DOI: 10.11817/j.issn.1672-7207.2017.05.004

铝合金覆层板成形极限图

王耀1,郎利辉1, 2,孔德帅1,张泉达1,高铁军3

(1. 北京航空航天大学 机械工程及自动化学院,北京,100191;

2. 北京航空航天大学 先进航空发动机协同创新中心,北京,100191;

3. 沈阳航空航天大学 航空航天工程学部,吉林 沈阳,110136)

摘要:提出一种创新的试验方法研究铝合金覆层板的成形极限图,即采用单拉试验获得成形极限图的左半区域,右半区域采用不同椭圆度的凹模得到不同应力状态下覆层板的成形极限应变,并且在成形极限图中引入方板对角拉伸试验数据,用于预测板材成形过程中起皱缺陷的产生,使成形极限图的预测功能更加完善。同时,进一步研究不同覆板材料和厚度对铝合金目标板材成形极限图的影响。研究结果表明:在覆层板方式下,目标板材成形极限图中的极限临界区向上移动,并向右移动,成形极限增大,并且成形极限图中起皱区域面积减小,抗失稳能力提高。成形过程选择强度系数K较高、加工硬化指数n较大及适当厚度的覆板有助于成形板材成形性能的提高。

关键词:铝合金;覆层板;厚度法向应力;成形极限图;椭圆胀形;方板对角拉伸试验

中图分类号:TG394 文献标志码:A 文章编号:1672-7207(2017)05-1149-06

FLDs of aluminum alloy by overlapping sheet metal

WANG Yao1, LANG Lihui1, 2, KONG Deshuai1, ZHANG Quanda1, GAO Tiejun3

(1. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China;

2. Collaborative Innovation Center of Advanced Aero-Engine, Beihang University, Beijing 100191, China;

3. Faculty of Aerospace Engineering, Shenyang Aerospace University, Shenyang 110136, China)

Abstract: A novel experimental approach to research the forming limit diagrams (FLDs) of aluminum alloy by overlapping sheet metal was presented, namely, the tension-compression side of the FLD was obtained by the uniaxial tension test. The limit strains of tension-tension side for the aluminum alloy by overlapping sheet metal were obtained by elliptical bulging test with different aspect ratios. In addition, the experimental data of YBT test were introduced into the FLD to predict the wrinkling defect in the sheet forming, in which the predictive features of FLDs were more improved. Meanwhile, the influence of the material performance and thickness of the overlapping sheet on the FLD of the target sheet were further investigated. The results show that, in the overlapping mode, the limit critical zone of FLD of the target sheet moves up and to the right, the forming limit increases and the area of wrinkling region decreases, and the anti-instability of the target sheet is improved correspondingly. Meanwhile, the formability of the target sheet can be improved by choosing higher strength coefficient K, larger work hardening exponent n and proper thickness of the overlapping sheet.

Key words: aluminum alloy; overlapping sheet; thickness normal stress; forming limit diagram (FLD); elliptical bulge; Yoshida bucking test

