DOI:10.19476/j.ysxb.1004.0609.2017.07.10

高温及氧化对WC-10Co4Cr涂层微观结构及性能的影响

吴燕明1, 2,赵 坚1, 2,陈小明1, 2,伏 利3, 4,毛鹏展2, 3,周夏凉2, 3

(1. 水利部产品质量标准研究所,杭州 310012;

2. 浙江省水利水电装备表面工程技术研究重点实验室,杭州 310012;

3. 水利机械及其再制造技术浙江省工程实验室,杭州 310012;

4. 水利部杭州机械设计研究所,杭州 310012)

摘 要:采用X射线衍射仪(XRD)、扫描电镜(SEM)、显微硬度计、摩擦磨损试验机、冲蚀试验机等手段研究高温及氧化对超音速喷涂WC-10Co4Cr涂层的显微组织、显微硬度、结合强度、耐磨性能、耐冲蚀性能等的影响。结果表明:在空气中经600℃热处理后,涂层发生了明显的高温氧化,涂层中WC、Co、Cr相的含量降低,转化为CoWO4、Cr2O5、C6WO6等氧化物相,孔隙率明显升高,结合强度有所降低,虽然涂层的显微硬度值有所提高,但耐磨损及耐冲蚀性能都明显降低;通过Ar保护,涂层只受到600℃的高温作用,涂层的相组成未发生明显改变,显微硬度有较大幅度的提高,且分布更加均匀,耐干摩擦磨损及耐泥沙冲蚀性能均获得大幅提高。

关键词:WC-10Cr4Cr涂层;高温;氧化;微观结构;性能

文章编号:1004-0609(2017)-07-1395-08 中图分类号:TG174.442 文献标志码:A

超音速热喷涂WC-10Co4Cr涂层因具有极高的硬度、良好的致密性、耐磨性、耐腐蚀性和耐泥沙冲蚀性,被广泛应用于现代工业各个领域,如航空航天、冶金、机械、钢铁、电力、水利等,可以起到良好的防护作用,大幅延长机械产品的使用寿命[1-5]。目前,对于热喷涂WC-10Co4Cr涂层的研究主要集中在涂层的制备方法和性能表征方面,如王群等[6]研究了超音速火焰喷涂WC-Co涂层的磨粒磨损行为;李松林等[7]研究了超音速火焰喷涂WC-10Co-4Cr涂层的耐滑动磨损行为,指出采用液体煤油燃料HVOF制备的WC涂层具有优异的抗滑动磨损性能;张光华等[8]研究了DJ-2700和JP-5000制备的WC-10Co4Cr的抗砂浆冲蚀行为,发现JP-5000制备的涂层的硬度高于DJ-2700制备的涂层的,且气孔率也较低。

通常情况下,WC-10Co4Cr涂层被直接用于各类的机械零部件表面,如飞机起落架、球阀、纸辊、启闭机活塞杆等,可以保持并发挥出良好的性能[9]。然而在实际的应用过程中许多机械零部件本身的一些特殊加工工艺要求对涂层性能提出了新的考验,如水轮机叶片等零部件在制造过程中需要进行焊接及去应力退火(退火温度一般为600 ℃以上)等,在这些工艺条件下涂层的性能可能会朝着有利的方向改变也可能是截然相反的情况,因此,研究高温热处理等工艺对涂层性能的影响对于热喷涂WC涂层在水轮机叶片等机械零部件上的应用具有重要意义。

本文作者重点研究分析600 ℃高温及氧化的综合作用以及600 ℃纯高温作用对涂层微观结构、显微硬度、耐干摩擦磨损性能及耐泥沙冲蚀性能的影响,以期为超音速热喷涂WC涂层在水轮机叶片等复杂工件上的应用提供一种新思路。

1 实验

试样采用0Cr13Ni4Mo不锈钢制成100 mm×80 mm×5 mm长方形薄片,主要化学成分(质量分数,%):≤0.07 C,≤1.00 Mn,≤1.00 Si,≤0.03 S,≤0.035 P,11.50~13.50 Cr,3.50~5.00 Ni,0.40~1.00 Mo,Fe余量。

表面经过除油、去离子水漂洗、超声波清洗处理后进行喷砂处理,砂子采用粒度为600~710 μm的白刚玉砂。粉末采用WC-10Co-4Cr金属陶瓷粉(粒径为15~45 μm),喷涂设备采用STR-50超音速火焰喷涂系统,该系统以航空煤油作为燃料,氧气作为助燃气,氮气作为载气,工艺参数为:煤油流量22 L/h、氧气流量52 m3/h,送粉量60 g/min,喷涂距离360 mm,涂层厚度为200~220 μm。

