DOI: 10.11817/j.issn.1672-7207.2018.07.012

基于机器视觉的热轧中间坯镰刀弯在线检测系统

徐冬,杨荃,王晓晨,孙友昭,刘克东,代振洋

(北京科技大学 国家板带生产先进装备工程技术研究中心,北京,100083)

摘要:为了能够实现对中间坯镰刀弯的非接触在线测量,提出通过基于机器视觉技术的镰刀弯在线测量方案。将面阵CCD相机布置在粗轧机出口倾斜拍摄中间坯表面形状:首先通过亚像素角点定位完成相机标定;再次,通过引入中间坯厚度变量实现对不同厚度的中间坯平面形状由图像坐标向世界坐标转化;最后通过中间坯边缘轮廓连续变化的原理,计算具有重叠区域的连续中间坯图像沿宽度方向的平移量和整体的旋转量,完成中间坯平面图像的拼接。研究结果表明:通过所提出的测量系统及算法可以获得完整的中间坯平面图像及镰刀弯值,通过与工业现场测宽仪的测量结果对比,可知系统测量结果能够反映中间坯弯曲的趋势及细节特征,为热连轧粗轧过程中间坯镰刀弯的控制提供了有效测量手段。

关键词:热轧粗轧;镰刀弯;机器视觉;测量系统

中图分类号:TP391.4 文献标志码:A 文章编号:1672-7207(2018)07-1657-10

Vision-based camber on-line measurement system in hot rough rolling

XU Dong, YANG Quan, WANG Xiaochen, SUN Youzhao, LIU Kedong, DAI Zhenyang

(National Engineering Research Center of Flat Rolling Equipment,

University of Science and Technology Beijing, Beijing 100083, China)

Abstract: To achieve non-contact and on-line measurement of camber in a hot rolling, the design and implementation of an image-based computer vision measurement system was proposed. In order to capture the plane images of intermediate slab, the area-scan charge-coupled device (CCD) camera was installed at the exit of the rough mill. The camber-detection algorithm consists of three parts. Firstly, the camera was calibrated by subpixel corner detection. Secondly, by introducing the thickness variable, the relationship between the physical positions on the intermediate slab and their relative image positions was formulated. Finally, the translation along the width direction and the rotation were calculated using the continuity of the intermediate slab edge shape, and then each frame capture with overlapped regions from the CCD camera was stitched. The results show that the propose camber measurement system and camber-detection algorithm can achieve the overall slab shape and camber values from the obtained image. The equipment and technique are validated through comparison with center-line deviation measured by width gauge. The accuracy of the system reflects that it can reflect the detailed character of the shape of intermediate slab, which provides a potential measurement tool for camber control.

Key words: hot rough rolling; camber; machine vision; measurement system

在热连轧生产中,粗轧中间坯的镰刀弯是热轧粗轧阶段板坯不对称缺陷的主要表现形式,产生镰刀弯现象的根本原因是轧制时中间坯两侧压下不同,使中间坯两侧的长度方向上的延伸不同[1-2]。粗轧出口中间坯的镰刀弯缺陷不仅会影响成品带钢的板形和尺寸,而且会影响后续精轧过程的轧制稳定性,严重时甚至会导致堆钢事故[3]。为了能够实现对中间坯镰刀弯的有效控制,首先要完成对中间坯镰刀弯的测量。中间坯温度高,生产节奏快,其镰刀弯程度难以人工测量,因此,生产现场主要依靠操作工直接观察中间坯表面形状,根据经验调整轧机辊缝的倾斜来消除和控制镰刀弯。近些年来,随着机器视觉技术的发展,很多研究者采用CCD相机对中间坯进行拍摄,从而获得中间坯的平面形状,为镰刀弯的控制提供检测手段[4]。在通常情况下,热轧中间坯的镰刀弯问题多发生在中间坯的头部和尾部3~5 m 处,许多学者采用CCD相机对中间坯头、尾局部区域进行拍摄,获取镰刀弯信息,包括:采用3台线阵相机同步采集图像,用三点法来检测中间坯头尾镰刀弯[5-6];采用单目[7]、双目[8]的线阵相机,通过连续取样测量中间坯头、尾带钢的平面形状;通过布置在粗轧机上方的单台面阵CCD相机完成对粗轧中间坯头部镰刀弯的检测[9-11]。除此之外,为了能够测量中间坯全长的镰刀弯信息,可以通过一次拍摄对粗轧前后的中间坯全长进行成像,此时面阵CCD相机只能安装在距离中间坯较远的地方,拍摄倾角较大,中间坯尾端在所成相中所占像素很少,测量误差较大[12-13]。为了进一步提高检测精度,采用面阵CCD相机对运动中间坯局部连续拍摄,并利用连续图片序列拼接成完整中间坯平面形状的测量方案被广泛认可,同时,随着图像处理技术的发展,这种方案也被应用于实际生产过程中,包括:采用中间坯速度和拍摄时间间隔计算2张图像中板坯沿长度方向的移动距离的方法[14-15];采用寻找2幅具有重叠区域的中间坯表面图像的特征点,通过匹配特征点的垂直距离确定2张中间坯图像的重叠距离的方法[16-18]。本文作者将面阵CCD相机布置在粗轧机出口倾斜拍摄中间坯表面形状,通过亚像素角点定位完成相机标定,通过引入中间坯厚度变量实现对不同厚度的中间坯品面形状由图像坐标向世界坐标的转化,最后通过中间坯边缘轮廓连续变化的原理,计算具有重叠区域的连续中间坯图像沿宽度方向的平移量和整体的旋转量,完成中间坯平面图像的拼接,得到完整的中间坯平面图像及镰刀弯值,为热连轧粗轧过程中间坯镰刀弯的控制提供了测量手段。

