DOI:10.11817/j.ysxb.1004.0609.2020-35698

基于正交试验的液态模锻Al-Sn-Cu轴套中Sn的宏观偏析

许 明1,尹延国1,李聪敏1,段聪翀2,丁曙光1

(1. 合肥工业大学 机械工程学院 摩擦学研究所,合肥 230002;

2. 合肥熠辉轻合金科技有限公司,合肥 230088)

摘 要:采用正交试验法分析了液态模锻Al-Sn-Cu轴套中Sn的宏观偏析规律。结果表明:液态模锻Al-Sn-Cu轴套不可避免的产生Sn的宏观偏析,铸件中同时存在着正偏析和逆偏析,正偏析出现在浇铸中心的近端,逆偏析主要存在于浇铸中心的远端;铸件凝固后期,低熔点液相被强制挤压至热节位置,形成粗晶区和细晶区相间的双峰组织,细晶区Sn的质量分数明显较高。液态模锻工艺参数对铸件宏观偏析产生较大影响,对Sn偏析影响由大到小依次是浇注温度、模具温度、保压时间及比压;本次实验条件下,当浇注温度为700 ℃,模具温度为240 ℃,比压为80 MPa,保压时间为5 s时,轴套铸件中Sn元素分布较均匀,Sn元素的宏观偏析得到减轻。

关键词:正交试验法;液态模锻;Al-Sn-Cu;双峰组织;宏观偏析

文章编号:1004-0609(2020)-01-0078-10 中图分类号:TG146.2;TG249.2 文献标志码:A

20世纪30年代,液态模锻工艺被前苏联学者研究出来并应用于工业生产,经过多年的发展和完善,液态模锻工艺已经广泛应用于高质量铸件的生产。液态模锻工艺集合了铸造和锻造两种工艺的优点,生产的铸件性能优越,成品率和材料利用率高,缺陷少,可实现近净成形。

铝铜合金作为高强铸造铝合金,被广泛应用于轴套铸件的生产,但其铸造性能较差,铸件容易产生裂纹和疏松等缺陷,对轴套铸件质量产生严重影响;同时,轴套铸件作为一种摩擦副零件,其对减摩性能提出了较高的要求。采用液态模锻工艺可以避免裂纹和疏松等缺陷的发生,提高铸件性能;同时,在轴套铸件中添加低熔点元素Sn可以实现轴套铸件减摩的目的。由于Sn元素在铝铜合金中的不混溶性,虽然采用液态模锻工艺可以避免缺陷、提高铸件性能,但在合金中仍不可避免的会出现Sn的偏析现象。针对Sn的偏析问题及其均匀化的控制方法已有学者开展了相关研究,如搅拌熔铸法[1]、快速凝固法[2-3]、气相沉积法[4]、电沉积法[5]、大塑性变形法[6]、机械合金化[7]、添加合金元素[2, 8-9]、密集的熔体剪切法[10]等。针对液态模锻工艺对铝合金中的元素偏析问题也有较多研究,如HONG等[11-12]研究了Al-4.5Cu合金液态模锻零件中的通道偏析、中心线偏析、V型偏析、微区偏析等的形成机理[11],就液态模锻不同工艺参数对Al-Cu合金收缩缺陷和宏观偏析的作用做了总结[12];GALLEMEAULT等[13]对液态模锻工艺中比压、浇注温度、模具预热以及晶粒细化剂对Al-4.5Cu合金冷却、凝固行为的作用进行了研究,对液态模锻工艺参数对合金铸件中组织偏析的影响进行了分析;甘耀强等[14]对Al5Cu0.4Mn合金宏观偏析进行了研究,利用正交试验法分析了液态模锻工艺参数对Cu元素偏析的影响;郭莉军等[15-16]研究了间接液态模锻工艺参数对Si偏析的影响,发现浇注温度是影响硅偏析的主要原因,同时采用螺旋线试样研究了流程长度对合金成分偏析及组织偏聚的影响。总体来讲,关于液态模锻偏析问题的研究主要集中在对溶质元素Cu、Si等在液态模锻工艺参数下的影响,而Sn作为一种非溶质元素,其在液态模锻工艺条件下的宏观偏析现象及规律的研究还未见报道。

