DOI:10.19476/j.ysxb.1004.0609.2017.09.13

液固分离法制备金刚石/铝封装材料的组织与性能

周洪宇1, 2,尹衍利2,吴春京1,刘俊友1, 2

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 北京科技大学 新兴产业技术研究院,北京 100083)

摘要:采用高性价比液固分离法(LSS)制备高性能金刚石/铝散热基板,研究金刚石镀铜对复合材料界面结合和导热性能的影响,利用SEM、EMPA、XRD分析复合材料的断口形貌及界面行为。结果表明:镀层元素向基体扩散与基体铝形成Al2Cu4化合物,中间相增强两相界面结合,改善材料性能。金刚石镀铜处理后,复合材料致密度提高1.16%,热导率提高9.50%,抗拉强度提高17.39%,复合材料的热物理性能优于CE13合金的。用Maxwell、Kerner理论模拟预测热导率(TC)、热膨胀系数(CTE)与实际测量结果相一致。

关键词:金刚石/铝复合材料;液固分离法;镀层;热导率;热膨胀系数;电子封装

文章编号:1004-0609(2017)-09-1855-07 中图分类号:TG132.1 文献标志码:A

随整机电子系统向大功率化、微型化、模块化方向发展,单位体积内芯片产生的热流密度不断提高,要求承载散热的封装材料必须具有良好的导热性能,以便及时有效地散发热量,保证电子装备的正常运 转[1-2]。金刚石颗粒不仅具有优异的热导率(TC),同时具有较低的热膨胀系数(CTE)[3]。因此,采用金刚石颗粒增强铝基复合材料兼顾高热导、低膨胀和低密度的特点,被誉为第四代电子封装材料[4-5]。

金刚石复合材料可加工性极差,为降低加工成本,希望在制备过程中实现近净成形。目前,制备高导热金刚石增强型复合材料的方法主要有气压浸渗[1]、压力浸渗[6]、无压浸渗[7]、放电等离子烧结[8]、真空热压烧结[9],但这些复合材料制备工艺方法由于自身限制,均无法在大规模工业生产中得到广泛的应用。因此,研制、开发一种高性价比适合连续批量生产的金刚石/铝复合材料制备技术已成当务之急。研究表明[10],金刚石/铝复合材料热物性的高低不仅受制备工艺影响,同时也取决于金属铝与金刚石颗粒间界面润湿情况。通常可对金刚石颗粒表面进行化学处理、镀层处理、高温碳化处理等方式提高界面润湿性[11]。

本文作者提出采用短流程适合产业化推广的液固分离法(liquid-solid separation, LSS)[12-14]先进工艺制备金刚石/铝复合材料,研究金刚石表面镀铜改性对复合材料两相界面行为及热物性的影响。分别采用Maxwell、Kerner理论模型对金刚石/铝复合材料热导率、热膨胀系数进行热模拟分析。

1 实验

1.1 实验材料

实验材料分别如下:工业铝粉(郑州宇航铝业有限公司生产)和金刚石颗粒(河南黄河旋风股份有限公司生产)。工业铝粉纯度为99.81%,平均粒径为37 μm;金刚石颗粒品级为MBD-4,平均粒径106 μm。人造单晶金刚石热导率与其表面氮元素含量呈线性关系[15],而镀层厚度,实验用金刚石颗粒氮含量约为(190~200)×10-6,经过计算热导率为1500 W·m-1·K-1。采用真空离子镀在金刚石颗粒表面镀Cu,镀层厚度约为100 nm。

