回复态Al-1.5%Mg单相合金大变形组织与强化机制

江苏大学先进制造与现代装备技术工程研究院

摘 要:

通过X射线衍射分析 (XRD) 、电子背散射衍射分析 (EBSD) 分析技术表征大应变后材料内部微观结构, 并结合拉伸实验通过公式定量计算出各部分强化因素对合金屈服强度的贡献, 研究了锻造及退火态铝镁单相合金 (Al-1.5%Mg) 在大变形过程中的组织演变及强化机制。结果表明:由于固溶镁元素的存在, 铝镁单相合金在大变形过程能有效累积位错。等通道转角大应变加工使得平均晶粒尺寸减小 (4.605μm降低至2.183μm) , 平均晶界角度提高 (4.43°提高至6.51°) , 低角度晶界比例减少 (0.97降低至0.89) , 晶体取向显著降低。后续的压缩大应变加工进一步降低平均晶粒尺寸 (2.183μm降低至1.328μm) , 提高高角度晶界的比例 (0.10提高至0.16) 。大应变铝镁合金的强化主要由晶格摩擦应力、位错强化、低角度晶界强化、高角度晶界强化和固溶强化组成, 其中位错强化和低角度晶界强化贡献占绝大部分。

关键词:

Al-1.5%Mg单相合金;大变形;组织演变;强化机制;等通道转角挤压;

中图分类号: TG146.21

作者简介:徐驰 (1990-) , 男, 江苏宿迁人, 硕士研究生, 研究方向:先进成形及装备制造的研究, E-mail:syxc1990@163.com;;许晓静, 教授, 电话:13952877885, E-mail:xjxu67@ujs.edu.cn;

收稿日期:2015-08-01

基金:国家自然科学基金项目 (51074079);江苏大学研究生科研创新计划项目 (KYXX_0031) 资助;

Microstructure and Strengthening Mechanism of Al-1.5%Mg Single-Phase Alloy by Recovery Annealing

Xu Chi Xu Xiaojing Ma Wenhai Dong Xiaofei Lu Yudong Guo Yunfei

Engineering Institute of Advanced Manufacturing and Modern Equipment Technology, Jiangsu University

Abstract:

The internal microstructure of the materials after large strains was characterized by X-ray diffraction ( XRD) and electron backscatter diffraction ( EBSD) analysis techniques, and tensile tests was combined to calculate the contribution of each strengthening factors on the yield strength of the alloy by quantitative formula. The microstructure evolution and strengthening mechanism of Al-1. 5%Mg single-phase alloy in as-cast and as-annealed states during large deformation were investigated. Results indicated that because of the presence of Mg in the alloy, large deformation could effectively accumulate dislocations. Average grain size ( from 4. 605 μm to 2. 183μm) , low angle grain boundary ( from 0. 97 to 0. 89) and crystal orientation of Al-1. 5% Mg showed a reduction after processed by equal channel angular pressing, with average grain boundary angles being improved ( from 4. 43° to 6. 51°) . The subsequent compression processing further reduced the average grain size ( from 2. 183 to 1. 328 μm) , and the proportion of high angle grain boundary increased ( from 0. 10 to 0. 16) . Strengthening contributions of large strain Al-1. 5% Mg were mainly from lattice friction stress, dislocation strengthening, low and high angle grain boundary strengthening and solid solution strengthening, and the low angle grain boundary and dislocation strengthening was dominant.

Keyword:

Al-1.5% Mg single-phase alloy; large deformation; microstructure evolution; strengthening mechanism; ECAP (equal channel angular pressing) ;

Received: 2015-08-01

等通道转角挤压 (ECAP, equal channel angular pressing) 是一种采用纯剪切方式来减小材料晶粒尺寸及调控晶体取向的剧烈塑性变形法

本文采用ECAP及后续压缩两种方式对Al-1.5%Mg单相合金进行大应变加工, 研究其在大变形过程中的组织演变, 并采用X射线衍射仪 (XRD) 与电子背散射衍射 (EBSD) 分析技术表征大应变后材料内部的组织结构。通过公式计算各强化因素的贡献值, 建立铝镁单相合金强化机制的数学模型。

1 实验

实验材料为Al-1.5%Mg的单相合金, 并经锻造和后续250℃×24 h退火处理。大应变加工采取的方法是3道次等通道转角挤压及后续50%的压缩大应变 (原ECAP后工件直径为20 mm, 压缩完后工件厚度为10 mm) 。

ECAP试验所用模具通道直径为Ф20 mm, 两通道间交角为Ф=100°。采用工艺路线Bc进行3道次挤压加工, 挤压速度为5 mm·s-1。选用含Mo S2的润滑脂涂在试样表面, 以减小挤压过程中试样与模具之间的摩擦力。压缩大应变加工在100 t的液压机上完成, 压缩速度为5 mm·s-1。

