压制压力对Si-Al电子封装材料性能的影响

冯 曦1,杨迎新2,郑子樵1,李世晨1,杨培勇1

(1.中南大学 材料科学与工程学院,湖南 长沙,410083;

2.江西理工大学 南昌分校机电系,江西 南昌,330013)

摘要: 采用粉末冶金液相烧结工艺制备Si-50Al电子封装材料,研究了压制压力对材料性能的影响。研究结果表明:增大压制压力可提高材料致密度,有效地促进界面的反应结合,使材料热导率提高;但当压制压力过大时,由于Si颗粒发生开裂甚至解理,界面热阻急剧上升,导致热导率下降;高压制压力导致Si-Al体系在945 ℃附近出现1个放热过程,这个放热过程对应于该温度下氧化铝薄膜的破裂以及随后Al与 Si颗粒表层SiO2的界面反应;诱发Al 和SiO2反应的是高压制压力所造成的界面处储能,这使体系润湿性大幅度提高,改善了材料的热导性能。

关键词: Si-Al电子封装材料; 液相烧结; 压制压力; 热导率

中图分类号:TF124.5 文献标识码:A 文章编号: 1672-7207(2005)02-0198-06

Effect of Pressing Pressure on Properties of Si-Al Electronic Packaging Materials

FENG Xi1,YANG Ying-xin2,ZHENG Zi-qiao1,LI Shi-chen1,YANG Pei-yong1

(1.School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2.Department of Mechanical and Electrical Engineering,

Nanchang Campus, Jiangxi University of Science and Technology, Nanchang 330013, China)

Abstract: Si-50%Al electronic packaging materials were fabricated by liquid phase sintering. The effects of pressing pressure on the microstructure and properties of the materials were investigated. The results show that thermal conductivity of the composites increases with pressing pressure as a result of improvements of densities and interface bonding, but a very high pressure can lead to many microcracks in Si particles, and then reduce thermal conductivities. An exothermic progress exists in Si/Al system under high pressing pressure at about 945 ℃. It mainly indicates the interface reaction between Al and silicon dioxide after the fracture of aluminum oxide film, which is encouraged by the boundary defect energy caused by high pressing pressure. Exothermic reaction improves the wettability of this system.

Key words: Si-Al electronic packaging materials; liquid phase sintering; pressing pressure; thermal conductivity

微电子技术高集成、高功率的发展趋势对电子封装材料的性能提出了更高的要求。理想的电子封装材料必须具有下列性能[1]:热膨胀系数小,与芯片材料相匹配;热导率高;密度低,以满足航空、航天和空间技术领域对减重的要求。此外,还应具有高的刚度,良好的机加工性能,焊接性能等综合性能。传统的电子封装材料已很难满足上述综合性能要求,而复合材料特别是金属基复合材料可使各组分的性能互相补充,获得同时满足各项封装要求的综合性能,已成为当前新型电子封装材料的开发热点之一。 -

在常用的金属中,Al的热导率仅次于Ag和Cu的热导率,且密度较低,Si本身就是芯片材料,具有较低的热膨胀系数和密度。将Si颗粒加入到Al基体中,通过适当调整Si的体积分数可以获得具有低膨胀、高热导和低密度等优良综合性能的Si-Al电子封装材料。美国采用喷射沉积和液态金属熔渗等方法,英国Osprey金属公司采用喷射沉积+热等静压的方法[2,3],C.W.CHIEN等采用压力熔渗的方法都制备出了综合性能优良的Si-Al电子封装材料[4],但这些方法均存在对设备要求较高、制造成本高的缺点。日本住友电器公司采用传统的粉末冶金方法制备了Si-60Al材料CMSHA-40。粉末冶金液相烧结方法具有两相混合均匀、成分控制和材料成形容易实现、致密度高等优点,是制备金属基复合材料特别是颗粒增强金属基复合材料的常用方法。在此,作者采用该方法制备Si-Al复合材料,并研究了压制压力对材料性能的影响以及体系润湿转变的机理。