本文探讨液态模锻轴套铸件中非溶质元素Sn在铝铜合金中的分布规律,并通过正交试验法研究液态模锻工艺参数对Sn宏观偏析的影响,以达到减轻Sn的宏观偏析,为轴套铸件液态模锻工艺生产提供技术参考。

1 实验

1.1 实验材料

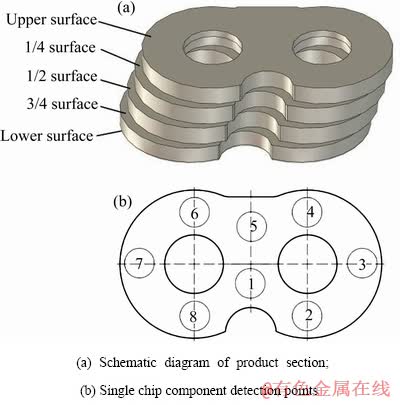

实验材料主要成分为Sn,Cu,其余为Al,具体配方如表1所示。采用碳化硅坩埚炉在井式电阻炉中熔炼,精炼除气后,启动机械手舀取定量的铝液,将铝液沿着模具中心位置浇入,在不同参数下成形“8”字形轴套试样,本次实验为了紧密结合生产实际情况,选择了一次压制成型3只铸件的模具,成型的样件如图1所示。经光谱成分分析,各铸锭平均成分含量不尽相同,且含有极少的Fe(质量分数,<0.2%)及其他不可避免的微杂质。

表1 实验材料主要成分及其质量分数

Table 1 Main components and their mass fraction of experimental materials (mass fraction, %)

图1 液态模锻工艺铸件示意图

Fig. 1 Liquid die forging product schematic diagram (Unit: mm)

1.2 取样分析及检测

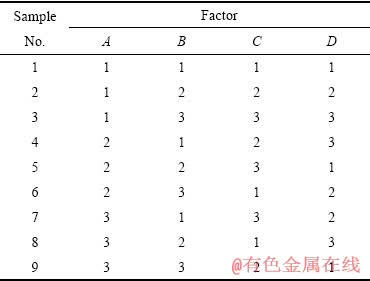

采用工业用雕刻机将产品的多余部分去除,采用线切割工艺将单个轴套样件进行切片处理,并标记为上表面(Upper surface)、1/4表面(1/4 surface)、1/2表面(1/2 surface)、3/4表面(3/4 surface)、下表面(Lower surface),如图2(a)所示,经过表面的抛光处理后,采用德国SPECTRO直读光谱仪对每片铸件进行成分检测,检测位置编号为点1~8,如图2(b)所示。根据需要每个检测位置可分别抛光、腐蚀,通过Leica DMI5000M卧式金相显微镜观察金相组织;结合JSM-6490LV环境扫描电子显微镜(SEM)对合金第二相进行分析,利用其自带的INCA能谱仪(EDS)测试合金相区成分。

图2 检测试样的取样及成分检测位置示意图

Fig. 2 Schematic diagram of sample sampling and component testing location

1.3 正交实验方法

正交实验方法作为一种铸件质量分析方法,在研究材料成型工艺参数时,可以大大简化实验过程,提高材料制备效率[17-18]。正交表和信噪比(S/N)作为其重要的分析工具,能够全面的反应各因素水平对指标影响的程度和衡量铸件质量的稳健性,从而节省了大量实验过程,有益于找到性能稳定的最佳技术参数,提高铸件质量[19]。

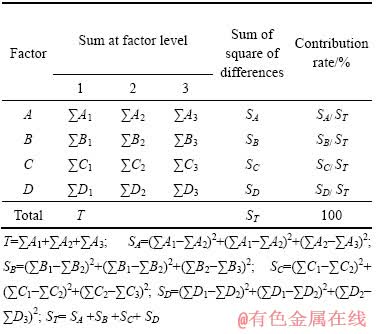

首先进行液态模锻工艺正交实验,探讨比压P、浇注温度Tp、模具温度Td、保压时间td对液态模锻轴套材料中Sn元素的分布以及组织的影响,表 2所列为正交因素水平表,表3所列为液态模锻正交试验表。其次,利用望小特性的信噪比S/N(dB),计算不同液态模锻工艺参数下轴套试样不同部位Sn含量与平均含量的方差;若信噪比越大,则说明在该条件下Sn元素的宏观偏析较小。最后,结合帕雷托方差分析综合评判液态模锻参数对Sn元素偏析的影响程度,表4所列为帕雷托方差分析表格[17]。

