铝电解电容器用铝箔发孔腐蚀工艺的研究

来源期刊:有色金属科学与工程2012年第1期

论文作者:杜海燕 梁晓鹏 徐晶 柴敏平 邓顺

文章页码:27 - 31

关键词:铝电解电容器;腐蚀箔;直流腐蚀工艺

Key words:aluminum electrolytic capacitor; corrosion foil; DC corrosion process

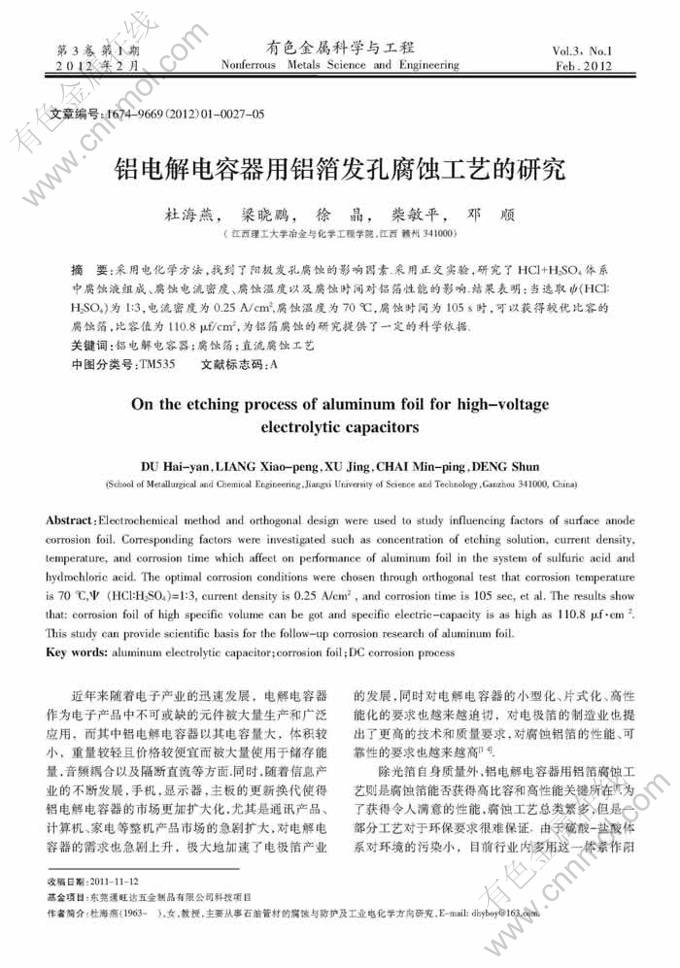

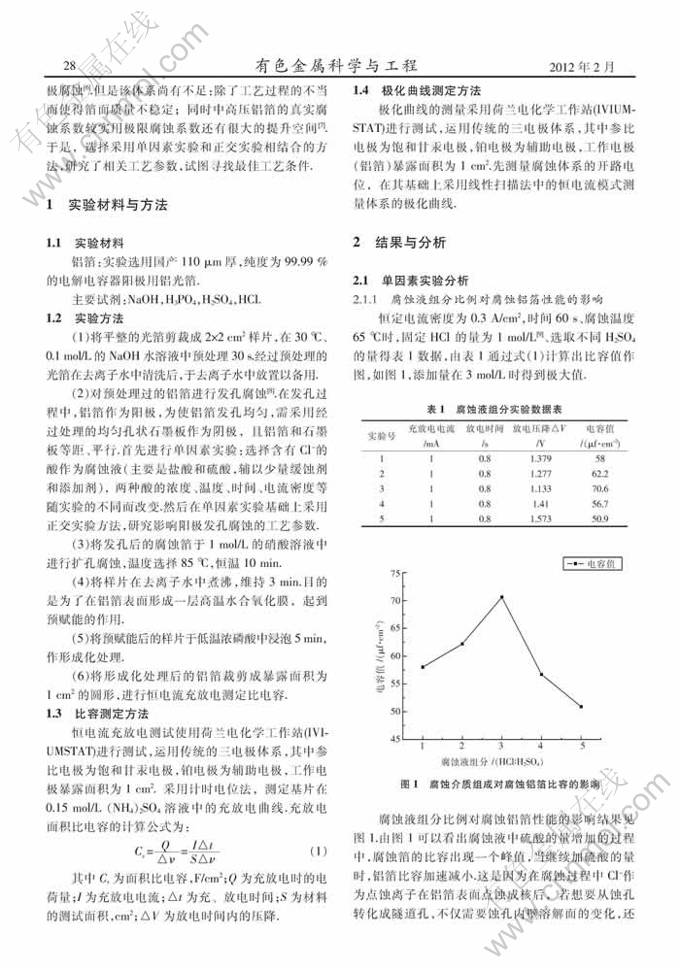

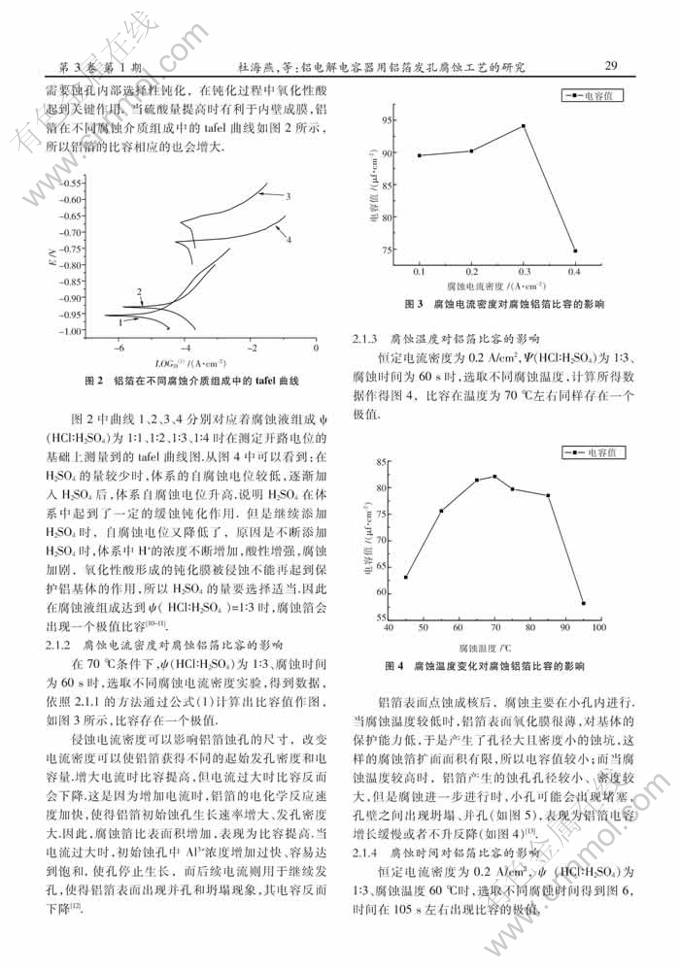

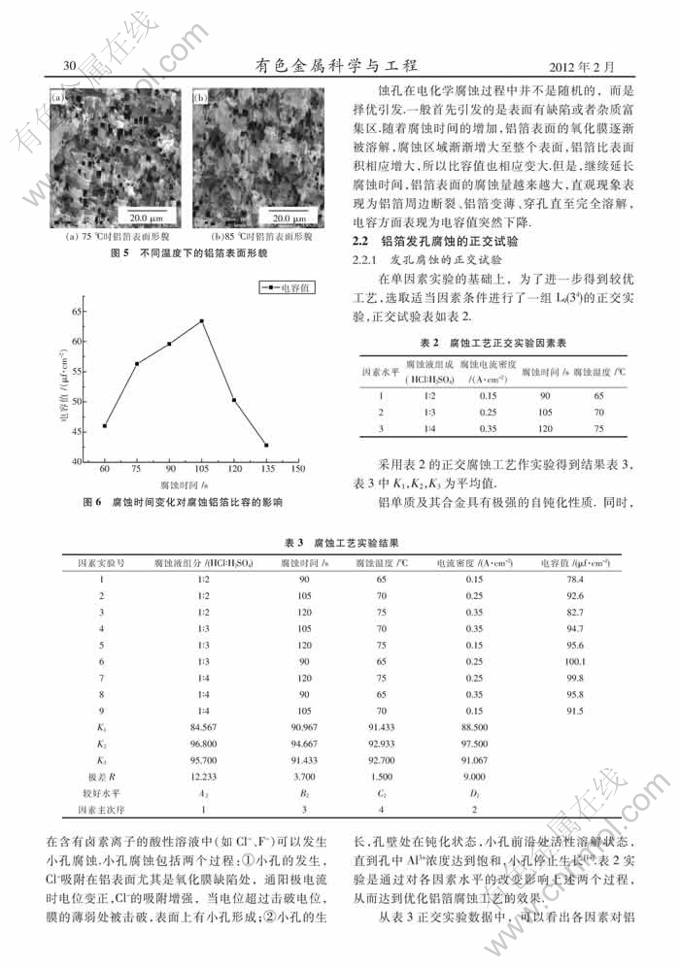

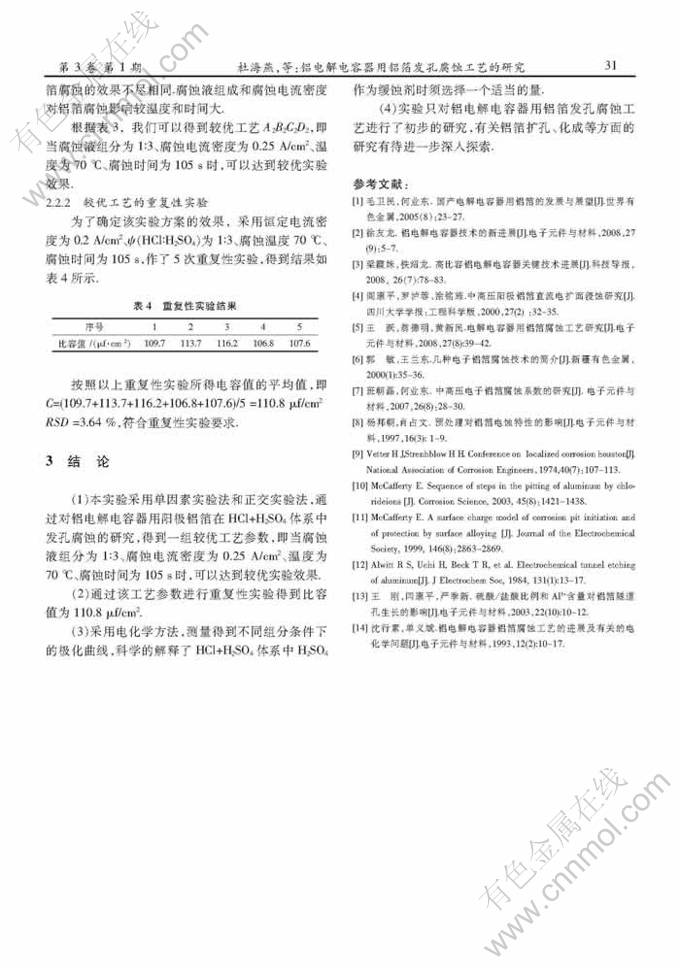

摘 要:采用电化学方法,找到了阳极发孔腐蚀的影响因素,采用正交实验,研究了HCl+H2SO4体系中腐蚀液组成、腐蚀电流密度、腐蚀温度以及腐蚀时间对铝箔性能的影响.结果表明:当选取沙(HCl: H2SO4)为1:3,电流密度为0.25 A/cm2,腐蚀温度为700℃,腐蚀时间为105 s时,可以获得较优比容的腐蚀箔,比容值为110.8 pLf/cm2,为铝箔腐蚀的研究提供了一定的科学依据.

Abstract: Electrocheruical method and orthogonal design were used to study influencing factors of surface anode corrosion foil. Corresponding factors were investigated such as concentration of etching solution, current density, temperature, and corrosion time which affect on performance of aluminum foil in the system of sulfuric acid and hydrochloric acid. The optimal corrosion conditions were chosen through orthogonal test that corrosion temperature is 70 ℃,Ψ(HCl:H2SO4)=1:3, current density is 0.25 A/cm2, and corrosion time is 105 sec, et al.The results show that: corrosion foil of high specific volume can be got and specific electric-capacity is as high as 110.8 μf.cm-2.