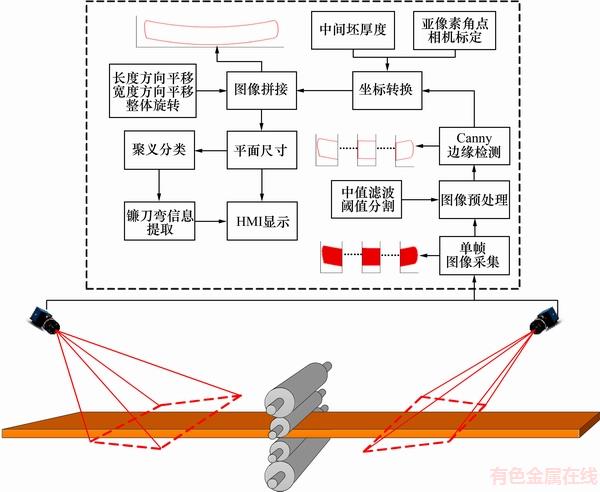

1 测量系统结构

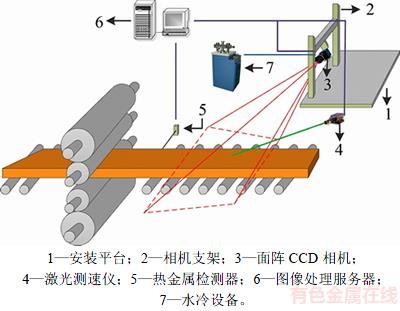

本文提出的镰刀弯在线检测系统结构和工作示意图如图1所示。当中间坯到达指定检测位置时,热金属检测器检测到中间坯头部位置,对应侧面阵 CCD 相机进行拍摄,激光测速仪开始测量中间坯运行速度,然后将拍摄的中间坯上表面图像及测量的中间坯运动速度经千兆网传输至图像处理服务器,经图像处理获得可视化中间坯平面形状和中间坯镰刀弯曲量,并显示在用户显示器上。

图1 测量系统示意图

Fig. 1 Schematic diagram of measurement system

1.1 光学器件

光学器件安装在轧机出口的辊道正上方安装平台上,对中间坯上表面进行倾斜拍摄。光学器件包含1个黑白面阵CCD相机、定焦镜头及千兆网线。其中面阵CCD感光传感器平面尺寸为12.7 mm×9.6 mm,像素为3 376×2 704,镜头为千万像素固定焦距镜头(焦距为16 mm),因此,2个方向对应的视场角分别为43.3°和33.4°。相机选择千兆网通讯,使得传输距离大于50 m且帧速能够达到9 帧/s。为了隔绝现场灰尘与水汽,相机和支架密封在密闭空间内,同时为了相机工作在额定温度范围内,整个系统配备了水冷防护系统。