表2 液态模锻因素水平表

Table 2 Control factors and levels for liquid die forging

表3 液态模锻正交实验表

Table 3 Orthogonal experimental table of liquid die forging

表4 三水平因素帕雷托方差分析表[17]

Table 4 Pareto ANOVA for three level factors[17]

2 结果与分析

2.1 铸件的宏观偏析

为了准确、清晰地反应铸件中Sn的分布情况,对9组铸件分别按图2所示检测位置进行成分检测。图3所示是上表面、1/4表面、1/2表面、3/4表面、下表面5层的点1~8 处Sn质量分数取均值对比分析的结果。从图3中可以看出,9组铸件均在点1和点5处 Sn的质量分数相对较高,而在点3和点7处相对较低,Sn的分布不均匀,存在明晰的偏析现象。根据模具结构特点,就单只检测铸件而言,点1和点5处由于距离浇铸中心较近且壁厚尺寸较大,属于近端热节区域,其中点5离热节最近,冷却速度慢,最迟凝固;点3和点7处由于距离浇铸中心最远且壁厚尺寸较小,冷却速度快,属于远端最先凝固区域,如图1所示。图3的分析结果表明,大部分铸件热节处Sn质量分数较高,先凝固区域Sn含量较低,即产生了Sn的正偏析。

由图1所示,铝液由浇铸中心浇注到压室内,远端最后充型,铝液经过压室的冷却作用,最后充型时温度已相对较低;合模之前,远端模壁处的铝液就开始凝固,合模后压力作用下促使铸件与模壁紧密结合,使得铸件与模壁间的热传导效率提升,冷却速度进一步加大,远端铸件凝固速度相对较快。由于Al-Sn合金为典型的二元互不相溶体系,液态时互溶而固态时几乎互不溶合,而且Al、Sn之间的熔点相差较大,分别为Al(660.45 ℃)、Sn(231.96 ℃),因此,Al合金凝固时,合金中的低熔点Sn被不断排出、富集,并与未凝固液态合金融合,低熔点Sn被不断排出、富集、再融合、再排出,并逐渐向铸件中温度较高的区域趋附、偏聚,即远端凝固较快区域被不断排出的Sn逐渐向近端热节处趋附、聚集;液态模锻压力的作用,会增加剩余液相流动、融合与趋附的速度,使得凝固之前近端剩余液相中Sn质量分数较高;所以最终凝固后近端热节位置Sn的质量分数较高,有明显的正偏析特征。

图3 正交实验铸件各检测位置点Sn质量分数均值

Fig. 3 Mean Sn mass fraction at each test point of orthogonal experimental casting

当浇铸温度较低时,充型至远端的过程中使得铝液温度降低,在上模合模前,远端几乎已近处于凝固状态,先凝固的铝合金将Sn不断排出,并向近端高温区域不断的趋附、富集,致使远端与近端Sn质量分数差距较大,如图3(a)、(d)、(g)所示;当温度较高时,充型完成时铝液处于较高温度状态,合模后,较高的铝液温度增加了合金的凝固时间,给富Sn液相流动提供了充足的时间,远端先凝固排出的低熔点Sn不断的相近端高温区域富集,致使近端与远端Sn质量分数偏差较大,如图3(c)、(f)、(i)所示;而适当的浇铸温度使得铝液在充型完成时接近于液相线,合模后压力作用下铸件快速凝固,虽然远端依然有Sn向近端高温区域趋附,但两端Sn质量分数有明显降低,减轻了Sn的偏析程度,如图3(b)、(e)、(h)所示。