1 实验材料及方法

本实验以Si-50Al作为研究对象。实验用的原料为水雾化法制备的Al粉和Si粉。Al粉为球形或椭圆形,Si粉为不规则多边形。将平均粒径130 μm的Si粉和平均粒径13 μm的铝粉按质量比1∶1混合均匀,然后将Si/Al混合粉分别在压制压力为120,300,480,600,720,900,1080,1200 MPa时压制成型。将压坯置于高纯Ar气保护下烧结,烧结温度为700℃和1000 ℃,烧结时间为2 h。

粉末冶金烧结样加工成10 mm×5 mm(直径×长)的圆柱体,用JR-2热物性测试仪测定材料在常温下的热扩散率,并计算出材料在常温下的热导率;用阿基米德排水法测定材料的密度;用MET-1型金相显微镜和KYKY-2800型扫描电镜观察材料的显微组织;用TC-436氮氧仪测定原始硅粉表面的含氧量。

2 结果与分析

2.1 压制压力对烧结体密度的影响

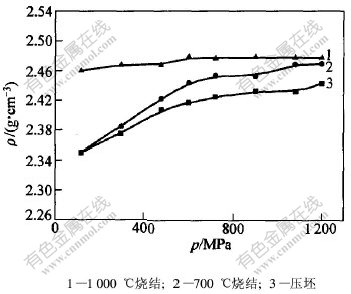

Si-Al复合材料烧结体密度随压制压力变化的关系如图1所示。由图1可见,在不同的烧结温度下,曲线出现了2种不同的变化规律:在700 ℃低温液相烧结时,烧结体密度随压制压力的变化与压坯密度随压制压力的变化趋势相一致,压制压力增大,密度增加,初始阶段增加较快,随后明显变缓;在1000 ℃高温液相烧结时,烧结体密度均较高,且密度随压制压力的增大变化不大。

图 1 Si-Al复合材料烧结体密度ρ与

压制压力p的关系

Fig. 1 Relationship between density of Si-Al composites and pressure

压坯密度取决于压坯内部孔隙度。随压制压力增大,孔隙减少,密度增加,当压制压力达到一定程度后,由于压坯内孔隙数量变化不大,密度逐渐趋于稳定。

烧结后密度的提高主要归功于液铝对孔隙的润湿和固体Si颗粒的重排。低温液相烧结时,由于Al液粘度大且与Si颗粒之间的润湿性很差,液相的流动对孔隙的填充作用有限,颗粒重排进行得不够充分,致密化程度不高,烧结体的密度相对于压坯密度稍有提高但提高幅度不太大。此时,压制压力是影响烧结体密度的主要控制因素。而高温液相烧结时,Si颗粒重排以及Al液对Si颗粒间孔隙浸润等致密化过程都能够充分进行,因此,在液相体积分数相同时,烧结体致密化程度基本一致,均高于低温烧结后的密度。此时,压制压力对烧结体密度的影响减弱,颗粒重排和润湿过程成为影响烧结体密度的主要控制因素。

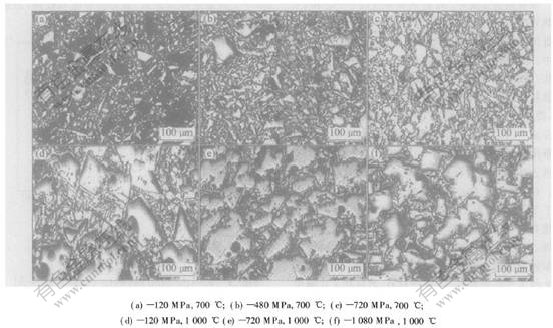

不同压制压力下Si-Al复合材料烧结体的显微组织如图2所示。从图2可见,低温(700 ℃)烧结时,随着压制压力的增大,材料内部的孔隙明显减少,Si颗粒堆积更加紧密。高温(1000 ℃)烧结时,Si颗粒发生了明显的烧结长大,但在不同压制压力下的微观组织形貌基本相似,内部的孔隙数量较少,Si颗粒均匀分布于Al基体中,Al基体形成连通致密的网状形态。考虑到孔隙度对材料密度的影响,这样的组织形貌与图1所示密度随压制压力变化的趋势相符。