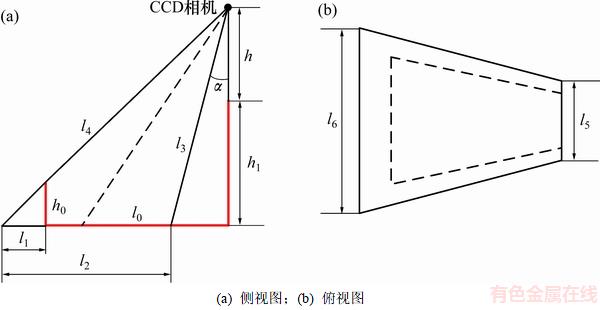

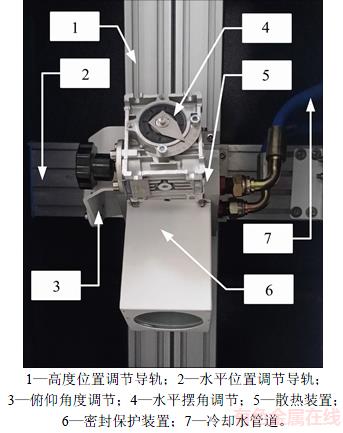

相机的安装高度h与拍摄角度 决定了测量范围及测量精度,如图2所示。图2中,h0为轧机出口测宽仪预留的挡板空隙高度,h1为安装平台距离辊道高度,l0为平台距离测宽仪挡板水平距离。图2中实线和虚线对应的视野范围为2个极限位置,不同相机安装高度及拍摄角度对应的测量长度l1和l2、宽l5和l 6及理论精度如表1所示。可知当相机安装在不同高度时,配合相应的拍摄角度,1次拍摄可以获取2.6~6.1 m长的带钢上表面图像,宽度范围精度在2 mm/像素以内。以某厂热连轧生产线为例,中间坯宽度小于1.5 m,粗轧时中间坯运行速度小于10 m/s,9 帧/s的帧速可以实现具有50%重叠区域的中间坯连续图像的获取。

决定了测量范围及测量精度,如图2所示。图2中,h0为轧机出口测宽仪预留的挡板空隙高度,h1为安装平台距离辊道高度,l0为平台距离测宽仪挡板水平距离。图2中实线和虚线对应的视野范围为2个极限位置,不同相机安装高度及拍摄角度对应的测量长度l1和l2、宽l5和l 6及理论精度如表1所示。可知当相机安装在不同高度时,配合相应的拍摄角度,1次拍摄可以获取2.6~6.1 m长的带钢上表面图像,宽度范围精度在2 mm/像素以内。以某厂热连轧生产线为例,中间坯宽度小于1.5 m,粗轧时中间坯运行速度小于10 m/s,9 帧/s的帧速可以实现具有50%重叠区域的中间坯连续图像的获取。

图2 光学器件安装及视野范围示意图

Fig. 2 Schematic diagram of optical devices and field of view

表1 光学器件不同安装位置的视野范围及精度

Table 1 Field of view and accuracy of different optical devices’ installation locations

1.2 图像处理器

图像处理器通过千兆网线接收轧机出口侧面阵CCD相机获取的连续的中间坯平面图像和激光测速仪获取的中间坯运行速度,经图像处理及计算后得到中间坯镰刀弯的信息。人机交互界面将显示整个中间坯的平面形状以及计算获取的镰刀弯信息,同时图像处理器将结果保存至质量管理数据库。

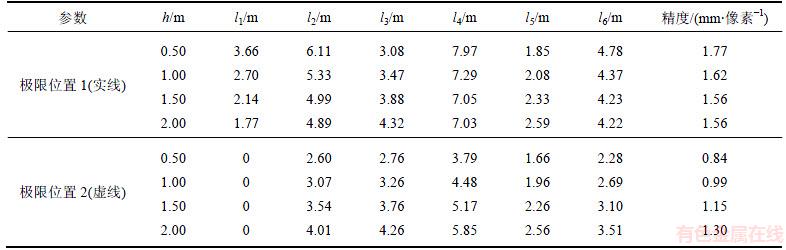

1.3 测量支架

相机支架通过地脚螺栓安装在辊道正上方的安装平台上,支架外部密封并留有安装、检修门以及位置可以调整的玻璃模块。其内部核心结构如图3所示,可以实现CCD相机高度和水平位置、俯仰角、水平摆角的调整,同时包含对相机进行密封保护的装置和水冷散热装置。

