不规则烧结矿余热回收竖罐内气体阻力特性

张四宗,温治,刘训良,张辉,王帅,刘晓宏

(北京科技大学 能源与环境工程学院,北京,100083)

摘 要:

烧结矿竖罐式冷却工艺的经济性和可行性,对比研究了单粒级和多粒级烧结矿填充床内气体阻力特性。首先,利用排水法、等效球体积法和称重法等表征烧结矿颗粒特性;然后,利用自制固定床试验台测量了不同粒度下单粒级和多粒级烧结矿填充床内气体阻力;最后,通过修正获得了ERGUN形式的阻力关联式。研究结果表明:气体速度对单粒级和多粒级烧结矿的单位高度气体阻力(△P/L)的影响一致,均呈二次关系增加;当量粒径(dp)对单粒级和多粒级烧结矿的△P/L的影响不同,单粒级的△P/L主要受空隙率影响,导致其随着dp增加呈指数下降,且衰减幅度也逐渐减小;多粒级的△P/L不仅取决于空隙率,还受粒度组成的影响,这导致△P/L不仅随着dp增大而下降,还造成△P/L的衰减幅度先上升后下降;本文得到的阻力关联式可以准确地预测单粒级和多粒级烧结矿填充床内气体阻力,平均相对误差分别为3.59%和3.39%;多粒级的粒度分布比单粒级的更宽,导致相同当量粒径下单粒级的△P/L比多粒级的△P/L平均低25%左右,表明单粒级的阻力关联式不适用于多粒级。

关键词:

中图分类号:TK11+5 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)06-1963-11

Gas resistance characteristics in vertical tank with irregular sinter for waste heat recovery

ZHANG Sizong, WEN Zhi, LIU Xunliang, ZHANG Hui, WANG Shuai, LIU Xiaohong

(School of Energy and Environmental Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To accurately evaluate the economy and feasibility of sinter vertical tank cooling process, the gas resistance characteristic in the packed bed with the mono-size and multi-size sinter was studied. Firstly, the characteristics of sinter particles were characterized by drainage method, equivalent sphere volume method and weighing method, etc. Then, the gas resistance in the packed bed of mono-size and multi-size sinter with different particle sizes was measured by self-made fixed bed test apparatus. Finally, the resistance correlation in the form of ERGUN was obtained by modifying. The results show that the influence of gas velocity on the gas resistance per unit height(△P/L) of mono-size and multi-size sinter is the same, which increases in a quadratic relationship. However, the effect of the equivalent particle size (dp) on △P/L of mono-size and multi-size sinter is different.△P/L of mono-size is mainly affected by the voidage, which leads to an exponential decrease of △P/L and the decrease of its attenuation amplitude with the increase in dp. △P/L of the multi-size is not only determined by voidage, but also depends on the particle size composition. This not only makes △P/L decrease with the increase of dp, but also causes its attenuation amplitude to ascend firstly and then descend. Furthermore, the resistance correlation obtained in this paper can accurately predict the gas resistance in the packed bed with mono-size and multi-size sinter with mean relative errors of 3.59% and 3.39%, respectively. However, the particle size distribution of multi-size is wider than that of the mono-size, which results in △P/L of mono-size with about 25% lower than that of multi-size with the same equivalent particle size. This indicates that the resistance correlation of mono-size is not suitable for multi-size.

Key words: waste heat recovery; irregular particle; gas resistance; mono-size; multi-size; sinter

能耗高是钢铁行业的一个重要特征[1-3]。在整个钢铁工业中,烧结工序的能耗约占总能耗的10%~15%[4]。然而,烧结矿余热约占整个烧结工序余热资源的70%[5]。因此,烧结矿余热的高效回收是降低烧结工序能耗最有效的途径[6-7]。目前,主要利用环冷工艺回收烧结矿余热。然而,环冷机的漏风率高达35%~50%[6],且冷却空气只能被加热到150~380 ℃,导致余热回收率不足30%[7]。

针对现有冷却工艺的不足,基于干熄焦工艺[8-10]提出了烧结矿竖罐式冷却工艺(简称竖冷工艺)[7]。首先,竖冷工艺的漏风率接近于零,大幅降低了颗粒污染物的排放;其次,竖冷工艺可将冷却空气加热到500~550 ℃,将余热回收率提高到80%左右[7]。竖冷工艺的可行性主要取决于气体阻力和气固传热特性2个方面[11]。气体阻力特性不仅影响着气固传热效率,还直接决定着风机的功率和能耗。因此,研究气体阻力特性对于评价竖冷工艺的经济性和可行性十分重要。在实际生产中烧结矿的形状极不规则,粒度分布广,具有多粒级混合的特点[12]。本质上,烧结矿余热回收罐是一种不规则大颗粒的非均质填充床[13]。

