Determination of strain criterion of Portevin–Le Chatelier effect for aluminum alloy sheets

WAN Min(万 敏)1, HAN Jin-quan(韩金全)1, JIN Hai-xia(金海霞)1,

WU Hui(伍 惠)2, DONG Jin-liang(董锦亮)2, LI Bing(李 兵)2, GU Wei(顾 伟)2

1. School of Mechanical Engineering and Automation, Beihang University, Beijing 100083, China;

2. Chengdu Aircraft Industrial Co Ltd, Chengdu 610092, China

Received 28 July 2006; accepted 15 September 2006

Abstract: According to the deformation state in skin stretch forming, an experiment was investigated to determine the critical strain, which make the slip line occur, and the strain criteria under different strain paths are obtained. The uniaxial tension tests of different specimens were carried out to determine the critical strains of different strain paths. Then, the slip line limited curve(SLC) is available from these critical strains. Two kinds of aluminum alloys, 2024-T3 and 2524-T3, were studied, and two SLCs are gained. The application of the SLC to an airplane skin stretch forming simulation was investigated, and the results show that the SLC can be used to control the slip lines occurring in practice.

Key words: aluminum alloy; PLC effect; strain path; slip line limited curve(SLC); stretch forming; airplane skin

1 Introduction

Slip line is one of the prime surface defects in skin forming because of the decrease of the aerodynamics performance, corrosion resistance and fatigue strength of airplane skin. Slip line has two kinds, namely Lüders line at the beginning of deformation and PLC line during deformation[1-4], the latter is generally considered as the main one in stretch forming of aluminum alloy skin, particularly for aluminum alloy mirror skins[5]. Slip line caused by PLC effect is the macroscopical phenomenon of dynamic strain aging(DSA) and dislocation interaction[6]. It shows that PLC bands propagate through specimens or parts and the stress-strain curves oscillate acutely[3,7]. Because it is microcosmic and theoretical, most of the researches on PLC effect are not applicable to the manufacturing. However, in practical processing, the stretch deformation value is usually controlled to avoid the slip lines occurring, but it consequentially reduces the shape fixability of skin parts. Hence, an accurate criterion is required in mirror skin forming to avoid the slip lines ocurring. It is one of key issues in aluminum mirror skin forming how to get balance between avoidance of slip lines and improvement of shape fixability[5,8].

2 Experimental

The strain state in airplane skin stretch forming is mainly intervenient between uniaxial tension and plane strain, and the strain path is approximately linear[9]. The specimens were designed in different shapes to obtain various strain paths. Two kinds of materials 2524-T3 and 2024-T3 with polishing surface on one side of sheet metal were investigated. Grids used to measure surface strain after deformation are printed on the unpolished surface of all specimens. Then, uniaxial tension test was carried out and loading would stop as soon as slip lines appeared. The deformations of grids were measured with the Grid Measurement Analysis System(GMAS) developed by Beihang University to gain the slip line critical strain of various strain paths. And the slip line limited curves(SLC) of 2524-T3 and 2024-T3 could be plotted on major-minor strain diagram with data obtained from measurement.

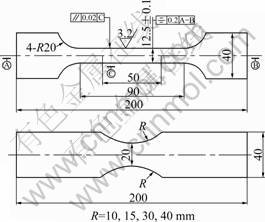

The shape and dimension of specimens are shown in Fig.1. The same specimens were applied to both of 2524-T3 and 2024-T3 because of the similar mechanical property, blank thickness (t=2 mm) and heat treating state. Anisotropism was ignored because the blank was stretched along rolling direction in actual processing, and the specimens were also cut along rolling direction. The test was simulated first to confirm the dimension of specimens and predict the conceivable results. The quarter models were founded because of the symmetry of specimens and assigned the two materials 2524-T3 and 2024-T3.

Fig.1 Schematic diagram of specimens (mm)

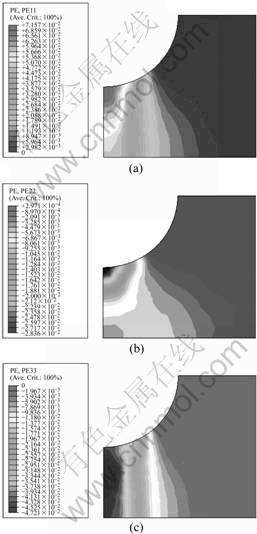

The simulation results of the specimen with R of 10 mm are shown in Fig.2. From Fig.2, the strain state in the centre is near plane strain state. And other results for different specimens indicate that the strain states are intervenient between uniaxial tension strain state and the plane strain state.