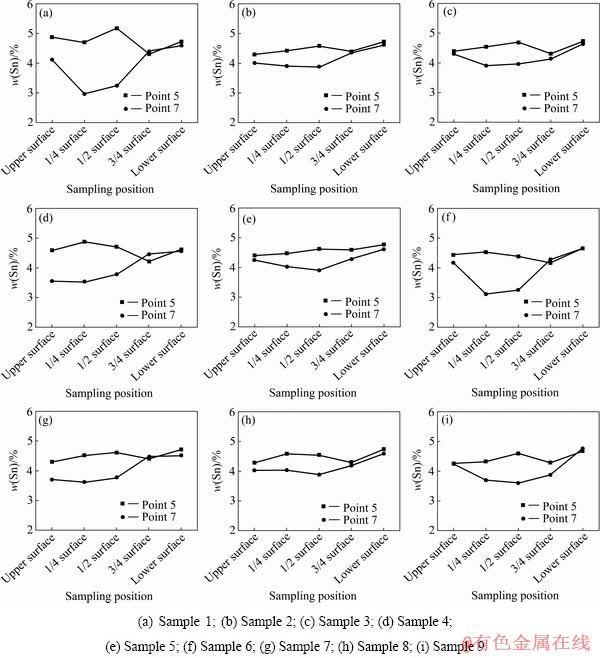

2.2 铸件轴向方向的正偏析和逆偏析

为了进一步研究铸件Sn偏析的情况,选取近端(检测位置点5)和远端(检测位置点7)对上表面至下表面轴向Sn的分布规律进行分析,结果如图4所示。无论是近端还是远端轴向方向的冷却速度也不是均匀一致的,铸件上表面和下表面凝固速度较快,中间层凝固速度较慢,即局部区域轴向方向的1/4表面和1/2表面属于热节。图4可以看出,近端Sn大多偏于1/4表面和1/2表面,产生Sn的正偏析,和铸件宏观偏析规律基本一致,这主要是由于一方面,合模后,压力增加了过冷度,铸件上表面和下表面凝固速度较快,中间层凝固速度较慢,剩余液相中Sn的质量分数较高;另一方面,近端热节是整个铸件冷却和凝固速度最慢的区域,邢书明等[20]指出,液态模锻过程中冷却凝固造成的体积收缩只能靠压力作用下发生塑性变形和金属流动进行补偿,如果压力足以使先凝固层发生塑性变形,根据最小阻力定理,这将使得固相及枝晶间液相向着阻力较小的固液两相区、液相区和缩孔区流动,从而进行强制补缩。近端热节位置凝固速度最慢,在凝固后期,枝晶间的剩余液相在压力作用下被挤压到热节处,也使Sn的质量分数提高。

与之相反,远端1/4表面和1/2表面Sn质量分数最低,在轴向方向上产生Sn的逆偏析,这主要是因为远端是铝液充型最后的位置,铝液到达远端时温度降低,且铸件远端壁厚较薄,凝固速度较快,其中远端上表面和3/4表面、下表面是整体铸件凝固最快的区域,虽然凝固过程中Sn也被排出,但由于冷速快、凝固迅速,排出的Sn很快被周围凝固的Al相包围而无排出通道,同时由于远端轴向热节处(1/4表面、1/2表面)先期凝固Al相排出的Sn还因比重较大而有下沉的趋势,使得远端3/4表面、下表面的含锡量普遍较高。而远端轴向热节处相对于近端热节处,它又是相对冷速较快的区域,一方面凝固Al相排出的Sn因比重较大而下沉;另一方面排出的Sn偏聚、融合、再排出,逐渐向铸件中温度较高的区域趋附、运动、偏析;同时,在液态模锻较高的压力作用下,此处固相及枝晶间的剩余低熔点液相向整体铸件缩孔区流动实现强制补缩;这几方面的综合作用,使得远端轴向热节处的含锡量较低,是整体铸件含锡量最低的区域。

图4 各正交实验铸件上检测位置点5和点7处各层Sn质量分数

Fig. 4 Sn mass fraction of each position Point 5 and Point 7 detected on each orthogonal experimental casting

同时,还可以看出,1~9组铸件近端和远端的3/4表面、下表面Sn的质量分数相差较小,这主要是由于近端的3/4表面、下表面冷速也较大,有与远端的3/4表面、下表面近似的凝固、偏析特性;而且3/4表面、下表面冷速较大凝固骨架的快速形成致使压力在传递的过程中的损失严重,液态模锻压力对3/4表面、下表面影响较小,从而该部位的凝固状态与重力铸造相近,Sn质量分数偏差较少。