在板料成形中,成形极限图的确定对于评定板料成形性和指导生产实践具有重要的意义,它可以全面反映板料在单向和双向拉应力作用下的局部成形极 限[1-2]。广泛用于确定板料成形极限图的方法有半球形凸模刚模胀形试验、圆柱形凸模刚模胀形试验和椭圆凹模液压胀形试验。针对不同的工艺条件,每种试验方法都有其局限性和适用性[3-4]。本文作者所研究的铝合金覆层板是在目标板材一侧覆一层同种或不同材料板材,成形过程中覆板同目标板材一起变形,给目标板材以约束并施加厚度法向应力,提高了目标板材的静水压应力水平,使目标板材的应力状态由无覆板时的双向等拉平面应力状态转变为双向受拉厚向受压的三维应力状态,有效提高了目标板材的成形性能[5-6]。对于覆层板成形极限的研究,相关报道较少。TSENG等[7]针对Al/Cu覆层板,通过胀形试验研究了不同厚度金属层条件下覆层板的极限变形能力,得到了覆层板成形极限图,并利用成形极限图对颈缩和破裂等缺陷进行了预测。ZHOU等[8]对AZ31镁合金覆层板进行了椭圆胀形试验和FE模拟,研究了覆层板材料塑性流动和局部应变,并对AZ31镁合金板材成形极限进行了预测。王永铭[9]建立了考虑厚向应力的M-K失稳模型,并进行了单层铝合金板材及带不锈钢覆板的铝合金板材液压胀形试验。结果表明,随着厚度法向应力的增大,铝合金板材成形极限曲线升高,成形性能提高。SEMIATIN等[10]通过试验研究了不锈钢覆铝板的成形极限。研究结果表明:在板间无润滑作用条件下,失效主要是由分散失稳产生的局部颈缩引起,板材的不稳定流动随着次应变的增加而增加,最终局部颈缩的发展决定了覆层板的成形极限。MASANORI等[11]使用刚性冲模对相同材料的纯铝板覆层在一起进行胀形试验,通过改变板厚证明了成形极限随着板厚的增加而增加,通过改变板间接触条件证明了内外层板材胀形过程中受力状态的不同引起颈缩位置的不同,两者相互抑制颈缩的发展,从而提高了板材的极限变形能力。本文作者提出了一种试验方法去研究铝合金覆层板的成形极限图,通过采取逐级递减目标板材试样宽度的单拉试验获得成形极限图的左半区域,右半区域采用不同椭圆度的凹模得到不同应力状态下覆层板的成形极限应变,从而确定成形极限图上不同的极限应变点位置。同时,在成形极限图中引入方板对角拉伸试验数据,用于预测板材成形过程中起皱缺陷的产生,使成形极限图的预测功能更加完善。本文进一步研究了不同覆板材料和厚度对目标板材成形极限图的影响。

1 试验

1.1 材料

试验目标板材选择航空制造领域常用的2系铝合金2B06-O,厚度为1.0 mm,化学成分如表1所示。覆板材料分别选用铝合金2B06,2024和不锈钢SUS321,力学性能见表2。板坯表面均印制直径为2.0 mm圆形网格,用于测量试验试件极限应变。

表1 铝合金2B06板材化学成分(质量分数)

Table 1 Chemical composition of aluminium alloy 2B06 sheet %

表2 覆板材料力学性能

Table 2 Mechanical properties of overlapping sheet materials

1.2 目标板材单向拉伸试验及方案

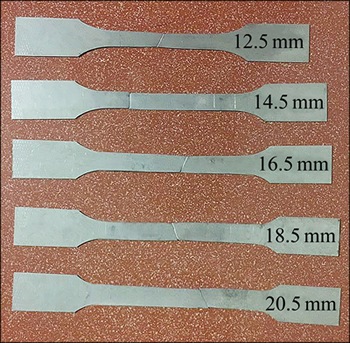

单向拉伸试验目的是获取板材成形极限图左半区域的成形极限曲线,覆层板主要是通过覆板对目标板材的厚度法向应力来提高目标板材的成形极限。单向拉伸时,覆板对目标板材无厚向应力,故无需施加覆板,只对目标板材单独进行拉伸试验即可。通过逐级递减试样宽度实现应变路径的变化,通过控制拉伸速度实现对应变率的控制,获得目标板材极限应变。拉伸试样尺寸如图1所示,试样宽度d分别取12.5, 14.5,16.5,18.5和20.5 mm。

图1 拉伸试样尺寸

Fig. 1 Dimensions of tensile sample

1.3 覆层板椭圆胀形试验及方案

覆层板液压胀形过程如图2所示。其中: 为覆板对目标板材施加的厚度法向应力;

为覆板对目标板材施加的厚度法向应力; 和

和 分别为目标板材所受的径向和周向应力;