喷涂后试样在SX JK-4-13型程序控制箱式电阻炉及SXZ16-12-13YZ型真空气氛烧结炉(保护气体为氩气,试验前排空炉内空气)中进行热处理,热处理工艺为600 ℃保温3 h。

采用SUPRA55型场发射扫描电子显微镜(SEM)分析涂层的微观形貌。采用XPer Powder型X射线衍射仪(XRD)测定粉末与涂层的相结构。采用KMM-500型金相分析仪测试涂层截面的孔隙率,测量5个视场取平均值。

采用WDW-50kN型微机控制电子万能试验机测试试样的结合强度,测试夹具及试样按照国标 GB/T8642—2002制作,采用FM1000薄膜胶进行粘结并固化,拉伸速率为0.5 mm/min,制备两组试样进行测试取平均值。

采用HXD-1000TMC型显微硬度计测试试样的显微硬度,峰值载荷为0.3 N,加载时间15 s,每个试样测量15个点,去掉极值后取平均值。采用HT-1000型球-盘摩擦磨损试验机考察试样在干摩擦下的磨损性能,采用d 4 mm 氮化硅陶瓷球进行对磨,试验时间为180 min,载荷为1000 g,摩擦圆半径为6 mm,转速1120 r/min,并采用LE225D型十万分之一电子天平进行质量损失称量。

采用LTM-200型冲蚀试验机模拟泥沙冲蚀,砂子密度为40%,搅动砂子的叶片转速为1200 r/min,并采用LE225D型十万分之一电子天平进行质量损失称量。

图1 涂层的SEM像

Fig. 1 SEM images of coatings

2 结果与分析

2.1 涂层微观形貌、孔隙率及结合强度

图1所示为涂层横截面的SEM像。由图1中可以看出,未经过热处理的涂层具有致密的结构,WC硬质合金相呈较大的颗粒状分布在Co相中;经过600 ℃的高温作用后,WC颗粒更加均匀的分布在Co相中(见图1(d)和(f))。并且在高温及氧化的共同作用下,涂层的孔隙率明显增大,同时部分孔隙发生了扩散,与临近的孔隙连接在一起形成微裂纹(如图1(d)所示)。而只受到高温作用时,涂层仍保持较好的致密性(见图1(f))[10-12]。

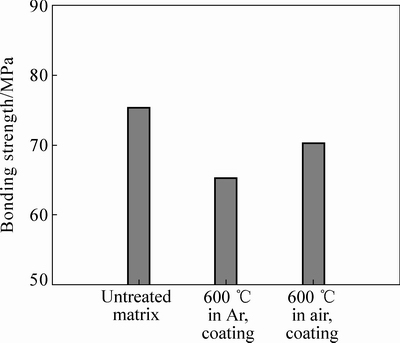

涂层与基体的结合强度测试结果如图2所示。由图2中可以看出,未经过热处理时涂层的结合强度为75 MPa;经过空气中的600 ℃热处理后,涂层的结合强度下降到65 MPa;经过Ar保护下的600 ℃热处理后,涂层的结合强度也有所下降(为70 MPa)。这是由于涂层的热膨胀系数与基体有较大的差别,经过热处理产生的热应力不同,涂层原本的压应力会向拉应力转变,影响涂层的结合强度,同时高温氧化会导致涂层的脆性提高,进一步影响涂层的结合强度[13-14]。

图2 涂层与基体的结合强度

Fig. 2 Bonding strength of coatings and matrix

2.2 涂层相组织结构分析

图3所示为涂层的XRD谱。由图3可看出,在常规大气环境中经过600 ℃热处理后,涂层的相组织结构发生了明显的改变,WC、Co及Cr经过氧化转变为CoWO4、CrWO4、Cr2O5、C2CoO4、WO3、C6WO6等新组织。通过物相分析K值法可知衍射峰强度与物相含量的关系为

(1)

(1)

式中:wX为X相的质量分数;IX为X相的衍射峰强度;wS为标准参比相的质量分数;IS为参比相的衍射峰强度;KX为X相的K值常数。

涂层中各物相的含量与其衍射峰的强度成正比,与其K值成反比:

(2)

(2)

根据Jade中的PDF卡片可以得到WC的K值为14.94、CoWO4的K值为5.6,并根据XRD测试结果(如图3(a)所示)可知WC的衍射峰强度为717,CoWO4的衍射峰强度为3013。通过式(2)可以计算出涂层中CoWO4相与WC相含量的质量比为11.2:1。说明经过高温氧化后涂层中WC含量大幅下降,其主要成分转变为CoWO4等氧化物;而在Ar保护下,涂层经过高温热处理后,相组织结构未发生明显改变。这说明高温对涂层的相组织结构基本不产生影响,而氧化使得涂层的相组织结构发生明显改变。涂层中WC、Co及Cr被氧化形成氧化物会导致涂层的脆性提高影响涂层性能[15-20]。

图3 涂层的XRD谱

Fig. 3 XRD patterns of coatings

2.3 涂层显微硬度分析

经过显微硬度测试发现,在经过600 ℃高温热处理后涂层的平均显微硬度值有了一定的提高,并且Ar保护下涂层获得更高的显微硬度值,如图4所示。从图4中还可以看出,经过空气中的高温热处理后,涂层局部的显微硬度值有了明显的提高,达到1510HV0.2,但硬度分布仍不均匀,平均显微硬度为1368HV0.2与未热处理涂层显微硬度(1319HV0.2)相当;而经过Ar保护下的高温热处理后,涂层的显微硬度分布变得均匀,并且有了显著的提高,平均显微硬度为1508HV0.2。

说明涂层在空气环境热处理过程中生成的CoWO4、Cr2O5、C6WO6等氧化物相会提高涂层的局部硬度,但这些氧化相脆性较高,并且涂层的孔隙率变大,使得显微硬度测试时压头压入涂层会造成局部塌陷(如图5(a)所示),得到较低的显微硬度值;而经过Ar保护下的热处理后,涂层中WC颗粒分布的更加均匀,因此涂层的显微硬度测试时压头基本作用在WC硬质相上(见图5(b)),并且WC本身的显微硬度高达1620HV0.2,使得涂层获得较高的平均显微硬度[21]。

图4 涂层显微硬度值测试分布

Fig. 4 Micro-hardness distribution of coatings and matrix

图5 涂层的显微硬度测试图

Fig. 5 Micro-hardness test graphs of coatings

2.4 涂层耐磨损性能测试分析

图6所示为涂层在180 min摩擦磨损试验后的磨损质量损失。从图6中可以看出,经过空气中600 ℃热处理后,涂层的磨损量较未热处理时明显升高;而经过Ar保护下600 ℃热处理后,涂层的磨损量较未热处理时大幅降低。这说明600 ℃条件下涂层的局部显微硬度有了一定的提高,但高温氧化对涂层的耐干磨损性能带来了不利的影响,涂层中新产生的氧化物组织具有较高的脆性,在与对磨球摩擦时发生破碎并产生微裂纹。图7所示为涂层的摩擦因数曲线。从图7可以看出,摩擦磨损过程中涂层的氧化物不断破碎与对磨球发生磨粒磨损,摩擦界面较为粗糙,摩擦因数较高,且波动较大;未经过热处理的涂层在与对磨球发生摩擦时,初期由于涂层表面较为粗糙,主要发生磨粒磨损,磨损量较大,摩擦因数较高[22]。经过一段时间的摩擦后,涂层表面凸起的部分被磨平,摩擦面趋向同一平面并变得光滑,摩擦因数降低,此时主要起到耐磨作用的是WC硬质颗粒,但是在摩擦的过程中WC硬质颗粒会被摩擦剥落形成凹坑(见图8(a)),不利于涂层的耐磨性能;由于涂层的平均显微硬度在经过Ar保护下热处理后有了显著的提高,促使涂层的耐磨性能有了相应的提高,并且由于涂层中WC颗粒更加均匀地分布在Co、Cr相中,使得WC颗粒在摩擦磨损过程中基本不发生剥落,形成平整光滑的摩擦界面(见图8(b)),有利于提高涂层的耐磨性能。

