Effect of high-intensity ultrasonic field on process of semi-continuous casting for AZ80 magnesium alloy billets

ZHANG Zhi-qiang(张志强), LE Qi-chi(乐启炽), CUI Jian-zhong(崔建忠)

Key Laboratory of Electromagnetic Processing of Materials of Ministry of Education,Northeastern University, Shenyang 110004, China

Received 23 September 2009; accepted 30 January 2010

Abstract: Under the high-intensity ultrasonic field, AZ80 magnesium alloy was semi-continuously cast. The effects of ultrasonic intensity on the as-cast microstructures and mechanical properties were investigated. The results show that the microstructures of the alloy cast under high-intensity ultrasonic field are fine and uniform, and the grains are equiaxed, rose-shaped or globular with an average size of 257 μm. High-intensity field significantly decreases the grain size, changes the morphologies of the β-Mg17Al12 phases and reduces their area fraction. It is also shown that a proper increase in ultrasonic intensity is helpful to obtain fine, uniform and equiaxed as-cast microstructures. The optimum ultrasonic parameters are that frequency is 20 kHz and ultrasonic intensity is 1 368 W. The mechanical tests show that the mechanical properties of the as-cast AZ80 magnesium alloy billets cast under ultrasonic field are greatly improved, and with increasing the ultrasonic intensity, the mechanical properties of the entire alloy billets are much higher and more uniform than those of the alloy without ultrasonic field.

Key words: magnesium alloy; ultrasonic field; semi-continuous casting; microstructure; mechanical properties

1 Introduction

Due to their low density, high damping capacity, high specific strength and specific stiffness, excellent machinability, good electromagnetic shielding characteristics and good castability[1-2], magnesium alloys are particularly attractive in the aerospace and automotive industries. Magnesium alloys not only offer a weight reduction potential when being used as structural material in transportation vehicles but also improve the fuel economy and emissions, regardless of the propulsion system used. Due to the advantageous properties of magnesium alloys produced by forming technology, an increasing interest in the possibilities of bulk forming is noticed.

It is well recognized that the mechanical properties are closely related to the microstructures with fine grains of metallic alloy. The microstructure refinement of magnesium alloys has become an important research field. In general, two different approaches to gain refinement by solidification processing are pursued: chemically stimulated[3-5] and physically induced routes[6-8]. The chemical route depends primarily on the selection of a nucleating catalyst, while the physical one relies mainly on the use of an external field. The chemical route is easy to apply but it is not always possible to find or develop a potent nucleation for a given group of alloys, for example, Mg-Al alloys[9-10]. This makes the physical route a necessary option for many cast alloys. CHIRITA et al[11] studied the treatment of molten metals with high frequency mechanical vibrations, and uniform and fine-grained casting was obtained. WANG et al[12] studied the changes of solidification parameters and the temperature profiles for the liquid in front of the solid/liquid interface caused by vibration. Ultrasonic vibration was applied during the solidification of metal alloys, and modified macro- and microstructures were obtained[8, 13-14]. VIVES[15-18] studied the effects of electromagnetic vibrations induced by the interaction of alternating electric and stationary magnetic fields during the solidi-fication of aluminium alloys and obtained good structural refinement.

As for magnesium alloys, considering the Hall- Petch coefficient is large for magnesium[10], a smaller grain size would be very desirable to obtain improved properties. Therefore, in this study, ultrasonic vibration is introduced and the aim of the present work is to study the effects of ultrasonic vibration on the microstructures and mechanical properties of direct chilling (DC) cast magnesium alloy AZ80, which is a commercially available wrought magnesium alloy.

2 Experimental

The composition of AZ80 magnesium alloy is shown in Table 1. The melting of AZ80 magnesium alloy was carried out in a resistance furnace with an iron crucible containing approximately 60 kg of metal and protected by CO2+0.5% (volume fraction) SF6 atmosphere in order to prevent severe oxidation. The melt was transferred to a semi-continuous casting machine at 650 ?C, about 50 ?C higher than the liquidus, and cast into billet with a diameter of 160 mm at a velocity of 150 mm/min. In the first casting, the billet was cast by the conventional process. After casting to about 300 mm in length, the ultrasonic field was applied. During casting, to evaluate the influence of electromagnetic fields, all conventional parameters were held constant.

