Trans. Nonferrous Met. Soc. China 23(2013) 977-982

Influence of technical parameters on strength and ductility of AlSi9Cu3 alloys in squeeze casting

Shi-bo BIN, Shu-ming XING, long-mei TIAN, Ning ZHAO, Lan LI

School of Mechanical, Electronic and Control Engineering, Beijing Jiaotong University, Beijing 100044, China

Received 23 December 2011; accepted 17 February 2012

Abstract: An orthogonal test was conducted to investigate the influence of technical parameters of squeeze casting on the strength and ductility of AlSi9Cu3 alloys. The experimental results showed that when the forming pressure was higher than 65 MPa, the strength (σb) of AlSi9Cu3 alloys decreased with the forming pressure and pouring temperature increasing, whereas σb increased with the increase of filling velocity and mould preheating temperature. The ductility (δ) by alloy was improved by increasing the forming pressure and filling velocity, but decreased with pouring temperature increasing. When the mould preheating temperature increased, the ductility increased first, and then decreased. Under the optimized parameters of pouring temperature 730 °C, forming pressure 75 MPa, filling velocity 0.50 m/s, and mould preheating temperature 220 °C, the tensile strength, elongation, and hardness of AlSi9Cu3 alloys obtained in squeeze casting were improved by 16.7%, 9.1%, and 10.1%, respectively, as compared with those of sand castings.

Key words: squeeze casting; AlSi9Cu3 alloy; strength; ductility

1 Introduction

AlSi9Cu3 alloys, which are widely used in industry, are featured with superior machinability and castability [1-5]. On the metallographic structure of AlSi9Cu3 alloys shaped by traditional sand casting or permanent mold casting, there are needle-like eutectic silicons on the dendrite skeleton of α solid solution, and CuAl2 hard phase on the grain boundary. Both of them have negative effects on the alloy’s strength and ductility [6-9]. Squeeze casting can effectively improve the mechanical properties of castings [1,10,11] by enhancing the quantity of α solid solution phase, and refining and homogenizing the eutectic silicon, which has the same effects as the complex modification treatment. However, the changes of technical parameters such as pouring temperature, forming pressure, filling velocity, and mould preheating temperature in squeeze casting, confer varied effects on the alloy’s strength and ductility. It is known that the ductility tends to decrease or remains unchanged when the strength increases [12-14]. Hence, optimizing these parameters in squeeze casting to improve the alloys’ strength and ductility simultaneously is of substantial interest and a fundamental focus of this work.

2 Experimental

2.1 Orthogonal test design

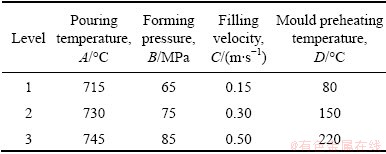

In order to explore the influence rules of technical parameters on the strength and ductility of AlSi9Cu3 alloys in squeeze casting, four main technical parameters, namely, pouring temperature, forming pressure, filling velocity, and mould preheating temperature, were taken into account as governing factors. Each parameter contains three levels. Accordingly, the tensile strength, elongation to failure, and hardness were targeted. The experiment was operated according to a L9(34) orthogonal array, as shown in Table 1.