图3 相机支架核心结构示意图

Fig. 3 Schematic diagram of camera support’s core structure

2 测量算法

热轧粗轧中间坯镰刀弯在线检测系统算法流程如图4所示,首先通过张正友标定法确定相机的内部参数和辊道平面的外部参数[19]。根据CCD相机视野范围确定相机采样频率,当中间坯进入检测区域后,利用面阵CCD相机获取中间坯上表面连续局部图像,对中间坯图像进行预处理,采用Canny算法提取中间坯上表面轮廓像素坐标,通过粗轧工作站读入本道次中间坯厚度,根据相机成像原理及标定结果,确定中间坯上表面某点空间坐标与对应图像像素坐标之间的转换关系,利用所建立的转换关系计算中间坯轮廓实际坐标。在获取中间坯局部轮廓实际坐标基础上,根据采样频率及带钢运动速度确定连续2幅中间坯图像沿长度方向的移动距离,通过中间坯边缘轮廓连续变化的原理,计算2幅中间坯图像沿宽度方向的平移量和整体的旋转量,完成中间坯平面图像的拼接,获取中间坯上表面完整轮廓,并计算镰刀弯值。

2.1 相机标定

相机的标定是视觉检测技术应用中的关键步骤,标定的精度和效果直接影响系统的检测精度。相机针孔成像模型中主要涉及到3个坐标系—图像坐标系、相机坐标系和世界坐标系,三者的几何对应关系如下:

(1)

(1)

式中: 和

和 分别为空间某点的世界 坐标与图像坐标;

分别为空间某点的世界 坐标与图像坐标; ,

, ;

;

;

; ;

; ;M1为相机的内部参数矩阵,只与相机内部结构有关;M2为相机的外部参数矩阵,只与相机和外界环境的相对位置有关;M为投影矩阵。

;M1为相机的内部参数矩阵,只与相机内部结构有关;M2为相机的外部参数矩阵,只与相机和外界环境的相对位置有关;M为投影矩阵。

图4 热轧粗轧中间坯镰刀弯检测系统算法流程图

Fig. 4 Algorithm flow chart of intermediate slab camber detection system in hot rough rolling

2.2 张正友标定法

本文的研究对象是粗轧中间坯的平面形状和尺寸,检测精度要求较高,而且一旦确定安装后,相机的内外参数不会经常变动,因此,本文使用张正友相机标定法[19],具体步骤如下。

通过棋盘格标定板确定一系列世界坐标已知的空间点以及其图像坐标,使用最小二乘法求解相机内外参数、采用四阶径向畸变模型求解畸变参数k1和k2。对于m幅图像,且每幅图像上均有n个特征点,将图像在世界坐标系中的三维坐标Mij通过计算得到的图像像素坐标 ,通过极大似然估计法建立非线性优化模型对相机的内外部参数及畸变参数进行优化,如式(2)所示,最终获得相机的内部参数以及辊道平面相对于相机安装位置的外部参数。

,通过极大似然估计法建立非线性优化模型对相机的内外部参数及畸变参数进行优化,如式(2)所示,最终获得相机的内部参数以及辊道平面相对于相机安装位置的外部参数。

(2)

(2)

其中:mij为在图像中提取处的特征点坐标; 为由世界坐标投影到图像上的坐标;A为相机的内部参数;

为由世界坐标投影到图像上的坐标;A为相机的内部参数; 和

和 为相机的外部参数。

为相机的外部参数。

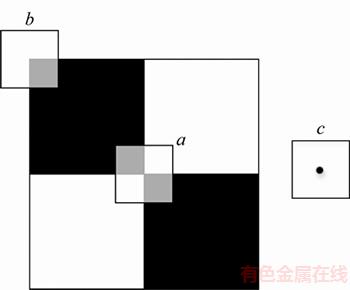

2.3 基于灰度梯度特征的角点亚像素精确定位

内棋盘格角点检测的精度对相机标定精度有着重要影响,本文在Harris角点检测算子对棋盘格图像进行角点检测的基础上,采用灰度梯度特征法进行亚像素级角点定位,使相机标定结果更为精确,减小标定误差,进而提高镰刀弯检测系统的检测精度。具体步骤如下。

1) 通过Harris角点检测算子[20],对棋盘格角点进行初定位。

2) 噪点及棋盘格外角点筛选去除。在所述的Harris角点检测结果中,可检测出棋盘格内角点、棋盘格外角点及噪点这3种类型的点,如图5中a,b,c所示。只有沿矩形框路径灰度跳跃变化次数为4次的才是棋盘格内角点,因此可实现对内角点的筛选。

3) 采用灰度梯度特征法对角点初定位坐标进行亚像素精确[21]。在棋盘格图像中,边缘上的点其灰度梯度垂直于该点与角点的连线,故可采用以初定位角点为中心的区域进行角点搜索,进行多次迭代,结果如图6所示。

