文章编号:1004-0609(2010)S1-s0838-05

低温用CT20钛合金的电子束焊接工艺

赵 彬,杨英丽,赵恒章,杜 宇,郭荻子

(西北有色金属研究院,西安 710016)

摘 要:采用真空电子束焊接工艺研究CT20钛合金的焊接性能,分析电子束焊接过程中不同工艺参数对焊缝形状的影响。通过对显微组织的观察以及显微硬度和低温拉伸性能的测试,分析焊接接头显微组织、断口形貌及焊缝中气孔的形成。结果表明:CT20钛合金的焊接性能优良,焊接接头的抗拉强度达到785 MPa,断口部位位于热影响区;焊缝和靠近焊缝热影响区的显微组织均为典型的魏式组织,母材显微组织为块状初生α相和β转变组织构成的双态组织。采用真空电子束焊焊接的CT20合金板材,其焊缝的硬度值比母材的高,焊缝和热影响区中较粗大的原始β相一部分转变为过饱和的针状马氏体。

关键词:CT20钛合金;电子束焊接;显微组织

中图分类号:TF 804.3 文献标志码:A

Electron beam welding process of CT20 Ti alloy

ZHAO Bin, YANG Ying-li, ZHAO Heng-zhang, DU Yu, GUO Di-zi

(Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: CT20 alloy plates was welded by using vacuum electron beam welding process, through observing the microstructure, testing the microhardness and the microstructure and property of welded joints, and the formation of porosities in the weld were analyzed. The results show that the porosities are formed in weld metal when CT20 alloy is welded by vacuum electron beam welding, the hardness value of weld metal is higher than that of the base metal, but the impact toughness value of the weld metal is lower than that of the base metal. The partial coarse original β phase in the weld and HAZ metals are changed into the supersaturated acicular martensite. There are a little acicular α′ phase in the middle of the weld metal, and the interlaced α structure is formed.

Key words: CT20 Ti alloy; electron beam welding; microstructure

CT20钛合金是西北有色金属研究院为航天低温管路构件而设计的一种近α钛合金。该合金在低温下具有比强度高、导热率低、热膨胀系数小、介质相容性好、抗氢脆等特点,可以很好地满足液体燃料储箱和低温管路使用[1-3]。目前,发动机低温钛合金管路多采用氩弧焊或等离子弧焊进行焊接加工,这两种方法均需填充焊接材料,由于保护气体的纯度以及保护效果的限制,导致焊接接头含氧量的增加和塑性下降,并且焊后形变较大。而真空电子束焊接方法因具有高能量密度、高熔透性、焊接形变小、易于控制以及能实现难熔和异种金属焊接等优点,在钛合金材料焊接中的应用越来越受到重视[4-5]。本文作者采用电子束焊接CT20钛合金板材,研究焊接工艺对CT20钛合金焊缝质量的影响规律,进而对合金焊接接头在室温及-196 ℃工作温度下的力学性能、组织及硬度分布进行研究,解决了低温钛合金管路焊缝的焊接问题,对于CT20钛合金在低温管路工程应用具有重要意义。

1 实验

实验所用CT20合金板材是采用二次真空自耗电弧熔炼的d150 mm铸锭,经β区开坯锻造、冷轧制成2.5 mm厚的板材,板材经600 ℃,1 h去应力退火。焊接试验采用ZD150-30A型高压电子束焊设备,焊接方式为电子束对接焊。试验时无外加拘束,试验过程中通过编程实现焊缝焊接工艺参数的选取,焊后对焊缝进行X射线检验,焊缝外观和内部质量检查参考GJB1718A标准内容。在对焊试板上沿垂直于焊缝方向切取试样,进行室温、低温力学性能测试和金相观察,焊接工艺参数见表1。

