文章编号:1004-0609(2010)S1-s0902-04

真空热处理对冷喷涂多孔Ti组织与拉伸性能的影响

李文亚1,余 敏1,LIAO Han-lin2

(1. 西北工业大学 材料学院,西北工业大学摩擦焊接陕西省重点实验室,西安 710072;

2. LERMPS, Université de Technologie de Belfort-Montbéliard (Site de Sévenans), 90010 Belfort, France)

摘 要:采用冷喷涂制备多孔Ti块材,并通过高温真空热处理改善多孔Ti块材的组织与性能。结果表明:热处理后Ti块材气孔增大和产生微小的气孔;同时热处理态多孔Ti块材表现出脆性断裂特征,但热处理加强了Ti颗粒间局部的冶金结合,从而其平均抗拉强度提高约95.7 MPa。

关键词:多孔Ti;冷喷涂;真空热处理;显微组织;拉伸性能

中图分类号:TG174 文献标志码:A

Effect of vacuum heat treatment on microstructure and tensile property of cold sprayed porous Ti bulk

LI Wen-ya1, YU Min1, LIAO Han-lin2

(1. Shaanxi Key Laboratory of Friction Welding Technologies, Northwestern Polytechnical University,

Xi’an 710072, China;

2. LERMPS, Université de Technologie de Belfort-Montbéliard (Site de Sévenans), 90010 Belfort, France)

Abstract: The porous Ti bulk was deposited by cold sprayed (CS) and subsequently modified by heat treatment aiming at improving its microstructure and tensile property. The results show that the porosity of Ti bulk increases and weeny pore is produced after annealing. Meanwhile, the stress-strain curves of the annealed porous Ti bulk showed a brittle fracture. However, due to the formation of the local metallurgical bonding between the Ti particles after heat treatment, the mean tensile strength increases to approximately 95.7 MPa.

Key words: porous Ti; cold spraying; vacuum heat treatment; microstructure; tensile strength

冷喷涂是通过高速固态颗粒流依次与固态基体碰撞后、经过适当的变形牢固结合在基体表面而依次沉积形成沉积层的方法[1]。通常,采用冷喷涂技术可以获得致密的Cu、Zn和Fe等涂层[2-4],但对于Ti[5-7, 9]或Ti合金[8-9]涂层,喷涂态涂层表现出一定的多孔性质。KARTHIKEYAN等[5]最早在2000年国际热喷涂会议上报道了多孔Ti涂层制备,由于他们采用的是多孔海绵钛粉,所以形成多孔的原因被总结为粉末多孔所致。而LI等[6]、MARROCCO等[7]和BLOSE [8]采用致密Ti粉也获得一定孔隙的Ti或Ti合金涂层。SUN等[10]利用冷喷涂Ti与Mg的复合涂层及烧结去除Mg的方法得到多孔的Ti涂层。此外,作者也采用冷喷涂方法获得了一定孔隙的Ti与Ti-6Al-4V涂 层[4, 6, 9, 11],而且发现后热处理可以改善Ti涂层的组织与性 能[9, 11]。本文作者将进一步研究真空热处理对冷喷涂多孔Ti组织与拉伸性能的影响。

1 实验

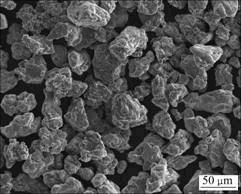

实验所用Ti粉(H.C. Starck公司生产)粒度为11~45 ?m,粉末形貌不规则,如图1所示。实验中采用低碳钢为基体,喷涂前用147 μm白刚玉砂粒进行表面清理与粗化。

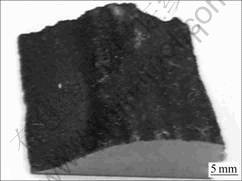

冷喷涂设备为德国CGT公司出售的Kinetic 3000系统。所用喷嘴为法国LERMPS自行设计,扩张比约4.9,下游长度170 mm。高压压缩空气用做加速气体,氩气作为送粉气体。喷枪入口空气压力约为2.8 MPa,温度约550 ℃。氩气压力为3.1 MPa。喷涂距离为 30 mm。本研究所制备的块材厚度超过5 mm,如图2所示。喷涂后对所制备块材进行真空热处理(温度 850 ℃,保温时间4 h,真空度约为10-2 Pa)。