图5 噪点及外角点去除示意图

Fig. 5 Schematic diagram of removing noisy points and external points

图6 灰度梯度特征法亚像素精确定位结果

Fig. 6 Result of corner detection by gray gradient method

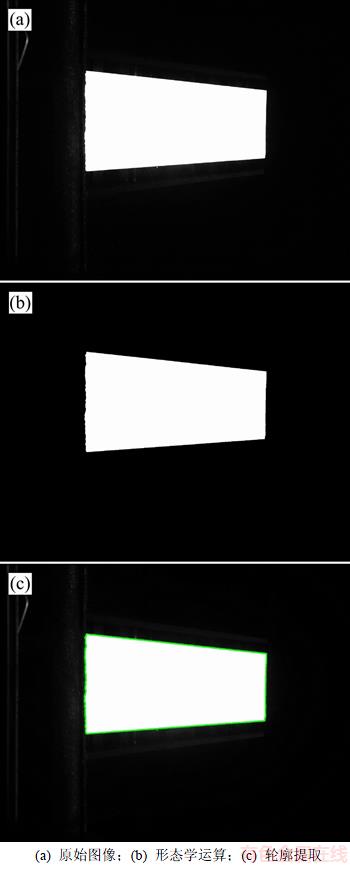

2.4 图像处理及轮廓提取

对于粗轧镰刀弯检测,关键的一步是获得中间坯的轮廓边缘坐标。通过现场的图像采集实验发现,对CCD相机曝光时间等相关参数进行适当调整,可以获得中间坯与环境区分度良好的图像。但受拍摄环境和中间坯高温辐射的干扰因素的影响,原始图像往往存在噪声干扰,会影响边缘检测的效果和检测精度。因此,在进行边缘检测之前,需要对原始图像进行一定的预处理。

1) 基于中值滤波的图像平滑。为了减少原始图像噪声干扰,将5×5中值滤波窗口按照一定的移动次序依次覆盖在粗轧中间坯图像上,同时将覆盖区域内的像素重新排列并计算中值,再以该中值代替覆盖区域的中心像素。

2) 基于灰度直方图的阈值分割法。中间坯图像灰度与背景有明显差异,图像是包含着2个峰的双峰直方图,两峰之间的波谷对应于对象边缘附近相对较少数目的点,可根据峰的形状确定阈值,对图像进行二值化处理。

3) 图像形态学运算。二值化之后的所得到的边界往往不是平滑的,中间坯区域由于氧化铁皮、冷却水残留也会出现一些噪声孔洞,通过图像形态学的膨胀、腐蚀、开和闭运算可有效消除中间坯上的“孔洞”和背景上的4邻域不连通区域,结果如图7(b)所示。

4) 基于Canny 算子的轮廓提取。使用Canny算子来计算x与y的2个偏导矩阵,然后采用非极值抑制技术对滤去噪声的图像进行处理,得到最后的边缘图像,并采用Freeman链码描述中间坯轮廓边界。如图7(c)所示使用Canny算子的边缘检测可以很好地区分出中间坯的边缘,并且保持了边缘的连续性和完整性。

图7 中间坯图像轮廓提取

Fig. 7 Profile of intermediate slab image

2.5 基于中间坯厚度的坐标转换

内通过相机标定可以确定相机内参以及辊道平面的外参,从而确定了辊道平面上点的世界坐标与图像坐标之间的转换关系,当中间坯厚度为hs时,中间坯上表面平面的外参相对于辊道平面发生了改变,此时投影矩阵变为

(3)

(3)

此时,世界坐标的 平面与中间坯上表面重合,中间坯上表面平面在世界坐标系内表示为

平面与中间坯上表面重合,中间坯上表面平面在世界坐标系内表示为 ,通过式(1)和(3)可得世界坐标系中中间坯上表面上点的平面坐标

,通过式(1)和(3)可得世界坐标系中中间坯上表面上点的平面坐标 与其投射形成的像点的图像像素坐标

与其投射形成的像点的图像像素坐标 的转换关系:

的转换关系:

(4)

(4)