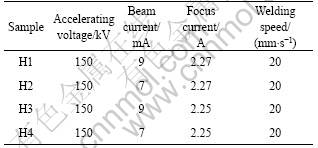

表1 电子束焊接工艺参数

Table 1 Parameters of electron beam welding

2 结果与讨论

2.1 焊接接头的显微组织

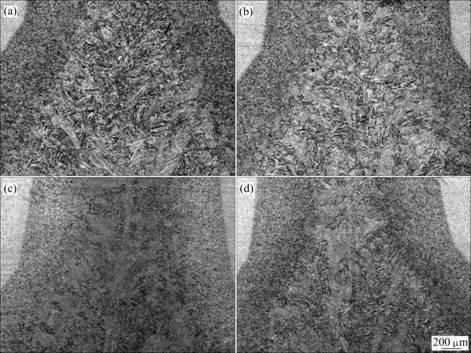

图1所示为CT20合金电子束焊接接头的低倍显微组织。电子束对接焊时接头间隙小,不添加填充金属,焊缝金属由熔化后重新结晶的母材组成。由图1可见,整个焊缝区域晶粒粗大,与合金铸态组织一样,由粗大的柱状晶组成。焊接热影响区非常窄,在试验条件下,为300~400 μm,焊接接头金属熔合良好。

电子束焊接工艺参数中电子束流、聚焦电流大小对焊缝形状影响最大。从图1中可以看出,4种焊接工艺焊缝形状有较大差别,在聚焦电流不变的情况下,电子束流增大,焊接熔深、熔宽和焊缝宽度都明显增加。这是因为其他焊接参数不变时, 增大电子束流会增加焊接热输入,因此熔深、熔宽和焊缝宽度同时增加,但是熔深增加显著,而熔宽略有增加,所以深宽比随电子束流的增大而增加。

聚焦电流也是影响焊缝形状的关键因素,其对焊缝形状的影响较为复杂,通过变化聚焦电流可以得到不同的焊缝形状。从图1可以看出,表面聚焦散焦量较大时(见H1和H2),束流作用于工件表面的加热面积增大,因此焊缝宽度变宽,焊接熔深变小,焊缝深宽比及丁头半角α均增大。对于一定厚度工件来说,熔

图1 CT20合金焊接接头宏观形貌

Fig.1 Macrographic of welding joint of CT20 alloy: (a) H1; (b); H2; (c) H3; (d) H4

宽位置向工件表面偏移,必然受到散焦带来的工件表面加热面积增大的影响,因此,其也有变宽的趋势[6]。

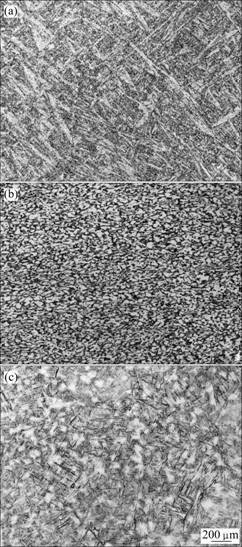

图2所示为CT20合金H4号对接焊板材焊缝和热影响区的高倍显微组织。由图2可看出,在去应力退火状态下,CT20合金冷轧板材主要为等轴α组织。焊接后热影响区的组织为针状α′与等轴α的混合组织。焊缝的组织为针状α′与片状α的混合组织。电子束焊接时,处于高温的β相快速冷却,快速冷却过程中β相析出α相的过程来不及充分进行;合金焊缝冷却时,β相的晶体结构不易受冷却所抑制,仍然发生了转变,产生了过饱和的马氏体。由于β相由体心立方晶格直接转变成密排六方晶格,这种具有六方晶格的六方马氏体一般为针状的α′组织[7]。因此,原始的β晶粒再结晶形成针状的α′组织。

图2 CT20合金电子束焊缝及热影响区显微组织

Fig.2 Microstructures of EB welding joint and HAZ of CT20 alloy: (a) Welding joint; (b) Base metal; (c) Heat effect zone

虽然焊接后冷却速度快,但由于焊接温度场的特点,从热影响区到焊缝中部的冷却速度不同。与焊缝加热温度相比,热影响区加热温度较低,合金元素主要以扩散为主,合金含量变化不大,也就是说在热影响区,影响组织转变的关键因素是冷却速度。该区金属的冷却速度比较快,该区域已经凝固了的β相中只能析出少量的针状α′相。而在焊缝区域,焊接温度高,在快速冷却条件下,具备产生针状的α′相的良好条件,但焊接温度过高时,保温时间相对较长,造成β相稳定元素含量增加,原始β相在快速冷却过程中转变成的α′相,束域尺寸小,且纵横交错排列,犹如编织网篮状。晶内之所以出现这种条纹亚结构,可能是由于焊接时温度和应力综合作用造成的。