目前,国内外大量研究了颗粒填充床内气体阻力特性。其中,ERGUN的研究最具代表性,并提出了著名的ERGUN方程[14]。为了准确地预测不同颗粒填充床内气体阻力,学者们从壁面效应[15-17]、颗粒形状[18-22]和粒径分布[21-25]等角度修正ERGUN方程。当床层直径D与颗粒直径dp之比(D/dp)大于10时,可以忽略壁面对气体阻力的影响[15]。原始的ERGUN方程可以准确地预测球形颗粒填充床内气体阻力,但在预测不规则颗粒时存在较大偏差[18,20-21]。粒度的多分散性增强了局部结构和气体流动的不均匀性,导致气体的阻力和湍流程度增加[25]。以往研究大多集中于规则的小颗粒(粒径为0.5~22.0 mm),而对于不规则大颗粒的研究较少。

因此,一些学者对烧结矿填充床气体阻力进行实验研究[11-13, 26-33],发现用ERGUN方程得到的气体阻力预测值比单粒级烧结矿填充床内气体阻力的实测值低40%左右[12]。为了准确预测单粒级烧结矿床层内气体阻力,将阻力系数分别修正为床层直径与粒径之比D/dp[11, 26]和空隙率

1 实验系统与方法

1.1 实验装置

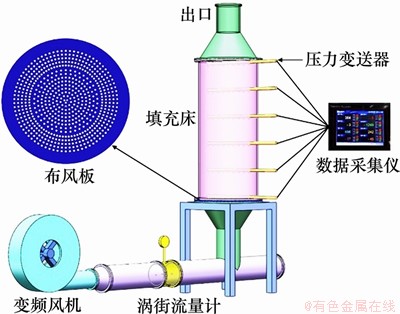

利用自制的实验装置测量烧结矿填充床内气体阻力,实验装置示意图如图1所示[34]。填充床的高度和直径分别为1 000 mm和400 mm。实验中选用变频风机精确地控制鼓入床层的气体流量,采用涡街流量计测量气体的流量,并利用压力变送器测量不同位置处的气体压力。基于工业实际,设计实验中气体的运行状态,详见文献[34]。仪器的基本参数如表1所示。

图1 烧结矿填充床内气体阻力实验装置示意图

Fig. 1 Sketch of experimental apparatus for measuring gas resistance in sinter packed bed

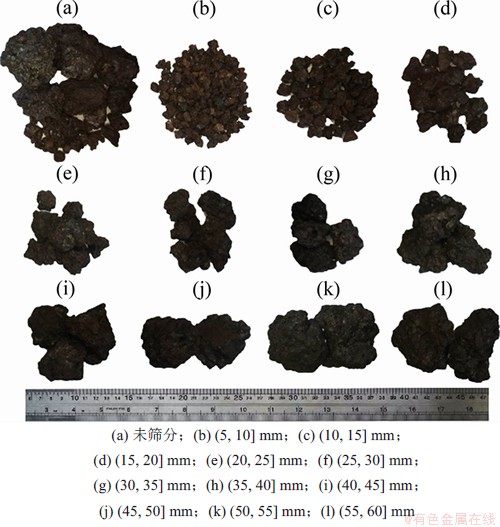

表1 实验仪器的基本参数

Table 1 Basic parameters of experimental instruments

1.2 烧结矿的颗粒特性

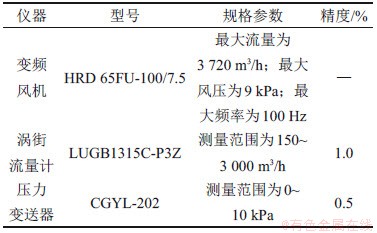

研究所用的烧结矿颗粒取自邯郸钢铁有限公司的2号烧结机。测试中烧结矿粒度范围为5~60 mm[12,34],包括未筛分的多粒级烧结矿和筛分的单粒级烧结矿,如图2所示。

图2 烧结矿的实物照片

Fig. 2 Photographs of sinter

为了更好地表征烧结矿,利用实验手段获得了烧结矿的颗粒特性参数。对于每种单粒级烧结矿,颗粒的表观密度

式中:

对于由多种单粒级烧结矿组成的多粒级烧结矿,其表观密度

式中:

烧结矿的堆积密度

式中:

床层的空隙率ε和颗粒的形状因子φ可分别通过式(6)[12, 28, 31]和式(7)[22]计算:

