Trans. Nonferrous Met. Soc. China 25(2015) 170-174

Microstructure and thermophysical properties of SiC/Al composites mixed with diamond

Hong GUO1,2, Yuan-yuan HAN1, Xi-min ZHANG1, Cheng-chang JIA2, Jun XU1

1. National Engineering Technology Research Center for Nonferrous Metals Composites,

Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. School of Materials and Engineering, University of Science and Technology Beijing, Beijing 100083, China

Received 8 January 2014; accepted 5 March 2014

Abstract: The thermophysical properties of the SiC/Al composites mixed with diamond (SiC-Dia/Al) were studied through theoretical calculation and experiments. The thermal conductivity and the thermal expansion coefficient of the SiC-Dia/Al were calculated by differential effective medium (DEM) theoretical model and extended Turner model, respectively. The microstructure of the SiC-Dia/Al shows that the combination between SiC particles and Al is close, while that between diamond particles and Al is not close. The experimental results of the thermophysical properties of the SiC-Dia/Al are consistent with the calculated ones. The calculation results show that when the volume ratio of the diamond particles to the SiC particles is 3:7, the thermal conductivity and the thermal expansion coefficient can be improved by 39% and 30% compared to SiC/Al composites, respectively. In other words, by adding a small amount of diamond particles, the thermophysical properties of the composites can be improved effectively, while the cost increases little.

Key words: SiC/Al composites mixed with diamond; thermal conductivity; thermal expansion coefficient; microstructure

1 Introduction

How to effectively transfer heat from the electronic devices with small size and high power is a serious problem in the electronic packaging field [1,2]. The substrate materials for the electronic devices need to have high thermal conductivity and suited thermal expansion coefficient [3,4]. For most good thermal conductors such as copper, aluminum and silver, the thermal expansion coefficient cannot meet the requirement. While the thermal expansion coefficient of the composites combined with two and more materials which are considered the most promising thermal management materials may meet the requirement.

SiC/Al and W/Cu composites are the traditional thermal management materials, but the thermal conductivity and the thermal diffusion capacity of these materials are limited, so it needs to find new solutions [5,6]. Diamond has great potential, but the cost is rather high [7-9]. Therefore, using only a small part of the diamond mixed with other materials is a new option [10]. In this work, part of the diamond particles were added to the SiC/Al composites to prepare SiC-Dia/Al composites to improve the thermal conductivity. And the microstructure and thermophysical properties of the SiC-Dia/Al composites were researched.

2 Experimental

Diamond and SiC particles used in the experiment were synthetic diamond and green α-SiC for industrial application, respectively. The purity of Al was above 99.9%. The main properties of the raw materials are given in Table 1. The diamond particles and SiC particles were mixed uniformly into prefabricated parts. Two kinds of SiC-Dia/Al composites were prepared by pressure infiltration technology. The total particle volume fraction of SiC and diamond is 60% and the particle size is 100 μm. The volume ratio of diamond particles to the SiC particles is 3:7 and 1:9, respectively. The thermal conductivity of the SiC-Dia/Al composite was calculated by DEM theoretical model [11] and measured by NetzschL FA447 flash thermal conductivity meter. The microstructure of the composites was observed by scanning electron microscope (SEM S-250MK3).

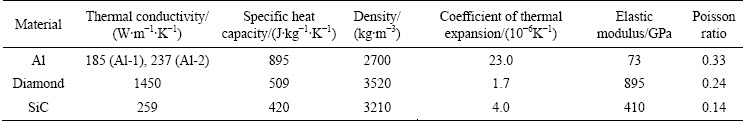

Table 1 Properties of materials

3 Theoretical calculation of thermal conductivity and thermal expansion coefficient

When the particles are spherical and distributed in the matrix uniformly and the interface of the particles and the matrix is negligible, the theoretical models to calculate the thermal conductivity of the composite are Maxwel1-Eucken model [12], Bruggeman model [13], Lord Rayleigh model [14], Klemens model [15] and Rom’s law [15]. The application of the above models has certain limitations that limit the composite to have two kinds of reinforcements with different diameters. DEM theory is very suitable for the thermal conductivity model of the composite with two kinds of reinforcements. For SiC-Dia/Al composites, two types of reinforcements of SiC composites and diamond with medium diameter distribute uniformly in the matrix, and the standard DEM theory can be revised to illustrate the effective thermal conductivity with two or more reinforcement as follows:

(1)

(1)

where λc is the thermal conductivity of the composites, λm is the thermal conductivity of the matrix, fi is the volume fraction of the type i reinforcement in the composites; S is the polarization factor of the reinforcement, being 1/3 when the reinforcement is spherical;  is the integral variable of the volume fraction and it is related to that of the effective reinforcement;

is the integral variable of the volume fraction and it is related to that of the effective reinforcement;  is the effective thermal conductivity of the reinforcement which can be given as follows:

is the effective thermal conductivity of the reinforcement which can be given as follows:

(2)

(2)

where hc is the intrinsic interface thermal conductivity of the matrix and the reinforcement;  is the intrinsic thermal conductivity of the reinforcement; r is the diameter of the particle. The intrinsic interface thermal conductivity of diamond/Al and SiC/Al is 3.7×107 W/(m·K) and 6.3×107 W/(m·K) respectively. The thermal conductivity of the SiC-Dia/Al composites can be calculated by Eq. (1).

is the intrinsic thermal conductivity of the reinforcement; r is the diameter of the particle. The intrinsic interface thermal conductivity of diamond/Al and SiC/Al is 3.7×107 W/(m·K) and 6.3×107 W/(m·K) respectively. The thermal conductivity of the SiC-Dia/Al composites can be calculated by Eq. (1).

The properties of the composite are connected with the factors such as particle volume fraction and particle size. For SiC-Dia/Al composite, because the thermal conductivity of diamond is very high, it plays the main role in the thermal conductivity of the composite. The particle volume fraction, particle size and volume ratio of the diamond particles on the total particles are studied by the theoretical calculation.

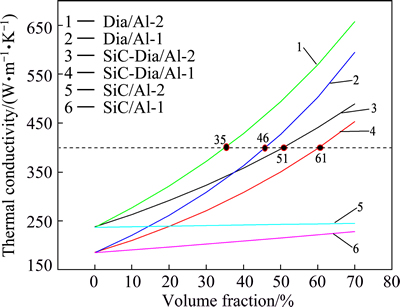

Because the volume fraction of the particles is much larger, a number of interfaces will be introduced, which will scatter the motion of the electron and phonon to hinder the heat transfer. The relationship between the volume fraction of the particles and the thermal conductivity of the composite is calculated by Eq. (1) as shown in Fig. 1. For Al based composite, the thermal conductivity increases with the increase of the particle volume fraction. Only when the particle volume fraction is above 35% and 51%, the thermal conductivity of Dia/Al and SiC-Dia/Al composite will achieve 400 W/(m·K).

Fig. 1 Volume fraction of particles vs thermal conductivity of composite

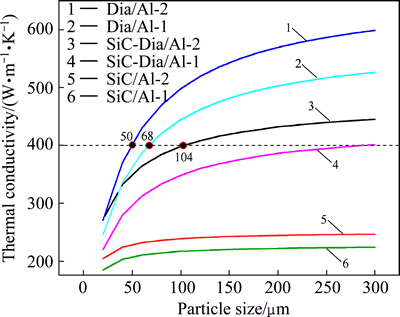

The effect of the particle size on the thermal conductivity of the composite are shown in Fig. 2. It is shown that as the particle size increases, the thermal conductivity of the composite first increases rapidly and then increases slowly. For Dia/Al and SiC-Dia/Al composites, the thermal conductivity has little change when the diameter of the particles is more than 50 μm and 104 μm, respectively.

Fig. 2 Particles size vs thermal conductivity of composite

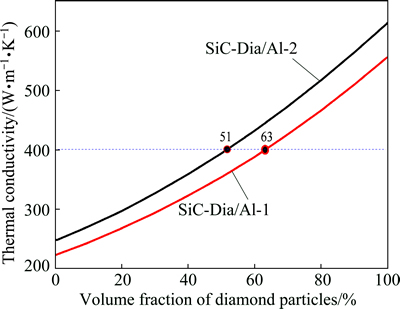

The effect of the volume fraction of the diamond particles, which refer to the volume fraction of the total particles on the thermal conductivity of the diamond hybrid SiC/Al composite, is shown in Fig. 3. It is shown that the thermal conductivity of the composite increases rapidly with the increase of the volume fraction of the diamond. When the volume fraction of the diamond reaches above 51%, the thermal conductivity of the composite can achieve 400 W/m·K.

Fig. 3 Volume fraction of diamond vs thermal conductivity of composite

The thermal expansion coefficient of the SiC-Dia/Al composites can be calculated by the extended Turner model as follows:

(3)

(3)

where am, ap1 and ap2 are the thermal expansion coefficients of the matrix, SiC particle and diamond particle, respectively; Vm, Vp1 and Vp2 are the final volume fractions of the matrix, SiC particle and diamond particle respectively; Km, Kp1, Kp2 are the body moduli of the matrix, SiC particle and diamond particle, respectively, which can be given as follows:

(4)

(4)

where E is the elastic modulus, ν is the Poisson ratio.