XRD分析在D/max-2500PC型X射线衍射仪进行, 设定其参数为扫描速率5 (°) ·min-1, 扫描范围30°~120°, Cu靶Kα射线 (波长为0.154nm) ;采用配备了EBSD探头的FEG-SEM型场发射扫描电子显微镜观察微观结构, 并通过HKL Channel 5软件包对实验数据进行分析;拉伸试验在国产WDW-200型微机控制式万能试验机上进行, 拉伸试样标距尺寸为7 mm×4 mm×2 mm, 初始应变速率为1.0×10-3s-1。

2 结果与讨论

2.1 XRD分析与位错强化

图1为不同大应变下铝镁合金的XRD谱。对比可以看出, 3道次ECAP大应变加工和后续的50%压缩大应变加工使得各衍射峰位置与峰间强度比率发生了明显的变化, 说明3道次ECAP大变形加工和50%压缩大应变加工均会影响材料组织的晶体取向。

XRD中相干衍射区尺寸 (d) 、晶格应变 (<e>) 与各衍射峰最大值位置 (θ0) 、测得的半高峰宽 (δ2θ) 及Cu Kα射线波长 (λ) 之间的关系如下公式描述

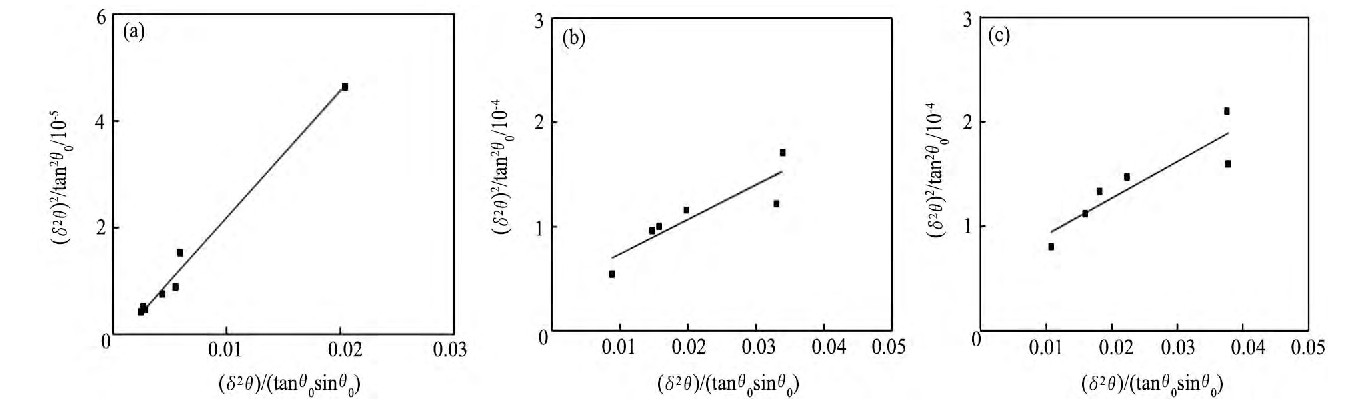

图2为不同大应变下铝镁合金 (δ2θ) 2/tan2θ0与δ2θ/ (tanθ0sinθ0) 之间的关系。通过线性拟合, 计算得到XRD相干衍射区尺寸和晶格应变, 结果列于表1。材料内部的位错密度 (ρ) 与XRD相干衍射区尺寸、平均晶格应变 (<e2>1/2) 之间的函数关系通常可用如下公式描述

图1 不同大应变下铝镁合金的XRD谱Fig.1 XRD patterns of Al-1.5%Mg with different large strains

(a) Forged+annealed; (b) Forged+annealed+ECAPed; (c) Forged+annealed+ECAPed+compressed

图2 根据积分宽度分析计算XRD中晶粒尺寸及晶格应变Fig.2 Integral breadth analysis to calculate grain size and lattice strain from XRD data

(a) Forged+annealed; (b) Forged+annealed+ECAPed; (c) Forged+annealed+ECAPed+compressed

式中参数b为柏氏矢量, 对于Al, 其值为0.286nm, 利用式 (2) 可以计算出位错密度, 其值列于表1。合金内部位错导致的强化 (σp) 与位错密度之间的关系用公式描述

式中参数M, α及G分别为材料的位向因子 (不考虑织构时为3.06) , 数值因子 (0.24) 和剪切模量 (对于Al其值为26 MPa) , 按照式 (3) 可以得到铝镁合金内部位错对强化贡献量, 其值列于表2。