2.2 电子束焊接接头的拉伸性能

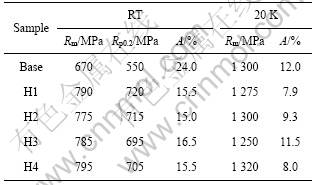

表2所列为CT20钛合金基材及电子束对接焊室温、20 K低温拉伸性能。由表2可见,母材的室温抗拉强度670 MPa,伸长率24%,而其焊态接头的抗拉强度775~795 MPa,伸长率不小于15%, 通过对拉伸试样断裂部位的观察,断口部位位于热影响区附近,焊缝强度较高。这说明采用电子束焊接CT20合金可获得性能良好的焊接接头。然而从焊接试样20 K下拉伸结果可见,试样断裂强度大幅提高,塑性下降接近一半。这主要是由于随着温度的降低,开动滑移的临界驱动力显著增高,滑移困难,表现为合金强度升高。滑移线穿过晶粒塞积于晶界,形成孔洞,由于低温下开动滑移驱动力的显著提高,很容易使孔洞达到临界状态,产生裂纹、扩展并断裂,产生的孔洞很难长大,表现为塑性急剧降低。由图3(b)可看出,试样断口孔洞少、尺寸小,形变不明显。

表2 CT20合金板材及焊接试样力学性能

Table 2 Mechanical property of CT20 alloy plate and welded samples

2.3 CT20钛合金焊缝的断口形貌

CT20钛合金焊接接头室温及低温20 K下拉伸断口形貌如图3所示。由图3可看出,合金室温拉伸时,试样宏观断口起伏较大,表明材料具有较高的塑性。由断口形貌可看出,合金室温焊接接头断口为延性韧窝断裂,韧窝大小、分布均匀。这与基材是等轴组织,拉伸断口位于热影响区与母材附近有关。20 K拉伸时,试样工作带内出现多个与拉伸轴成45°切变带。试样宏观断口较为平整,断口特征如图3(b)所示。试样20 K拉伸断口上均出现了少量的孔洞和解离台阶,这些台阶可能沿着HCP的基面,合金表现出一定的低温脆断特征,这说明合金低温下塑性下降。

图3 CT20合金焊接接头断口形貌

Fig.3 Fractographs of EB welding joint of CT20 alloy: (a) Tensile at RT; (b) Tensile at 20 K

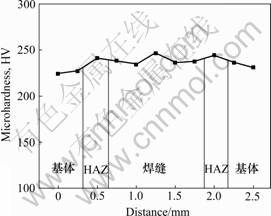

图4所示为电子束焊接接头的显微硬度曲线。由图4可见,焊缝金属的硬度值略高于母材金属的硬度值。通常随着硬度值的增加,金属的塑性和韧性随之降低。焊缝及热影响区的显微硬度分布与加热冷却过程中β相的过冷转变和焊缝区的凝固特点有关。焊接接头在快速冷却条件下,发生马氏体转变,β相向针状α′相转变。而针状α′相具有高的位错密度和孪晶,针状组织的出现造成了大量的相界,使焊缝区金属的硬度提高[8]。钛合金中的马氏体不能像钢中的马氏体那样显著提高合金的强度和硬度,钛合金的马氏体α′相的硬度只略高于α固溶体,对合金的强化作用小,所以母材与焊缝间的硬度值总体来说相差不大。同时,CT20合金中焊缝的硬度与焊缝中针状α′相的含量有一定的关系,针状α′相越多,金属硬度越高。焊缝区有大量的针状α′相,母材为等轴的α和少量β相组成,所以CT20合金焊缝的硬度略高于母材的。焊缝与热影响区硬度值相差不大,焊缝中部略微低一些,进一步说明焊缝中部的针状α′组织要比其他焊缝区域的少些。