图6 涂层摩擦磨损试验的磨损质量损失

Fig. 6 Wear mass loss of coatings and matrix

图7 涂层的摩擦因数曲线

Fig. 7 Friction coefficient curves of coatings and matrix

图8 涂层摩擦磨损形貌

Fig. 8 Worn morphologies of coatings and matrix

2.5 涂层耐泥沙冲蚀性能测试分析

经过12 h泥沙冲蚀后涂层的质量损失如图9所示。从图9中可以看出,经过空气中600 ℃热处理涂层的冲蚀质量损失明显高于未热处理涂层的(升高了86%),而经过Ar保护600 ℃热处理涂层的冲蚀质量损失较未热处理涂层有所降低。这说明高温氧化虽然使涂层的显微硬度有所提高,但由此带来的涂层脆性的升高以及大量氧化相的生成使得涂层的耐冲蚀性能大幅降低,表现为涂层表面脆性较高的氧化物在受到泥沙冲击时氧化物容易破碎形成较大的凹坑,以及高温氧化形成的大孔隙、微裂纹也容易被冲击破坏形成大的凹坑(见图10(a));在Ar保护下,涂层仅受到高温作用而未发生氧化,使得涂层的显微硬度大幅提高,并且WC相与Co、Cr相更加紧密的结合在一起,使涂层的耐冲蚀性能获得一定幅度的提高,被泥沙冲蚀出的凹坑也较小,并且经过泥沙冲刷,涂层表面变得光滑(见图10(b)),涂层的耐冲蚀性能得到进一步强化。

图9 涂层的冲蚀质量损失

Fig. 9 Errosion wear mass loss of coatings and matrix

图10 涂层的冲蚀形貌

Fig. 10 Errosion morphologies of coatings

3 结论

1) WC-10Co4Cr涂层在空气中进行600 ℃热处理后发生了氧化,涂层中WC、Co、Cr相的含量逐渐降低,转化为CoWO4、Cr2O5、C6WO6等氧化物相,涂层孔隙率明显升高并出现微裂纹,涂层的结合强度有所降低。

2) 通过Ar保护后,涂层在热处理过程中只受到高温的作用,涂层未发生明显氧化,仍保持良好的结合强度。

3) 在高温及氧化的双重作用下,涂层局部的显微硬度明显提高,但平均显微硬度未明显改变,并且涂层的耐干磨损性能及耐泥沙冲蚀性能大幅下降。

4) 在单一的高温作用下,涂层中的WC相更加均匀地分布在Co、Cr相中,涂层表面获得更加均匀的显微硬度分布,显微硬度值显著提高,并且涂层的耐干磨损性能及耐泥沙冲蚀性能大幅提高。

REFERENCES

[1] 王海军, 蔡 江, 韩志海. 超音速等离子与HVOF喷涂WC-Co涂层的冲蚀磨损性能研究[J]. 材料工程, 2005(4): 50-54.

WANG Hai-jun, CAI Jiang, HAN Zhi-hai. Study on erosion wear of WC-Co coatings prepared by supersonic plasma spray and HVOF spray[J]. Journal of Materials Engineering, 2005(4): 50-54.

[2] 周夏凉, 陈小明, 赵 坚, 王莉容, 程文韬, 伏 利, 毛鹏展. HVOF喷涂WC-12Co涂层性能及磨蚀机理[J]. 腐蚀与防护, 2014, 35(10): 994-996.

ZHOU Xia-liang, CHEN Xiao-ming, ZHAO Jian, WANG Li-rong, CHEN Wen-tao, FU Li, MAO Peng-zhan. Properties and abrasion mechanism of WC-12Co coating prepared by HVOF[J]. Corrosion & Protection, 2014, 35(10): 994-996.

[3] 王瑞雪, 刘 阳, 李 曙. 爆炸喷涂WC-12%Co涂层的滑动磨损性能[J]. 中国有色金属学报, 2015, 15(11): 1687-1691.

WANG Rui-xue, LIU Yang, LI Shu. Sliding wear resistance of detonation-gun sprayed WC-12%Co coatings[J]. The Chinese Journal of Nonferrous Metals, 2015, 15(11): 1687-1691.

[4] 吴燕明, 赵 坚, 陈小明, 杨 潇, 毛鹏展, 赵 鹏. 超音速喷涂纳米WC复合涂层与电镀铬层的组织及性能[J]. 材料热处理学报学报, 2015, 36(S1): 171-176.

WU Yan-ming, ZHAO Jian, CHEN Xiao-ming, YANG Xiao, MAO Peng-zhan, ZHAO Peng. Microstructure and properties of high velocity sprayed nano WC composite coatings and chromium platings[J]. Transactions of Materials and Heat Treatment, 2015, 36(S1): 171-176.

