DOI:10.11817/j.ysxb.1004.0609.2020-37474

5754铝合金板材冲压成形材料模型研究与应用

傅 垒,李 利,黄鸣东,刘贞山,刘 成

(中铝材料应用研究院有限公司,北京 102209)

摘 要:建立准确的材料模型是冲压数值模拟的基础,通过3个方向的单向拉伸试验、以及单向压缩试验和成形极限试验,获得5754铝合金材料性能数据,基于Voce硬化模型、Barlat89屈服准则和成形极限,建立5754铝合金成形用材料模型。利用Pamstamp-2G软件,对5754铝合金汽车大梁的冲压成形进行数值模拟,并与冲压试验结果进行对比。结果表明:数值模拟获得的应变数据与试验测量获得的应变数据比较接近,且各区域最大减薄率误差在±10%以内,验证数值模拟的可靠性。

关键词:5754铝合金;硬化模型;屈服准则;成形极限;数值模拟

文章编号:1004-0609(2020)-01-0018-08 中图分类号:TG386 文献标志码:A

随着汽车保有量的增加,给资源、环境带来了越来越大的压力,减轻汽车质量,提高燃油效率,降低排放以减少环境污染成为各汽车厂商的重要发展方 向[1-2]。铝合金具有密度低、比强度高、耐腐蚀性好、抗冲击性好等优点,是汽车轻量化的重要材料之一[3-4]。与钢板相比,铝合金板总伸长率偏小,在室温下成形性不如钢板,冲压成形时容易出现开裂、缩颈、起皱等缺陷,通过试错的方法消除这些缺陷,会导致修模周期长,开发费用高[5-6]。采用数值模拟技术,可以有效地预测铝合金冲压成形中的开裂、起皱等缺陷,然后进行优化设计,降低成形缺陷发生的风险,以指导冲压模具开发和成形工艺制定,随着计算机技术的发展,数值模拟技术在铝合金板材成形分析上得到广泛应用[7-8]。

梁宾[9]基于Barlat89屈服准则,对铝合金引擎盖内板进行冲压数值模拟,从起皱和开裂方面对比分析,数值模拟结果和实验结果吻合较好。池也[10]基于Hockett-Sherby硬化模型、Barlat89屈服准则,对铝合金前围板进行拉延成形数值模拟,指导前围板模具开发和冲压工艺制定,产品没有明显起皱和破裂缺陷。金飞翔等[11]基于Hollomon、Krupskowsky、Power硬化模型,对杯形件拉深成形进行数值模拟,从拉深深度、截面厚度对比分析了数值模拟与实验结果。随着光学测量技术的发展,张学广[12]在成形极限试样上印制网格,通过ARGUS光学应变测量系统,全面表征了试样变形后的应变状态。因此,在冲压成形过程中,采用光学应变测量系统可以更好地对比数值模拟与实验结果,全面了解冲压零件的变形状态。

为了提高铝合金冲压成形数值模拟的可靠性,需要建立准确的材料模型,并求解出相关的材料参数,以表征铝合金材料的成形性能。通常情况下,冲压成形用材料模型主要由硬化模型、屈服准则和成形极限组成[13-14]。本文以中铝西南铝生产的1.5 mm厚5754-H111铝合金为研究对象,分别进行单向拉伸试验、单向压缩试验和成形极限试验,研究适合5754-H111铝合金的成形用材料模型。基于该材料模型,以某汽车大梁为对象,对其进行冲压成形仿真分析,并通过冲压试验,在板料上印制网格,采用光学应变测量系统测量变形后的应变,与数值模拟结果对比分析,验证模型的可靠性。