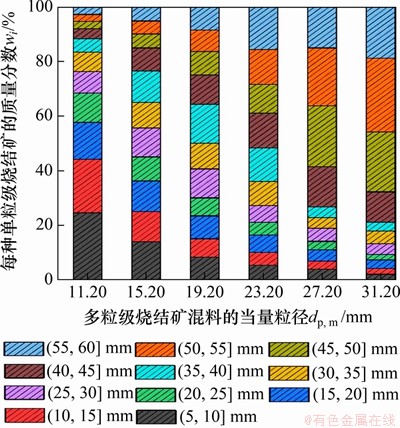

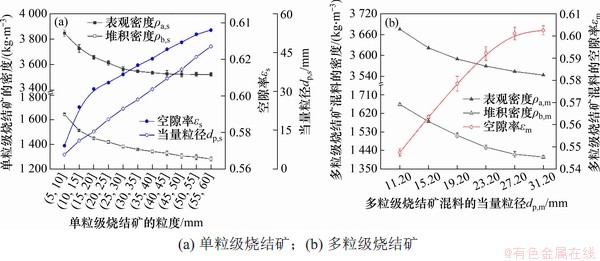

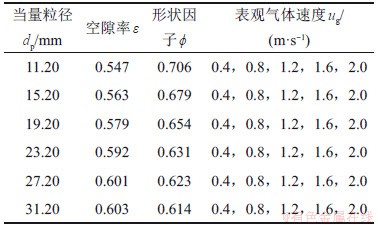

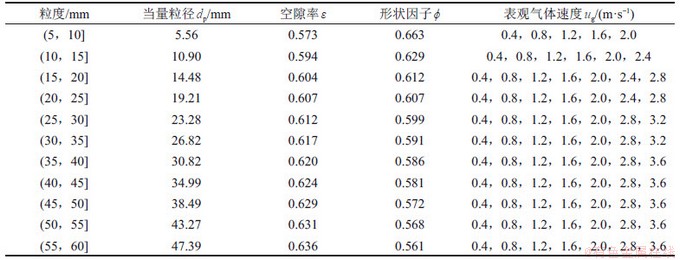

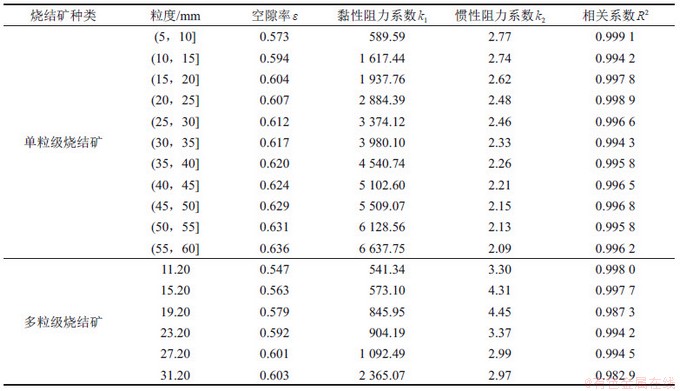

在测试中,基于当量粒径设计了6种由11种单粒级烧结矿组成的多粒级烧结矿,如表2所示。图3所示为6种多粒级烧结矿的粒度组成。本研究还测量了11种单粒级烧结矿填充床内气体阻力作为对照,如表3所示。利用上述方法测定的11种单粒级烧结矿和6种多粒级烧结矿的颗粒特性参数如图4所示。

图3 6种多粒级烧结矿的粒度组成

Fig. 3 Particle size composition of six kinds of multi-size sinter

图4 烧结矿的颗粒特性参数

Fig. 4 Particle characteristic parameters of sinter

表2 6种多粒级烧结矿的试验工况参数

Table 2 Experimental condition parameters of six kinds of multi-size sinter

表3 11种单粒级烧结矿的试验工况参数

Table 3 Experimental condition parameters of 11 kinds of mono-size sinter

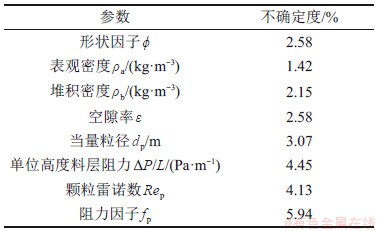

1.3 不确定度分析

表4所示为根据误差传递理论[30]计算的本研究中主要参数的相对不确定度,具体介绍详见文献[34]。例如雷诺数

表4 主要参数的相对不确定度

Table 4 Relative uncertainty of main parameters

2 填充床内气体阻力的影响因素

2.1 气体速度

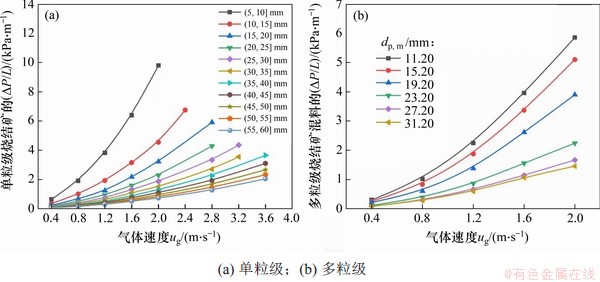

图5所示为不同单粒级和多粒级烧结矿填充床内单位高度气体阻力(△P/L)随着气体速度(ug)的变化。由图5(a)可见:随着ug增加,△P/L逐渐增大且与二次函数拟合良好。所有曲线的相关系数R2均大于0.992。这与文献[11,13,26和27]的结论一致。随着ug增加,气体与颗粒之间的碰撞加剧,造成气体流动的紊乱程度增加。因此,气体流动的阻力急剧增加。此外,拟合函数的系数a和b随着粒度增大而减小,归因于床层空隙率随着粒度增大而增大。

图5 不同单粒级和多粒级烧结矿的单位高度气体阻力(△P/L)随着气体速度(ug)的变化

Fig. 5 Change of gas resistance per unit height (△P/L) for different mono-size and multi-size sinters with gas velocity (ug)