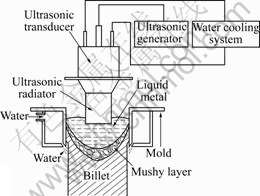

The experimental apparatus for ultrasonic treatment is shown in Fig.1. The semi-continuous casting system

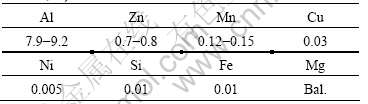

Table 1 Chemical composition of A280 magnesium alloy (mass fraction, %)

Fig.1 Schematic diagram of semi-continuous casting of AZ80 magnesium alloy billet under ultrasonic vibration condition

used in this research consisted of a metallurgic ultrasonic system, a billet mold, a casting control system, a melting furnace and a water cooling system. The ultrasonic vibration is produced in magnesium melt during semi- continuous casting by the application of an ultrasonic field. The ultrasonic field is generated by supplying a metallurgic ultrasonic system. It consisted of a ultrasonic generator with a frequency of (20±2) kHz, a magnetostrictive transducer made of high purity nickel sheets and an acoustic radiator made of mild steel. Ultrasonic power of the unit could be adjusted from 0 to 2 kW.

In order to evaluate the influence of ultrasonic vibration on the microstructures and mechanical properties of the as-cast AZ80 magnesium alloy billet, the molten metal in the mold during semi-continuous casting is treated by ultrasonic with power of 500, 940 and 1 368 W, respectively. For convenience, vibration treatment without ultrasonic is defined as 0 W ultrasonic treatment. The specimens for macro- and micro-observation were taken from different locations of cross-section in the billets. They were ground and polished and then etched. The as-cast macro- and microstructures of edge, R/2 and center region of billets were observed by a stereoscopic microscope (Olympus SZX16) and an optimal microscope (Leica DMR), respectively. The grain size analyses were carried out from the pictures taken using software SISCIA S8.0. The mechanical tests were conducted at room temperature. The tensile strength was measured using CMT5105 universal test machine at a constant ram velocity of 1 mm/min. All the cylindrical samples are parallel to the axes of the billets. The average value of three tests results was used as the final value.

3 Results and discussion

3.1 Effects of ultrasonic field on macro- and micro- structures of AZ80 alloy billet

3.1.1 Macrostructures of billets with normal DC and ultrasonic field DC casting

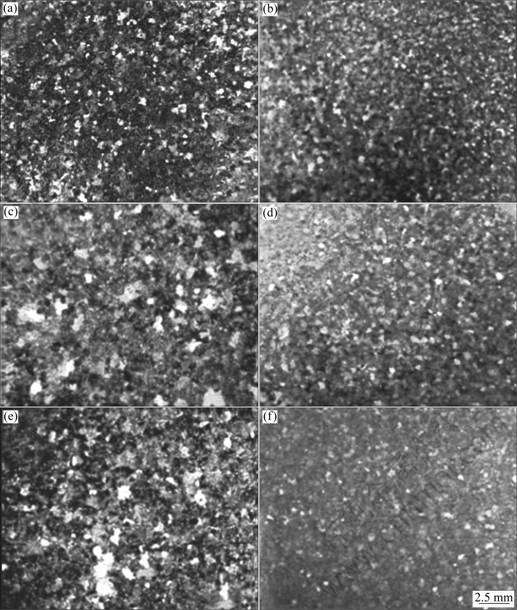

Fig.2 shows the as-cast macrostructures of d160 mm AZ80 billet with normal DC and ultrasonic field DC casting. It is clear that the grain size of the billet with ultrasonic field DC casting is much finer compared with the billet with normal DC casting. Fig.2(a) shows coarse grain size, which is taken at the edge of the billet with normal DC casting. As for casting under ultrasonic vibration field, however, the grain size on the edge of the billets are fine and uniform as shown in Fig.2(b). As shown in Figs.2(c) and (d), the macrostructures in the R/2 region of the billet with normal DC casting are characterized by coarse grains, while in the billets with

Fig.2 OM images of AZ80 billets: (a), (c), (e) Normal DC casting; (b), (d), (f) Ultrasonic field DC casting; (a), (b) Edge; (c), (d) R/2; (e), (f) Center

ultrasonic field DC casting, the macrostructures in the R/2 region are very fine. It can be seen from Figs.2(e) and (f) that the macrostructures at center of billet with normal DC casting are very coarse grains while the macrostructures at center of billet with ultrasonic field DC casting are fine grains. In addition, the distribution of the grain size of the billet with normal DC casting is non-uniform throughout the billet. From the edge to the center, the grain size gradually changes from fine to coarse in all billets with normal DC casting, and some grains are even visible without magnification. However, the macrostructures of the billets with ultrasonic field DC casting from the edge to the center is all fine grains and are more uniform than those of the billets with normal DC casting.

