升温速率对1933铝合金铸锭均匀化组织的影响

张新明,周新伟,刘胜胆,刘文军

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用光学显微镜、扫描电镜、能谱分析、透射电镜和X线衍射分析等试验手段,研究升温速率对1933铝合金铸锭均匀化显微组织的影响。研究结果表明:合金铸态中主要存在α(Al)+η(MgZn2)非平衡共晶组织、AlZnCu相和AlCuFe相;均匀化处理后共晶组织被消除,η相溶解,合金中残留有AlZnCu相和AlCuFe相;合金经 465 ℃/24 h、升温速率为200 ℃/h均匀化处理后,晶界附近存在一个明显的无Al3Zr粒子析出带(DFZ),宽度为3~5 μm,晶粒中心Al3Zr粒子的密度较小,约为120 个/μm3,粒子尺寸较大,半径约为15 nm;均匀化慢速升温(20 ℃/h)将无弥散析出区(DFZ)的宽度减小到0.5 μm,晶内Al3Zr粒子分布更弥散细小,粒子半径为10 nm,粒子密度约为400 个/μm3。

关键词:1933铝合金;均匀化;Al3Zr粒子;无弥散析出区(DFZ);升温速率

中图分类号:TG146 文献标志码:A 文章编号:1672-7207(2011)04-0915-07

Effect of heating rate on homogenization microstructures of 1933 aluminum alloy ingot

ZHANG Xin-ming, ZHOU Xin-wei, LIU Sheng-dan, LIU Wen-jun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of heating rate on the homogenization microstructures of 1933 aluminum alloy ingot were investigated by optical microscopy, scanning electron microcopy, energy dispersive spectrometry, transmission electron microcopy and X-ray diffractometry. The results show that the as-cast microstructures involve eutectic (α(Al)+η(MgZn2)), AlZnCu and AlCuFe phases. The lamellar eutectic is dissolved through homogenization, and the particles presented in the alloy ingot are AlZnCu and AlCuFe phases. Compared with the fast-heating rate treatment, the slower apparently leads to a higher density of fine Al3Zr dispersoids, the dimension of the dispersoids decreases from 15 nm to 10 nm, the width of dispersoid-free-zone (DFZ) decreases from 3-5 μm to 0.5 μm, and the number density of Al3Zr particle in the center in the grains increases from 120/μm3 to 400/μm3.

Key words: 1933 aluminum alloy; homogenization; Al3Zr particle; dispersoid-free-zone (DFZ); heating rate

1933铝合金是俄罗斯研制的一种高强变形铝合金,属于Al-Zn-Mg-Cu系,具有较高的强度、良好的断裂韧性和优异的抗应力腐蚀性能,尤其1933合金板的断裂韧性比同系7050-T74,7175-T73以及7040铝合金的强[1];此外,该合金具有很好的淬透性,适用于制造复杂形状的大型锻件,其在航空工业中的应用可进一步提高飞机构件抗疲劳、耐损伤和抗应力腐蚀的能力[2]。目前,俄罗斯大部分飞机的隔框材料采用1933铝合金。超高强Al-Zn-Mg-Cu合金由于合金化程度高,在凝固过程中枝晶偏析严重,铸态晶界存在非平衡的粗大共晶组织,晶内和晶界化学成分和组织分布不均匀,导致合金塑性降低,热加工性能恶化,制品强度降低,各向异性和腐蚀敏感性增加[3-4];因此,均匀化成为合金变形前必需的热处理工序。均匀化处理主要有4个作用[5-6]:(1) 消除非平衡低熔点相和枝晶;(2) 消除成分偏析,使合金元素在固溶体中均匀分布;(3) 形成细小弥散含Cr,Mn和Zr的粒子以控制晶粒尺寸;(4) 球化硬的第二相粒子。超高强铝合金添加微量Zr的主要作用有[7]:控制晶粒尺寸,抑制再结晶,提高合金的强度、断裂韧性及抗应力腐蚀性能。这些作用主要与均匀化过程析出的Al3Zr弥散粒子有关。通常Zr凝固后往往在铝基体中以过饱和固溶体的形式存在。由于固溶度较小,因此,在均匀化过程中,往往析出Al3Zr粒子,其与基体有良好的共格关系,且稳定性较好。为了调节这些微量Zr在超高强铝合金中的不同作用,需要合理选择合金铸锭均匀化的条件。传统的均匀化中[8-10],人们大都是研究如何最大限度地溶解非平衡共晶组织和使溶质原子更均匀分布,而对优化弥散粒子析出的研究往往集中于温度的影响,对升温速率影响的研究较少。在此,本文作者研究不同均匀化升温速率对1933铝合金组织尤其是对Al3Zr粒子析出行为的影响,以期为优化均匀化工艺和实际生产提供依据。