2.3 工艺参数对轴向Sn偏析的影响

Sn的偏析主要取决于固液界面锡原子的排出速率以及富锡液相的量及流动状态。本次研究Sn元素的宏观分布对浇铸温度、模具温度非常敏感,保压时间也具有一定的影响,而比压产生的影响较小。由图3和4可知,浇铸温度较高或较低都使得偏析程度增加,而适当的浇铸温度使得铝液在充型完成时接近于液相线,合模后压力作用下铸件快速凝固,虽然远端依然有Sn排出并向近端高温区域的趋附、富集,但两端Sn质量分数有明显降低,减轻了Sn的偏析程度。

从金相组织看,凝固后期枝晶间的剩余液相在压力作用下被挤压到热节处,会形成粗晶区和细晶区交错出现的双峰组织[21],如图5(a)、(b)和(c)所示,而远端热节处晶粒大小一致,未发现双峰组织,如图5(f)、(g)、(h)、(i)和(j)所示。甘耀强等[14]在研究铝铜合金偏析行为时也发现了双峰组织,并推断其产生于凝固后期,细晶区主要是由于剩余液相在压力作用下被挤压到最终凝固补缩区域枝晶间,溶质元素的浓度高,过冷度大,致使同时大量形核产生的。据此可推断,Al-Sn轴套铸件近端热节位置在凝固后期,大量的低熔点液相被强制挤压至热节位置,形成双峰组织,如图5(a)、(b)和(c)所示,剩余液相在压力作用下向1/2表面流动,使得上表面、1/4表面及1/2表面均出现双峰组织;观察发现,近端3/4表面和下表面未出现双峰组织,如图5(d)和(e)所示,这主要是因为合模前模壁处先形成了一层凝固壳,致使压力在传递中损失严重,致使3/4表面和下表面受压力影响较小。对铸件粗晶区和细晶区进行EDS能谱扫描,结果如图6所示,可以看出,细晶区Sn的能量峰较高,Sn的质量分数约是粗晶区的16倍。

图5 铸件5近端和远端不同表面金相显微组织

Fig. 5 Optical microstructures at different surfaces in proximal ends((a), (b), (c), (d), (e)) and distal ends((f), (g), (h), (i), (j)) of Sample 5

图6 双峰组织不同组织的EDS分析

Fig. 6 EDS spectra of different tissues in bimodal tissues

图5(f)、(g)、(h)、(i)和(j)是铸件5远端的金相显微组织。观察发现,在远端各切片表面未发现双峰组织,这主要是因为远端是铝液最后充型的位置,当充型完毕后,此时的铝液温度较低,3/4表面及下表面几乎处于凝固状态,当合模后,上模与上表面接触,较大的过冷度及压力作用,使得铸件上表面及1/4表面快速凝固,来不及排出Sn,致使此时1/2表面残余液相对上下表面的先凝固组织进行补缩,同时在凝固过程中不断的排出Sn向近端高温区趋附、富集,致使远端轴向出现逆偏析现象。