1 实验

1.1 试验材料

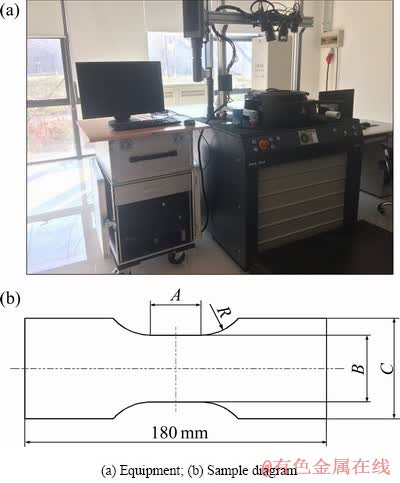

试验材料为中铝西南铝板带有限公司生产的1.5 mm厚的5754-H111铝合金汽车板,其化学成分如表1所列。

表1 5754铝合金化学成分

Table 1 Chemical composition of 5754 aluminum alloy

1.2 单向拉伸试验

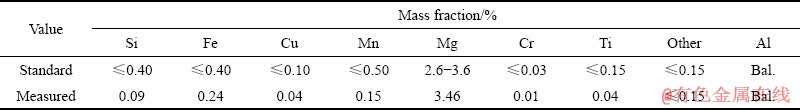

为了获取5754铝合金的力学性能,与轧向成0°、45°、90°分别切取3个试样,按照国家标准《GBT 228—2002 金属材料室温拉伸试验方法》和《GBT 5027—2007 金属材料 薄板和薄带塑性应变比(r值)的测定》进行单向拉伸试验,试验设备及设计的试样尺寸如图1所示,在试样上分别安装引伸计和宽度规,监测材料在拉伸过程中的的长度方向与宽度方向变形,以用于计算拉伸后的真应力-应变曲线和r值,试验拉伸速度为2 mm/min。

图1 单向拉伸试验

Fig. 1 Uniaxial tensile test

1.3 单向压缩试验

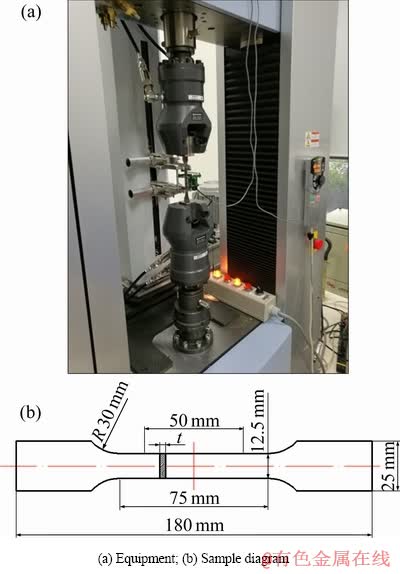

为了获取大变形量下的应力-应变曲线,按照国家标准《GBT 7314—2005 金属材料 室温压缩试验方法》,对5754-H111板材进行单向压缩试验,试验设备为100 kN的万能试验机。首先将板材精加工为15 mm×15 mm宽的小片,然后用特定胶水将若干个小片粘接起来,由于胶层非常薄,且试验时有预压,因此,可忽略胶层厚度,制备的样品示意图如图2所示[15]。