1 实验方法

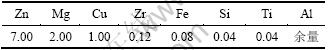

实验合金1933铝锭坯的配料选用高纯铝、工业纯锌、工业纯镁、铝铜中间合金和Al-5%Zr中间合金;细化剂采用Al-5Ti-B中间合金;除气剂采用C2Cl6。合金的熔炼在石墨坩埚电阻炉内进行,熔炼温度为780~800 ℃,精炼温度为730~740 ℃,浇铸温度为710~720 ℃,用铁模铸成厚度为30 mm的锭坯。合金名义成分(质量分数)如表1所示。

表1 1933铝合金的名义成分(质量分数)

Table 1 Nominal composition of 1933 aluminum alloy %

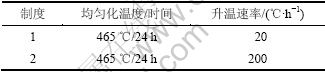

铸锭经铣面后,将铸锭分割成长×宽×高为12 mm×12 mm×2 mm的小片,采用可编程空气电阻炉进行均匀化处理。均匀化制度如表2所示。主要考虑升温速率的影响,对均匀化后样品出炉水淬,以用于下一步试验。

在XJP-6A 型光学显微镜(OM),KYKY-2800型与Philips Sirion200型扫描电镜 (SEM)下观察铸态及均匀化态的第二相形貌和成分分布;在TecnaiG220型透射电镜(TEM)下观察Al3Zr粒子的形貌和分布。

表2 均匀化制度

Table 2 Homogenization treatment parameters

2 试验结果

2.1 合金铸态显微组织及其成分分布

1933铝合金铸态SEM显微组织如图1所示。由图1(a)可知:合金铸态组织晶界上存在低熔点的非平衡共晶组织,非平衡共晶组织颜色较亮。图1(b)显示还存在白色和深灰色的粗大第二相嵌在共晶组织中。分别对这些相进行能谱分析,结果显示亮色的B相含AlZnMgCu元素,白色的A相主要含AlZnCu元素,深灰色的C相主要含AlCuFe元素。第二相能谱分析结果(原子数分数)如表3所示。

图1 铸态合金SEM下的显微组织

Fig.1 SEM Microstructure of (a) low and (b) high magnification of as-cast alloy

表3 第二相能谱分析结果(原子数分数)

Table 3 EDX results of the second phase particles %

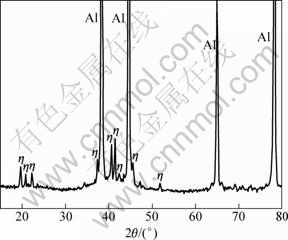

铸态组织XRD分析结果如图2所示。从图2可以看出:除了Al基体的衍射峰外,还存在较强的η(MgZn2)相的衍射峰。结合能谱分析和XRD分析可知:枝晶间亮色的层片状非平衡共晶组织由α+η相组成。亮色的AlZnMgCu相主要为Al和Cu原子溶解于η相中形成的η(Mg(Zn,Al,Cu)2)相[11]。而白色的AlZnCu相和深灰色的AlCuFe相由于含量太小,其衍射峰较弱。

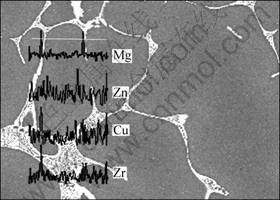

对铸态组织中的合金元素进行线扫描,结果如图3所示。由图3可见:合金铸锭存在一定程度的枝晶偏析,Zn,Mg和Cu元素在晶界上不同程度地富集,其含量由晶界向晶内降低,而Zr元素的峰值略偏向于枝晶中央的峰值。