根据轮廓提取步骤得到的中间坯轮廓点图像坐标,经过式(4)的计算后,可以得到中间坯轮廓的实际坐标。

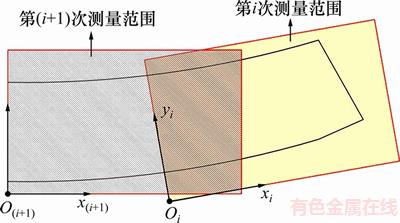

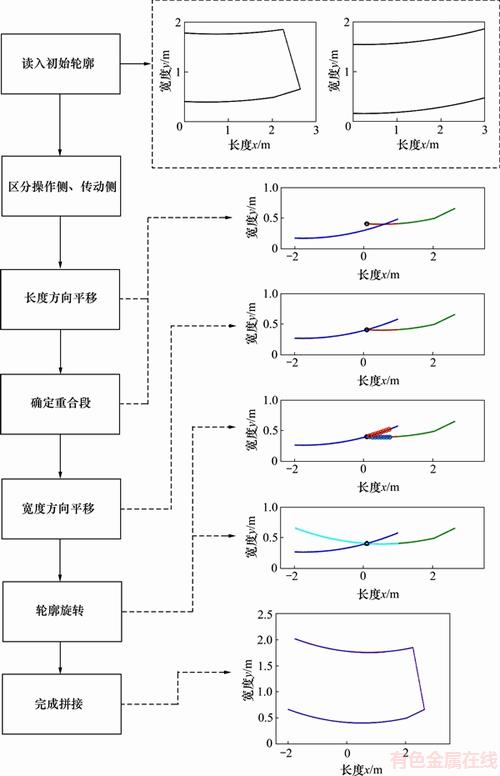

2.6 图像拼接

为了获取中间坯全长的镰刀弯信息,需要将具有重叠区域的局部中间坯图像进行拼接。在实际生产过程中中间坯在辊缝内会出现跑偏现象,同时当镰刀弯出现时,轧机出口的中间坯会出现弯曲。以中间坯为参考系,CCD相机运动,2次拍摄的区域如图8所示,拍摄区域除了中间坯运动引起的沿长度方向的平移,还会出现沿宽度方向的平移(对应跑偏)和转动(对应镰刀弯)。

图像拼接流程如图9所示,通过对轮廓点纵坐标的比较,完成操作侧、传动侧轮廓的分类,针对操作侧和传动侧轮廓,分别通过测速仪获取的轧件速度与相机的拍摄频率计算2次拍摄间隔中间坯长度方向的运动距离,通过中间坯边缘连续变化的特点确定沿宽度方向轮廓平移距离和轮廓整体旋转量,最后通过操作侧和传动侧轮廓数据计算得到的值取平均值,完成对整体中间坯轮廓的拼接。

图8 运动中间坯镰刀弯引起的相机视野内坐标系变化

Fig. 8 Change of coordinate system in camera’ view by moving intermediate slab camber

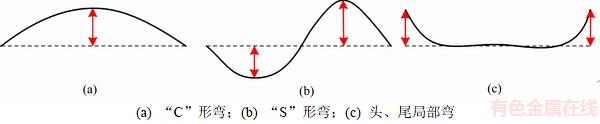

2.7 镰刀弯信息提取

建立热轧中间坯镰刀弯检测系统的目的是为了定量地得到中间坯全长的弯曲程度信息。关于镰刀弯的定量表征目前还没有统一的认识。粗轧中间坯镰刀弯常见的形式如图10所示,包括普通“C”形弯、复杂的“S”形弯和头、尾局部镰刀弯。通过镰刀弯测量系统可以获取中间坯全长的轮廓信息,通过计算可以得到中间坯中心线,经曲线聚义分类后[22],可以将测量的中间坯进行归类,进而计算中心线上标志点 到标志线

到标志线 的距离来表征中间坯的镰刀弯弯曲程度:

的距离来表征中间坯的镰刀弯弯曲程度:

(5)

(5)

其中:C为中间坯镰刀弯弯曲量,单位为mm,其正负可以用来表示中间坯的弯曲方向,正值表示弯向传动侧,负值表示弯向操作侧。

图9 中间坯局部图像拼接过程

Fig. 9 Stitching process of intermediate slab local imager

图10 粗轧中间坯镰刀弯常见的形式

Fig. 10 Diagrams of intermediate slab camber in rough rolling

3 测量系统安装及验证

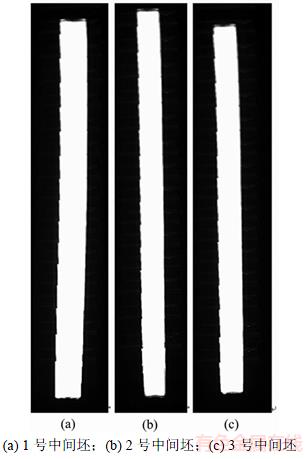

系统安装在某厂热连轧粗轧机R2出口后,连续获取的中间坯图像经过图像处理、轮廓提取、坐标转化和图像拼接,最终获取中间坯的平面形状,图11所示为3种不同弯曲形式的中间坯形状。