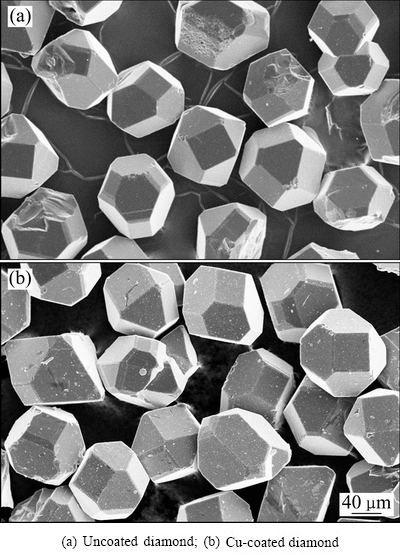

图1所示为金刚石表面镀Cu前后的SEM像。图1(a)显示 MBD-4品级金刚石颗粒大小均匀,圆整程度较高,自然面由四方形的(100)面和三角形的(111)面组成,形成完整的六-八面体结构,部分颗粒表面存在宏观缺陷;图1(b)所示为真空离子镀Cu金刚石显微形貌,经过镀Cu处理的金刚石颗粒被一层连续、均匀的不光滑颗粒状物质包裹,颗粒物填补金刚石了表面的细微裂纹等缺陷,镀层在金刚石颗粒表面附着较好。

图1 金刚石颗粒的SEM像

Fig. 1 SEM images of diamond

1.2 实验方法

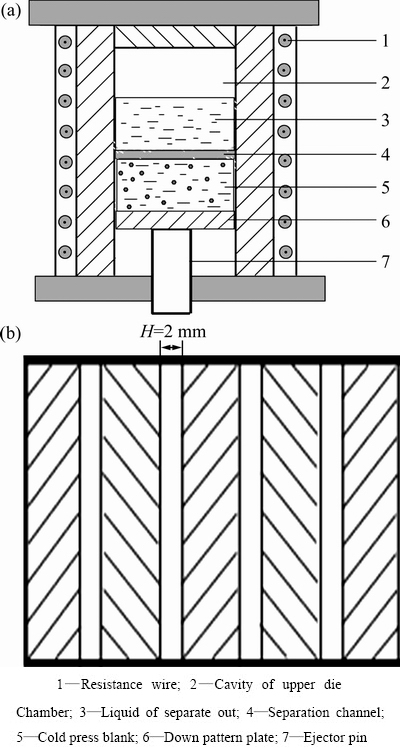

图2(a)所示为液固分离模具系统结构图。该系统具有液固分离通道、液相定量控制、定向凝固关键结构。分离通道是开有2 mm缝隙的过滤挡板,如图2(b)所示。通过确定缝隙尺寸来控制铝液及金刚石颗粒的流动。在触变成形过程中,液固分离通道可以将液态铝定向挤出,并阻止金刚石颗粒通过。分离出液相通过分离通道进入并充满上模腔,通过设计上模腔体积可以制备不同体积分数的金刚石/铝复合材料。

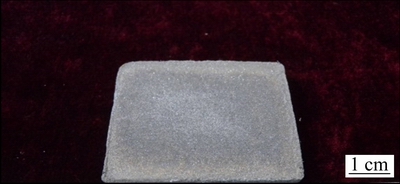

40%(体积分数)金刚石/铝复合材料的制备方法如下:1) 将20%单晶金刚石颗粒与纯铝粉机械混合1 h,在500 MPa压力,保压1 min,制成冷压坯料;2) 将冷压坯料放置液固分离腔加热至683 ℃,保温40 min,使坯料处于半固态状态;3) 半固态浆料在50 MPa压力油缸推动进行挤压、分离,液固分离液相通过2 mm分离通道进入并充满上模腔,持续保压15 min。最终制备尺寸为50 mm×40 mm×3 mm的散热基板,结果如图3所示。