2.2 Experimental methods and procedures

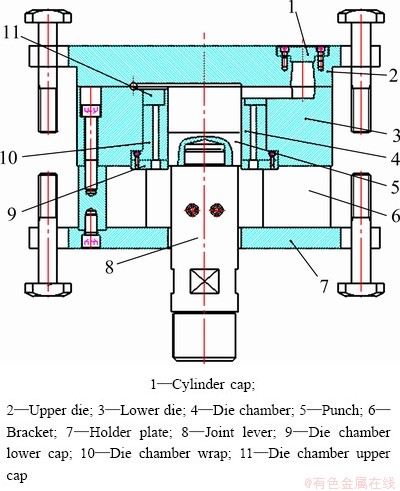

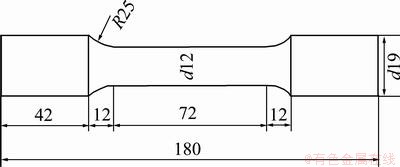

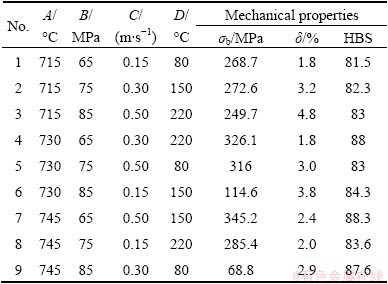

The chemical compositions of AlSi9Cu3 alloys which were used in this experiment are 3.0%-3.5% Cu, 11.0%-11.5% Si, 0.35%-0.40% Mg, 0.25%-0.30% Zn, 0.75%-0.80% Fe, 0.35%-0.40% Mn, and the balanced Al. The experimental apparatus is shown in Fig. 1. Firstly, the AlSi9Cu3 alloys were melted in electromagnetic induction furnace. Secondly, the molten metal was quickly poured into the metal pressure chamber, and flowed into cavity under an extra pressure offered by the liquid forging machine. Lastly, the AlSi9Cu3 alloys were shaped into tensile test samples with the outline dimension shown in Fig. 2. The above procedures were repeated by changing one of the governing factors while keeping the other parameters unchanged. The tensile test samples were solution treated at 535-540 °C for 2 h, quick water quenched at 60-80 °C, and aged at 165 °C for 4 h. The tensile strength and hardness were gained under DEW-30 universal testing machine and HB-3000 sclerometer, and the results are shown in Table 2, where each item is the mean value of three replicates. The microstructures of tensile test samples were observed on DM2000X optical microscope.

Table 1 Factor-level list in orthogonal test

Fig. 1 Schematic diagram of mould design

Fig. 2 Outline dimension of tensile test sample (unit: mm)

Table 2 Results of orthogonal test

3 Results

3.1 Influence of technical parameters on strength

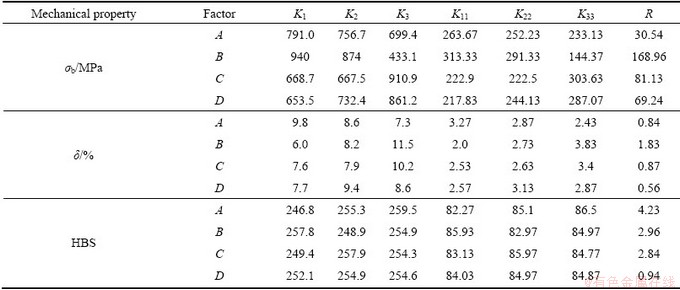

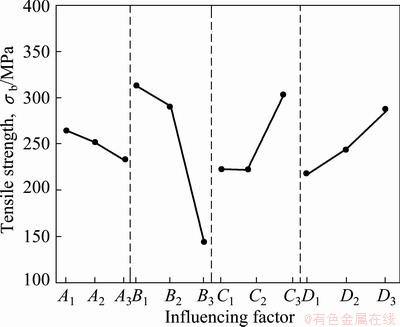

The range analysis results of the mechanical properties are shown in Table 3. According to the value of range (R) in Table 3, the effect of four factors A, B, C, and D on the tensile strength in sequence is B>C>D>A. It is clear that the effect of forming pressure on the strength is the most significant, which is twice as that of the filling velocity. However, the effect of pouring temperature on the strength is the weakest. All these indicate that the strength is mainly controlled by the forming pressure. The effects of technical parameters on σb are shown in Fig. 3. It is obvious that σb decreases with the increase of forming pressure and pouring temperature, and increases with the increase of filling velocity and mould preheating temperature.

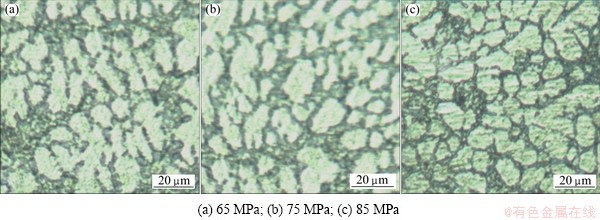

As known, pressure can change the equilibrium temperature according to solidification theory. The eutectic temperature of AlSi9Cu3 alloys increases and the region of α phase enlarges when AlSi9Cu3 alloys crystallize under an extra pressure. The microstructures of AlSi9Cu3 alloys under different forming pressures are shown in Fig. 4. It is obvious that the number of α phase (white) increases with the increase of forming pressure, but the number of α+Si eutecticum (black) decreases. The strength and hardness of α phase are lower than those of α+Si eutecticum, so σb decreases with the increase of α phase.