图2 铸态合金XRD分析结果

Fig.2 XRD analysis of 1933 as cast alloy

图3 合金铸态的元素成分分布

Fig.3 Elements linear distribution of as-cast alloy

2.2 不同升温速率均匀化态的显微组织

不同升温速率下合金铸态和均匀化态的金相照片如图4所示,其中,图4(b)和(c)所示为合金经2种不同升温速率均匀化处理后试样的金相照片。对比图4(b),(c)和(a)可知:合金经表2中所列制度1和制度2均匀化处理后,共晶组织已基本溶解,晶界较平直;合金在制度2下以升温速率200 ℃/h快速加热均匀化,残留的共晶组织较少(图4(c))。为探明不同升温速率均匀化对合金微观组织的影响,采用扫描和透射电镜进行观察分析。

图4 合金铸态和均匀化态的金相照片

Fig.4 Optical microstructures of as-cast and homogenized alloys

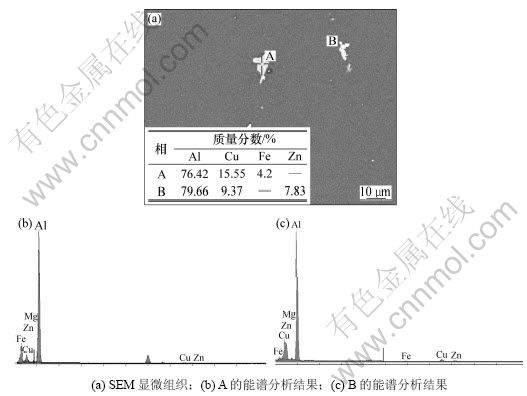

对合金均匀化态的扫描组织进行分析,结果表明:经2种不同升温速率均匀化处理后的试样组织形貌及其分布也较相似,无明显差异。图5所示是合金经制度1以升温速率20 ℃/h均匀化处理后的SEM照片及能谱分析结果。由图5可知:晶界上低熔点共晶组织已溶解,枝晶组织基本消除,但在晶界处还残留一些不规则的灰色相A,能谱分析结果为Al7Cu2Fe相;此外,晶界处还残留少量白色的B相为AlZnCu相,这2种相在2种制度中均匀化前、后均存在,说明这2种相在均匀化过程中基本不溶解,但形貌从不规则的块状逐渐球化。

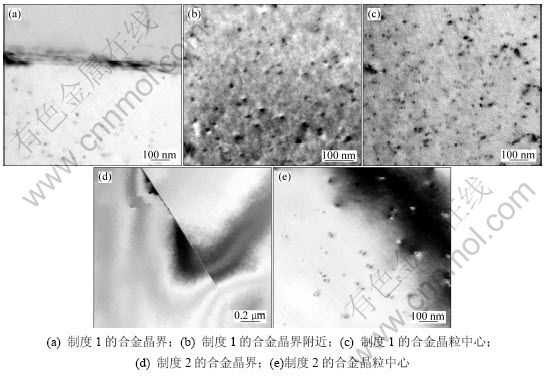

2.3 不同升温速率均匀化态合金的TEM组织

对均匀化态试样进行TEM组织观察,结果见图6。其中:图6(a),(b)和(c)所示分别为合金经制度1 以升温速率为20 ℃/h均匀化处理后晶界、晶界附近和晶内的透射电镜照片。由图6可知:合金经单级慢速均匀化处理后,Al3Zr分布在晶界附近和晶粒中央存在较大差别;在晶界附近,存在一个明显的无Al3Zr粒子弥散析出区(DFZ),宽度约为0.5 μm,如图6(a)所示;同时,晶界附近的Al3Zr密度较低,尺寸较粗大,半径为15 nm左右,如图6(b)所示;晶粒中心均匀化后析出了大量细小弥散的Al3Zr粒子,密度较高,粒子半径约为10 nm,如图6(c)所示。

图5 1933合金经200 ℃/h均匀化处理后SEM显微组织和能谱分析

Fig.5 SEM images and EDX analysis of the second phases in cast alloy homogenized at 400 ℃ for 12 h plus 465 ℃/h for 24 h at 20 ℃/h

图6 合金经过不同均匀化处理之后的透射电镜照片

Fig.6 TEM images of 1933 aluminum alloy ingot after homogenization

图6(d)和(e)所示是合金经制度2在升温速率为 200 ℃/h均匀化处理后晶界和晶内的透射照片。与制度1相比,晶界无析出带的宽度大大增加,为3~5 μm;晶粒中心Al3Zr粒子的密度明显减小,尺寸明显增大,约15 nm。