图2 5754-H111板材的压缩试验

Fig. 2 Compression test of 5754-H111 sheet

将制备好的试样进行压缩试验,记录相应的位移载荷曲线,然后通过计算获得压缩真应力-应变曲线。

1.4 成形极限试验

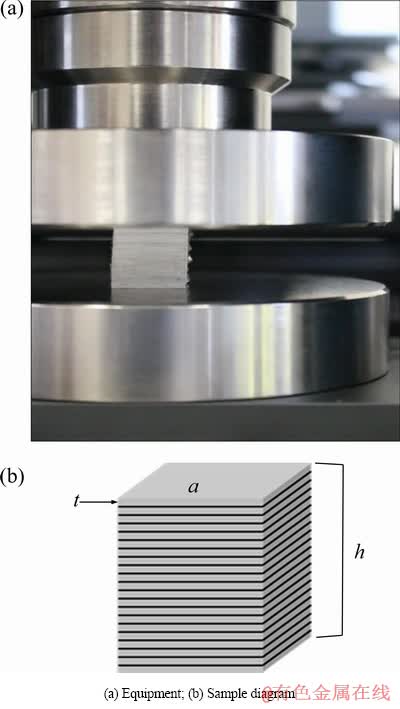

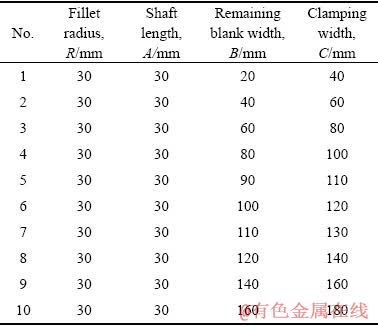

试验设备采用德国Zwick BUP600成形试验机,并带有ARAMIS光学动态应变测量系统,根据国家标准《GBT 15825.8—2008 金属薄板成形性能与试验方法 第8部分:成形极限图(FLD)测定指南》和《GBT 24171.2—2009 金属材料 薄板与薄带 成形极限曲线的测定 第2部分:实验室成形极限曲线的测定》对5754-H111进行成形极限试验。为了防止矩形试样在拉深筋处或凹模孔口处开裂,设计的试样示意图如图3所示,试样的具体尺寸如表2所列。将制备好的试样喷上黑白相间的散斑,在成形试验机进行刚性凸模胀形,采用ARAMIS系统记录试样变形过程中的应变变化,以及破裂前的应变状态,通过计算获得材料的成形极限曲线[12, 16]。

图3 成形极限试验

Fig. 3 Forming limit test

表2 成形极限试样尺寸

Table 2 Dimension of forming limit sample

2 5754-H111铝合金材料模型

2.1 硬化模型

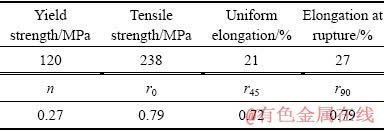

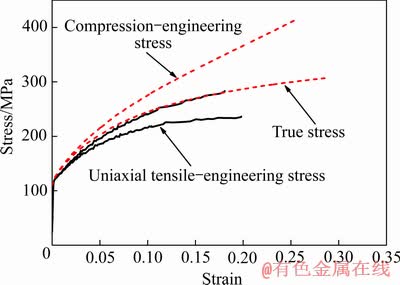

单向拉伸试验获得的材料力学性能数据如表3所列。其中n为应变硬化指数,r0、r45、r90代表与轧制方向分别为0°、45°、90°时试样的塑性应变比。拉伸和压缩应力-应变曲线如图4所示。

表3 5754铝合金力学性能

Table 3 Mechanical properties of 5754 aluminum alloy

图4 5754铝合金拉伸与压缩应力-应变曲线

Fig. 4 Tensile and compression stress-strain curves of 5754 aluminum alloy

由图4可知,压缩试验能获得较大的变形量,但由于板材压缩试验制样比较复杂,通常采用拉伸试验来获取材料的真应力-应变曲线,并采用硬化方程来拟合曲线,求取方程的参数值。常用的硬化方程有Hollomon方程、Krupknowsky方程和Voce方程[11, 17],其表达式如下。

Hollomon方程:

(1)

(1)

Krupknowsky方程:

(2)

(2)

Voce方程:

(3)

(3)

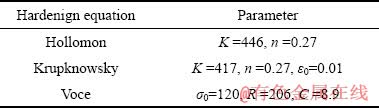

本文通过拉伸数据求解硬化方程的参数值如表4所列。

表4 硬化方程参数值

Table 4 Parameter values of hardening equation

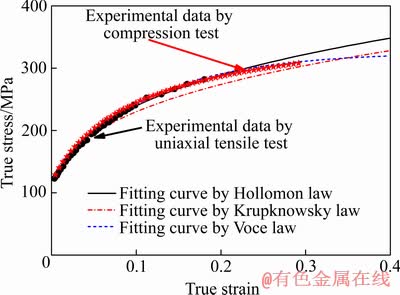

将硬化方程拟合的曲线与拉伸和压缩真应力-应变曲线进行对比分析如图5所示,由图5可知,Voce方程不仅能够很好地拟合拉伸曲线,而且能够较好地预测大变形条件材料的应力-应变曲线。因此,Voce硬化模型比较适合5754-H111铝合金板材。

图5 不同的硬化曲线对比

Fig. 5 Comparison of different hardening curves

2.2 屈服准则

由于铝板材经过轧制后具有明显的各向异性,BARLAT等[18]提出了Barlat89屈服准则,该准则对平面应力状态下的各向异性材料的冲压成形模拟效果较好[19],其表达式为