采用激光切割机和金刚石砂轮对复合材料进行机械加工。采用德国蔡司EVO-18型扫描电镜(SEM)观察金刚石颗粒表面及三点弯曲断口形貌。采用日本电子JXA-8230型电子探针(EMPA)能谱线扫描测定Al、C、Cu元素分布。采用日本理学D/MAX-RB型旋转阳极衍射仪(XRD)进行物相分析,采用Cu靶,工作电压40 kV,工作电流150 mA。采用中国群隆GH-120E型密度仪测量复合材料密度(ρ)。采用德国耐驰LFA 427型激光散射热导仪测定复合材料室温热扩散系数(α),试样尺寸为直径12.7 mm×3 mm。根据理论模型计算复合材料定压比热容(cp)。复合材料的热导率(λ)通过关系式计算:λ=ραcp。采用德国耐驰DIL 402C型热膨胀仪测定复合材料从室温到200 ℃平均热膨胀系数(α),试样尺寸为25 mm×4 mm×3 mm,升温速度5 ℃/min。采用中国中科科仪ZQJ-530氦质谱检漏仪进行气密性检测,将试样放置在5 MPa压力氦气当中保压4 h,测定复合材料漏气量大小。采用中国瑞格尔RGM-3010型万能电子试验机测定复合材料抗弯强度(σf),试样尺寸为25 mm×4 mm×3 mm。

图2 液固分离法示意图

Fig. 2 Schematic diagram of die of LSS (a) and separation channel (b)

图3 金刚石/铝复合材料散热基板照片

Fig. 3 Photo of fabricated diamond/Al composite in application of heat dissipation prepared by LSS process

2 结果与分析

2.1 分离出的液相显微组织

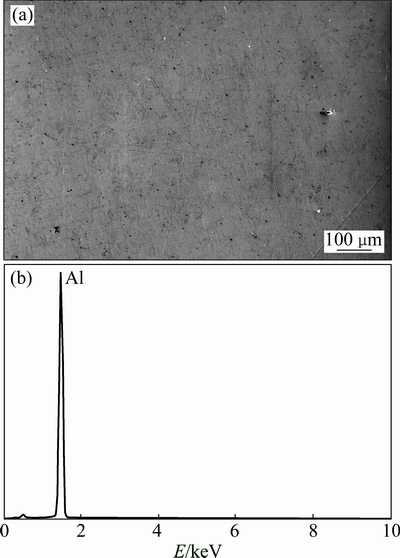

图4(a)所示为制备40%金刚石/铝复合材料分离出液相显微组织。从图4(a)可以看出,分离出的液相中没有金刚石颗粒存在。图4(b)所示为分离出的液相EDS分析结果,证明视野范围内为纯铝,这说明2 mm的分离通道可以有效地阻隔金刚石颗粒流出,保证原始冷压坯料的金刚石颗粒最终完全保留在复合材料当中。因此,可通过改变上模腔的大小,获得不同体积分数的金刚石/铝复合材料。此外,冷压制坯过程中铝粉和金刚石颗粒间存在一些孔隙[16]可在液相液固分离流动、挤出过程中得到焊合,提高材料致密度。