图11 粗轧中间坯平面形状

Fig. 11 Plane shapes of intermediate slab in rough rolling

热连轧生产节奏快、板坯温度高,因此,难以进行人工离线测量。为了验证测量系统的检测精度,在获取中间坯的平面形状之后,通过中间坯两侧边缘中值确定中心线,并与粗轧机出口的测宽仪获取的中间坯中心线进行比较。图12所示为与图11对应的中间坯CCD检测结果与通过测宽仪测量的中心线偏移量,通过比较可知这2种测量方法测得的中间坯平面形状形式是一致的,且具有相同的细部特征。但采用CCD测量的中间坯中心线偏移量明显大于通过测宽仪测量的结果,这也从侧面证明了采用测宽仪测量的结果因为没有考虑中间坯整体的旋转会引起测量结果偏小。

图12 中间坯中心线偏移量

Fig. 12 Offset value of intermediate slab center line

系统投入应用后运行稳定,生产检验结果证明,在R2粗轧机不同道次轧制之前,可以给轧机操作人员10 s左右的预告时间。在这个时间内,轧机操作人员可以根据操作画面显示的板坯形状对轧机进行相关优化设置,从而减少甚至消除镰刀弯对轧制的影响。

4 结论

1) 为了克服现有测量方法存在的缺陷,实现热轧中间坯镰刀弯缺陷的在线非接触测量,提出了一种由面阵CCD相机、激光测速仪、安装支架及冷却设备组成的镰刀弯测量系统。

2) 利用亚像素精确定位的角点检测技术完成了相机的标定,并通过引入厚度变量实现了不同厚度中间坯轮廓图像坐标向实际坐标的转化,最后通过中间坯边缘轮廓连续变化的原理完成图像拼接。

3) 测量系统及算法可以获得完整的中间坯平面图像及镰刀弯值,满足工程需要。同时,测量系统机械结构简单、易于维护,算法具有较高的鲁棒性和计算效率,适用于工业生产现场中间坯镰刀弯的在线实时测量。

参考文献:

[1] KANG Y, JANG Y, CHOI Y, et al. An improved model for camber generation during rough rolling process[J]. ISIJ International, 2015, 55(9): 1980-1986.

[2] WANG Haiyu, YANG Quan, WANG Xiaochen, et al. Study and application of camber control model of intermediate slab in rough rolling[J]. Journal of Iron and Steel Research International, 2014, 21(9): 817-822.

[3] JEONG D, KANG Y, JANG Y J, et al. Development of FEM simulator combined with camber reducing output feedback fuzzy controller for rough rolling process[J]. ISIJ International, 2013, 53(3): 511-519.

[4] 陈江宁. 现代宽厚板特殊检测仪表的应用与展望[J]. 自动化仪表, 2001, 22(1): 1-5, 8.

CHEN Jiangning. The application and prospects of modern special detecting instrument for the heavy plate[J]. Process Automation Instrumentation, 2001, 22(1): 1-5, 8.

[5] Harris Instrument Corporation. Continuous online camber measurement[EB/OL]. [2016-01-01]. http://harris-instrument. com/wp-content/uploads/2016/01/HIC-Continuous-Online-Camber- Measurement-1.pdf

[6] 张向磊. 基于线阵相机的带钢镰刀弯在线检测技术研究[D]. 北京: 北京科技大学机械工程学院, 2009: 50-67.

ZHANG Xianglei. Research on online detection technique of sickle-curved strip steel using line scan camera[D]. Beijing: University of Science and Technology Beijing. School of Mechanical Engineering, 2009: 50-67.

[7] 李毅杰, 王力飞, 孙一康, 等. 线阵CCD用于热轧带钢头部形状检测[J]. 北京科技大学学报, 1994, 16(3): 280-282, 288.

LI Yijie, WANG Lifei, SUN Yikang, et al. Detecting the shape of hot strip head area with linear CCD[J]. Journal of University of Science and Technology Beijing, 1994, 16(3): 280-282, 288.

[8] 雷凤翔. 热轧带钢端部形状视觉检测研究[D]. 天津: 河北工业大学控制科学与工程学院, 2014: 13-14.

LEI Fengxiang. Research on vision detection of the hot rolled strip end’s shape[D]. Tianjin: Hebei University of Technology. School of Control Science and Engineering, 2014: 13-14.

[9] KAMPMEIJER L, HOL C, DE R J, et al. Strip tracking measurement and control in hot strip rolling[J]. Metallurgia Italiana, 2014, 106(3): 29-34.