4 Results and discussion

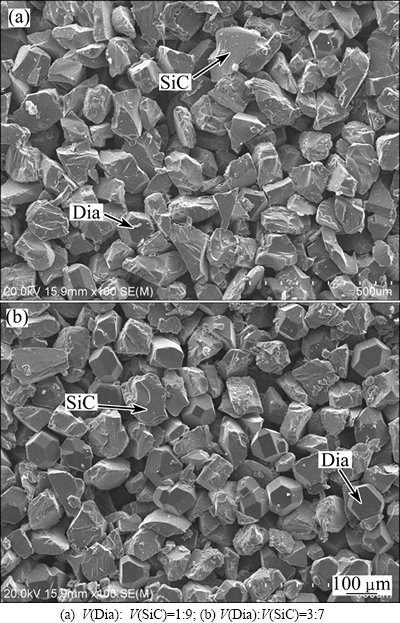

The microstructures of the two kinds of SiC-Dia/Al composites are shown in Fig. 4. It can be seen that the diamond particles distribute evenly among the SiC particles and there is no agglomeration. The porosity of the preform relies on the natrual pack of diamond particles and SiC particles. There is no crack on the particles and the particles pack closely.

Fig. 4 Microstructures of SiC-Dia/Al composite

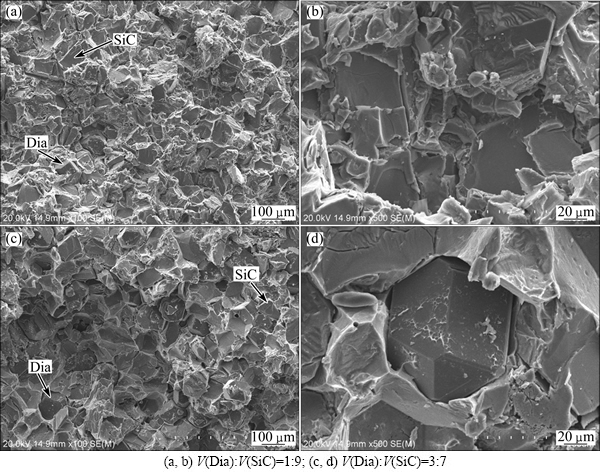

The microstructures of SiC-Dia/Al composites are shown in Fig. 5. It can be seen that when the volume ratio of the diamond particles to the SiC particles is 1:9, the microstructure of the composites is different from that of the SiC/Al composites when small amount of diamond particles are added. The combination between SiC particles and Al is close, while that between the diamond particles and Al is not close and there are some intercrystalline cracks. When the volume ratio of the diamond particles to the SiC particles is 3:7, the combination between diamond particles and Al is also close. Since the volume fraction of the particles increases, most of the cracks are intercrystalline ones.

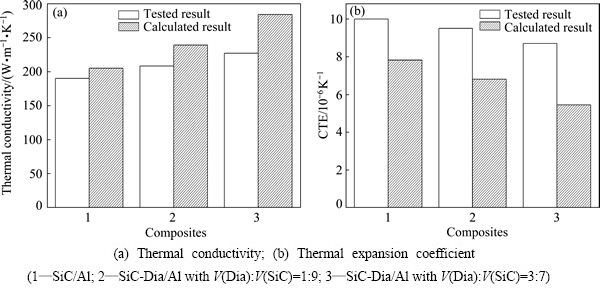

The thermal conductivity and the thermal expansion coefficient of the two kinds of the SiC-Dia/Al composites were calculated and measured, and the results are shown in Fig. 6. It can be seen that with the diamond particles increasing, the thermal conductivity of the SiC-Dia/Al composites increases and the thermal expansion coefficient decreases. The measured results of the thermophysical properties of the SiC-Dia/Al composites are consistent with the calculated ones. When the volume ratio of the diamond particles to the SiC particles is 3:7, the measured results of the thermal conductivity and the thermal expansion coefficient of the composites are 227 W/(m·K) and 8.7×10-6/K, respectively, which is increased by 20% and decreased by 13% compared to that of the SiC/Al composites. However, the calculation results show that when the volume ratio of the diamond particles to the SiC particles is 3:7, the thermal conductivity and the thermal expansion coefficient can be improved by 39% and 30% compared to that of the SiC/Al composites respectively. With the maturation the preparation process, the thermophysical properties of the SiC-Dia/Al composites can be improved much better. In summary, adding a small amount of the diamond particles, the thermophysical properties of SiC/Al composites can be improved effectively, while the cost increases little.

Fig. 5 Microstructures of SiC-Dia/Al composites

Fig. 6 Thermal physical properties of SiC-Dia/Al composite

5 Conclusions

1) For SiC-Dia/Al composites, the combination between SiC particles and Al is close and that between diamond particles and Al is not close.

2) With the diamond particles increasing, the thermal conductivity of the SiC-Dia/Al composites increases and the thermal expansion coefficient decreases.

3) The measured results of the thermophysical properties of the SiC-Dia/Al composites are consistent with the calculated ones.