由以上分析可以看出:与快速升温(200 ℃/h)单级均匀化相比,慢速升温(20 ℃/h)有利于减小晶界无Al3Zr粒子析出带的宽度,而且晶粒中心Al3Zr粒子密度增加,尺寸减小。

3 分析和讨论

试验结果表明:在2种不同升温速率下均匀化对于消除共晶组织和成分偏析的作用差别不大。在均匀化过程中,铸态合金中α(Al)+η(MgZn2)非平衡结晶共晶组织由于其熔点较低,随着均匀化温度升高、时间延长,将逐渐溶解,同时,溶质原子向晶内扩散。而 Al7Cu2Fe相在465 ℃时较稳定[12],不易溶解,为了降低其表面能,在均匀化处理后其形貌由块状向球化转变。此外,均观察到合金在铸态和均匀化态中白色的AlZnCu相。这种相还未见报道,结合相图[13]分析可能是CuZn相,但这需要进一步研究确定。

TEM结果显示:在不同升温速率下均匀化处理对Al3Zr粒子的析出形貌有明显的影响,这也是本文研究的重点。通常,在均匀化过程中,Al3Zr粒子的形核速率N可以用下式[14]来表示:

(1)

(1)

G*=4/(3πr*2σ) (2)

(3)

(3)

式中:Va为原子体积;c为Zr在基体中的瞬时浓度;N为单位体积内的形核速率;K为常数;G*为形核功;Q为Zr原子扩散到Al基体中的激活能;T为热力学温度; 为假设一平界面时,与Al3Zr平衡的基体Zr浓度;σ为形核表面能;r*为临界晶核半径。由式(1)可知形核率受2方面的控制:

为假设一平界面时,与Al3Zr平衡的基体Zr浓度;σ为形核表面能;r*为临界晶核半径。由式(1)可知形核率受2方面的控制:

一是临界形核功G*,由式(2)和式(3)可知,G*∝1/ΔT2,ΔT为过冷度,所以,温度越低,过冷度越大,形核功G*越小,exp(-G*/(KT))就越大,故形核率越大;温度越高,形核率降低。

二是温度控制的扩散过程。由于晶胚的形成是原子由基体向第二相的扩散过程,而原子的扩散需要克服一定的能垒Q。温度越低,原子扩散速度越小,这将导致形核率减小;温度越高,扩散越快,形核率增加。因此,应存在1个适宜的温度,使Al3Zr粒子的形核速率达到峰值。

铸态组织中Zr元素的偏析对Al3Zr粒子的分布也有一定的影响。合金在凝固过程中,对于溶质分配系数[15]K<1的合金元素如Zn,Mg和Cu等,倾向于在晶界和枝晶边界集中;而溶质分配系数K>1的合金元素如Cr,Ti和Zr等,倾向于在枝晶网络内富集,因此,溶质原子将出现偏析,如图3所示。合金经20℃/h均匀化处理后,Al3Zr在晶界和晶粒中央的分布明显不同。这是由于在铸态合金中Zr元素在枝晶中央富集,而在晶界处含量比较低。晶界处由于Zr含量低于亚稳相的极限固溶度,基体没有弥散粒子析出。而Zr含量从晶界到晶粒中心逐渐增加,随着过饱和度增加,形成Al3Zr的驱动力增加,形核速率也增加,因此,在晶界附近析出少量的Al3Zr粒子。在晶粒中心,Zr富集,形成Al3Zr的驱动力大大增加,均匀化后析出了大量细小弥散的Al3Zr粒子,如图6(c)所示。