2.4 正交试验分析及工艺参数优化

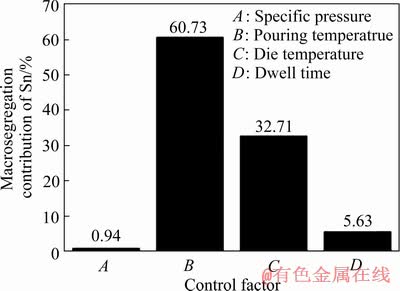

由图3和4既可以看出液态模锻Al-Sn轴套中存在明显的Sn的宏观成分偏析,又可看出模锻工艺对Sn的成分分布与宏观偏析有较大的影响。采用正交试验法可以分析工艺参数对Sn的偏析的影响,通过Sn元素宏观成分分布的信噪比[22]评定不同铸件的Sn的成分分布情况,信噪比越高,则说明该试样的低熔点元素Sn分布越均匀。表5所列为9组正交试验各检测部位Sn含量与其平均含量方差之和的信噪比S/N,可以看出,Sn元素分布的信噪比变化由小到大依次是铸件1、6、9、4、3、7、8、2、5,表明铸件1低熔点元素Sn的分布均匀性最差,而铸件5低熔点元素Sn的分布均匀性较好。由表6所列是各试样Sn元素含量方差之和的帕雷托方差分析,对Sn元素含量分布差异贡献由大到小的因素依次为模具温度、浇铸温度、保压时间以及比压。可以看出,实验范围内的比压变化对Sn元素的偏析影响较小。图5和6所示分别为液态模锻工艺参数对Sn元素分布差异的影响大小及各水平的信噪比。结果表明,Sn元素的宏观分布对浇铸温度、模具温度非常敏感,保压时间也具有一定的影响,而比压产生的影响较小。

表5 不同部位Sn含量与其平均含量方差之和的信噪比S/N

Table 5 S/N ratio for sum of variance of Sn content

图7 液态模锻参数对Sn宏观偏析的影响

Fig. 7 Effect of liquid die forging parameters on Sn macrosegregation

图8 参数水平对Sn宏观偏析的影响

Fig. 8 Effect of parameter level on Sn macrosegregation

利用正交试验法分析所得液态模锻工艺最佳技术参数,预测了Sn的宏观偏析。由于比压对Sn元素偏析影响较小,故将其视为误差因素,主要考虑浇注温度、模具温度和保压时间3个技术参数的影响。先对9组试样在各参数最佳水平(B2、C3、D3)下Sn元素偏析的信噪比求平均的B2*、C3*、D3*,再对所有Sn元素偏析的信噪比求平均的T*,计算结果如下:

(S/N)m,Sn=B2*+C3*+D3*-2T*=16.7+15.5+14.9-2×14.76=17.63 (dB) (1)

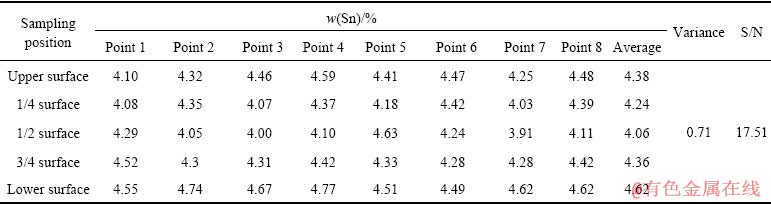

在优化了的液态模锻工艺参数的条件下进行成型实验验证,即比压80 MPa,浇注温度700 ℃,模具温度240 ℃,保压时间5 s。试样各点Sn的含量及其方差、信噪比的具体检测、计算结果如表7所示,可以看出,Sn的含量分布总体均匀性较好,宏观偏析的信噪比(S/N)为17.51,与预测结果基本符合。

表6 Sn含量方差之和的帕雷托方差分析

Table 6 Pareto ANOVA for sum of variance of Cu content

表7 验证试验中Sn宏观偏析的信噪比S/N

Table 7 S/N of Sn macrosegregation verified in experiment

3 结论

1) 液态模锻Al-Sn-Cu轴套不可避免的产生Sn的宏观偏析,并且轴套铸件中同时存在着正偏析和逆偏析,正偏析出现在浇铸中心的近端,逆偏析主要存在于浇铸中心的远端。

2) 铸件凝固后期,低熔点液相被强制挤压至热节位置,形成粗晶区和细晶区相间的双峰组织,细晶区Sn的质量分数明显较高。

3) 本文条件下对Sn偏析影响由大到小的工艺参数依次是浇注温度、模具温度、保压时间及比压,适当的液态模锻工艺可得到低熔点Sn元素分布较均匀,宏观偏析得到减轻的轴套铸件。

REFERENCES

[1] PATHAK J P, MOHAN S. Tribological behaviour of conventional Al-Sn and equivalent Al-Pb alloys under lubrication[J]. Bulletin of Materials Science, 2003, 263: 15-320.

[2] YAN N, HONG Z Y, GENG D L, WANG W L, WEI B. Phase separation and structure evolution of ternary Al-Cu-Sn immiscible alloy under ultrasonic levitation condition[J]. Journal of Alloys and Compounds, 2012, 544: 6-12.