由图5(b)可见:多粒级烧结矿的△P/L也随着ug增大呈二次关系增加。拟合曲线的相关系数R2均大于0.994。这表明气体速度对多粒级烧结矿和单粒级烧结矿△P/L的影响相同,但不同当量粒径拟合函数的系数a和b并不一致。6种多粒级烧结矿的粒度组成不同,导致填充床内颗粒的堆积结构不同。因此,多粒级烧结矿的粒度分布会直接影响着填充床内气体阻力。

2.2 当量粒径

2.2.1 当量粒径对单粒级烧结矿气体阻力的影响

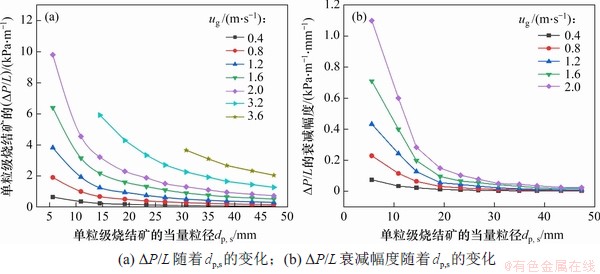

图6所示为当量粒径(dp,s)对单粒级烧结填充床内单位高度气体阻力(△P/L)的影响。由图6可知:

1) 不同气体速度下,△P/L随着dp,s增加而降低,且与指数函数拟合良好。所有曲线的相关系数R2均大于0.993。这与文献[11,13,27]的结果一致。由于床层空隙率随着dp,s增大而增加,且较大空隙率床层内气体流动的紊乱程度和比表面积较低,从而导致惯性阻力和黏性阻力降低。

2) △P/L的衰减幅度为气体阻力△P/L对当量粒径dp,s的导数,也随着dp,s增加而下降。这归因于床层空隙率增加幅度也随着dp,s增加而减小。

图6 当量粒径(dp,s)对单粒级烧结矿填充床内单位高度气体阻力(△P/L)的影响

Fig. 6 Influence of equivalent particle size (dp,s) on gas resistance per unit height (△P/L) in packed bed with mono-size sinter

2.2.2 当量粒径对多粒级烧结矿气体阻力的影响

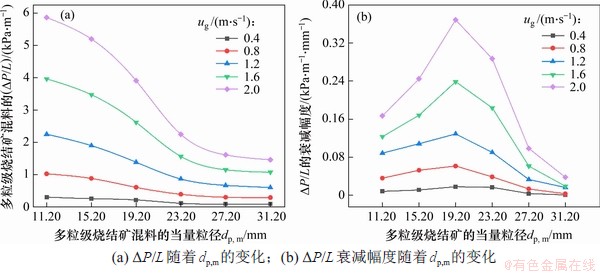

图7所示为当量粒径(dp,m)对多粒级烧结矿填充床内单位高度气体阻力(△P/L)的影响。由图7(a)可见:不同气体速度下,△P/L也随着dp,m增加而降低。但图7(b)表明△P/L衰减幅度随着dp,m增大先上升后下降,这不同于当量粒径对单粒级烧结矿△P/L的影响。如在气体速度为1.6 m/s的工况下,当dp为11.20,19.20和31.20 mm时,△P/L的衰减幅度分别为123.29,238.91和18.92 Pa·m-1·mm-1。

图7 当量粒径(dp,m)对多粒级烧结矿填充床内单位高度气体阻力(△P/L)的影响

Fig. 7 Influence of equivalent particle size (dp,m) on gas resistance per unit height (△P/L) in packed bed with multi-size sinter

对于多粒级烧结矿而言,小粒度烧结矿会填充在大粒度烧结矿颗粒的间隙中[22],导致床层内空隙分布不均匀[25]。因此,多粒级烧结矿填充床内气体阻力不仅取决于床层空隙率,还受粒度组成的影响。由于小粒度烧结矿(5~10 mm)的掺混会导致多粒级烧结矿的气体阻力急剧上升[32-33],因此,对于dp,m较小的多粒级烧结矿而言,小粒度烧结矿的比例是△P/L变化的主导因素。在dp,m为11.20 mm的多粒级烧结矿中,(5,10] mm的单粒级烧结矿比例高达24.57%。随着dp,m从11.20 mm增至19.20 mm,小粒度烧结矿的比例逐渐下降,导致△P/L的降低幅度随着dp,m增加而增大,这与彭岩等[33]的研究结果类似。而当多粒级烧结矿的dp,m增大到23.20 mm时,(5,10] mm的小粒度烧结矿比例只有5.31%。因此,对于dp,m较大的多粒级烧结矿而言,△P/L变化的主导因素不再是小粒度烧结矿,而是床层空隙率。从图4(b)可知,随着dp,m从19.20 mm增至31.20 mm,多粒级烧结矿床层空隙率的增加幅度逐渐减小,这导致△P/L的衰减幅度随着dp,m继续增大而降低。