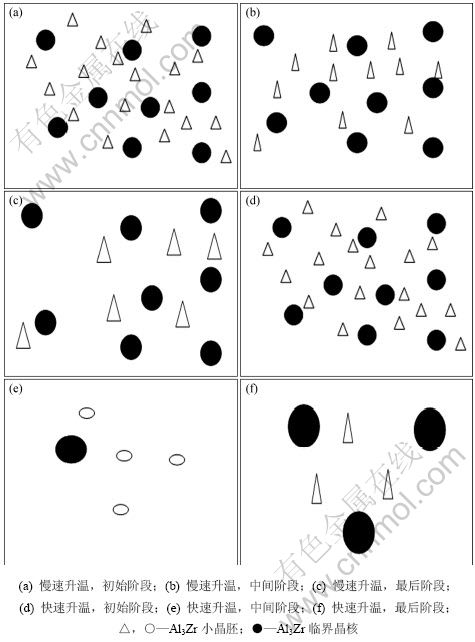

此外, Al3Zr临界晶核半径与过冷度成反比(见式(3))。在温度较低时,Al3Zr临界晶核半径较小,达到临界值的晶胚数较多;慢速升温时,大量晶胚随温度缓慢升高持续长大,在更高温度下能够稳定存在,如图7(a),(b)和(c)所示。而在快速升温过程中,在低温时形成的临界晶核很快溶解。实际上,Al3Zr析出是在高温下发生的,如图7(d),(e)和(f)所示。

最终均匀化后得到的Al3Zr粒子密度A可由下式计算[16]:

(4)

(4)

其中:V(Al3Zr)为Al3Zr粒子的体积;a为Al3Zr晶格常数;N为摩尔常数;ρ(Al)为铝的密度;w(Zr)为Zr的质量分数。对于慢速升温均匀化制度,晶粒中心Al3Zr半径约为10 nm(见图6(c)),此时,经计算得到晶粒中心Al3Zr粒子密度为400 个/μm3;而对于快速升温的均匀化制度,晶粒中心Al3Zr半径约为15 nm(见图6(d)),计算得到晶粒中心Al3Zr粒子密度为120 个/μm3,如表4所示。

图7 不同升温速率时Al3Zr的粒子析出模型

Fig.7 Precipitation models of Al3Zr particles at different heating rates

表4 不同升温速率均匀化处理后Al3Zr相关参数

Table 4 Parameters of Al3Zr particles at different heating rates during homogenization

因此,与200 ℃/h均匀化处理相比,于20 ℃/h均匀化处理后的试样其Al3Zr粒子密度明显增加,尺寸均匀、细小,分布弥散。

此外,据文献[14],Al3Zr会在η相上优先形核,这也有可能是慢速升温均匀化导致Al3Zr粒子弥散析出的原因之一。因为在低温时,细小弥散的η相分布促使Al3Zr粒子在η相上非均匀形核,有利于最终Al3Zr粒子的分布,晶界附近DFZ宽度约为0.5 μm;而在快速升温过程中,η相很快长大并溶解消失,不会形成细小弥散的η相,Al3Zr来不及附在η相上非均匀形核,此时,Al3Zr粒子主要通过均匀形核析出,所以,快速升温较慢速升温的Al3Zr密度较小,DFZ宽度较大,为3~5 μm。关于这种形核机制还有待进一步通过实验确定。

4 结论

(1) 1933铝铸态合金中主要存在α(Al)+η(MgZn2)非平衡共晶组织、AlZnCu相和AlCuFe相;均匀化处理之后该共晶组织溶解,合金晶界处残留有难溶的AlZnCu相和Al7Cu2Fe相。

(2) 合金均匀化处理后晶界附近出现一定宽度的无Al3Zr粒子析出带,而晶内有高密度Al3Zr粒子,这与铸造过程Zr元素的偏析有关。

(3) 慢速升温均匀化(20 ℃/h)与快速升温均匀化(200 ℃/h)相比可减小粒子弥散析出区(DFZ)的宽度,DFZ的宽度由3~5 μm减小到0.5 μm;晶内Al3Zr粒子分布更弥散细小,粒子半径由15 nm减小为10 nm,粒子密度由120 个/μm3增加为400 个/μm3。

参考文献:

[1] Guo H Z, Zhao J, Yuan S C. Effect of ECPA hot processing on grain refinement and superplasticity of 1933 aluminum alloy[J]. Materials Science Forum, 2007, 551/552: 193-198.

[2] 陈石卿. 俄罗斯的航空用铝合金的发展及其历史经验: 一[J]. 航空工程与维修, 2001, 3: 17-18.

CHEN Shi-qing. Russian aeronautical aluminum alloy development and its historical rxperience: I[J]. Aviation Engineerging & Mainienance, 2001, 3: 17-18.