2.2 EBSD分析与晶界强化

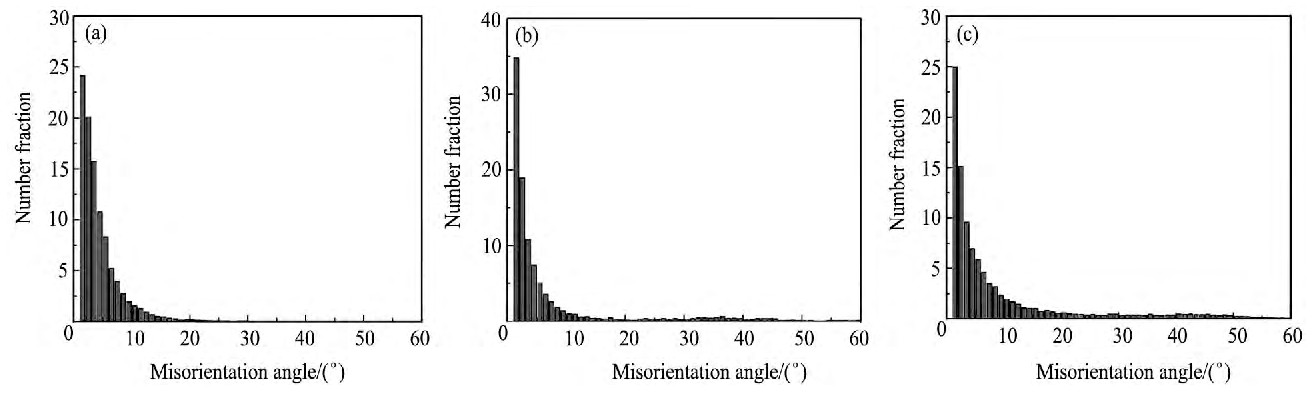

图3和4分别为EBSD分析得到的不同大应变下铝镁合金的晶粒尺寸和晶界角度分布图 (低角度晶界取向差为1°~15°, 高角度晶界取向差>15°) 。表3为EBSD分析得到的不同大应变下铝镁合金的组织参数。从图3, 4及表3分析的数据可以看出, ECAP大应变加工使合金平均晶粒尺寸 (L) 明显降低, 绝大多数晶粒尺寸细化到5μm以下, 此时合金中存在一定数量的高角度晶界, 高角度晶界比例 (fH) 为0.103;进一步压缩大应变后, 平均晶粒尺寸又大幅降低, 高角度晶界继续增多。这是因为, 对于铝镁合金而言, 添加镁元素的限制位错移动降低了层错能, 从而导致了固溶强化。这反作用于组织上使晶粒得到细化, 大大减少了晶界间距离, 使位错更容易到达晶界产生聚积, 从而在晶界处集中淹没而使晶界角度增大, 变成高角度晶界。

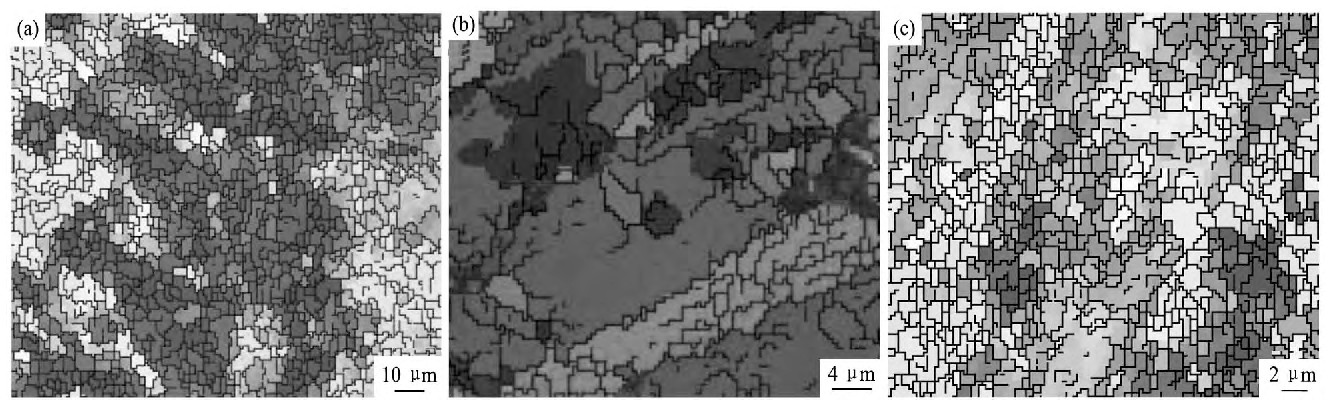

图5为EBSD得到的不同大应变下铝镁合金的晶界图。对比可以看出, 锻压及退火态的铝镁合金内部组织呈现带状;3道次ECAP大应变加工后, 大块带状晶粒被剪切破碎成尺寸较小的晶粒;进一步50%压缩大应变加工后, 带状晶粒非常少, 晶粒尺寸变得更加细小, 组织更加均匀。