3 烧结矿填充床内气体阻力预测关联式的分析

为了便于研究结果的应用,将床层内单位高度气体阻力△P/L与各参数之间的关系拟合成类似于ERGUN方程的经验关联式:

式中:

由于烧结矿的形状非常不规则,因此,将形状因子φ考虑到修正的关联式中,如下式所示[11, 28]:

根据文献[11-13,26-30]可知,主要是通过修正黏性阻力系数k1和惯性阻力系数k2来改进阻力经验关联式。因此,将式(10)除以黏性阻力项

为了简化上式,引入2个量纲一参数即阻力因子fp和颗粒雷诺数Rep:

则式(11)可简化为量纲一公式:

根据式(14)可知,fp和Rep呈线性关系。

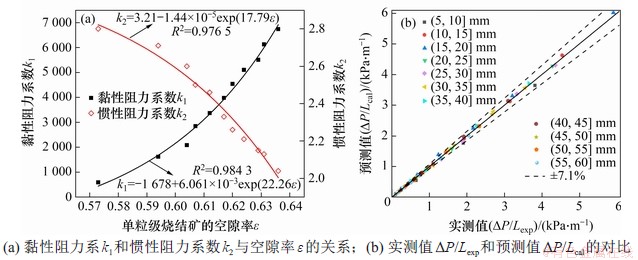

3.1 单粒级烧结矿

首先,将图5(a)中单位高度气体阻力△P/L数据和图4(a)中颗粒特性参数代入式(12)和(13)中,即可获得不同单粒级烧结矿的阻力因子fp和颗粒雷诺数Rep。其次,利用最小二乘法对fp和Rep进行线性拟合,得出不同粒度烧结矿的黏性阻力系数k1和惯性阻力系数k2,如表5所示。所有的相关系数R2均大于0.994 2,表明每个粒度烧结矿的fp均与Rep呈良好的线性关系。由于空隙率ε是与颗粒特性相关的量纲一参数,因此将其引入到k1和k2的拟合函数中,如图8(a)所示。因此,单粒级烧结矿阻力因子fp的表达式如下:

表5 不同单粒级和多粒级烧结矿的黏性阻力系数k1和惯性阻力系数k2

Table 5 Viscous resistance coefficient k1 and inertial resistance coefficient k2 of different mono-size and multi-size sinters

图8(b)所示为式(15)获得的单粒级烧结矿单位高度气体阻力的预测值△P/Lcal和实测值△P/Lexp的对比。由图8(b)可见:单位高度气体阻力△P/L的预测值与实测值吻合良好,平均和最大不确定度分别为3.59%和12.07%。因此,式(15)可以准确地预测单粒级烧结矿填充床内气体阻力。

图8 单粒级烧结矿气体阻力关联式的分析

Fig. 8 Analysis of gas resistance correlation of mono-size sinter

3.2 多粒级烧结矿

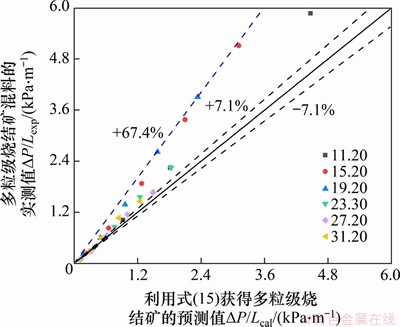

利用单粒级烧结矿的阻力关联式即式(15)预测6种多粒级烧结矿的气体阻力,如图9所示。由图9可见:单位高度气体阻力预测值△P/Lcal和实测值△P/Lexp的平均不确定度和最大不确定度分别高达24.58%和67.4%,且实测值大多高于预测值。因此,单粒级烧结矿的阻力关联式不适用于多粒级烧结矿气体阻力的预测。多粒级烧结矿的粒度分布比单粒级烧结矿的更宽,造成多粒级烧结矿床层的空隙分布更不均匀[25]。这导致多粒级烧结矿填充床内气体流动更加紊乱[35-36]。因此,利用单粒级烧结矿阻力关联式计算的预测值比多粒级烧结矿的实测值平均低25%左右。

图9 式(15)获得的多粒级烧结矿的气体阻力预测值△P/Lcal与实测值△P/Lexp的对比

Fig. 9 Comparison between predicted value △P/Lcal obtained by Eq.(15) and experimental value △P/Lexp of gas resistance for multi-size sinter

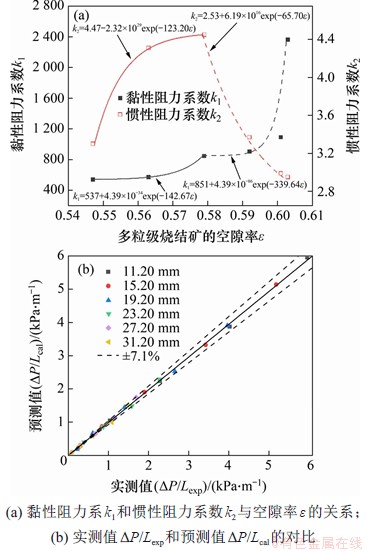

基于此,利用最小二乘法对多粒级烧结矿的阻力因子fp和颗粒雷诺数Rep进行了线性拟合,如表5所示。所有的相关系数R2均大于0.982 9,表明每种多粒级烧结矿的fp与Rep都具有良好的线性关系。同样地,将黏性阻力系数k1和惯性阻力系数k2拟合为空隙率ε的函数,如图10(a)所示。根据2.2.2节的分析可知,当量粒径dp大于和小于19.20 mm时,多粒级烧结矿气体阻力的主要影响因素不同。