分别为目标板材所受的径向和周向应力; 和

和 分别为覆板所受的径向和周向应力。胀形试验在自行研制的板材液压成形设备上进行。该设备提供最大500 kN合模力,压力产生装置为自行设计的增压器,增压比为1:5.25,最大液室压力为120 MPa。液压泵站为设备主缸、增压器逻辑动作提供动力源。试验过程的实时数据采集处理可以通过监测终端界面进行并进行图形化显示。椭圆胀形试验模具如图3所示。椭圆凹模长轴(a)为100 mm,短轴(b)依次为100,90,80和60 mm,椭圆度(b/a)分别为1.0,0.9,0.8和0.6。

分别为覆板所受的径向和周向应力。胀形试验在自行研制的板材液压成形设备上进行。该设备提供最大500 kN合模力,压力产生装置为自行设计的增压器,增压比为1:5.25,最大液室压力为120 MPa。液压泵站为设备主缸、增压器逻辑动作提供动力源。试验过程的实时数据采集处理可以通过监测终端界面进行并进行图形化显示。椭圆胀形试验模具如图3所示。椭圆凹模长轴(a)为100 mm,短轴(b)依次为100,90,80和60 mm,椭圆度(b/a)分别为1.0,0.9,0.8和0.6。

图2 铝合金覆层板成形过程示意图

Fig. 2 Sketch of aluminum alloy overlapping sheet forming process

图3 椭圆胀形试验模具

Fig. 3 Elliptical bulge test dies

通过2种类型试验研究覆板参数对目标板材成形极限图的影响。第1种是不同覆板材料椭圆胀形试验。分别选用相同厚度为1.0 mm的铝合金2B06,2024和不锈钢SUS321作为覆板,厚度为1.0 mm铝合金2B06作为目标板材进行胀形试验,研究覆板材料对目标板材FLD的影响。第2种是不同覆板厚度椭圆胀形试验。采用厚度分别为0.5,1.0和1.5 mm的不锈钢SUS321板材作为覆板,厚度为1.0 mm的铝合金2B06作为目标板材进行胀形试验,进一步研究覆板厚度对目标板材FLD的影响,试验方案如表3所示。在上述试验中,板坯平面长×宽均为180 mm×180 mm。

1.4 覆层板YBT试验及方案

YBT试验是对方形板料进行对角拉伸,以评估金属板料在非均匀拉应力状态下其抵抗压缩失稳起皱的能力的一种试验方法。由于该试验结果与实际冲压成形质量具有一定的对应关系,可以用来预测板料的起皱趋势,丰富成形极限图预测功能[12-15]。试验在自行研制的双向拉伸试验机上进行。设备主要由密封箱体、拉伸装置、位移传感器、测量系统和数据采集处理装置等几部分组成。试验板材外形尺寸(长×宽)为100 mm×100 mm方板,拉伸标距为75 mm,沿着试样的某一指定对角线加载拉伸,至试样的拉伸标距伸长1%时,测量方板中部的应变分布,得到相应起皱应变。通过改变试样夹持宽度,实现应变路径的变化,设备拉伸夹头宽度分别为50 mm和80 mm各1副,试样夹持宽度分别取30,40,50,60和70 mm。

表3 椭圆胀形试验/YBT试验方案

Table 3 Elliptical bulging test / YBT test schemes

对覆层板进行对角拉伸试验,试验方案见表3。目标板材为1.0 mm的铝合金2B06,覆板材料分别为铝合金2B06,2024和不锈钢SUS321,取不锈钢SUS321覆板厚度分别为0.5,1.0和1.5 mm,研究不同覆板材料和厚度对目标板材起皱趋势的影响,得到成形极限图起皱曲线。