(4)

(4)

(5)

(5)

(6)

(6)

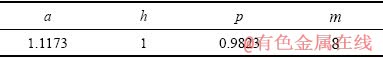

式中:a、h、p为材料参数,可由各向异性系数r0、r45、r90计算得到[17-18],铝合金为面心立方晶体结构,m值为8。

本文选用Barlat89屈服准则进行数值模拟,将3个方向拉伸试验获得的r值,代入到方程中,通过数值计算获得5754-H111铝合金的材料系数如表5所列。

表5 Barlat89 屈服准则参数值

Table 5 Parameter values of Barlat89 yield criterion

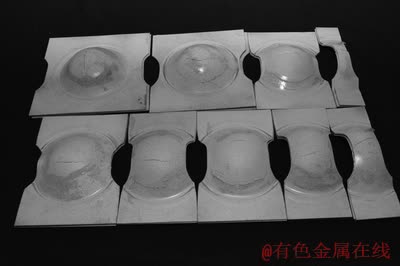

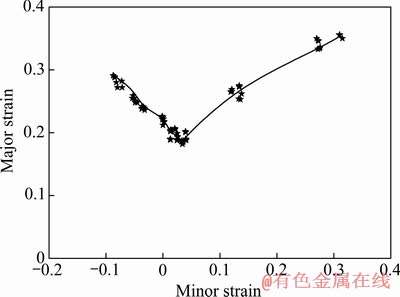

2.3 成形极限

设计平行段宽度不同的试样,并在试验过程中对试样进行充分润滑,以获取不同应变路径下材料的成形极限。为了便于ARAMIS光学动态应变测量系统采集数据,需要在试样上喷上黑白相间的散斑,并采用成形试验机进行刚性凸模试验,变形后的成形极限试样如图6所示。本文以ARAMIS测量系统观测到产生裂纹的前一张照片为基础进行计算,在每个试样上画3条线,根据《GBT 24171.2—2009 金属材料 薄板与薄带 成形极限曲线的测定第二部分:实验室成形极限曲线的测定》所述的计算方法,由ARAMIS测量系统自动计算,每一个试样可获得3个极限主次应变数据,并根据极限应变散点在成形极限图中的分布特征,连成适当的曲线,如图7所示,由此获得的5754-H111铝合金的成形极限曲线。

图6 变形后的成形极限试样

Fig. 6 Forming limit specimen after deformation

图7 5754铝合金的成形极限图

Fig. 7 Forming limit diagram of 5754 aluminum alloy

3 汽车大梁的冲压数值模拟与验证

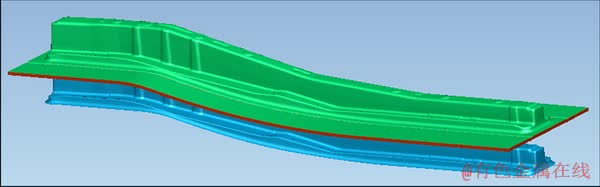

以某汽车大梁为研究对象,对其进行冲压数值模拟分析,然后通过冲压试验,在板料上印制网格,测量变形区域的应变,将试验结果与模拟结果进行对比分析,验证5754-H111铝合金材料模型和数值模拟结果的可靠性。