[5] 伍超群, 周克崧, 刘 敏, 邓畅光, 邓春明. 热处理对NiCrWB-WC复合涂层组织和性能的影响[J]. 金属热处理, 2007, 32(7): 47-50.

WU Chao-qun, ZHOU Ke-song, LIU Min, DENG Chang-guang, DENG Chun-ming. Effects of heat treatment on microstructure and properties of NiCrWB-WC composite coating[J]. Heat Treatment of Metals, 2007, 32(7): 47-50.

[6] 王 群, 屈帮荣, 唐瞾肸, 熊浩奇. 超音速火焰喷涂WC-10Co4Cr涂层的耐滑动磨损行为[J]. 中国有色金属学报, 2015, 25(7): 1920-1927.

WANG Qun, QU Bang-rong, TANG Zhao-xi, XIONG Hao-qi. Abrasive wear behavior of WC-Co coating deposited by high velocity oxygen flame process[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1920-1927.

[7] 李松林, 向锦涛, 周伍喜, 李玉玺, 陈 文. 超音速火焰喷涂WC-10Co4Cr涂层的耐滑动磨损行为[J]. 中国有色金属学报, 2012, 22(5): 1371-1376.

LI Song-lin, XIANG Jing-tao, ZHOU Wu-xi, LI Yu-xi, CHEN Wen. Sliding wear behavior of high-velocity oxy-fuel sprayed WC-0C04Cr coatings[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1371-1376.

[8] 张光华, 李 曙, 刘 阳, 王华仁. HVOF喷涂WC-10Co-4Cr涂层的砂浆冲蚀行为[J]. 中国表面工程, 2007, 20(4): 16-28.

ZHANG Guang-hua, LI Shu, LIU Yan, WANG Hua-ren. Slurry erosion behavior of HVOF sprayed WC-10Co-4Cr coatings[J]. China Surface Engineering, 2007, 20(4): 16-28.

[9] 赵 坚, 陈小明, 吴燕明, 王莉容, 伏 利, 马红海. 启闭机活塞杆表面超音速火焰喷涂WC-10Co-4Cr涂层的性能[J]. 中国表面工程, 2014, 27(3): 71-75.

ZHAO Jian, CHEN Xiao-ming, WU Yan-ming, WANG Li-rong, FU Li, MA Hong-hai. Properties of WC-10Co-4Cr coatings sprayed by HVOF on hoist piston rod surface[J]. China Surface Engineering, 2014, 27(3): 71-75.

[10] DING Z X, CHEN W, WANG Q. Resistance of cavitation erosion of multimodal WC-12Co coatings sprayed by HVOF[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2231-2236.

[11] WANG Q, CHEN Z Z, LI L X, YANG G B. The parameters optimization and abrasion wear mechanism of liquid fuel HVOF sprayed bimodal WC-12Co coating[J]. Surface and Coatings Technology, 2012, 206(8/9): 2233-2241.

[12] KARIMI A, VERDON C, BARBEZAT G. Microstructure and hydroabrasive wear behaviour of high velocity oxy-fuel thermally sprayed WC-Co(Cr)coatings[J]. Surface & Coatings Echnology, 1993, 57(1): 81-89.

[13] ZHAO X Q, ZHOU H D, CHEN J M. Comparative study of the friction and wear behavior of plasma sprayed conventional and nanostructured WC-12%Co coatings on stainless steel[J]. Materials Science and Engineering A, 2006, 431(1/2): 290-297.

[14] CHEN H, GOU G, TU M, LIU Y. Research on the friction and wear behavior at elevated temperature of plasma-sprayed nanostructured WC-Co coatings[J]. Journal of Materials Engineering and Performance, 2010, 19(1): 1-6.

[15] 廖立兵. X射线衍射方法与应用[M]. 北京: 地质出版社, 2008.

LIAO Li-bing. X-ray diffraction method and application[M]. Beijing: Geological Publishing House, 2008.

[16] STEWART D A, SHIPWAY P H, MCCARTNEY D G. Influence of heat treatment on the abrasive wear behaviour of HVOF sprayed WC-Co coatings[J]. Surface and Coatings Technology, 1998, 105(1/2): 13-24.

[17] KHAMENEH S A, HEYDARZADEH M S, HOKAMOTOA K, et al. Effect of heat treatment on wear behavior of HOVF thermally sprayed WC-Co coatings[J]. Wear, 2006, 260(11/12): 1203-1208.