3.1.2 Effect of ultrasonic power on microstructures of AZ80 billets

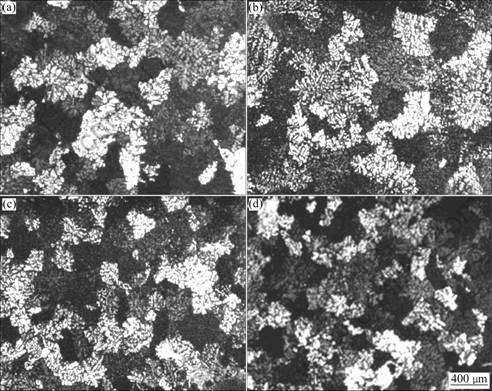

Because the macrostructures of the billets with ultrasonic field DC casting are uniform as shown above, only the microstructures at the R/2 region of cross-section in the billets cast by different ultrasonic power vibrations are reported. The effects of ultrasonic power on the microstructures can be visualized from Fig.3. With increasing the ultrasonic power from 0 to 1 368 W, the microstructures change from coarse grains to fine and uniform grains. Fig.3(a) shows that without

Fig.3 OM images of R/2 region of cross-section in AZ80 billets cast by different ultrasonic power vibration: (a) 0 W; (b) 500 W; (c) 940 W; (d) 1 368 W

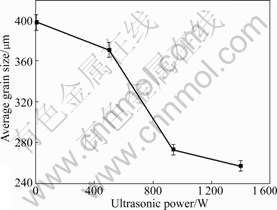

ultrasonic vibration, grains are coarse with an average size of 398 μm. With 500 W ultrasonic vibration, although the morphology of the grains is coarse because of small energy of ultrasonic introduced into the liquid metal, there are still fine grains, as shown in Fig.3(b). However, obvious changes can be found in 940 W ultrasonic vibrations and the average size of the fine grains is 273 μm, as shown in Fig.3(c). When the applied ultrasonic power is 1 368 W, the average grain size is decreased to 257 μm, as shown in Fig.3(d), which is the best result among the four different ultrasonic vibrations applied in semi-continuous casting. The effect of ultrasonic power on average size of the R/2 region of cross-section in AZ80 alloy billets is shown in Fig.4.

3.1.3 Morphology and distribution of phase in billets with normal DC and ultrasonic field DC casting

For AZ80 magnesium alloy, the solidification structures consist of primary α-Mg, β-Mg17Al12 and eutectic which form under non-equilibrium cooling conditions. Fig.5 shows the morphology and distribution of phase at the center region of cross-section in the AZ80 billet by normal DC and ultrasonic field DC casting. In Fig.5(a), it is clear that many of the continuous bulk skeletal phases segregate in the interdendritic regions and grain boundaries. In Fig.5(b), the size and area fraction of phases in the billets decreased; the continuous bulk skeletal phases become fine, uniform and are changed

Fig.4 Effect of ultrasonic power on average grain size of R/2 region of cross-section in billets

into almost discontinuous nets and particles; and their amounts obviously reduced. It is supposed that ultrasonic vibration produces evident refining effect in AZ80 alloy. Because of cavitation and acoustic streaming, the grains of AZ80 alloy are very fine. Thus, the finer the grains are, the lower the content and the smaller the size of the phases is.

3.2 Effects of ultrasonic field on mechanical properties of AZ80 alloy billet

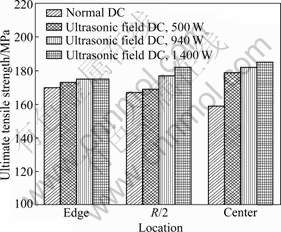

As shown in Fig.6, the ultimate tensile strength of

Fig.5 Morphology and distribution of phase in AZ80 billets: (a) Normal DC casting; (b) Ultrasonic field DC casting

Fig.6 Ultimate tensile strength in different locations of billet cast in different processes

different locations in the billet with ultrasonic field DC casting is almost at the same level, while the ultimate tensile strength in different locations of the billet with normal DC casting decreases from edge to center. It is clear that the ultimate tensile strength in different locations of the billet with ultrasonic field DC casting is higher than that of the billet with normal DC casting. In the normal DC casting, the ultimate tensile strength of the billet is relatively low. The strength values are 170 MPa at edge, 167 MPa at R/2 and 159 MPa at center, respectively. While under the ultrasonic field DC casting with a relatively high ultrasonic power, 1 400 W, the ultimate tensile strengths of billet at corresponding location are higher and they are 174, 177 and 182 MPa, respectively. There is a large increase at the center region of the billet due to the microstructure refinement. Further, when the ultrasonic power is increased, the ultimate tensile strength increases smoothly from the edge to the center of the billet. It appears that the ultimate tensile strength of AZ80 billet is depended on the microstructures, i.e., fine-grained and fine-phased billet exhibits high ultimate tensile strength. The difference of ultimate tensile strength between the edge and the center is reduced with increasing the ultrasonic power.

4 Conclusions

1) With ultrasonic field DC casting, the microstructures of AZ80 billet from edge to center are all fine grains and are much finer and more uniform than those of the billet with normal DC casting.