采用Pamstamp软件建立的大梁冲压数值模型如图8所示。

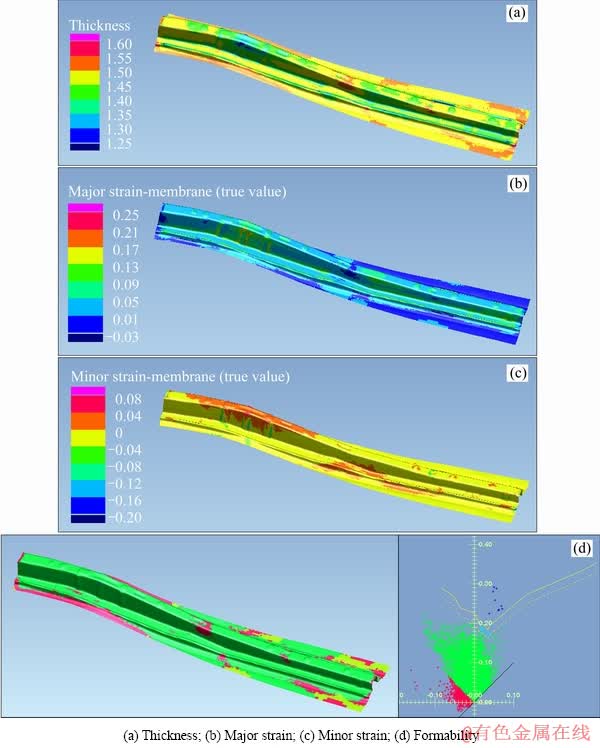

在压边力为200 kN,摩擦因数为0.12 的情况下,数值模拟计算后的厚度分布、主应变分布、次应变分布、成形性能分布如图9所示。

图8 铝合金大梁冲压数值模型

Fig. 8 Numerial model for aluminum alloy grider stamping

图9 铝合金大梁冲压数值模拟结果

Fig. 9 Simulation results of aluminum alloy grider stamping:

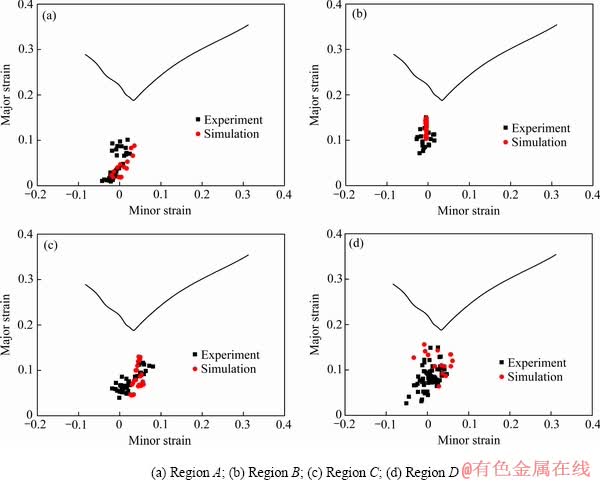

在大梁的A、B、C、D区域印制网格,具体位置如图10所示,然后进行冲压试验,冲压后测量获得的应变数据与数值模拟应变数据对比结果如图11所示,由图11可知,数值模拟结果与试验结果比较接近。

图10 大梁冲压样件与网格测试区域

Fig. 10 Grider sample and grid measurement areas

图11 模拟与试验应变数据对比

Fig. 11 Comparison strain of simulation and experimental results

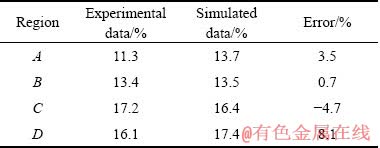

通过网格应变测量系统,可以获得大梁各区域的主应变和次应变,并在成形极限图上直观表示,能更全面的反映数值模拟结果与实验结果的差别。而且,由主应变和次应变数据,通过一定的数学计算转换为减薄率,转换表达式(7)所示。

(7)

(7)

式中: 为减薄率;e为工程应变;

为减薄率;e为工程应变; 为真实主应变;

为真实主应变; 为真实次应变。

为真实次应变。

通过数学计算,得到大梁各区域的最大减薄率如表6所列。由表6可知,各区域的最大减薄率误差在±10%以内,进一步证明本文建立的5754-H111铝合金材料模型和大梁冲压数值模型是可靠的。

表6 铝合金大梁不同区域最大减薄率

Table 6 Maximal reduction rate in different regions of aluminum alloy grider stamping

4 结论

1) 通过单向拉伸和单向压缩试验,获得了5754-H111铝合金的硬化曲线,并采用Hollomon方程、Krupknowsky方程和Voce方程进行拟合,结果表明Voce方程拟合效果较好。

2) 通过0°、45°、90°三个方向拉伸试验获得的r值,求解得到了5754-H111铝合金Barlat89屈服准则的材料参数分别为a=1.1173、p=0.9823、h=1、m=8。

3) 通过设计不同宽度的试样,获得了不同应变路径下5754-H111铝合金的成形极限曲线,该曲线可以用于判断铝合金零件的开裂区、风险区。

4) 通过对大梁进行冲压数值模拟和实际冲制,并采用光学应变测量系统,对大梁特定区域变形后的应变进行测量,并与数值模拟结果进行对比,结果表明,建立的5754-H111铝合金材料模型和冲压数值模型是可靠的。

REFERENCES

[1] 彭志明. 汽车铝合金覆盖件冲压成型工艺设计[D]. 长沙: 湖南大学, 2016.