图4 分离出的液相SEM像和EDS谱

Fig. 4 SEM image (a) and EDS pattern (b) of squeezed-out liquid phase

2.2 复合材料的界面形貌

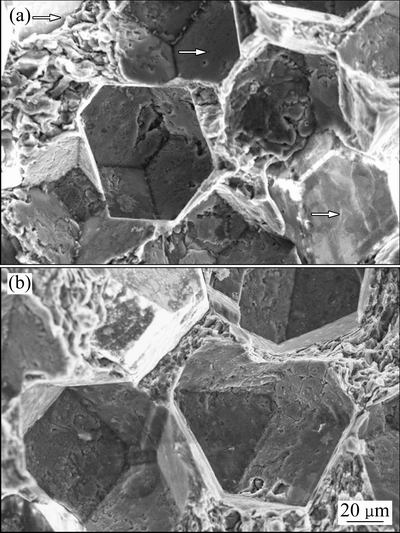

图5所示为采用LSS技术制备复合材料三点弯曲断口形貌。试样的增强相分别为未镀与镀铜金刚石颗粒,将分别将复合材料命名为金刚石/铝、铜-金刚石/铝。对比两图可以发现金刚石颗粒在基体铝当中分布比较均匀,且无论金刚石是否经过表面镀覆处理,其颗粒都能很好地镶嵌在铝基体中,界面周围并没有观察导致热导率降低的空洞[17],这说明LSS制备的金刚石/铝复合材料散热基板具有组织均匀、致密度高等特点。从图5(a)红色箭头所示的区域可以观察到有部分金刚石颗粒并没有被铝完全包覆,裸露在外的界面相对光洁、平滑,而断裂方式以界面断裂为主。由于断裂通常先发生在界面结合较弱处,说明基体与增强相颗粒间的界面结合较弱;图5(b)显示镀铜金刚石颗粒被铝完全包覆,断口区域金刚石没有开放结构,断裂方式则主要为基体断裂,界面结合紧密。此外,经过镀铜处理后,不完整金刚石颗粒凹陷处被镀层覆盖,减少尖角效应,提高凹陷处与金属基体的界面结合。

图5 复合材料的断口SEM像

Fig. 5 SEM images showing fracture surfaces reinforced with diamond/Al (a) and Cu-diamond/Al (b)

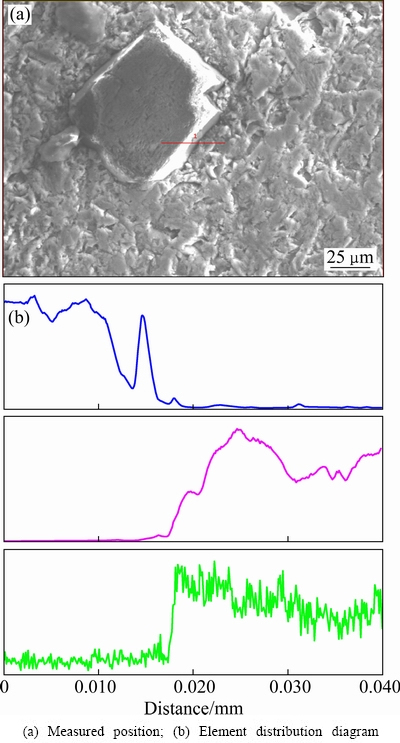

2.3 复合材料的界面行为

研究铜-金刚石/铝界面行为,分析金刚石镀铜对两相界面的影响。借助EMPA分析铜-金刚石/铝界面元素分布及界面反应,实验结果见图6。在图6(a)两相界面区域尽心线扫描,图6(b)所示为实验结果,显示C元素(蓝色曲线)、Al元素(红色曲线)和Cu元素(绿色曲线) 3种不同元素在复合材料界面处的分布情况。从图可知,Al基体与金刚石(C) 两相中间可以存在大约10 μm的过渡区域,说明基体和增强相固溶度较低仅有很小的相互扩散区域。Cu元素在Al、C两相过渡区具有较高的信号强度,随测试位置逐步深入到铝基体强度有所降低,在本实验中检测到Cu元素信号距离接近25 μm,而真空离子镀层厚度仅约为100 nm,这证明金刚石表面Cu镀层存在明显向基体扩散行为。

图6 镀铜金刚石/铝复合材料中界面处EMPA

Fig. 6 EMPA image showing Cu-diamond/Al composites interfaces

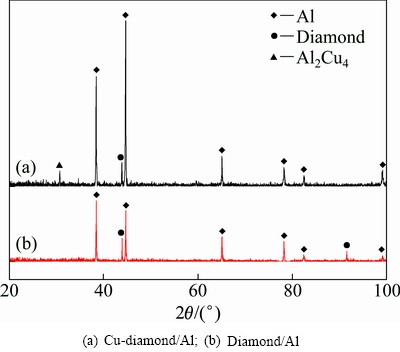

为了更清晰地了解铜-金刚石/铝的界面反应,对复合材料进行XRD物相分析,结果如图7所示。图7(b)为金刚石/铝物相分析结果,证实复合材料仅有铝和金刚石相,并没有界面反应的其他产物生成;而图7(a)相同条件下铜-金刚石/铝物相分析,证实有Al2Cu4中间相生成。界面反应对于基体铝和金刚石增强相的界面结合起重要作用,一方面,真空离子镀使镀层与金刚石增强相紧密连接;另一方面,Al-Cu中间相与金属基体形成冶金结合。因此,镀层可显著提高基体与增强相间的界面结合。