2 结果与讨论

2.1 覆板材料对目标板材成形极限图的影响

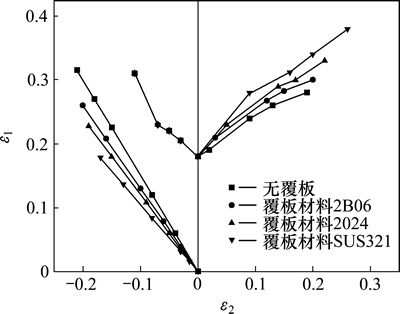

铝合金覆层板FLD试验试件如图4~6所示。不同覆板材料下获得的目标板材2B06铝合金FLDs如图7所示。图7中,成形极限图左半区域的极限应变通过目标板材单拉试验获得,由于单拉时覆板对目标板材无厚向压应力作用,与目标板材单独拉伸时获得的极限应变相同,故没有施加覆板。在右半区域,覆板和目标板材整体在面内双拉作用下成形,目标板材的应力状态为面内双拉厚向受压,压应力的作用可以延缓其破裂缺陷的产生,故图中所获得的成形极限图可以较准确反映覆层板方式下目标板材的成形性能。从图7可以看出:随着覆板选择塑性较好的材料,目标板材极限应变增大,成形极限曲线整体向上移动幅度明显,并向右移动,表明材料成形极限图中的极限临界区向上移动,成形极限增大;无覆板时,成形极限曲线双拉区域最高点的主应变为0.28,当覆板材料分别选择铝合金2B06,2024和不锈钢SUS321时,对应的成形极限曲线上最高点主应变分别为0.3,0.33和0.38,分别增加7.14%,17.86%和35.71%,增幅明显。同时,不同的覆板材料对目标板材起皱区域的影响也较大,覆板材料塑性越好,成形过程其较大的加工硬化指数n可以有效地改变目标板材厚度法向应力的分布方式,约束和控制目标板材的变形行为,使目标板材在覆板的包覆作用下变形规律同覆板变形过程相同或相近,依靠覆板较好的变形过程提高目标板材的变形均匀性,使得目标板材成形极限图中起皱区域面积减小,抗失稳能力提高。综上所述,试验中,当覆板材料为不锈钢SUS321时,试件成形极限最高,成形性能最好,其次是覆板材料为铝合金2024的试件;铝合金2B06的目标板材成形性能最差。

图4 2B06板材单向拉伸试件

Fig. 4 Uniaxial tensile specimen of 2B06 sheet

图5 覆层板椭圆胀形试验得到2B06试件

Fig. 5 2B06 specimens obtained by overlapping elliptical bulge test

图6 覆层板YBT试验得到2B06试件

Fig. 6 2B06 specimens obtained by overlapping YBT test

图7 不同覆板材料下2B06目标板材成形极限图

Fig. 7 FLDs of 2B06 target sheets with different overlapping sheet materials

目标板材成形性能的改善与覆板对目标板材的厚度法向应力有关,而这又与覆板材料本身力学性能参数密切相关。覆层板成形时,覆板任意一点对目标板材的反向压力与该点覆板和目标板材所处的变形阶段有关,由于覆板和目标板材厚度较小,假设任意一点的变形相似,那么覆板和目标板材变形的难易程度就可通过其变形抗力来反映。假设覆板和目标板材均满足Hollomon本构模型,对其求导可得:

(1)

(1)

(2)

(2)