[10] EICHERT G, DEVORICH S. Position and camber measurement in the hot rolling process: EMG hotCAM[C]// Proceedings of the Iron and Technology Conference. Warrendale, PA, United States: Association for Iron and Steel Technology, 2013: 2329-2337.

[11] 何纯玉. 中厚板轧制过程高精度侧弯控制的研究与应用[D]. 沈阳: 东北大学材料与冶金学院, 2009: 98-124.

HE Chunyu. Study and application of high accuracy camber control in plate rolling[D]. Shenyang: Northeastern University. School of Materials and Metallurgy, 2009: 98-124.

[12] OLLIKKALA A V H, KANANEN T P, MAKYNEN A J, et al. Camera-based curvature measurement of a large incandescent object[C]// Proceedings of SPIE: the International Society for Optical Engineering. Bellingham, WA, United States: Society of Photo-Optical Instrumentation Engineers, 2013: 87883D1-6.

[13] MONTAGUE R J, WATTON J, BROWN K J. A machine vision measurement of slab camber in hot strip rolling[J]. Journal of Materials Processing Technology, 2005, 168(1): 172-180.

[14] FRAGA C, GONZALEZ R C, CANCELAS J A, et al. Camber measurement system in a hot rolling mill[C]// Conference Record of the 2004 IEEE Industry Applications Conference: 39th IAS Annual Meeting. Piscataway, NJ, United States: Institute of Electrical and Electronics Engineers Inc, 2004: 897-902.

[15] YANG Y Y, CHEN C M, HO C Y, et al. Development of a camber measurement system in a hot rolling mill[C]// Conference Record: IEEE Industry Applications Society Annual Meeting. Piscataway, NJ, United States: Institute of Electrical and Electronics Engineers Inc, 2008: 379-384.

[16] LEE J, CHOI Y J. Development of camber and steering control system in hot strip mill[C]// 19th IEEE International Conference on Emerging Technologies and Factory Automation, ETFA 2014. Piscataway, NJ, United States: Institute of Electrical and Electronics Engineers Inc, 2014: 1-4

[17] KONG N, YOO J, LEE J, et al. Vision-based camber measurement system in the endless hot rolling process[J]. Optical Engineering, 2011, 50(10): 107202-107210.

[18] YOO J, LEE W, KONG N, et al. An edge detection algorithm for steel bar in hot rolling process (ICCAS 2014)[C]// International Conference on Control, Automation and Systems. Gyeonggi-do, Korea: IEEE Computer Society, 2014: 1389-1391.

[19] ZHANG Zhengyou. Flexible camera calibration by viewing a plane from unknown orientations[C]// Proceedings of the IEEE International Conference on Computer Vision. Piscataway, NJ, United States: Institute of Electrical and Electronics Engineers Inc, 1999: 666-673.

[20] BELLAVIA F, TEGOLO D, VALENTI C. Improving Harris corner selection strategy[J]. IET Computer Vision, 2011, 5(2): 87-96.

[21] 谭晓波. 摄像机标定及相关技术研究[D]. 长沙: 国防科学技术大学机电工程及自动化学院, 2004: 32-34.

TAN Xiaobo. Study on calibration and its correlation technique[D]. Changsha: National University of Defense Technology. Institute of Mechanical and Electrical Engineering & Automation, 2004: 32-34.

[22] 叶明, 王惠文, 寇薇. 大规模曲线的自动分类方法及其应用[J]. 系统管理学报, 2010, 19(6): 640-644.

YE Ming, WANG Huiwen, KOU Wei. Automatic classification method of large-scale curves and application[J]. Journal of Systems & Management, 2010, 19(6): 640-644.

(编辑 杨幼平)

收稿日期:2017-07-10;修回日期:2017-09-17

基金项目(Foundation item):国家自然科学基金资助项目(51604024);中央高校基本科研业务费专项资金资助项目(FRF-TP-17-002A2);清华大学摩擦学国家重点实验室开放基金资助项目(SKLTKF16B11);北京市自然科学基金资助项目(3182026) (Project(51604024) supported by the National Natural Science Foundation of China; Project(FRF-TP-17-002A2) supported by the Fundamental Research Funds for the Central Universities; Project(SKLTKF16B11) supported by the Tribology Science Fund of State Key Laboratory of Tribology; Project(3182026) supported by the Beijing Natural Science Foundation)

通信作者:徐冬,博士,从事板带轧制过程板形与表面形貌控制研究;E-mail: xudong@ustb.edu.cn