图7 复合材料的XRD谱

Fig. 7 XRD patterns of composites

金刚石颗粒的界面能较高,与金属材料之间的润湿角较大,即使在1500 ℃以上的高温下情况下,金刚石颗粒与铝液的润湿角仍大于90°。在两相界面润湿角大于90°属于不润湿结合,增加界面结合难度。此外,由于基体和增强相热膨胀系数的差异,很容易在凝固过程中产生脱附现象,导致界面较差,造成复合材料孔隙率高等问题[18]。因此,要想制备高性能金刚石/铝必须提高界面结合强度。经过EMPA、XRD实验结果,结合SEM显微断口形貌,铜-金刚石/铝的金属镀层在界面处发生扩散,并与基体发生反应生成Al2Cu4化合物,铜镀在铝和金刚石颗粒间其起桥梁、纽带作用,改善两相间的界面结合,同时金刚石颗粒被基体完全包裹,断裂方式由界面断裂优化为基体断裂。因此,可以判断金刚石经过镀铜处理可以显著增强界面连接强度。

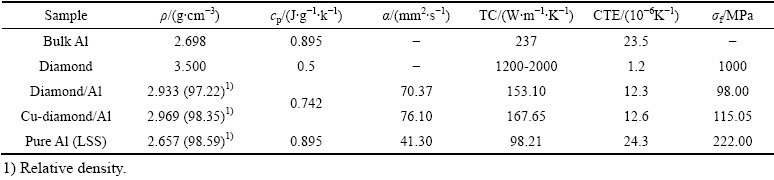

2.4 复合材料的热物性及力学性能

采用LSS技术制备复合材料热物性及力学性能列于表1。通过实验结果可以发现,铜-金刚石/铝具有比金刚石/铝更高的致密度,这说明LSS制备复合材料的致密度取决于基体铝与金刚石颗粒的界面润湿情况,Cu镀层在基体和增强相间起关键桥梁作用。表中可见,铜-金刚石/铝与金刚石/铝相比致密度提高1.16%,导热性能提高9.50%,抗拉强度提高17.39%。金刚石/铝的热物性优于Osprey Metal公司生产的CE13铝硅合金[19],证明镀层处理后的复合材料的综合性能更为优异。同样采用LSS技术制备纯铝件热导率值仅为98 W·m-1·K-1,远低于纯铝的理论值237 W·m-1·K-1。分析原因是由于铝粉极为活泼,表面会形成一层致密的氧化层,而Al2O3的热导率只有35~40 W·m-1·K-1[16]。

表1 金刚石/铝复合材料热物性及力学性能

Table 1 Thermo-physical and mechanical Properties of Al and Al/Diamond composites

2.4.1 热导率

为更深入分析LSS技术制备复合材料的热导率,将实验结果与理论预测模型相比较。金刚石/铝复合材料的热导率受增强相几何形态和体积分数及两相固有的热力学性能影响较大[4, 10, 20],MAXWELL[21]理论模型以其综合考虑界面热导、声子失配理论等诸多因素,在金属基金刚石复合材料热导率预测领域应用广泛。经Maxwell模型预测金刚石/铝复合材料的(λc)如下:

(1)

(1)

式中:λm为铝基体的热系数(LSS制备纯铝实验结果得出,λm =98.21 W·m-1·K-1);φd为增强相体积分数,%; 为金刚石颗粒的有效热导率,W·m-1·K-1。