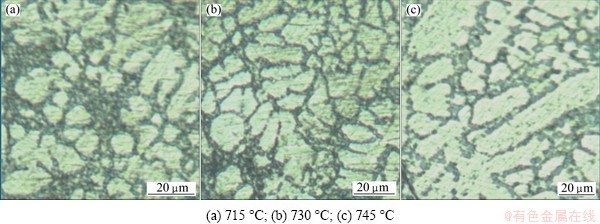

The microstructural evolution of AlSi9Cu3 at different pouring temperatures is shown in Fig. 5. There are gross dendrites with the increase of pouring temperature. The reason is that during the solidification of AlSi9Cu3 melt, superheat scattering time (t) can be gained according to the following formula [15]:

(1)

(1)

where TP is the pouring temperature, TM is the metal cavity temperature, and TL is the liquidus temperature. According to Eq. (1), t will increase with the increase of Tp, which will lead to the increase of solidification time, making the grain size of primary α phase increase, even grow into dendrites. So σb drops down with the increase of pouring temperature.

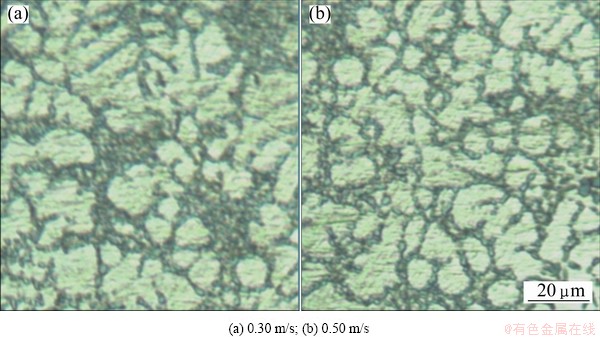

The microstructural evolution of AlSi9Cu3 at different filling velocities is shown in Fig. 6. It can be seen that the grain sizes of α phase and hard phase in Fig. 6(b) are smaller than those in Fig. 6(a). Moreover, the distribution of grain in Fig. 6(b) is more homo- geneous. This is because the higher shearing rate can be gained at the greater filling velocity, and the turbulence of AlSi9Cu3 melt will become stronger under higher shearing rate, which increases the probability of crash and friction among crystalline grains, making the primary α phase and hard phase spherical [1,16], thus, the strength and hardness will be improved with the increase of filling velocity.

Table 3 Range analysis results of mechanical properties

Fig. 3 Effect of factors on σb

3.2 Influence of technical parameters on ductility

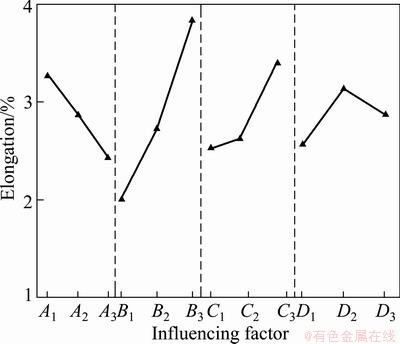

According to the value of R in Table 3, the effect of four factors A, B, C, and D on the ductility in sequence is B>C>A>D. Thereinto, the effect of forming pressure on ductility is much stronger than that of filling velocity, while the effects of filling velocity and pouring temperature are almost the same, and the effect of mould preheating temperature is the weakest. The effects of influencing factors on δ is shown in Fig. 7. It is clearly found that δ increases with the increase of forming pressure and filling velocity, decreases with the increase of pouring temperature, and first increases and then drops with the increase of mould preheating temperature.