式中: 和

和 分别为覆板和目标板材等效应力的一阶导数;K1和K2分别为覆板和目标板材的强度系数;n1和n2分别为覆板和目标板材的加工硬化指数。

分别为覆板和目标板材等效应力的一阶导数;K1和K2分别为覆板和目标板材的强度系数;n1和n2分别为覆板和目标板材的加工硬化指数。

假设覆板与目标板材加工硬化指数相同(n1= n2)、变形规律相似,覆板材料选择强度系数大于目标板材时的强度系数(K1>K2),成形过程中由于覆板强度较大,在一定作用力下覆板变形比目标板材困难,可以为目标板材提供较大的反向压应力,使目标板材的成形性能提高。同时覆板K1越大,目标板材受到覆板的反向压应力越大,成形性能也越好;反之,若覆板材料的强度小目标板材强度大(K1<K2),那么覆板变形更加容易,故提供的反向压力较小,对提高目标板材成形性能帮助较小。覆板加工硬化指数决定了目标板材变形的均匀性,假设覆板与目标板材强度系数相同(K1=K2),当覆板材料选择加工硬化指数大于目标板材时的加工硬化指数(n1>n2),覆板材料的应变强化效应较目标板材的强,抵抗变形的能力更强,变形均匀性也更好,对目标板材的变形起到抑制作用,使目标板材变形均匀性提高。覆板n1越大,上述抑制效果越明显,目标板材成形性能也越好。反之,当覆板加工硬化指数小于目标板材时(n1<n2),覆板的应变强化效应和变形均匀性较差,对于提高目标板材的成形性能帮助较小。因此,成形过程中选择强度系数高、加工硬化指数大的覆板材料,可以有效改善目标板材成形性能,提高其成形极限。

2.2 覆板厚度对目标板材成形极限图的影响

不同覆板厚度下获得的目标板材2B06铝合金FLDs如图8所示。由图8可以看出:与覆板材料对目标板材成形极限的影响规律相同,随着覆板厚度的增大,目标板材成形极限图中的极限临界区向上移动,并向右移动,成形极限增大。同时,成形极限图中起皱区域面积减小,抗失稳能力提高。由于覆板厚度越大,成形过程覆板向目标板材提供的反向压力就越大,越有利于目标板材抗失稳能力和极限变形能力的提高。但考虑到成本和成形难度,成形过程覆板厚度尽量选择与目标板材厚度相接近。

图8 不同覆板厚度下2B06目标板材成形极限图

Fig. 8 FLDs of 2B06 target sheets with different overlapping sheet thickness

3 结论

1) 对铝合金覆层板成形极限图进行试验研究,通过单拉试验和椭圆液压胀形试验准确获得目标板材成形极限曲线,并通过方板对角拉伸试验,得到目标板材起皱极限曲线,将两者结合在一起,完整描绘目标板材的FLD,使其预测功能更加完善。

2) 覆板材料对目标板材成形极限图的影响很大。覆层板成形时,覆板提供的反向压力与覆板强度系数K和加工硬化指数n有关,成形过程选择强度系数和加工硬化指数较大的覆板材料有助于提高目标板材厚度法向应力水平,使目标板材成形极限图中的极限临界区向上移动,并向右移动,成形极限增大,并且成形极限图中起皱区域面积减小,抗失稳能力提高,这种规律随着覆板厚度的增加而增强。

3) 在实际生产中,可以采用覆层板方式提高低塑性板材的成形性能,但必须考虑到成本和成形工艺条件,同时成形过程覆板厚度应尽量与目标板材厚度相接近。

参考文献:

[1] LI Xiaoqiang, SONG Nan, GUO Guiqiang. Experimental measurement and theoretical prediction of forming limit curve for aluminum alloy 2B06[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S2): 335-342.

[2] 杨希英, 郎利辉, 刘康宁, 等. 基于修正M-K模型的铝合金板材成形极限图预测[J]. 北京航空航天大学学报, 2015, 41(4): 675-679.

YANG Xiying, LANG Lihui, LIU Kangning, et al. Prediction of forming limit diagram of AA7075-O aluminum alloy sheet based on modified M-K model[J]. Journal of Beijing University of Aeronautics and Astronautics, 2015, 41(4): 675-679.

[3] 李春峰, 李雪春, 杨玉英. 椭圆凹模液压胀形法制作成形极限图[J]. 材料科学与工艺, 1996, 4(2): 101-105.

LI Chunfeng, LI Xuechun, YANG Yuying. Study on forming limit diagram by bulging with elliptic die[J]. Materials Science & Technology, 1996, 4(2): 101-105.

[4] 王辉, 高霖. 凸模直径以及试件形状对成形极限图的影响[J]. 机械科学与技术, 2006, 25(11): 1291-1293.