为金刚石颗粒的有效热导率,W·m-1·K-1。

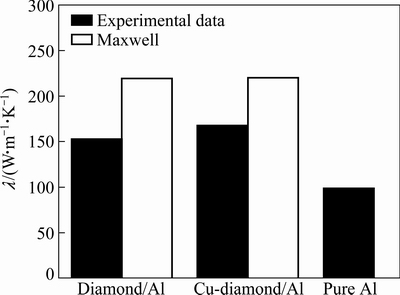

根据金刚石颗粒粒径、热导率(取1500 W·m-1·K-1)、界面热导(ITC)、声子散射系数(η1-2)及德拜模型(CD)综合计算金刚石/铝复合材料Maxwell理论热导率为219.27 W·m-1·K-1。由于金刚石/铝和铜-金刚石/铝试样当中增强相具有几乎相同的粒径尺寸,可认为Maxwell模型预测值也一致。图8所示为LSS技术制备的复合材料热导率实验数据与理论模型对比。相比之下,金刚石颗粒经过表面镀铜处理后,复合材料热导率显著提高,增加到168 W·m-1·K-1,达到理论预测值的76%,与金刚石/铝相比热导率增加近10%。

图8 金刚石/铝复合材料的热导率

Fig. 8 Experimental data and theoretical predictions for the thermal conductivity in Al/diamond composites

采用表面镀铜处理的金刚石作为增强相制备金刚石/铝复合材料热导率更接近与理论预测模型,这说明界面反应可生成一种热量传导层,提高两相间的界面润湿,从而降低铝基体与金刚石颗粒间的声子失配作用[20]。需要说明的是,理论预测模型中忽略了孔洞对于复合材料热导率的影响,孔洞可以促进声子散射,降低复合材料热导率[22],这也是实际测量值低于理论

计算模型的原因。

2.4.2 热膨胀系数

由于Kerner模型[23]模拟复合材料热膨胀系数,不仅考虑到复合材料的微观应力,同时也考虑剪切力对晶界的影响,因此,应用相对广泛。Kerner模型预测金刚石/铝复合材料热膨胀系数(αc)如下:

(2)

(2)

式中:αm为基体热膨胀系数,10-6K-1;αd为增强相热膨胀系数,10-6K-1;φm为基体体积分数,%;φd为增强相体积分数,%;Km为基体体积模量,GPa;Kd为增强相体积模量,GPa;Gm为基体剪切模量,GPa。

通过Kerner模型预测LSS技术制备金刚石/铝与铜-金刚石/铝复合材料热膨胀系数理论值为12.7×10-6 K-1,与表1所示金刚石/铝复与铜-金刚石/铝实验测量值几乎相同,远低于纯铝(24.3×10-6 K-1)。这说明在铝中添加金刚石颗粒可以显著降低材料热膨胀系数,而金刚石颗粒是否经过表面镀铜处理及复合材料致密度高低对于材料热膨胀系数影响不大。

2.5 复合材料的气密性

气密性是考察封装材料合格与否的关键性能指标。采用高压氦气吸附实验测试复合材料气密性,金刚石/铝与铜-金刚石/铝漏气速率分别为4.8×10-9 Pa·m3·s-1、3.6×10-9 Pa·m3·s-1,完全满足电子封装材料军用装配标准(<2×10-8 Pa·m3·s-1, GJB548A-96)。这说明采用LSS技术制备金刚石/铝复合材料气密性数值较高的,满足封装测试行业要求,具有较强的工业化应用前景。

3 结论

1) 采用高性价比液固分离法制备40%的金刚石/铝电子封装材料。新工艺制备复合材料中金刚石颗粒在基体铝中均匀分布,界面处无其他化合物生成。该工艺所制备的金刚石/铝具有较高的致密度,致密度为97.22%,热导率为153.10 W·m-1·K-1。金刚石/铝物性能优于CE13合金的。

2) 金刚石经过镀铜处理后所制备的铜-金刚石/铝界面处存在明显过渡区,铜元素向基体扩散,生成Al2Cu4化合物,显著增强界面连接强度,致密度提高到98.35%,提高复合材料导热和力学性能。

3) 铜-金刚石/铝与金刚石/铝相比,热导率提升近10%,达到Maxwell模型预测值的76%。镀层对于复合材料热膨胀系数影响不大,热膨胀系数基本与Kerner模型预测值相同。

REFERENCES

[1] 王新宇, 于家康, 朱晓敏. 镀TiC金刚石/铝复合材料的界面及热膨胀性能[J]. 中国有色金属学报, 2012, 22(6): 1718-1724.