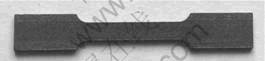

采用扫描电镜(SEM)研究所制备多孔块材的组织及断口形貌,并制备了微型拉伸试样,如图3所示(拉伸样厚度1 mm,平行长度15 mm,平行部分宽度

图1 实验所用Ti粉形貌

Fig.1 Morphology of used Ti powder

图2 实验所制备的Ti块材

Fig.2 Ti bulk produced by CS

图3 微拉伸试样

Fig.3 Micro-tensile sample

3 mm,过渡圆弧半径为2 mm),采用拉伸实验表征块材的结合强度。

2 结果与讨论

2.1 涂层组织

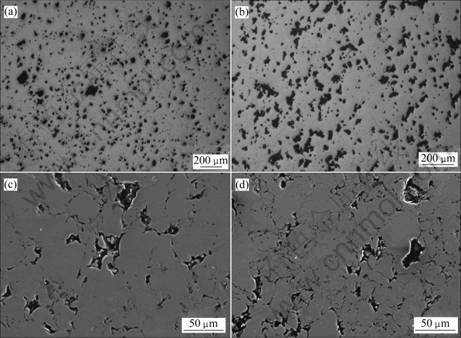

图4所示为所制备Ti块材喷涂态和热处理态断面

图4 冷喷涂Ti块材喷涂态断面组织和热处理态微观形貌

Fig.4 Micrographs of as-cold-sprayed Ti deposits ((a), (c)) and annealed deposits ((b), (d))

组织。由图4(a)可以看出,喷涂态块材表现出明显的多孔特性,其气孔率平均值约为11%[11]。真空热处理后,多孔块材仍然保持了多孔的特性,且孔隙分布均匀性有所增加(如图4(b)所示),涂层平均气孔率增加约为15%[11]。关于热处理使得Ti块材气孔率的增加,文献[11]推测这与气孔率的统计有关。喷涂态涂层内存在一些未结合面,而一些未结合面观察时呈线状,没有被统计在内。热处理后,由于这些未结合面的球化与聚合,使得统计时线性未结合面又被考虑在内。因此,这样统计下来,气孔率有所增加[11]。图4(d)可部分证实这一推测,比较图4(c)和(d)可见,热处理后,未结合面和微结合面发生球化与聚合,使Ti块材气孔增大和产生微小的气孔。

2.2 热处理对多孔Ti性能的影响

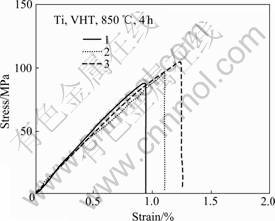

图5所示为热处理后多孔Ti块材的应力—应变曲线。由图5可看出,热处理态多孔Ti块材表现出脆性金属特有的脆断失效行为,块材在线性弹性变形后达到屈服极限,发生断裂。其平均抗拉强度约为95.7 MPa,与喷涂态多孔Ti块材强度约25 MPa[11]相比,抗拉强度增大近4倍。热处理引起多孔Ti块材气孔率增加,并未降低块材的强度,反而使得材料的抗拉强度增加。为探寻其原因,对块材的断口进行分析。

图5 热处理态Ti块材应力—应变曲线

Fig.5 Stress—strain curves of heat treated Ti deposits

2.3 断口形貌

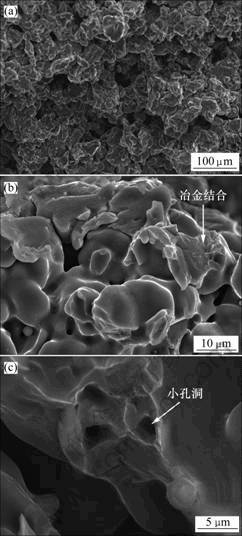

图6所示为热处理态多孔Ti块材拉伸试样断口形貌。对于Ti涂层的多孔特性,是由于固态Ti颗粒碰撞沉积时变形有限所造成[6, 12],从图6(a)和4(d)可看出,热处理后,Ti颗粒仍保持喷涂态的形貌,未形成例如Cu颗粒形成的大变形扁平颗粒[2-4]。前期研究还表明,Ti颗粒间的界面反应对于多孔Ti涂层的形成起着重要的作用[12]。从图6(a)可看到热处理Ti块材中孔洞的分布,进一步从图6(c)中观察到,热处理态块材中除了Ti颗粒间的孔洞外,还存在被Ti颗粒所包覆的小孔洞存在(图6(c)箭头所示),这些孔洞可能是未结合界面聚合的结果。同时,从图6(b)可以看到,热处理态多孔Ti颗粒间的局部冶金结合,这也是多孔Ti涂层抗拉强度增加的原因。因此,后热处理对于改善冷喷涂层的性能有着重要的作用。