PENG Zhi-ming. Stamping forming and process design of aluminum alloy automotive covering parts[D]. Changsha: Hunan University, 2016.

[2] 郑 晖, 赵曦雅. 汽车轻量化及铝合金在现代汽车生产中的应用[J]. 锻压技术, 2016, 41(2): 1-5.

ZHENG Hui, ZHAO Xi-ya. Lightweight automobile and application of aluminum alloys in modern automobile production[J]. Forging and Stamping Technology, 2016, 41(2): 1-5.

[3] 申国哲, 葛永鹏, 刘立忠, 赵坤民. 工艺参数对AA5754铝合金温成形回弹的影响[J]. 华中科技大学学报(自然科学版), 2016, 44(8): 111-114.

SHEN Guo-zhe, GE Yong-peng, LIU Li-zhong, ZHAO Kun-min. Effect of process parameters on springback of warm forming aluminum alloy AA5754[J]. Journal of Huazhong University of Science and Technology(Natural Science Edition), 2016, 44(8): 111-114.

[4] 余海燕, 王 友. 5052铝合金冲压成形过程中韧性断裂的仿真研究[J]. 中国有色金属学报, 2015, 25(11): 2975-2981.

YU Hai-yan, WANG You. Bulging simulation of ductile fracture of 5052 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 2975-2981.

[5] ZHOU Jing, WANG Bao-yu, LIN Jian-guo, MA Wen-yu. Forming defects in aluminum alloy hot stamping of side-door impact beam[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(11): 3611-3620.

[6] ZHANG Zhi-chao, XU Yong-chao, YUAN Shi-jian. Reverse deep drawability of 5A06 aluminum alloy plate at elevated temperatures[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1538-1545.

[7] 居 龙, 毛婷婷, 李洪波, 张 杰. 冲压速度对铝合金5182-O拉深性能的影响[J]. 中南大学学报(自然科学版), 2016, 47(8): 2643-2649.

JU Long, MAO Ting-ting, LI Hong-bo, ZHANG Jie. Effects of forming speed on drawability of aluminum alloy 5182-O[J]. Journal of Central South University(Science and Technology), 2016, 47(8): 2643-2649.

[8] 李桂琴, 卢仲珺. 铝合金前门加强板零件冲压成形数值模拟及参数优化[J]. 锻压技术, 2018, 43(10): 52-56.

LI Gui-qin, LU Zhong-jun. Numerical simulation and parameter optimization on stamping process of front door reinforcing plate parts for aluminum alloy[J]. Forging and Stamping Technology, 2018, 43(10): 52-56.

[9] 梁 宾. 汽车用铝合金板材变形机理与冲压成形条件及裂纹扩展研究[D]. 重庆: 重庆大学, 2017.

LIANG Bin. Research of automotive aluminum alloy sheet deformation mechanism and stamping conditions and crack propagation[D]. Chongqing: Chongqing University, 2017.

[10] 池 也. 某型乘用车铝合金前围板拉延成形数值模拟分析[D]. 济南: 山东大学, 2018.

CHI Ye. Numerical simulation analysis of drawing forming of aluminum alloy front panel for a typical vehicle[D]. Jinan: Shangdong University, 2018.

[11] 金飞翔, 钟志平, 李凤娇, 孟 辉. 不同硬化模型对铝合金板冲压成形模拟结果的影响[J]. 机械工程学报, 2017, 53(22): 57-66.

JIN Fei-xiang, ZHONG Zhi-ping, LI Feng-jiao, MENG Hui. Influence of different hardening model for the simulating results of the aluminum alloy sheet stamping[J]. Journal of Mechanical Engineering, 2017, 53(22): 57-66.