The space between dendrites becomes small with the increase of forming pressure, even disappears in the end, as shown in Fig. 4. There are more fine grains and homogenous microstructures when the forming pressure increases. When AlSi9Cu3 melt crystallizes under an extra pressure, the nucleation rate (N) can be calculated by [17]

(2)

(2)

where a, b and c are the functions of temperature; p is the forming pressure. According to Eq. (2), N increases with the increase of forming pressure. So crystal nucleus grows up by reciprocal inhibition and grain refinement is achieved, which improves the ductility.

The influence rules of filling velocity and pouring temperature on δ are similar to those on σb, but δ drops more dramatically with the pouring temperature increasing, which illustrates that the effect of pouring temperature on δ is much stronger than that of σb. From the Al-Si binary phase diagram, it can be seen that the lower the pouring temperature when it exceeds liquidus, the easier to reach the supercooled state and to get the faster cooling velocity, which is good for α phase refining [18,19]. So δ decreases with the increase of pouring temperature.

Fig. 4 Microstructural evolution of AlSi9Cu3 at different forming pressures

Fig. 5 Microstructural evolution of AlSi9Cu3 at different pouring temperatures

Fig. 6 Microstructural evolution of AlSi9Cu3 at different filling velocities

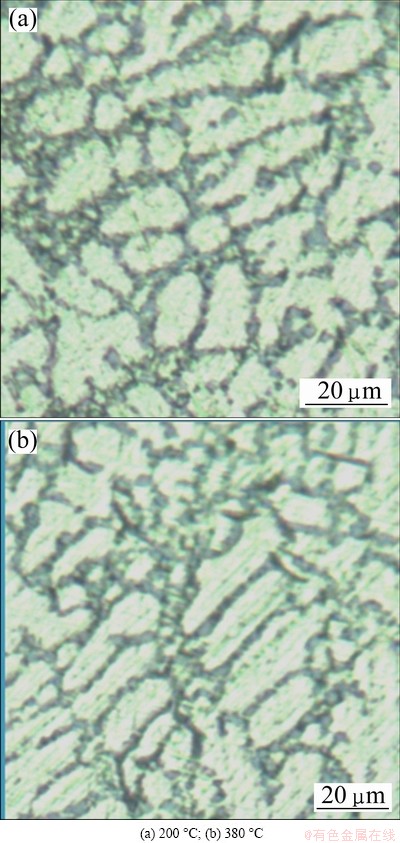

The microstructural evolution of AlSi9Cu3 at different mould preheating temperatures are shown in Fig. 8. It can be found that there are coarse grains and dendrites as the mould preheating temperature exceeds 200 °C. This is because when the mould preheating temperature arrives at a particular point, there is a large amount of superheat coming from AlSi9Cu3 melt [20], causing the primary crystal nucleus to develop gradually into columnar dendrites, which reduces the ductility.

3.3 Optimal parameters for strength and ductility

It can be seen from Fig. 3 that the maximum value of σb can be obtained in the combination of A1B1C3D3. That’s to say, it’s possible to gain the optimum value of σb when the pouring temperature is 715 °C, forming pressure is 65 MPa, filling velocity is 0.50 m/s, and mould preheating temperature is 220 °C. According to Fig. 7, the maximum value of δ can be achieved in the combination of A1B3C3D2. At this point, the pouring temperature is 715 °C, forming pressure is 85 MPa, filling velocity is 0.50 m/s, and mould preheating

temperature is 150 °C. It’s possible to achieve the harmony between the strength and ductility by coordinating the factors according to the value of R in Table 3. 1) Both σb and δ decrease with the increase of A, so the smaller the A, the better the σb and δ. But A is the fourth subordinate influence factor to σb and the third to δ, which means that the effects of A on σb and δ are not significant. On the other hand, there is a necessary allowance of pouring temperature for castings’ excellent forming quality, therefore, A2 is selected but not A1. 2) B is the main influence factor on σb and δ. σb decreases with the increase of B, while δ behaves on the contrary. So the smaller the B, the better the σb, and the bigger the B, the better for δ. It’s clear that σb changes more gently with B, which means that the effect of B on σb is less significant. So B2 should be prioritized for the coordination between the strength and ductility. 3) Both σb and δ present an increasing tendency towards factor C, so C3 is selected. 4) The maximum value of σb can be realized according to D3, and the effect of D3 on δ is almost the same as that of D2. Hence, for the coordination between the strength and ductility, D3 is selected.