4) The calculation results show that when the volume ratio of the diamond particles to the SiC particles is 3:7, the thermal conductivity and the thermal expansion coefficient can be improved by 39% and 30% compared to that of SiC/Al composites, respectively.

5) Adding a small amount of the diamond particles, the thermophysical properties of SiC/Al composites can be improved effectively, while the cost increases little.

References

[1] SCHELLING P K, SHI L, GOODSON K E. Managing heat for electronics [J]. Materials Today, 2005, 6: 30-35.

[2] HE Xing-bo, QU Xuan-hui, REN Shu-bin. Net-shape forming of composite packages with high thermal conductivity [J]. Science in China Series E: Technological Sciences, 2009, 52(1): 238-242.

[3] VETTERLIA M, TAVANGARB R, WEBERB L. Influence of the elastic properties of the phases on the coefficient of thermal expansion of a metal matrix composite [J]. Scripita Materialia, 2011, 64(2): 153-156.

[4] LIENHARD J H. A heat transfer textbook [M]. Cambridge, MA, USA: Phlogiston Press, 2005: 698-699.

[5] YANG B, GERMAN R M. A study on controlling the thermal conductivity and sintering properties of W-Cu composites [C]// Proceedings of the 1994 International Conference and Exhibition on Powder Metallurgy and Particulate Materials, Toronto, Ontario, Canada, 1994: 317-327.

[6] RAO B S, HEMAMBAR C, PATHAK A V, PATEL K J. Al/SiC carries for microwave integrated circuits by a new technique of pressureless infiltration [J]. IEEE Transactions on Electronics Packaging Manufacturing, 2006, 1: 58-63.

[7] EKIMOV E A, SUETIN N V, POPOVICH A F, RALCHENKO V G. Thermal conductivity of diamond composites sintered under high pressures [J]. Diamond and Related Materials, 2008, 17(4-5): 838-843.

[8] WEBER L, TAVANGAR R. Diamond based metal matrix composites for thermal management made by liquid metal infiltration—Potential and limits [J]. Advanced Materials Research, 2009, 59: 111-115.

[9] KIDALOV S V, SHAKHOV F M. Thermal conductivity of diamond composite [J]. Materials, 2009(2): 2467-2495.

[10] MOLINA J M,  M, CARRON J. Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles [J]. Scripta Materialia, 2008, 58: 393-396.

M, CARRON J. Thermal conductivity of aluminum matrix composites reinforced with mixtures of diamond and SiC particles [J]. Scripta Materialia, 2008, 58: 393-396.

[11] NORRIS A N, CALLEGARI A T, SHENG P. A generalized differential effective medium theory [J]. J Mech Phys Solids, 1985, 53: 525-530.

[12] ERVIN V J, KLETT J W, MUNDT C M. Estimation of the thermal conductivity of composites [J]. J Mater Sci, 1999, 34: 3545.

[13] BRUGGEMAN D A G. Effective medium model for the optical properties of composite materials [J]. Ann Phys Leipzig, 1935, 24: 636.

[14] YOUNG T H, CHUANG W Y, HSIEH M Y. Assessment and modeling of poly (vinyl alcohol) bioartificial pancreas in vivo [J]. Biomaterials, 2002, 23(16): 3495.

[15] XIU Zi-yang. Thermal properties and mechanical properties of SiP/LD11 composite materials for electronic packaging [D]. Harbin: Harbin Institute of Techonolgy, 2003: 15. (in Chinese).

金刚石混杂碳化硅/铝复合材料的组织与热物理性能

郭 宏1,2,韩媛媛1,张习敏1,贾成厂2,徐 骏1

1. 北京有色金属研究总院 国家有色金属复合材料工程技术研究中心,北京 100088;

2. 北京科技大学 材料科学与工程学院,北京 100083

摘 要:采用理论计算与实验相结合的方法对金刚石混杂SiC/Al复合材料的热物理性能进行研究,采用微分有效介质(DEM)理论和扩展的Turner模型分别计算金刚石混杂SiC/Al复合材料的热导率和热膨胀系数。从金刚石混杂SiC/Al复合材料的微观组织可以看到SiC颗粒与Al之间结合较紧密,金刚石颗粒与Al之间结合不紧密。金刚石混杂SiC/Al复合材料的热物理性能的实验结果与理论计算趋势一致。当金刚石颗粒与SiC颗粒的体积比为3:7时,混杂SiC/Al复合材料的热导率和热膨胀系数分别提高了39%和30%。因此,当在复合材料中加入少量金刚石颗粒时,其热物理性能得到显著提高,而复合材料的成本略有提高。

关键词:金刚石混杂SiCp/Al复合材料;热导率;热膨胀系数;显微组织

(Edited by Yun-bin HE)

Corresponding author: Hong GUO; Tel: +86-10-60689832; E-mail: guohong@grinm.com

DOI: 10.1016/S1003-6326(15)63592-0