WANG Xin-yu, YU Jia-kang, ZHU Xiao-min. Interface and thermal expansion properties of TiC-coated diamond/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1718-1724.

[2] 李婷婷, 彭超群, 王日初, 王小锋, 刘 兵. 电子封装陶瓷基片材料的研究进展[J]. 中国有色金属学报, 2010, 20(7): 1365-1374.

LI Ting-ting, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing. Research progress in ceramic substrate material for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1365-1374.

[3] KHALID F A, BEFFORT O, KLOTZ U E, KELLER B A, GASSER P. Microstructure and interfacial characteristics of aluminium–diamond composite materials[J]. Diamond and Related Materials, 2004, 13(3): 393-400.

[4] CACCIA M,  A, NARCISO J. Diamond surface modification to enhance interfacial thermal conductivity in Al/diamond composites[J]. Journal of the Minerals Metals and Materials Society, 2014, 66(6): 920-925.

A, NARCISO J. Diamond surface modification to enhance interfacial thermal conductivity in Al/diamond composites[J]. Journal of the Minerals Metals and Materials Society, 2014, 66(6): 920-925.

[5] 曾 婧, 彭超群, 王日初, 王小锋. 电子封装用金属基复合材料的研究进展[J]. 中国有色金属学报, 2015, 25(12): 3255-3270.

ZENG Jing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng. Research and development of metal matrix composites for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3255-3270.

[6] GUO H, HAN Y Y, ZHANG X M, JIA C C, JUN X U. Microstructure and thermophysical properties of SiC/Al composites mixed with diamond[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 170-174.

[7] SHI J, CHE R C, LIANG C Y, CUI Y, XU S B, ZHANG L. Microstructure of diamond/aluminum composites fabricated by pressureless metal infiltration[J]. Composites Part B- Engineering, 2011, 42(6): 1346-1349.

[8] TAO J M, ZHU X K, TIAN W W, YANG P, YANG H. Properties and microstructure of Cu/diamond composites prepared by spark plasma sintering method[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3210-3214.

[9] TAN Z Q, LI Z Q, FAN G L, KAI X Z, JI G, ZHANG L T, ZHANG D. Fabrication of diamond/aluminum composites by vacuum hot pressing: Process optimization and thermal properties[J]. Composites Part B- Engineering, 2013, 47: 173-180.

[10] MONJE I E, LOUIS E, MOLINA J M. On critical aspects of infiltrated Al/diamond composites for thermal management: Diamond quality versus processing conditions[J]. Composites Part A- Applied Science and Manufacturing, 2014, 67: 70-76.

[11] 马如龙, 彭超群, 王日初, 张 纯, 解立川. 电子封装用diamond/Al复合材料研究进展[J]. 中国有色金属学报, 2014, 24(3): 689-699.

MA Ru-long, PENG Chao-qun, WANG Ri-chu, ZHANG Chun, XIE Li-chuan. Research progress of diamond/aluminum composites for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 689-699.

[12] LI Y X, LIU J Y, WANG W S, LIU G Q. Microstructures and properties of Al-45%Si alloy prepared by liquid-solid separation process and spray deposition[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 970-976.

[13] JIA Q J, LIU J Y, LI Y X, WANG W S. Microstructure and properties of electronic packaging box with high silicon aluminum-base alloy by semi-solid thixoforming[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(1): 80-85.

[14] ZHOU H Y, YIN Y L, SHI Z L, WU C J, LIU J Y. The fabrication of Al-diamond composites for heat dissipation by liquid–solid separation technology[J]. Journal of Materials Science Materials in Electronics, 2017, 28(1): 721-728.