图10 多粒级烧结矿气体阻力关联式的分析

Fig. 10 Analysis of gas resistance correlation of multi-size sinter

因此,将多粒级烧结矿的fp分段表示:

图10(b)所示为式(16)获得的多粒级烧结矿床层内气体阻力预测值△P/Lcal和实测值△P/Lexp之间的比较。由图10(b)可见:气体阻力的预测值均匀地分布在实测值两侧,且平均不确定度为3.39%。这表明式(16)可以准确地预测多粒级烧结矿填充床内气体阻力。

4 结论

1) 气体速度对单粒级和多粒级烧结矿填充床内气体阻力的影响相同,即单位高度气体阻力(△P/L)均随着气体速度增加呈二次关系增加。

2) 单粒级烧结矿的△P/L随当量粒径(dp)增大呈指数降低,△P/L衰减幅度逐渐减小。虽然多粒级烧结矿的△P/L也随着dp增加而降低,但由于粒度组成和床层空隙率的综合作用,导致△P/L的衰减幅度呈先上升后下降趋势。

3) 单粒级烧结矿和多粒级烧结矿阻力关联式可以准确地预测烧结矿填充床内气体阻力,平均不确定度分别为3.59%和3.39%。多粒级烧结矿的粒度分布比单粒级烧结矿的更宽,导致单粒级烧结矿关联式获得的气体阻力预测值比多粒级烧结矿气体阻力的实测值平均低25%左右。

参考文献:

[1] CHEN Wenying, YIN Xiang, MA Ding. A bottom-up analysis of China's iron and steel industrial energy consumption and CO2 emissions[J]. Applied Energy, 2014, 136: 1174-1183.

[2] LI Yuan, ZHU Lei. Cost of energy saving and CO2 emissions reduction in China's iron and steel sector[J]. Applied Energy, 2014, 130: 603-616.

[3] CHEN Lingen, YANG Bo, SHEN Xun, et al. Thermodynamic optimization opportunities for the recovery and utilization of residual energy and heat in China's iron and steel industry: a case study[J]. Applied Thermal Engineering, 2015, 86: 151-160.

[4] ZHANG Xiaohui, CHEN Zhuo, ZHANG Jiayuan, et al. Simulation and optimization of waste heat recovery in sinter cooling process[J]. Applied Thermal Engineering, 2013, 54(1): 7-15.

[5] 董辉, 林贺勇, 张浩浩, 等. 烧结热工测试与分析[J]. 钢铁, 2011, 46(11): 93-98.

DONG Hui, LIN Heyong, ZHANG Haohao, et al. Thermal test and analysis of sintering cooling system[J]. Iron & Steel, 2011, 46(11): 93-98.

[6] 董辉, 赵勇, 蔡九菊, 等. 烧结-冷却系统的漏风问题[J]. 钢铁, 2012, 47(1): 95-99.

DONG Hui, ZHAO Yong, CAI Jiuju, et al. Leakage of sintering-cooling system[J]. Iron & Steel, 2012, 47(1): 95-99.

[7] 董辉, 李磊, 刘文军, 等. 烧结矿余热竖罐式回收利用工艺流程[J]. 中国冶金, 2012, 22(1): 6-11.

DONG Hui, LI Lei, LIU Wenjun, et al. Process of waste heat recovery and utilization for sinter in vertical tank[J]. China Metallurgy, 2012, 22(1): 6-11.

[8] ERRERA M R, MILANEZ L F. Thermodynamic analysis of a coke dry quenching unit[J]. Energy Conversion and Management, 2000, 41(2): 109-127.

[9] FENG Yanhui, ZHANG Xinxin, YU Quan, et al. Experimental and numerical investigations of coke descending behavior in a coke dry quenching cooling shaft[J]. Applied Thermal Engineering, 2008, 28(11/12): 1485-1490.

[10] SUN Kai, TSENG C T, SHAN-HILL WONG D, et al. Model predictive control for improving waste heat recovery in coke dry quenching processes[J]. Energy, 2015, 80: 275-283.

[11] 冯军胜, 董辉, 李明明, 等. 烧结余热回收竖罐内固定床层的阻力特性[J]. 中南大学学报(自然科学版), 2014, 45(8): 2566-2571.

FENG Junsheng, DONG Hui, LI Mingming, et al. Resistance characteristics of fixed bed layer in vertical tank for recovering sinter waste heat[J]. Journal of Central South University (Science and Technology), 2014, 45(8): 2566-2571.