图6 冷喷涂Ti块材热处理后断口的显微组织和局部放大像

Fig.6 Micrographs(a) of fractured surfaces of heat treated Ti bulk and high magnification micrographs((b), (c))

3 结论

1) 真空热处理后,多孔Ti块材中的未结合面和微结合面发生球化与聚合,使块材气孔增大和产生微小的气孔。

2) 热处理后,多孔Ti块材表现出脆性断裂特征,其平均抗拉强度提高为95.7 MPa。

3) 热处理态Ti块材中除了Ti颗粒间的大孔洞外,还存在聚合的小孔洞。热处理加强了颗粒界面间局部冶金结合,从而涂层的抗拉强度增加。

REFERENCES

[1] 李长久. 中国冷喷涂研究进展[J]. 中国表面工程, 2009, 22(4): 5-14.

LI Chang-jiu. The state-of-art of research and development on cold sparying in China[J]. China Surface Engineering, 2009, 22(4): 5-14.

[2] van STEENKISTE T H, SMITH J R, TEETS R E, MOLESKI J J, GORKIEWICZ D W. Kinetic spray coatings[J]. Surface and Coatings Technology, 1999, 111: 62-71.

[3] STOLTENHOFF T, KREYE H, RICHTER H J. An analysis of the cold spray process and its coatings[J]. Journal of Thermal Spray Technology, 2002, 11(4): 542-550.

[4] LI C J, LI W Y. Microstructure evolution of cold-sprayed coating during deposition and through post-spraying heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(S2): 49-54.

[5] KARTHIKEYAN J, KAY C M, LINDEMAN J, et al. Cold spray processing of titanium powder[C]//BERNDT C C. Thermal Spray: Surface Engineering via Applied Research. OH: ASM International, 2000: 255-262.

[6] LI C J, LI W Y. Deposition characteristics of titanium coating in cold spraying[J]. Surface and Coating Technology, 2003, 167: 278-283.

[7] MARROCCO T, MCCARTNEY D G, SHIPWAY P H, et al. Production of titanium deposits by cold gas dynamic spray[C]//LUGSCHEIDER E. Thermal Spray connects: Explore its Surfacing Potential. Düsseldorf: DVS, 2005.

[8] BLOSE R E. Spray forming titanium alloys using the cold spray process[C]//LUGSCHEIDER E. Thermal Spray Connects: Explore its Surfacing Potential. Düsseldorf: DVS, 2005.

[9] LI W Y, ZHANG C, GUO X P, XU J L, LI C J, LIAO H L, CODDET C, KHOR K A.. Fabrication and characterization of Ti and Ti-6Al-4V coatings by cold spraying and microstructure modification by heat treatment[J]. Advanced Engineering Materials, 2007, 9(5): 418-423.

[10] SUN J, HAN Y, CUI K. Innovative fabrication of porous titanium coating on titanium by cold spraying and vacuum sintering[J]. Material Letter, 2008, 62(21/22): 3623-3625.

[11] 李文亚, LIAO Han-lin, CODDET C. 基于冷喷涂的多孔钛与钛合金的制备与表征[J]. 稀有金属材料与工程, 2009, 38(z3): 260-263.

LI Wen-ya, LIAO Han-lin, CODDET C. Preparation and characterization of porous titanium and titanium alloy by cold spraying[J]. Rare Metal Materials and Engineering, 2009, 38(z3): 260-263.

[12] LI W Y, ZHANG C, WANG H T, GUO X P, LIAO H L, LI C J, CODDET C. Significant influences of metal reactivity and oxide films at particle surfaces on coating microstructure in cold spraying[J]. Applied Surface Science, 2007, 253(7): 3557-3562.

(编辑 陈爱华)

基金项目:教育部新世纪优秀人才计划资助项目(NCET-08-0463);西北工业大学翱翔之星计划资助项目(2008R08)

通信作者:李文亚;电话:029-88495226;E-mail: liwy@nwpu.edu.cn