呈条状,且在中部磨痕深度达到最大。由图11(a,b)磨痕深度和宽度图可知,在相同的倍率下,随TiB2含量的增加,复合材料的磨损体积先减小后增加:磨痕宽度由1079.75?m先减小到828.84?m再升高至1037.69?m。磨痕深度同样由42.61?m先减小到22.44?m,再增加至44.26?m。这与摩擦系数和磨损率的变化趋势规律相同。

图1 0 不同含量TiB2/Ti2AlNb复合材料摩擦磨损后三维白光图

Fig.10 Three-dimensional white light map after friction and wear of TiB2/Ti2AlNb composites with different contents(a)TB01;(b)TB02;(c)TB03;(d)TB04

图1 1 不同含量TiB2/Ti2AlNb复合材料摩痕深度图和摩痕宽度图

Fig.11 Friction depth map(a)and friction width map(b)of TiB2/Ti2AlNb composites with different TiB2contents

由上述实验得出结论:原位生成的TiB颗粒利于材料的耐磨性,而二次生成的TiB2相均匀分布在基体中增强基体强度,起到耐磨骨架的作用。由于复合材料的烧结制度和冷却速度相同,且组织均含O和B2相,在室温摩擦时发现复合材料的相分布不发生变化,原位生成的TiB和TiB2对材料耐磨性的影响占主导地位。复合材料的磨损机制为磨粒磨损和轻微黏着磨损共同作用。

3结论

1.通过干法球磨和放电等离子烧结法制备了TiB2/Ti2AlNb复合材料,TiB2添加量较少时,TiB2可以均匀分散,烧结后块体界面接触紧密;随着TiB2的添加,烧结后块体析出O相的板条长度减小。

2.烧结时TiB2与Ti2AlNb基体中的Ti反应生成TiB。原位生成的TiB的含量随TiB2含量的增加呈上升趋势,过量的TiB二次反应原位生成TiB2相。

3.TiB2的添加,可以很大程度上提高基体的硬度。随着TiB2含量的增加,复合材料的显微硬度整体呈上升趋势。当加入TiB2含量增加到20%时显微硬度达到最大HV 1446.3相比于未经强化的Ti2AlNb提高了380.2%。材料硬度的增加一定程度可以减小摩擦系数和磨损率。

4.随TiB2含量的增加,复合材料的摩擦系数,磨损率和磨损量均先减小后增大。10%TiB2/Ti2AlNb复合材料摩擦系数最小为0.554,磨损率最小为3.363×10-4mm3·N-1·m-1。

5.摩擦磨损时原位生成的TiB起到减摩作用,原位生成的TiB2相起耐磨骨架作用。相的分布和形态对摩擦系数影响较小。复合材料的磨损机制为磨粒磨损和轻微黏着磨损共同作用。

参考文献