Fig. 7 Effect of influencing factors on δ

Fig. 8 Microstructural evolutions of AlSi9Cu3 at different mould preheating temperatures

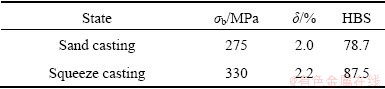

According to the above analyses, the combination of A2B2C3D3, with the pouring temperature of 730 °C, forming pressure of 75 MPa, filling velocity of 0.50 m/s, and mould preheating temperature of 220 °C, can compatibly improve the strength and ductility of AlSi9Cu3 alloys in squeeze casting. The mechanical properties can be improved by 9%-17% compared with the traditional sand casting, as shown in Table 4.

Table 4 Mechanical properties of AlSi9Cu3 alloy

4 Conclusions

1) The effect of technical parameters considered in this experiment on the tensile strength (σb) in sequence is forming pressure (B) > filling velocity (C) > mould preheating temperature (D) > pouring temperature (A). Under the condition of forming pressure > 65 MPa, the strength of AlSi9Cu3 alloys (σb) decreases with the increase of forming pressure and pouring temperature, whereas σb increases with the increase of filling velocity and mould preheating temperature.

2) The effect of technical parameters considered in this experiment on the ductility (δ) in sequence is forming pressure (B) > filling velocity (C) > pouring temperature (A) > mould preheating temperature (D). The ductility is improved by increasing the forming pressure and filling velocity, but decreases at higher pouring temperature. When the mould preheating temperature increases, the ductility increases firstly, and then decreases.

3) In the combination of optimized parameters in squeeze casting, the tensile strength is improved by 16.7%, elongation is improved by 9.1%, and hardness is improved by 10.1% respectively, as compared with those of the sand casting.

References

[1] LUO Shou-jing, CHEN Bing-guang, QI Pi-xiang. Squeeze casting and squeeze casting technology [M]. Beijing: Chemical Industry Press, 2006. (in Chinese)

[2] ZHANG Ke-wu, ZHAO Hai-dong, OUYANG Xiao-xian, ZHANG Wei-wen, LI Yuan-yuan. Microstructures and mechanical properties of Al-Si-Cu-T4 solidified at different squeeze pressures [J]. The Chinese JournaI of Nonferrous Metals, 2009, 19(4): 625-631. (in Chinese)

[3] ZEREN M. Effect of copper and silicon content on mechanical properties in Al-Cu-Si-Mg alloys [J]. Journal of Materials Processing Technology, 2005, 169: 292-298.

[4] PUCHER P, ANTREKOWITSCH H,  H, KAUFMANN H, UGGOWITZER P J. Influence of compositional variations on microstructural evolution, mechanical properties and fluidity of secondary foundry alloy AlSi9Cu3 [J]. International Journal of Cast Metals Research, 23(6): 375-383.

H, KAUFMANN H, UGGOWITZER P J. Influence of compositional variations on microstructural evolution, mechanical properties and fluidity of secondary foundry alloy AlSi9Cu3 [J]. International Journal of Cast Metals Research, 23(6): 375-383.

[5] PUGA H, COSTA S, BARBOSA J, RIBEIRO S, PROKIC M. Influence of ultrasonic melt treatment on microstructure and mechanical properties of AlSi9Cu3 alloy [J]. Journal of Materials Processing Technology, 2011, 211: 1729-1735.

[6] IBRAHIM M F, SAMUEL E, SAMUEL A M, AL-AHMARI A M A, SAMUEL F H. Effect toughness and fractography of Al-Si-Cu-Mg base alloys [J]. Materials and Design, 2011, 32: 3900-3910.

[7] JIANG Ju-fu, LUO Shou-jing, WANG Ying. Interface of components with large ratio of altitude to diameter formed by laminated pouring and accumulated liquid forging technology [J]. Transactions of Nonferrous Metals Society of China, 2003, 13(6): 1306-1310.

[8] LEE C D. Variability in the tensile properties of squeeze-cast Al-Si-Cu-Mg alloy [J]. Materials Science and Engineering A, 2008, 488: 296-302.