图 2 不同压制压力下Si-Al复合材料烧结体的金相组织(腐蚀后)

Fig. 2 Micrographs of Si-Al composites with different pressures

2.2 压制压力对烧结体热导性能的影响

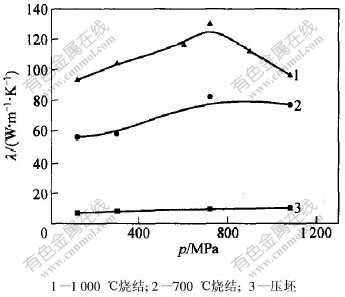

Si-Al复合材料热导率与压制压力变化的关系如图3所示。由图3可见,烧结体的热导率随着压制压力的增大而提高,在720 MPa左右达到峰值,随后热导率下降。

图 3 Si-Al复合材料热导率λ与压制压力p的关系

Fig. 3 Relationship between thermal conductivity of Si-Al composites and pressure

孔隙内气体的导热能力极弱,且孔隙的存在严重破坏了铝基体的连通分布,因此,降低烧结体内部的孔隙、提高其致密度对提高材料的热导是十分有利的。当压制压力低于720 MPa时,低温(700 ℃)烧结体的热导性能随压制压力的增大而提高,其变化规律与图1和图2(a)~2(c)所示烧结体密度以及铝相连通性随压制压力的变化趋势基本一致。这表明低温液相烧结Si/Al时,材料热导性能的提高主要是由于烧结体内孔隙度的大幅度降低。而从图1、图2(d)~2(f)可见:随着压制压力增大,高温(1000 ℃)下烧结体的密度和微观组织形貌均未发生明显变化,但热导率却出现了一个明显的峰值。在高体积分数增强相成分一定的前提下,复合体的热导性能取决于复合材料的孔隙度、微观组织形貌以及基体/增强相的界面结合状态[5]。因此,高温烧结时,热导率随压制压力上升的主要原因是Si/Al界面结合状态的改善,有效地降低了界面热阻。

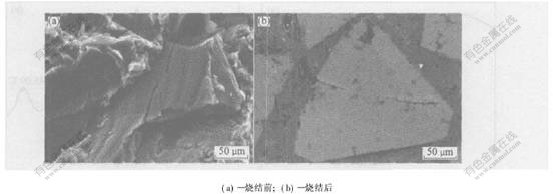

当压制压力超过720 MPa后, 脆性Si粉内部会出现很多的微裂纹、缺陷, 甚至颗粒已经发生解理、破碎(如图4(a)所示), 这就导致Si粉内的晶格结构受到严重的破坏。高压力下产生的这些大量裂纹缺陷即使在1000 ℃烧结的过程中也不能得到完全恢复(如图4(b)所示), 新的解理面增强了对声子和自由电子的散射, 致使界面热阻增加的效应明显大于由于密度提高或界面结合状态改善而引起的热导率提高的效应, 因而,总体上使热导率没有升高,反而降低。

2.3 高压制压力诱发Si-Al体系反应润湿的机理

根据热力学规律,Si在空气中极易氧化,表面形成一薄层SiO2膜层。实验用Si粉表面的含氧量测试值为0.23%,假设粉末为球形,估算的表面SiO2薄膜层厚度约为 5 nm。

图 4 高压制压力下Si粉产生的裂纹

Fig. 4 Microcracks in Si particles under high pressure

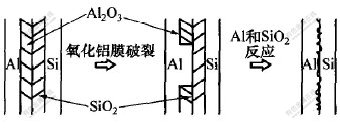

Si粉表面这层紧密、连续、稳定的玻璃状SiO2薄膜阻止了Al基体与Si颗粒之间的直接接触,而Al也是易氧化的金属,真空度即使为目前能够达到的最高真空度,其环境中氧的残余分压也不会低于1×10-9 Pa,远远高于Al熔点温度时Al2O3的分解压力(1×10-48 Pa)[6],在现有的实验条件下要完全避免Al的氧化是不可能的,还必须考虑到铝液表面氧化铝薄膜的作用。因此,Si-Al体系的界面结构为:Si/SiO2/Al2O3/Al,其界面反应示意图如图5所示。