[18] 王引真, 孙永兴, 曹文军. 超音速火焰喷涂工艺参数对镍基涂层结构和性能的影响[J]. 机械工程材料, 2005, 26(3): 70-72.

WANG Yin-zhen, SUN Yong-xing, CAO Wen-jun. Effect of technical parameters of high velocity oxygen fuel spraying on the structure and properties of nickel alloy coatings[J]. Materials for Mechanical Engineering, 2005, 26(3): 70-72.

[19] NERZ J, KUSHNER B, ROTOLICO A. Microstructural evaluation of tungsten carbide-cobalt coatings[J]. Journal Thermal Spray Technology, 1992, 1(2): 147-152.

[20] 潘荣伟, 李 晃, 佟月宇, 陈益兰. 用K值法对硫铝酸钙含量进行定量分析研究[J]. 无机盐工业, 2013, 45(6): 43-45.

PAN Rong-wei, LI Huang, TONG Yue-yu, CHEN Yi-lan. Quantitative analysis of calcium sulphoaluminate content with K value method[J]. Inorganic Chemicals Industry, 2013, 45(6): 43-45.

[21] 肖逸锋, 贺跃辉, 丰 平, 谢 宏, 马自省, 张丽娟, 黄自谦, 黄伯云. 渗碳工艺对WC-Co梯度硬质合金的梯度结构和硬度的影响[J]. 中国有色金属学报, 2008, 18(3): 465-470.

XIAO Yi-feng, HE Yue-hui, FENG Ping, XIE Hong, MA Zi-xing, ZHANG Li-juan, HUANG Zi-qian, HUANG Bai-yun. Effects of carburizing process on gradient structure and hardness of WC-Co gradient cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 465-470.

[22] GAHR K H Z. Microstructure and wear of materials[M]. Amsterdam: Elsevier Science Publishers, 1987: 340-345.

Effect of high temperature and oxidation on microstructure and properties of WC-10Co4Cr coatings

WU Yan-ming1, 2, ZHAO Jian1, 2, CHEN Xiao-ming1, 2, FU Li3, 4, MAO Peng-zhan2, 3, ZHOU Xia-liang2, 3

(1. Standard and Quality Control Research Institute, Hangzhou 310012, China;

2. Hydraulic Machinery and Remanufacturing Technology Engineering Laboratory of Zhejiang Province, Hangzhou 310012, China;

3. Hydraulic Machinery and Remanufacturing Technology Engineering Laboratory of Zhejiang Province, Hangzhou 310012, China;

4. Hangzhou Mechanical Research Institute, Hangzhou 310012, China)

Abstract: The effects of temperature and oxidation on the microstructure, microhardness, binding strength, wear resistance, corrosion wear resistance of high velocity sprayed WC-10Co4Cr coatings were investigated by using X-ray diffraction (XRD), scanning electron microscopy (SEM), microhardness measurement, wear testing machine and wear corrosion testing machine. The results show that the coatings are high temperature oxidized obviously after heat treatment at 600 ℃ in air. WC, Co, Cr content are reduced and converted into CoWO4, Cr2O5, C6WO6, and so on, the porosity of coatings increases significantly, the bonding strength reduces. Although the microhardness value of the coatings increases, but the wear resistance and corrosion wear resistance reduce significantly. The coatings is only subjected at high temperature of 600 ℃ in Ar, the microstructures of the coatings do not change obviously, the microhardness is improved by large margin and distributes more uniformly, the wear resistance and corrosion wear resistance are improved by large margin.

Key words: WC-10Co4Cr coatings; high temperature; oxidation; microstructure; properties

Foundation item: Project (2014C31156, 2016C3791) supported by Science and Technology Plan of Zhejiang Province, China; Project(2015132-4) supported by Bureau of Comprehensive Ministry of Water Resource Top-notch Talent, China

Received date: 2016-05-26; Accepted date: 2016-10-28

Corresponding author: WU Yan-ming; Tel: +86-571-88082887; E-mail: wuyanming2193@126.com

(编辑 李艳红)

基金项目:浙江省科技计划项目(2014C31156,2016C3791);水利部综合事业局拔尖人才专项(2015132-4)

收稿日期:2016-05-26;修订日期:2016-10-28

通信作者:吴燕明,教授级高级工程师;电话:0571-88082887;E-mail:wuyanming2193@126.com