[9] YAN Hong-jiang. Effect of FeSiAl intermetallic compounds of the die-cast aluminum alloy on the mechanical properties [J]. Test Technology and Testing Machine, 2006(1): 29-30. (in Chinese)

[10] FANG Min, YANG Zhi, QU Ju-xin, ZHANG Wei-qiang. Effect of technological parameters on microstructure and mechanical properties of ZL102 alloys in liquid forging technology [J]. Journal of Plasticity Engineering, 2007, 14(5): 83-86. (in Chinese)

[11] FANG Min, WANG Tie-jun. Studying of liquid forging process for ZL102 alloys [J]. Hot Working Technology, 2008, 37(9): 52-56. (in Chinese)

[12] GROSSELLE F, TIMELLI G, BONOLLO F. Doe applied to microstructural and mechanical properties of Al-Si-Cu-Mg casting alloys for automotive applications [J]. Materials Science and Engineering A, 2010, 527: 3536-3545.

[13] GUO Hong-min, LIU Xu-bo, YANG Xiang-jie, ZHANG Ai-sheng, LIU Yong. Microstructure evolution behavior of AlSi9Cu3 alloy during rheocasting [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s815-s820.

[14] WANG Yong-xin, LU Ru-hui. Technology for improving the yield strength of AlSi9Cu3(Fe) alloys [J]. Foundry Technology, 2008, 10: 1429-1430.

[15] LI Xiang-wei, CHEN Ti-jun, HAO Yuan, ZHANG Da-hua, LIU Er-yong, WANG Rui-quan. Effect of pouring temperature on dendrite morphologies of ZA27 alloy [J]. China Foundry, 2010, 59(7): 704-707. (in Chinese)

[16] TSOUKALAS V D. Optimization of porosity formation in AlSi9Cu3 pressure die castings using genetic algorithm analysis [J]. Materials and Design, 2008, 29: 2027-2033.

[17] ZHAO Zu-de. Solid-Liquid forming theory and technology of composites [M]. Beijing: Metallurgical Industry Press, 2008. (in Chinese)

[18] PUGA H, BARBOSA J, SEABRA E, RIBEIRO S, PROKIC M. The influence of processing parameters on the ultrasonic degassing of molten AlSi9Cu3 aluminium alloy [J]. Materials Letters, 2009, 63: 806-808.

[19] YE Miao. Studying on improving the machinability of AlSi9Cu3 alloys castings [D]. Shanghai: Shanghai Jiao Tong University, 2008. (in Chinese)

[20] GAO Ping-ping, CHEN Gang, FAN Cai-he, HUANG Zai-gao. Effect of squeeze casting die temperature and pressure on microstructure and properties of 2024 aluminium alloy [J]. Hot Working Technology, 2009, 38(21): 64-67. (in Chinese).

液态模锻工艺参数对AlSi9Cu3强度和塑性的影响

宾仕博,邢书明,田龙梅,赵 宁,李 兰

北京交通大学 机械与电子控制工程学院,北京 100044

摘 要:采用正交试验研究浇注温度、液锻压力、充型速度和模具预热温度等液态模锻工艺参数对AlSi9Cu3铝合金强度和塑性的影响。结果表明,当成形压力超过65 MPa以后,抗拉强度σb随液锻压力和浇注温度的增大而下降,随充型速度和模具预热温度的增大而增加;伸长率δ随液锻压力和充型速度的增大而增加,随浇注温度的增大而下降,随模具预热温度的增大先增大后减小。当浇注温度为730 °C、液锻压力为75 MPa、充型速度为0.50 m/s、模具预热温度为220 °C时,与砂型铸造合金相比,液锻AlSi9Cu3合金的抗拉强度提高16.7%、延长率提高9.1%、硬度提高10.1%。

关键词:液态模锻;AlSi9Cu3合金;强度;塑性

(Edited by Sai-qian YUAN)

Foundation item: Project (11C26211304055) supported by Small to Medium Enterprise Innovation Fund

Corresponding author: Shu-ming XING; Tel: +86-10-51682036; E-mail: smxing@bjtu.edu.cn

DOI: 10.1016/S1003-6326(13)62555-8