图 5 Si-Al体系界面反应示意图

Fig. 5 Schematic diagram of interfacial reactions of Si-Al system

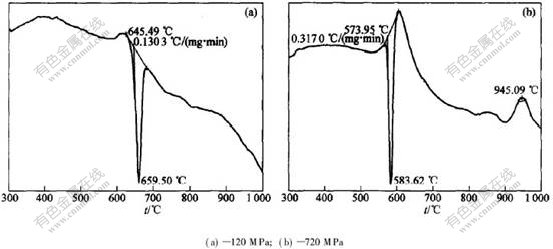

不同压力压坯试样的差热分析(DTA)曲线如图6所示。小压力(120 MPa)压坯试样的差热曲线中仅在659.50 ℃出现1个吸热峰,与纯铝的熔化吸热过程相一致,而大压力(>720 MPa)压坯试样的差热曲线则在945 ℃附近有1个较小的放热峰,这表明:高的压制压力导致Si-Al体系在945 ℃附近发生了明显的化学反应。根据界面反应体系润湿理论,化学反应一旦发生,系统自由能的降低程度比单纯的界面吸附造成的自由能降低程度要大得多,因而界面张力降低,接触角减小,Si-Al体系的润湿性必然得到改善。同时,反应使界面从机械结合转变为反应结合,加强了界面结合力,改善了材料性能。这与压制压力对材料性能的影响结果相一致。

马晓春等通过研究陶瓷/Al体系认为[7-9],在900~1000 ℃高温下Al表面的氧化膜发生破裂。V. LAURENT等通过研究得到SiO2-Al体系接触角的变化规律[10]:随着烧结温度逐步升高, SiO2与液Al间的接触角在前70 min始终为150°,体系非浸润,而当温度到达1073 K,接触角开始急速下降到120°。这种变化主要是由于温度小于1073 K时,Al基体表面存在的氧化铝薄膜阻碍了液固两相的直接接触,而在1073 K温度附近,氧化铝薄膜破裂并逐渐消失,导致接触角大约降低至90°[10,11]。一般认为高温下氧化铝薄膜的破裂机理为:温度高于一定值时,铝和三氧化二铝发生气化反应,生成了气相产物Al2O[12-15]。

当氧化铝薄膜破裂后,新鲜Al液开始与Si颗粒表面的SiO2接触,由于形成铝氧化物的自由能比形成硅氧化物的自由能更负(对SiO2,ΔG298=-805.0 kJ/mol;对Al2O3,ΔG298=-1582.3 kJ/mol)[16],则可能发生Al与SiO2间的化学反应。

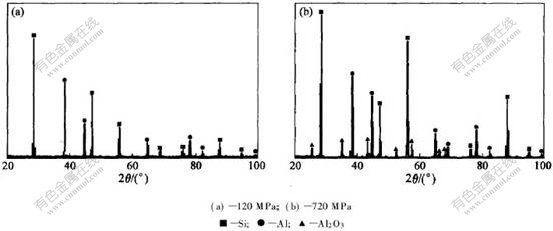

Si-Al烧结体XRD图谱如图7所示。 可见,经1000 ℃,120 MPa压制压力烧结的烧结样的物相组成为Al和Si, 无新的物相出现, Al和SiO2的界面反应没有发生。 而压制压力为720 MPa的烧结样新出现了少量的Al2O3, 是Al和SiO2的反应产物。

由图7可见,对高压制压力下的Si-Al体系,在其压坯试样的DTA曲线中,945 ℃附近的放热峰表征了如下2个反应过程:

Al氧化膜的破裂:

图 6 不同压力下压坯试样的DTA曲线

Fig. 6 DTA curves of different pressure compacts

图 7 不同状态下1000 ℃烧结样品的X射线物相分析

Fig. 7 XRD patterns of sintered samples at different pressures 4Al(l)+Al2O3(s)=3Al2O(g);(1)

Al/SiO2界面的适度反应:

4Al(l)+3SiO2(s)=2Al2O3(s)+3Si(s)。(2)

在945 ℃,Al表面氧化铝膜破裂,高压制压力效应促使了新鲜Al液和SiO2的反应发生。只有当体系热、动力学条件都满足,反应式(1)和反应式(2)同时发生时,这种明显的放热反应及其所导致的润湿转变才会出现。温度条件满足即可引起反应式(1)发生,因此,在此润湿转变中,高压制压力下的反应式(2)起到了更关键的作用。Al/SiO2界面反应的适度进行,可有效地降低界面热阻,从而提高界面的热导性能。

增大压制压力能够促进界面反应(2)发生,这是外加机械力造成粉末表面缺陷富集,活性提高的结果。吴音等的研究结果表明[17],外冲击力预处理过的AlN粉末,表面会产生大量缺陷,原子组态发生改变,从而导致能量提高,活性增强,促进了烧结进行。在Si/Al体系中,当压制压力增大到一定程度后,Si颗粒表面的SiO2层也将产生大量缺陷,新增富集的缺陷提供了界面处额外的缺陷能,在其后的烧结过程中,缺陷能释放,促进了烧结以及界面反应的发生,从而改善了Si/Al界面的结合状况,使Si/Al界面形成适当的冶金结合形态,与小压力烧结所形成的机械结合界面、润湿非扩散结合界面等界面形态相比,能更有效地降低界面对电子和声子的散射,大幅度降低界面热阻[18],起到提高材料热导率的作用。但压力更高时,会导致Si颗粒解理、破碎,从而使材料热导率降低。

3 结 论

a. 低温液相烧结时,烧结体密度随压制压力的增大而呈上升趋势,初始阶段上升较快,随后减缓,压制压力是烧结体密度的控制因素。高温液相烧结时,由于体系润湿性的提高,烧结体的密度明显高于低温液相烧结体的密度,且随压制压力的变化不明显,压制压力不再是控制烧结体密度的主要因素。

b. 低温烧结时,随着压制压力的增大,烧结体内部的孔隙明显减少,Si颗粒堆积更加紧密。高温烧结时,Si颗粒发生了烧结长大,但内部的孔隙数量都较少,压制压力对烧结体微观组织形貌影响不大。

c. 增大压制压力可导致Si-Al体系的适度反应润湿过程,从而有效地提高烧结体的热导性。但压制压力过大时,会使脆性Si粉内出现大量的微裂纹,甚至发生解理,造成大量新的界面出现,使界面热阻急剧上升,降低材料导热性能。

d. Si-Al体系在945 ℃附近会发生Al表面致密Al2O3薄膜的破裂,而高压制压力所导致的界面储能可促进新鲜Al液与Si颗粒表层的SiO2界面放热反应。反应使体系润湿性大幅度提高,改善了材料的界面结合方式,最终提高热导性能。

参考文献:

[1]黄强, 顾明元, 金燕萍. 电子封装材料的研究现状[J]. 材料导报,2000, 14(9): 28-32.

HUANG Qiang, GU Ming-yuan, JIN Yan-ping. Current Status of Research on Electronic Packaging Materials[J]. Materials Review, 2000, 14(9): 28-32.

[2]JACOBSON D M. Lightweight Electronic Packaging Technology Based on Spray Formed Si-Al[J]. Powder Metallurgy, 2000, 43(3): 200-202.

[3]SANGHA S P S, JACOBSON D M, OGILVY A J W, et al. Novel Aluminum-Silicon Alloys for Electronic Packaging[J]. Engineering Science and Education Journal, 1997, 6(5): 195-201.