[12] 张学广. 基于损伤理论的铝合金板料成形极限研究[D]. 长春: 吉林大学, 2016.

ZHANG Xue-guang. Research on the forming limit of aluminum alloy sheet based on the damage theory[D]. Changchun: Jilin University, 2016.

[13] 张飞飞, 陈劼实, 陈 军, 黄晓忠, 卢 健. 各向异性屈服准则的发展及实验验证综述[J]. 力学进展, 2012, 42(1): 68-80.

ZHANG Fei-fei, CHEN Jie-shi, CHEN Jun, HUANG Xiao-zhong, LU Jian. Review on development and experimental validation for anisotropic yield criterions[J]. Advances in Mechanics, 2012, 42(1): 68-80.

[14] 徐园慧.不同加载路径下金属板料的成形极限[D]. 北京: 北方工业大学, 2017.

XU Yuan-hui. The forming limit of sheet metal under different loading parhs[D]. Beijing: North China University of Technology, 2017.

[15] AN Y G, VEGTER H. Analytical and experimental study of frictional behavior in through-thickness compression test[J]. Journal of Materials Processing Technology, 2005, 160: 148-155.

[16] LI Xiao-qiang, SONG Nan, GUO Gui-qiang. Experimental measurement and theoretical prediction of forming limit curve for aluminum alloy 2B06[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): s335-s342.

[17] 余海燕, 沈嘉怡, 王 友. 屈服准则和硬化模型对5052铝板回弹仿真的影响[J]. 材料科学与工艺, 2015, 23(3): 29-34.

YU Hai-yan, SHEN Jia-yi, WANG You. Influence of yield criterion and hardening model on springback simulation for 5052 aluminum sheet[J]. Materials Science and Technology, 2015, 23(3): 29-34.

[18] BARLAT F, LIAN J. Plastic Behavior and stretchability of sheet metals. Part I: A yield function for orthotropic sheets under plane stress conditions[J]. International Journal of Plasticity, 1989, 5: 51-66.

[19] 何维均, 张士宏, 程 明, 黄光杰, 栾佰峰, 刘 庆. 宏观弹性本构模型的研究进展[J]. 塑性工程学报, 2015, 22(3): 1-11.

HE Wei-jun, ZHANG Shi-hong, CHENG Ming, HUANG Guang-jie, LUAN Bai-feng, LIU Qing. Review on the development of macroscopic elastic-plastic constitutive models[J]. Journal of Plasticity Engineering, 2015, 22(3): 1-11.

Investigation and application on material model in sheet forming of 5754 aluminum alloy

FU Lei, LI Li, HUANG Ming-dong, LIU Zhen-shan, LIU Cheng

(CHINALCO Materials and Application Research Institute, Beijing 102209, China)

Abstract: An accurate material model is the basis for numerical simulation of stamping. By means of tensile tests in three directions, uniaxial compression tests and forming limit tests, the material property data of 5754 aluminum alloy is obtained. Based on the Voce hardening model, Barlat89 yield criterion and forming limit curves, the material model of 5754 aluminum alloy for stamping was established. With the Pamstamp-2G software, the stamping operation of automobile girders of 5754 aluminum alloy was simulated, which was compared with the actual stamping operation. The results show that the plastic strain calculated by the simulation is close to the experimental measurement one, the maximum thinning rate error is within ±10%, which verifies the reliability of numerical simulation.

Key words:5754 aluminum alloy; hardening model; yield criterion; forming limit; numerical simulation

Foundation item: Project(2017MXJH06) supported by Chinalco Star Program Fund; Project(Z171100002317027) supported by Beijing Municipal Science and Technology Project, China

Received date: 2018-12-07; Accepted date: 2019-09-02

Corresponding author: FU Lei; Tel: +86-10-66600123; E-mail: fulei41@163.com

(编辑 王 超)

基金项目:中铝明星计划基金项目(2017MXJH06);北京市科委基金资助项目(Z171100002317027)

收稿日期:2018-12-07;修订日期:2019-09-02

通信作者:傅 垒,工程师,博士;电话:010-66600123;E-mail:fulei41@163.com