表1 XRD数据分析出的微观结构参数Table 1 Some micro-structural parameters calculated from XRD data 下载原图

表1 XRD数据分析出的微观结构参数Table 1 Some micro-structural parameters calculated from XRD data

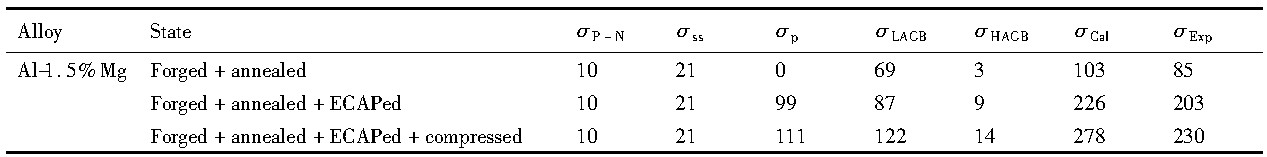

表2 不同大应变下铝镁合金的强化组成Table 3 Strengthening composition of Al-1.5%Mg with different large strains (MPa) 下载原图

表2 不同大应变下铝镁合金的强化组成Table 3 Strengthening composition of Al-1.5%Mg with different large strains (MPa)

图3 不同大应变下铝镁合金的晶粒尺寸分布Fig.3 Grain size distributions of Al-1.5%Mg with different large strains

(a) Forged+annealed; (b) Forged+annealed+ECAPed; (c) Forged+annealed+ECAPed+compressed

图4 不同大应变下铝镁合金的晶界角度分布Fig.4 Misorientation angle distributions of Al-1.5%Mg with different large strains

(a) Forged+annealed; (b) Forged+annealed+ECAPed; (c) Forged+annealed+ECAPed+compressed

表3 EBSD分析得到的不同大应变下铝镁合金的组织参数Table 3 Structural parameters of Al-1.5%Mg with different large strains obtained from EBSD 下载原图

表3 EBSD分析得到的不同大应变下铝镁合金的组织参数Table 3 Structural parameters of Al-1.5%Mg with different large strains obtained from EBSD

图5 不同大应变下铝镁合金的晶界图Fig.5 Grain boundary maps of Al-1.5%Mg with different large strains

(a) Forged+annealed; (b) Forged+annealed+ECAPed; (c) Forged+annealed+ECAPed+compressed

材料组织中低角度晶界对强度的贡献值 (σLAGB) 与低角度晶界参数之间的关系可以用函数描述

式中

高角度晶界对强度的贡献值 (σHAGB) 与高角度晶界参数之间的关系可以用Hall-Petch函数关系描述

式中, 参数kH-P为Hall-Petch系数 (对于Al其值为0.04 MPa·m-1) 。将表3相关数据代入上式计算可以得出铝镁合金高角度晶界对强度的贡献值, 其值列于表2。从表2可以看出, 大应变铝镁合金中高角度晶界对强度的贡献值比小角度晶界小很多。

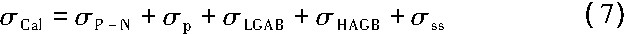

2.3 强化机制分析

对于Al-1.5%Mg而言, 由于纯铝中加入了一定比例的镁元素, 则在合金中形成了固溶粒子, 产生了固溶强化作用。元素固溶对强度的贡献值与固溶元素溶度 (C) 之间的关系一般用下面函数描述

式中H=13.8 MPa·%α, α=1

大应变铝镁单相合金的强化主要由晶格摩擦应力 (σP-N) (纯铝为10 MPa

根据式 (7) 可以得到, Al-1.5%Mg单相合金经过不同大应变加工后的屈服强度σCal, 其值列于表2。从表2可以看出, 大应变铝镁合金中位错和低角度晶界对强度的贡献值占很大比例。而拉伸实验得到的材料屈服强度σExp已列于表2。对比可以看出, 理论计算得到的屈服强度和试验结果基本吻合。

3 结论

1.等通道转角大应变加工使得平均晶粒尺寸减小, 低角度晶界减少, 晶体取向显著降低。而后续的压缩大应变加工进一步降低了平均晶粒尺寸, 提高了高角度晶界的比例。

2.由于固溶镁元素的存在, 铝镁单相合金经挤压及后续压缩大应变加工后, 其内部均能有效积累位错。

3.大应变铝镁合金的强化主要由晶格摩擦应力、位错对强度的贡献值、低角度晶界对强度的贡献值、高角度晶界对强度的贡献值和元素固溶对强度的贡献值组成, 其中位错和低角度晶界对强化的贡献占绝大部分。

参考文献