[3] Engdahl T, Hansen V, Warren P J, et al. Investigation of fine scale precipitates in Al-Zn-Mg alloys after various heat treatments[J]. Materials Science and Engineering A, 2002, 327(1): 59-64.

[4] 夏卿坤, 刘志义, 余日成. 一种新型耐热铝合金均匀化工艺的研究[J]. 铸造, 2007, 56(1): 23-25.

XIA Qing-kun, LIU Zhi-yi, YU Ri-cheng. Study on homogenization processes of a new type heat resistant aluminum alloy[J]. Foundry, 2007, 56(1): 23-25.

[5] Fan X G, Jiang D M, Meng Q C. The microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization[J]. Materials Letters, 2006, 60(12): 1457-1479.

[6] 肖亚庆, 谢水生, 刘静安. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2005: 281-282.

XIAO Ya-qing, XIE Shui-sheng, LIU Jing-an. Manual of aluminum alloy and its processing[M]. Beijing: Metallurgical Industry Press, 2005: 281-282.

[7] 谢优华, 杨守杰, 戴圣龙, 等. 含锆超高强铝合金的研究及发展概况[J]. 材料导报, 2002, 16(5): 8-10.

XIE You-hua, YANG Shou-jie, DAI Sheng-long, et al. Research and development of ultra-high strength aluminum alloys containing zirconium[J]. Material Review, 2002, 16(5): 8-10.

[8] 李国锋, 张新明, 朱航飞. 7B50高强铝合金的均匀化[J]. 中国有色金属学报, 2008, 18(5): 764-770.

LI Guo-feng, ZHANG Xin-ming, ZHU Hang-fei. Homogenizing treatment of 7B50 high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 764-770.

[9] 孙凤仙, 高凤华, 李念奎. Al-6.1Zn-2.6Mg-1.6Cu超高强铝合金铸锭均匀化处理研究[J]. 轻合金加工技术, 2007, 35(1): 16-19.

SUN Feng-xian, GAO Feng-hua, LI Nian-kui. Homogenization treatment of ingot of Al-6.1Zn-2.6Mg-1.6Cu higher strength aluminum alloy[J]. Light Alloy Fabrication Technology, 2007, 35(1): 16-19.

[10] 仲志国, 左秀荣, 翁永刚. 变形铝合金均匀化热处理的应用现状与研究进展[J]. 轻合金加工技术, 2006, 34(1): 11-13.

ZHONG Zhi-guo, ZUO Xiu-rong, WENG Yong-gang. The application situation and the study development of the wrought aluminum alloy's homogenization[J]. Light Alloy Fabrication Technology, 2006, 34(1): 11-13.

[11] 樊喜刚. Al-Zn-Mg-Cu-Zr合金组织性能和断裂行为的研究[D]. 哈尔滨: 哈尔滨工业大学材料学院, 2007: 29-34.

FAN Xi-gang. Study on the microstructures and mechanical properties and the fracture behavior of the Al-Zn-Mg-Cu-Zr alloys[D]. Harbin: Harbin Institute of Technology. School of Materials Science, 2007: 29-34.

[12] Xie F Y, Yan X Y. A study of microstructure and microsegregation of aluminum 7050 alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 144-153.

[13] Ahlers M. Martensite and equilibrium phases in Cu-Zn and Cu-Zn-Al alloys[J]. Prog Mater Sci, 1986, 30(3): 135-186.

[14] Robson J D, Prangnell P B. Dispersoid precipitation and process modelling in zirconium containing commercial aluminium alloys[J]. Acta Materialia, 2001, 49(4): 599-613.

[15] Schaffer G B, Huo S H, Drennan J, et al. The effect of trace elements on the sintering of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2001, 49(14): 2671-2678.

[16] Wu L M, Wang W H, Hsu Y F. Effects of homogenization treatment in recrystallization behavior and dispersoid distribution in an Al-Zn-Mg-Sc-Zr alloy[J]. Journal of Alloy and Compounds, 2008, 456(1/2): 163-169.

(编辑 陈灿华)

收稿日期:2009-12-08;修回日期:2010-03-25

基金项目:国家重大基础研究计划(“973”计划)项目(2005CD623700)

通信作者:张新明(1946-),男,湖南安乡人,教授,从事轻合金组织结构、织构及性能研究;电话:0731-88830265;E-mail:xmzhang_cn@yahoo.com.cn