[3] PRAMANICK A, CHATTERJEE S, BHATTACHARYA V, CHATTOPADHYAYN K. Synthesis and microstructure of laser surface alloyed Al-Sn-Si layer on commercial aluminum substrate[J]. Journal of Materials Research, 2005, 20: 15801589.

[4] PERRONE A, ZOCCO A, ROSA H D, ZIMMERMANN R, BERSANI M. Al-Sn thin films deposited by pulsed laser ablation[J]. Materials Science and Engineering C, 2002, 22: 465-468.

[5] UEDA M, INABA R, OHTSUKA T. Composition and structure of Al-Sn alloys formed by constant potential electrolysis in an AlCl3-NaCl-KCl-SnCl2 molten salt[J]. Electrochimica Acta, 2013, 100: 281-284.

[6] NOSKOVA N I, VIL’DANOVA N F, FILIPPOV Y I, CHURBAEV R V, PERETURINA I A, KORSHUNOV L G, KORZNIKOV A V. Preparation, deformation, and failure of functional Al-Sn and Al-Sn-Pb nanocrystalline alloys[J]. Physics of Metals and Metallography, 2006, 102: 646651.

[7] PATEL J, MORSI K. Effect of mechanical alloying on the microstructure and properties of Al-Sn-Mg alloy[J]. Journal of Alloys and Compounds, 2012, 540: 100-106.

[8] KONG C J, BROWN P D, HARRIS S J, MCCARTNEY D G. The microstructures of a thermally sprayed and heat treated Al-20wt.%Sn-3wt.%Si alloy[J]. Materials Science and Engineering A, 2005, 403: 205-214.

[9] WU Xiao-feng, ZHANG Guang-an, WU Fu-fa. Influence of Bi addition on microstructure and dry sliding wear behaviors of cast Al Mg2Si metal matrix composite[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1532-1542.

[10] KOTADIA H R, DOERNBERG E, PATEL J B, FAN Z, SCHMID-FETZER R. Solidification of Al-Sn-Cu based immiscible alloys under intense shearing[J]. Metallurgical and Materials Transactions A, 2009, 40: 2202-2211.

[11] HONG C P, SHEN H F, LEE S M. Prevention of macrodefects in squeeze casting of an Al-7wt pct Si alloy[J]. Metallurgical and Materials Transactions B: Process Metallurgy and Materials Processing Science, 2000, 31(2): 297-305.

[12] LEE S M, SHEN H F, HONG C P. Formation criterion of macrosegregation in a squeeze-cast Al-7mass%Si alloy[J]. ISIJ International, 1999, 39(11): 1160-1168.

[13] GALLEMEAULT M, DURRANT G, CANTOR B. Squeeze casting of hypoeutectic binary Al-Cu[J]. Metallurgical and Materials Transactions A, 1996, 27A(12): 4121-4132.

[14] 甘耀强, 张大童, 张卫文, 张 文, 李元元. 基于田口方法的挤压铸造Al5Cu0.4Mn合金宏观偏析[J]. 中国有色金属学报, 2012, 22(12): 3386-3394.

GAN Yao-qiang, ZHANG Da-tong, ZHANG Wei-wen, ZHANG Wen, LI Yuan-yuan. Macrosegregation in squeeze-cast Al5Cu0.4Mn alloy based on Taguchi method[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(12): 3386-3394.

[15] 郭莉军, 邢书明, 鲍培玮, 邱常明, 刘文鑫. 间接挤压铸造工艺参数对铝合金中Si偏析的影响[J]. 工程科学学报, 2016, 38(2): 257-262.

GUO Li-jun, XING Shu-ming, BAO Pei-wei, QIU Chang-ming, LIU Wen-xin. Effect of process parameters on Si segregation in an aluminum alloy during squeeze casting[J]. Chinese Journal of Engineering, 2016, 38(2): 257-262.

[16] 郭莉军, 邢书明, 敖晓辉, 等. 挤压铸造零件沿流程方向的成分偏析及组织偏聚[J]. 工程科学学报, 2017, 39(7): 1041-1046.