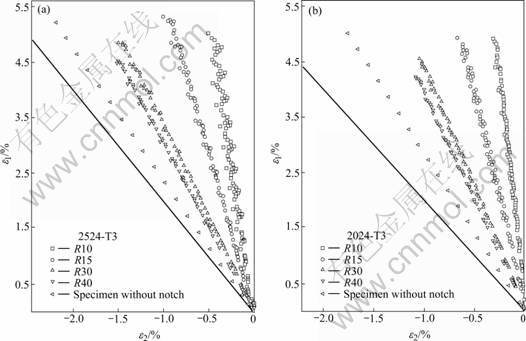

Nodes in the centre of each specimen in simulation were selected to draw the major-minor strain diagram with their major strain and minor strain to obtain the strain path during deformation. The strain paths of all specimens are shown in Fig.3. The exactitude of specimens design was validated by the simulation, and the results are shown in Fig.3. Every strain path is different from others, and all the paths distribute between the strain states of uniaxial tension and plane strain.

Fig.2 Plastic principal strain of specimen with R of 10 mm: (a) Major strain on plane; (b) Minor strain on plane; (c) Thickness strain

Fig.3 Strain paths of central nodes: (a) 2524-T3; (b) 2024-T3

3 Results and discussion

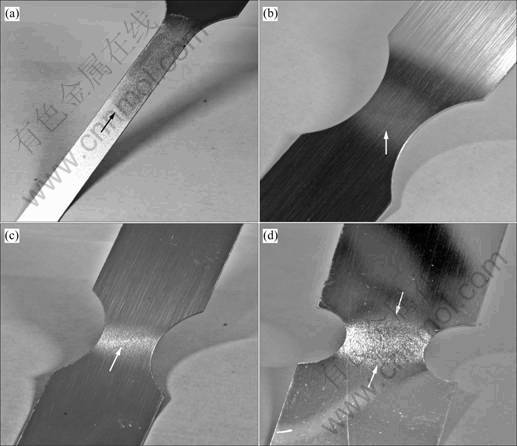

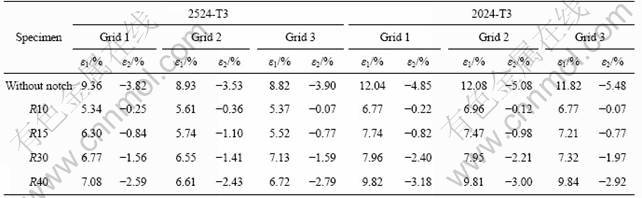

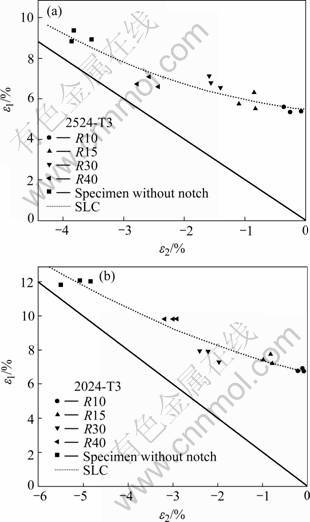

The specimens with slip lines in the centre predicted in simulation are shown in Fig.4. The strain distribution of each specimen was measured by GMAS, and strain data of three grids are shown in Table 1.

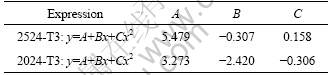

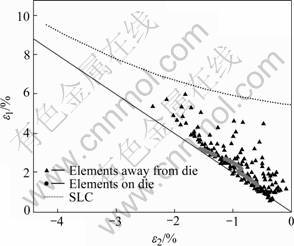

In order to obtain SLCs of 2524-T3 and 2024-T3, the software MATLAB was applied to fit the data (listed in Table 1). Quadratic power function is adopted to fit the data, and the smooth curves are obtained with the smallest residual error which is shown in Fig.5 and Table 2. It is concluded from Fig.5 that the occurrence of slip lines is concerned with the strain state of material and slip lines occur more easily in plane strain state than in uniaxial tension strain state. And it is indicated that slip lines with the material appear easier 2524-T3 than 2024-T3.