图4 CT20合金焊接接头显微硬度曲线

Fig.4 Microhardness curve of welding joint of CT20 alloy

3 结论

1) 采用真空电子束焊接2.5 mm厚CT20合 金,热影响区只有300~400 μm,焊接接头金属融合良好,未见焊接过程产生气孔。焊缝和热影响区组织均为较粗大的原始β相和一部分转变为过饱和的针状马氏体相。

2) CT20合金电子束焊接接头具有较高的室温及低温力学性能,其断裂全部发生在热影响区附近,焊缝的室温抗拉强度不低于母材的。20 K下,焊接接头的拉伸强度迅速提高,同时,表现出一定的低温脆性,但塑性仍能达到10%左右。

3) 室温拉伸断口形貌为浅韧窝型的延性断裂,20 K下,断口上均出现了少量的孔洞和解离台阶。

4) CT20合金电子束焊焊缝区的显微硬度与母材的相当,焊缝中心的显微硬度最高,为HV 246。由中心区域向两侧焊缝区,随着距离的增加,硬度有下降的趋势。

REFERENCES

[1] 刘 伟, 杜 宇. 低温钛合金的研究现状[J]. 稀有金属快报, 2007, 26(9): 6-10.

LIU Wei, DU Yu. Research situation of the cryogenic titanium alloy[J]. Rare Metals Letters, 2007, 26(9): 6-10.

[2] 杜 宇, 蔡学章, 杨冠军. CT20钛合金20 K下的应变行为与组织关系分析[J]. 钛工业进展, 2005, 26(6): 14-17.

DU Yu, CAI Xue-zhang, YANG Guan-jun. Analysis of the relationship between strain behavior and microstructure of CT20 titanium alloy at 20 K[J]. Titanium Industry Progress, 2005, 26(6): 14-17.

[3] 范承亮, 杨冠军, 于振涛, 蔡学章, 杜 宇, 刘 伟. CT20合金的不同显微组织与拉伸性能研究[J]. 稀有金属, 2004, 28(2): 330-333.

FAN Cheng-liang, YANG Guan-jun, YU Zhen-tao, CAI Xue-zhang, DU Yu, LIU We. Various microstructures and tensile properties of CT20 alloy[J]. Chinese Journal of Rare Metals, 2004, 28(2): 330-333.

[4] 袁双喜, 沙庆涛, 徐培麒. 钛合金电子束焊接的研究进展[J]. 航空制造技术, 2009(9): 51-53.

YUAN Shuang-xi, SHA Qing-tao, XU Pei-qi. Research progress of titanium alloy by electron beam welding[J]. Aeronautical Manufacturing Technology, 2009(9): 51-53.

[5] 周广德, 陶守林. 电子束焊接技术在航天领域中应用[J]. 电工电能新技术, 1999(1): 25-28.

ZHOU Guang-de, TAO Shou-lin. Application of electron beam welding technique in the flight[J]. Advanced Technology of Electrical Engineering and Energy, 1999(1): 25-28.

[6] 宫 平, 罗 宇, 王亚军, 毛智勇. TC4钛合金电子束焊接工艺参数对焊缝形状的影响[J]. 航空制造技术, 2008(6): 72-75.

GONG Ping, LUO Yu, WANG Ya-jun, MAO Zhi-yong. Effect of TC4 titanium alloy electron beam welding parameters on weld shape[J]. Aeronautical Manufacturing Technology, 2008(6): 72-75.

[7] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005.

ZHANG Xi-yan, ZHAO Yong-qin, BAI Chen-guang. Titanium alloy and application[M]. Beijing: Chemical Industry Press, 2005.

[8] 钟 玉, 屈金山, 陈文静, 潘全喜, 赵成东. TC4钛合金的电子束焊[J]. 热加工工艺, 2007, 36(15): 24-26.

ZHONG Yu, QU Jin-shan, CHEN Wen-jing, PAN Quan-xi, ZHAO Cheng-dong. Electron beam welding of TC4 alloy[J]. Hot Working Technology, 2007, 36(15): 24-26.

(编辑 杨幼平)

基金项目:国家科技支撑计划资助项目(2007BAE07B03);国家重点基础研究发展计划资助项目(2007CB613807;2006CB601202)

通信作者:赵 彬;电话:029-86231078-429;E-mail: zhaobin_51@126.com