WANG Hui, GAO Lin. Influence of punch diameter and specimen shape on formation limit diagram[J]. Mechanical Science and Technology, 2006, 25(11): 1291-1293.

[5] 高铁军, 陈鹏, 王耀, 等. 铝合金半球形件覆不锈钢粘性介质拉深成形及数值模拟[J]. 锻压技术, 2014, 39(9): 17-20.

GAO Tiejun, CHEN Peng, WANG Yao, et al. Forming and numerical simulation of aluminum alloy hemispherical part overlapped included viscous medium of stainless steel[J]. Forging & Stamping Technology, 2014, 39(9): 17-20.

[6] GAO Tiejun, LIU Yang, CHEN Peng, et al. Analysis of bulging process of aluminum alloy by overlapping sheet metal and its formability[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1050-1055.

[7] TSENG Huangchi, HUNG Chinghua, HUANG Chinchuan. An analysis of the formability of aluminum/copper clad metals with different thicknesses by the finite element method and experiment[J]. International Journal of Advanced Manufacturing Technologies, 2010, 49(1): 1029-1036.

[8] ZHOU G, ANANTHAESWARA K, MITUKIEWICZ G, et al. FE simulations of gas blow forming and prediction of forming limit diagram of AZ31 magnesium sheet[J]. Journal of Materials Processing Technology, 2015, 218: 12-22.

[9] 王永铭. 板材充液成形关键技术及回弹控制研究[D]. 北京: 北京航空航天大学机械工程及自动化学院, 2013: 23-32.

WANG Yongming. Research on the key technologies and springback mechanism of sheet hydroforming[D]. Beijing: Beihang University. School of Mechanical Engineering and Automation, 2013: 23-32.

[10] SEMIATIN S L, PIEHLER H R. Forming limits of sandwich sheet materials[J]. Metallurgical Transactions A, 1979, 10(8): 1107-1118.

[11] MASANORI K, NOBUKAZU H, YASUSHI K. Improvement of pure stretch ability by overlapping sheet metals[J]. Journal of the Japan Society for Technology of Plasticity, 2001, 42(43): 328-332.

[12] KIMA Y S, SON Y J. Study on wrinkling limit diagram of anisotropic sheet metals[J]. Journal of Materials Processing Technology, 2000, 97(1/2/3): 88-94.

[13] 柳玉起, 胡平, 刘军华, 等. 方板对角拉伸分叉、鼓动与起皱[J]. 力学学报, 1998, 30(1): 77-82.

LIU Yuqi, HU Ping, LIU Junhua, et al. Bifurcation, bulging and wrinkling of a square sheet metal with non-uniform tension[J]. Acta Mechanica Sinica, 1998, 30(1): 77-82.

[14] 刘磊, 温彤, 岳远旺, 等. 轿车顶盖冲压成形塌陷研究[J]. 中南大学学报(自然科学版), 2015, 46(5): 1622-1627.

LIU Lei, WEN Tong, YUE Yuanwang, et al. Surface deflection of automotive roof in stamping forming[J]. Journal of Central South University (Science and Technology), 2015, 46(5): 1622-1627.

[15] 郭禅, 郎利辉, 蔡高参, 等. TA1板材对角拉伸试验及数值模拟研究[J]. 锻压技术, 2015, 40(2): 138-144.

GUO Chan, LANG Lihui, CAI Gaocan, et al. Experiment and simulation research of Yoshida Buckling Test on TA1 sheet[J]. Forging & Stamping Technology, 2015, 40(2): 138-144.

(编辑 陈爱华)

收稿日期:2016-07-14;修回日期:2016-09-19

基金项目(Foundation item):国家科技重大专项(2014ZX04002041);国家自然科学基金资助项目(51175024) (Project(2014ZX04002041) supported by the National Science and Technology Major Project; Project(51175024) supported by the National Natural Science Foundation of China)

通信作者:郎利辉,教授,博士生导师,从事液压柔性成形技术及装备研究;E-mail: lang@buaa.edu.cn