2) Ultrasonic power plays an important role in the microstructure of the billet with ultrasonic field DC casting. With increasing the ultrasonic power, the grains become finer and more uniform. Compared with the morphology and distribution of phase in the billet with normal DC casting, the morphologies in the AZ80 billet with ultrasonic field DC are finer, more uniform and are changed into almost discontinuous net shape and particles, and their amounts obviously reduced.

3) With ultrasonic field DC casting, the tensile strength of different locations in AZ80 billet from edge to center is higher than that of the billet with normal DC casting. When ultrasonic power is increased, the differences of tensile strength between the edge and center of the billet become small.

References

[1] LU Y Z, WANG Q D, DING W J, ZENG X Q, ZHU Y P. Fracture behavior of AZ91 magnesium alloy [J]. Mater Lett, 2000, 44(5): 265-268.

[2] KAMADO S, KOIKE J, KONDOH K, KAWAMURA Y. Magnesium research trend in Japan [J]. Mater Sci Forum, 2003, 419/422(1): 21- 34.

[3] NOGITA K, DAHLE A K. Effects of boron on eutectic modification of hypoeutectic Al-Si alloys [J]. Scripta Materialia, 2003, 48(3): 307-313.

[4] LU L, DAHLE A K, StJOHN D H. Grain refinement efficiency and mechanism of aluminium carbide in Mg-Al alloys [J]. Scripta Materialia, 2005, 53(5), 517-522.

[5] EMLEY E F. Principles of magnesium technology [M]. Oxford: Pergamon Press, 1966: 200-208.

[6] GUO Shi-jie, LE Qi-chi, ZHAO Zhi-hao, WANG Zhong-jun, CUI Jian-zhong. Microstructural refinement of DC cast AZ80 Mg billets by low frequency electromagnetic vibration [J]. Materials Science Engineering A, 2005, 404(2): 323-329.

[7] ESKIN G I. Broad prospects for commercial application of the ultrasonic (cavitation) melt treatment of light alloys [J]. Ultrasonics Sonochemistry, 2001, 8(3): 319-325.

[8] ZHNAG Zhi-qiang, LE Qi-chi, CUI Jian-zhong. Ultrasonic treatment of magnesium alloy melts and its effects on solidification microstructures [J]. Materials Science Forum, 2007, 546/549: 129-132.

[9] StJOHN D H, MA Q, EASTON M A, Grain refinement of magnesium alloys [J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1669-1679.

[10] LEE Y C, DAHLE A K, StJOHN D H. The role of solute in grain refinement of magnesium [J]. Metallurgical and Materials Transactions A, 2000, 31(11): 2895-2906.

[11] CHIRITA G, STEFANESCU I, SOARES D, SILICA F S. Influence of vibration on the solidification behaviour and tensile properties of an Al-18wt.%Si alloy [J]. Materials and Design, 2009, 30(5): 1575-1580.

[12] WANG Feng-quan, CHEN Shi-you, HE Deng-ping, WEI Bing-bo. Solidification parameters of the solid-liquid interface in crystal growth in response to vibration [J]. Journal of Materials Science, 1994, 29(15): 3997-4000.

[13] JIAN X, WEEK T T, HAN Q. Refinement of eutectic silicon phase of aluminum A356 alloy using high-intensity ultrasonic vibration [J]. Scripta Materialia, 2006, 54(5): 893-896.

[14] ABRAMOV V, ABRAMOV O, BULGAKOV V, SOMMER F. Solidification of aluminium alloys under ultrasonic irradiation using water-cooled resonator [J]. Materials Letters, 1998, 37(1/2): 27-34.

[15] VIVES C. Electromagnetic refining of aluminum alloys by the CERM process: Part Ⅰ. Working principle and metallurgical results [J]. Metall Trans B, 1989, 20: 623-629.

[16] VIVES C. Electromagnetic refining of aluminum alloys by the CREM process: part Ⅱ. Specific practical problems and their solutions [J]. Metall Trans B, 1989, 20: 631-643.

[17] ZHANG B, CUI J, LU G, ZHANG Q, BAN C. Effect of frequency on microstructure of electromagnetic casting 7075 aluminum alloy [J]. Acta Metall Sin, 2002, 38(2): 215-218.

[18] VIVES C. Effects of electromagnetic vibrations on the micro- structure of continuously cast aluminum alloys [J]. Mater Sci Eng A, 1993, 173(1/2): 169-172.

(Edited by FANG Jing-hua)

Foundation item: Projects(2007CB613701, 2007CB613702) supported by the National Basic Research Program of China; Projects(50974037, 50904018) supported by the National Natural Science Foundation of China; Project(NCET-08-0098) supported by New Century Excellent Talents in University of China; Projects(N09040902, N090209002) supported by the Special Foundation for Basic Scientific Research of Central Colleges

Corresponding author: ZHANG Zhi-qiang; Tel: +86-24-83687734; E-mail: zqzhang@mail.neu.edu.cn