Fig.4 Specimens with slip lines: (a) R10; (b) R15; (c) R30; (d) R40

Table 1 Strain of each specimen

Fig.5 Slip line curves of 2524-T3 and 2024-T3

Table 2 Expression of two curves

4 Application

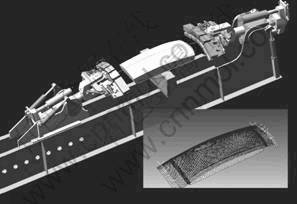

In order to analyze the validity of SLC obtained above, the numerical simulation of the longitudinal stretch forming process is performed for airplane head skin of aluminum alloy and the SLC is used to estimate whether slip lines appear on local regions of the blank.

The skin part material is 2524-T3, and the simulation code is ASSFCAE developed by Beihang University[10]. The process simulation is shown in Fig.6, and the major and minor strains after stretching are picked up from the regions contacting and not contacting the die, respectively, the results are plotted on major-

minor diagram in Fig.7. The results show that the slip lines do not appear and the process of stretch forming is safe.

Fig.6 Simulation of skin stretch forming

Fig.7 Distribution of in-plane strain on SLC

So, the SLC is very useful in simulation, which can be used to optimize the process parameters to prevent the slip lines.

5 Conclusions

The numerical simulation of the longitudinal stretch forming process is performed for airplane head skin of aluminum alloy and the SLC is used to estimate whether slip lines appear on local regions of the blank. The result shows that SLC is very useful in simulation, which can be used to optimize the process parameters to prevent the slip lines.

Acknowledgements

The author would like to take this opportunity to express their apprecation.

References

[1] LEBYODKIN M, BRECHET Y, ESTRIN Y, KUBIN L. Statistical behaviour and strain localization patterns in the Portevin-Le chatelier effect [J]. Acta Materialia, 1996, 44: 4531-4541.

[2] LEBYODKIN M A, ESTRIN Y. Multifractal analysis of the Portevin-Le chatelier effect: general approach and application to AlMg and AlMg/Al2O3 alloys [J]. Acta Materialia, 2005, 53: 3403-3413.

[3] RIZZI E, H?HNER P. On the Portevin-Le chatelier effect: Theoretical modeling and numerical results [J]. International Journal of Plasticity, 2004, 20: 121-165.

[4] HENNING M, VEHOFF H. Local mechanical behavior and slip band formation within grains of thin sheets [J]. Acta Materialia, 2005, 53: 1285-1292.

[5] WAN M,. ZHOU X B, LI X X, WU H. Process parameters in stretch forming of mirror skins [J]. Acta Aeronautica ET Astronautica Sinica, 1999, 20(4): 326-330. (in Chinese)

[6] KLOSE F B, ZIEGENBEIN A, HAGEMANN F, NEUH?USER H, H?HNER P, ABBADI M, ZEGHLOUL A. Analysis of Portevin-Le chatelier serrations of type bin Al–Mg [J]. Materials Science and Engineering B, 2004, 369(1/2): 76-81.

[7] ZHANG Qing-chuan, JIANG Zhen-yu, JIANG Hui-feng, CHEN Zhong-jia, XU Xiao-ping. On the propagation and pulsation of Portevin-Le Chatelier deformation bands: An experimental study with digital speckle pattern metrology [J]. International Journal of Plasticity, 2005, 21(11): 2150-2173.

[8] WU H. Stretch forming processes of double curved mirror skin [J]. Aeronautical Manufacturing Technology, 2002, 3: 55-57. (in Chinese)

[9] JIN H X. Basic Experiment Research and Numerical Simulation on Mirror Aluminum Alloy Skin Stretch Forming [D]. Beijing: Beihang University, 2006. (in Chinese)

[10] LI W D, WAN M. Computer aided engineering system for aircraft stretch forming [J]. Journal of Plasticity Engineering, 2005, 12(sup): 200-203. (in Chinese)

(Edited by LI Yan-hong)

Foundation item: Project(K0604020509) supported by Chengdu Aircraft Industrial Co. Ltd and National Foundation of Research of China

Corresponding author: WAN Min; Tel: +86-10-82338788; E-mail: mwan@buaa.edu.cn