[12] TIAN Fuyou, HUANG Lianfeng, FAN Liwu, et al. Pressure drop in a packed bed with sintered ore particles as applied to sinter coolers with a novel vertically arranged design for waste heat recovery[J]. Journal of Zhejiang University: science A, 2016, 17(2): 89-100.

[13] FENG Junsheng, DONG Hui, LIU Jingyu, et al. Experimental study of gas flow characteristics in vertical tank for sinter waste heat recovery[J]. Applied Thermal Engineering, 2015, 91: 73-79.

[14] ERGUN S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48: 89–94.

[15] EISFELD B, SCHNITZLEIN K. The influence of confining walls on the pressure drop in packed beds[J]. Chemical Engineering Science, 2001, 56(14): 4321-4329.

[16] GUO Zehua, SUN Zhongning, ZHANG Nan, et al. Influence of confining wall on pressure drop and particle-to-fluid heat transfer in packed beds with small D/d ratios under high Reynolds number[J]. Chemical Engineering Science, 2019, 209: 115200.

[17] GORMAN J M, ZHENG A, SPARROW E M. Bounding wall effects on fluid flow and pressure drop through packed beds of spheres[J]. Chemical Engineering Journal, 2019, 373: 519-530.

[18] NEMEC D, LEVEC J. Flow through packed bed reactors: 1. Single-phase flow[J]. Chemical Engineering Science, 2005, 60(24): 6947-6957.

[19] OZAHI E, GUNDOGDU M Y, CARPINLIOGLU M O. A modification on Ergun's correlation for use in cylindrical packed beds with non-spherical particles[J]. Advanced Powder Technology, 2008, 19(4): 369-381.

[20] MAYERHOFER M, GOVAERTS J, PARMENTIER N, et al. Experimental investigation of pressure drop in packed beds of irregular shaped wood particles[J]. Powder Technology, 2011, 205(1/2/3): 30-35.

[21] ALLEN K G, VON B T W , KROGER D G. Packed bed pressure drop dependence on particle shape, size distribution, packing arrangement and roughness[J]. Powder Technology, 2013, 246: 590-600.

[22] KOEKEMOER A, LUCKOS A. Effect of material type and particle size distribution on pressure drop in packed beds of large particles: Extending the Ergun equation[J]. Fuel, 2015, 158: 232-238.

[23] PARK J H, LEE M, MORIYAMA K, et al. Adequacy of effective diameter in predicting pressure gradients of air flow through packed beds with particle size distribution[J]. Annals of Nuclear Energy, 2018, 112: 769-778.

[24] LI Liangxing, MA Weimin. Experimental characterization of the effective particle diameter of a particulate bed packed with multi-diameter spheres[J]. Nuclear Engineering and Design, 2011, 241(5): 1736-1745.

[25] RONG L W, DONG K J, YU A B. Lattice-Boltzmann simulation of fluid flow through packed beds of spheres: Effect of particle size distribution[J]. Chemical Engineering Science, 2014, 116: 508-523.

[26] FENG Junsheng, DONG Hui, DONG Hongda. Modification of Ergun's correlation in vertical tank for sinter waste heat recovery[J]. Powder Technology, 2015, 280: 89-93.

[27] 冯军胜, 董辉, 高建业, 等. 烧结矿余热回收竖罐内气体流态的实验研究[J]. 东北大学学报(自然科学版), 2016, 37(4): 517-521.

FENG Junsheng, DONG Hui, GAO Jianye, et al. Gas flow regime in vertical tank for sinter waste heat recovery[J]. Journal of Northeastern University(Natural Science), 2016, 37(4): 517-521.

[28] TIAN Fuyou, HUANG Lianfeng, FAN Liwu, et al. Wall effects on the pressure drop in packed beds of irregularly shaped sintered ore particles[J]. Powder Technology, 2016, 301: 1284-1293.

[29] FENG Junsheng, ZHANG Sheng, DONG Hui, et al. Frictional pressure drop characteristics of air flow through sinter bed layer in vertical tank[J]. Powder Technology, 2019, 344: 177-182.

[30] LIU Yan, WANG Jingyu, CHENG Zhilong, et al. Experimental investigation of fluid flow and heat transfer in a randomly packed bed of sinter particles[J]. International Journal of Heat and Mass Transfer, 2016, 99: 589-598.

[31] 田付有, 黄连锋, 范利武, 等. 双粒度混合烧结矿颗粒填充床压降实验[J]. 浙江大学学报(工学版), 2016, 50(11): 2077-2086.

TIAN Fuyou, HUANG Lianfeng, FAN Liwu, et al. Experimental study on pressure drop of packed beds with binary sintered ore particle mixtures[J]. Journal of Zhejiang University(Engineering Science), 2016, 50(11): 2077-2086.

[32] PAN Lisheng, WEI Xiaolin, PENG Yan, et al. Experimental study on convection heat transfer and air drag in sinter layer[J]. Journal of Central South University, 2015, 22(7): 2841-2848.

[33] 彭岩, 王为术, 时小宝, 等. 烧结矿炉式冷却装置料层阻力试验研究[J]. 烧结球团, 2019, 44(1): 6-8.