[4]CHIEN C W, LEE S L, LIN J C, et al. Effects of Sip Size and Volume Fraction on Properties of Al/Sip Composites[J]. Materials Letters, 2002, 52(4-5): 334-341.

[5]RANDALL M. A Model for the Thermal Properties of Liquid-phase Sintered Composites[J]. Metallurgical Transactions A, 1993, 24:1745-1752.

[6]GARCIA-CORDOVILLA C, LOUIS E, NARCISO J. Pressure Infiltration of Packed Ceramic Particulates by Liquid Metals[J]. Acta Materialia, 1999,47(18):4461-4479.

[7]马晓春,吴锦波. Al-SiC系润湿性与界面现象的研究[J].材料科学与工程,1994,1(12): 37-41.

MA Xiao-chun, WU Jing-bo. An Investigation on Wettability and Interfacial Phenomena of Al-SiC System[J]. Materials Science and Engineering, 1994,1 (12) :37-41.

[8]HASHIM J. The Wettability of SiC Particles by Molten Aluminium Alloy[J]. Journal of Materials Processing Technology, 2001, 119(1-3):324-328.

[9]ZHANG X. Powder Metal Matrix Composites[J]. Materials Science and Engineering A, 1998, 244(1):80-85.

[10]LAURENT V, CHATAIN D, EUSTATHOPOULOS N. Wettability of SiO2 and Oxidized SiC by Aluminum[J]. Materials Science and Engineering A, 1991, 135(1-2): 89-94.

[11]LEE Jae-chul, AHN Jae-pyoung, SHI Zhong-liang, et al. Modification of the Interface in SiC/Al Composites[J]. Metallurgical and Materials Transactions A, 2000, 31 (9): 2361-2368.

[12]HASHIM J. The Enhancement of Wettability of SiC Particles in Cast Aluminium Matrix Composites[J]. Journal of Materials Processing Technology, 2001, 119(1-3): 329-335.

[13]MOLINA J M, SARAVANAN R A, ARPORON R, et al. Pressure Infiltration of Liquid Aluminium into Packed SiC Particulate with a Bimodal Size Distribution[J]. Acta Materialia, 2002, 50(2): 247-257.

[14]DELANNAY F, FROYEN L, DERUYTTERE A. Review the Wetting of Solids by Molten Metals and Its Relation to the Preparation of Metal-matrix Composites[J]. Journal of Materials Science, 1987,22:1-16.

[15]张雄飞,王达健,陈书荣,等. 液态铝与陶瓷的润湿性改变机理[J]. 粉末冶金技术,2003,21(1):42-45.

ZHANG Xiong-fei, WANG Da-jian, CHEN Shu-rong, et al. Mechanism of Wettability between Ceramics and Liquid Aluminum[J].Powder Metallurgy Technology, 2003,21(1):42-45.

[16]LEE J C, BYUN J Y, OH C S, et al. Effect of Various Processing Methods on the Interfacial Reactions in SiCp/2024 Al Composites[J].Acta Materialia,1997,45:5303-5315.

[17]吴音,周和平,廖卫国. 冲击波处理的AlN粉体的低温烧结特性[J]. 无机材料学报,1998,13(2):229-233.

WU Yin, ZHOU He-ping, LIA Wei-guo. Characteristics of Low-temperature Sintering of Shocked Aluminium Nitride Powder[J].Journal of Inorganic Materials, 1998,13(2):229-233.

[18]陈治明,王建农. 半导体器件中的材料物理学基础[M]. 北京:科学出版社,1999.

CHEN Zhi-ming, WANG Jian-nong. Materials Pysics Based in Semiconductor Device[M]. Beijing: Science Press,1999.

收稿日期:2004-11-08

基金项目:国防科工委民口配套项目(MKPT-04-107)

作者简介:冯 曦(1979-),女,湖南醴陵人,硕士,从事功能复合材料研究

论文联系人: 李世晨,男,讲师;电话:0731-8830270(O);E-mail: s-maloy@mail.csu.edu.cn