[15] YAMAMOTO Y, IMAI T, TANABE K, TSUNO T, KUMAZAWA Y, FUJIMORI N. The measurement of thermal properties of diamond[J]. Diamond and Related Materials, 1997, 6(8): 1057-1061.

[16] KWON H, LEPAROUX M, HEINTZ J M, SILVAIN J F, KAWASAKI A. Fabrication of single crystalline diamond reinforced aluminum matrix composite by powder metallurgy route[J]. Metals and Materials International, 2011, 17(5): 755-763.

[17] 陈代刚, 于家康, 于 威, 袁 曼. 镀层厚度对镀钛金刚石/铝复合材料热导率的影响[J]. 中国有色金属学报, 2013, 23(3): 802-808.

CHEN Dai-gang, YU Jia-kang, YU Wei, YUAN Man. Effect of coating thickness on thermal conductivity of Ti-coated diamond/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2013(3): 802-808.

[18] CHEN G Q, XIU Z Y, YANG W S, JIANG L T, WU G H. Effect of thermal-cooling cycle treatment on thermal expansion behavior of particulate reinforced aluminum matrix composites[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2143-2147.

[19] XIA Y, SONG Y Q, LIN C G, CUI S, FANG Z Z. Effect of carbide formers on microstructure and thermal conductivity of diamond-Cu composites for heat sink materials[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1161-1166.

[20] TAN Z Q, LI Z Q, XIONG D B, FAN G L, JI G, ZHANG D. A predictive model for interfacial thermal conductance in surface metallized diamond aluminum matrix composites[J]. Materials and Design, 2014, 55(6): 257-262.

[21] MAXWELL J C. A treatise on electricity and magnetism[M]. Humphrey Milford: Oxford University Press, 1937.

[22] JANG B K. Influence of temperature on thermophysical properties of EB-PVD porous coatings and dense ceramics of 4 mol% Y2O3-stabilized ZrO2[J]. Journal of Alloys and Compounds, 2009, 480(2): 806-809.

[23] KERNER E H. The elastic and thermo-elastic properties of composite media[J]. Proceedings of the Physical Society B, 1956, 69(8): 808-813.

Microstructures and properties of diamond/Al composites prepared by liquid-solid separation technology

ZHOU Hong-yu1, 2, YIN Yan-li2, WU Chun-jing1, LIU Jun-you1, 2

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Institute of Emerging Technology and Industry, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: High performance diamond/Al composites for heat dissipation were manufactured by advanced cost-effective liquid-solid separation (LSS) technology. The effect of Cu coating on the interface bonding and thermal conductivity of composite materials were researched. The fracture morphology and interfacial behavior of composite materials were analyzed by SEM, EMPA and XRD. The result show that the Al2Cu4 compounds form from coating element diffuse and Al matrix, which can enhance the interfacial bonding between the two phases and improve the properties of the materials. After Cu coating, the density of the composites increases by 1.16%, the thermal conductivity increases by 9.50%, the tensile strength increases by 17.39%. The thermal physical properties of Cu-diamond/Al are better than that of CE13 (controlled expansion) alloy. Additionally, the experimental data of thermal conductivity and coefficient of thermal expansion of diamond/Al composites show the similar tendency with those by Maxwell and Kerner models, respectively.

Key words: diamond/Al composites; liquid-solid separation technology; coating; thermal conductivity; coefficient of thermal expansion; electronic packaging

Foundation item: Project (Z121100001312012) supported by the Scientific Research Project of Beijing Education Commission, China

Received date: 2016-08-15; Accepted date: 2017-02-23

Corresponding author: LIU Jun-you; Tel: +86-10-62332982; E-mail: ljy158@yeah.net

(编辑 龙怀中)

基金项目:北京市教育委员会科学研究项目(Z121100001312012)

收稿日期:2016-08-15;修订日期:2017-02-23

通信作者:刘俊友,教授,博士;电话:010-62332982;E-mail:ljy158@yeah.net