PENG Yan, WANG Weishu, SHI Xiaobao, et al. Experimental study on material bed resistance of furnace type sinter cooling device[J]. Sintering and Pelletizing, 2019, 44(1): 6-8.

[34] 张四宗, 温治, 刘训良, 等. 颗粒形状对烧结矿填充床内渗透系数和阻力系数的影响[J]. 中南大学学报(自然科学版), 2020, 52(4): 1066-1075.

ZHANG Sizong, WEN Zhi, LIU Xunliang, et al. Effects of the particle shape on the permeability and resistance coefficients of the sinter packed bed[J]. Journal of Central South University(Science and Technology), 2020, 52(4): 1066-1075.

[35] KEYSER M J, CONRADIE M, COERTZEN M, et al. Effect of coal particle size distribution on packed bed pressure drop and gas flow distribution[J]. Fuel, 2006, 85 (10/11): 1439-1445.

[36] LEONG J C, JIN Kunwu, SHIAU J S, et al. Effect of sinter layer porosity distribution on flow and temperature fields in a sinter cooler[J]. International Journal of Minerals, Metallurgy and Materials, 2009, 16(3): 265-272.

(编辑 秦明阳)

收稿日期: 2020 -08 -28; 修回日期: 2020 -11 -03

基金项目(Foundation item):国家重点研发计划项目(2017YFC0210304) (Project(2017YFC0210304) supported by National Key Research & Development Program of China)

通信作者:刘训良,博士,教授,从事冶金工程中低温余热利用研究;E-mail:liuxl@me.ustb.edu.cn

DOI: 10.11817/j.issn.1672-7207.2021.06.026

引用格式:张四宗, 温治, 刘训良, 等. 不规则烧结矿余热回收竖罐内气体阻力特性[J]. 中南大学学报(自然科学版), 2021, 52(6): 1963-1973.

Citation:ZHANG Sizong, WEN Zhi, LIU Xunliang, et al. Gas resistance characteristics in vertical tank with irregular sinter for waste heat recovery[J]. Journal of Central South University(Science and Technology), 2021, 52(6): 1963-1973.

摘要:为了准确地评价烧结矿竖罐式冷却工艺的经济性和可行性,对比研究了单粒级和多粒级烧结矿填充床内气体阻力特性。首先,利用排水法、等效球体积法和称重法等表征烧结矿颗粒特性;然后,利用自制固定床试验台测量了不同粒度下单粒级和多粒级烧结矿填充床内气体阻力;最后,通过修正获得了ERGUN形式的阻力关联式。研究结果表明:气体速度对单粒级和多粒级烧结矿的单位高度气体阻力(△P/L)的影响一致,均呈二次关系增加;当量粒径(dp)对单粒级和多粒级烧结矿的△P/L的影响不同,单粒级的△P/L主要受空隙率影响,导致其随着dp增加呈指数下降,且衰减幅度也逐渐减小;多粒级的△P/L不仅取决于空隙率,还受粒度组成的影响,这导致△P/L不仅随着dp增大而下降,还造成△P/L的衰减幅度先上升后下降;本文得到的阻力关联式可以准确地预测单粒级和多粒级烧结矿填充床内气体阻力,平均相对误差分别为3.59%和3.39%;多粒级的粒度分布比单粒级的更宽,导致相同当量粒径下单粒级的△P/L比多粒级的△P/L平均低25%左右,表明单粒级的阻力关联式不适用于多粒级。

[5] 董辉, 林贺勇, 张浩浩, 等. 烧结热工测试与分析[J]. 钢铁, 2011, 46(11): 93-98.

[6] 董辉, 赵勇, 蔡九菊, 等. 烧结-冷却系统的漏风问题[J]. 钢铁, 2012, 47(1): 95-99.

[7] 董辉, 李磊, 刘文军, 等. 烧结矿余热竖罐式回收利用工艺流程[J]. 中国冶金, 2012, 22(1): 6-11.

[11] 冯军胜, 董辉, 李明明, 等. 烧结余热回收竖罐内固定床层的阻力特性[J]. 中南大学学报(自然科学版), 2014, 45(8): 2566-2571.

[14] ERGUN S. Fluid flow through packed columns[J]. Chemical Engineering Progress, 1952, 48: 89–94.

[27] 冯军胜, 董辉, 高建业, 等. 烧结矿余热回收竖罐内气体流态的实验研究[J]. 东北大学学报(自然科学版), 2016, 37(4): 517-521.

[31] 田付有, 黄连锋, 范利武, 等. 双粒度混合烧结矿颗粒填充床压降实验[J]. 浙江大学学报(工学版), 2016, 50(11): 2077-2086.

[33] 彭岩, 王为术, 时小宝, 等. 烧结矿炉式冷却装置料层阻力试验研究[J]. 烧结球团, 2019, 44(1): 6-8.

[34] 张四宗, 温治, 刘训良, 等. 颗粒形状对烧结矿填充床内渗透系数和阻力系数的影响[J]. 中南大学学报(自然科学版), 2020, 52(4): 1066-1075.