GUO Li-jun, XING Shu-ming, AO Xiao-hui. Microstructure and composition segregation along the fluidity length of aluminum alloy in squeeze casting[J]. Chinese Journal of Engineering, 2017, 39(7): 1041-1046.

[17] VIJIAN P, ARUNACHALAM V P. Optimization of squeeze casting process parameters using Taguchi analysis[J]. International Journal of Advanced Manufacturing Technology, 2007, 33(11/12): 1122-1127.

[18] VIJIAN P, ARUNACHALAM V P. Optimization of squeeze cast parameters of LM6 aluminium alloy for surface roughness using Taguchi method[J]. Journal of Materials Processing Technology, 2006, 180(1/3): 161-166.

[19] 贺小明, 于忠奇, 来新民. 基于正交试验法的大型锻件微观组织健壮参数控制方法[J]. 塑性工程学报, 2008, 15(4): 94-97.

HE Xiao-ming, YU Zhong-qi, LAI Xin-min. Microstructure of heavy forgings robust parameters control methodology based on Taguchi method[J]. Journal of Plasticity Engineering, 2008, 15(4): 94-97.

[20] 刑书明, 马 静, 陈维视. 挤压铸造的无缩孔判据[J]. 中国有色金属学报, 1998, 8(S1): 205-209.

XING Shu-ming, MA Jing, CHEN Wei-shi. Squeeze casting shrinkage predicting process designing[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S1): 205-209.

[21] MALEKI A, NIROUMAND B, SHAFYEI A. Effects of squeeze casting parameters on density, macrostructure and hardness of LM13 alloy[J]. Materials Science and Engineering A, 2006, 428(1/2): 135-140.

[22] 高平平, 陈 刚, 范才河, 黄在告. 挤压铸造模温及压力对2024铝合金组织性能的影响[J]. 热加工工艺, 2009, 38(21): 64-67.

GAO Ping-ping, CHEN Gang, FAN Cai-he, HUANG Zai-gao. Effects of squeeze casting die temperatures and pressure on microstructure and properties of 2024 aluminum alloy[J]. Hot Working Technology, 2009, 38(21): 64-67.

Macrosegregation of Sn in squeeze-cast Al-Sn-Cu sleeve based on orthogonal experiment

XU Ming1, YIN Yan-guo1, LI Cong-min1, DUAN Cong-chong2, DING Shu-guang1

(1. Institute of Tribology, School of Mechanical Engineering, Hefei University of Technology, Hefei 230002, China;

2. Hefei Yihui Light Alloy Technology Co., Ltd., Hefei 230088, China)

Abstract: Orthogonal test was used to investigate the macrosegregation of Sn in Al-Sn-Cu sleeve in the squeeze casting. The results show that the macrosegregation of Sn is inevitable in Al-Sn-Cu sleeve in the squeeze casting. In the casting, both positive segregation and inverse segregation exist. The positive segregation appears near the casting center, while the reverse segregation mainly exists at the far end of the casting center. At the later solidification stage, the liquid phase with low melting point is forced to be extruded to the thermal center, which formed bimodal structure of coarse crystal region and fine crystal region, and the Sn mass fraction of fine crystal region was obviously higher. The process parameters have a great influence on the macrosegregation of castings. The influence sequence of squeeze casting parameters on macrosegregation from large to small is pouring temperature, die temperature, dwell time and specific pressure. Under this experiment condition, the distribution of Sn element in shaft sleeve casting is uniform and the macrosegregation of Sn element is reduced, when the pouring temperature is 700 ℃, mold temperature is 240 ℃, the pressure is 80 MPa, the holding time is 5 s.

Key words: orthogonal experiment; squeeze casting; Al-Sn-Cu; bimodal structure; macrosegregation

Foundation item: Project(51575151) supported by the National Natural Science Foundation of China

Received date: 2018-12-14; Accepted date: 2019-04-18

Corresponding author: YIN Yan-guo; Tel: +86-18919661022; E-mail: abyin@sina.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51575151)

收稿日期:2018-12-14;修订日期:2019-04-18

通信作者:尹延国,研究员,博士;电话:18919661022;E-mail:abyin@sina.com