文章编号: 1004-0609(2005)07-1051-06

用Ti3SiC2粉料连接反应烧结SiC陶瓷

董红英1 , 李树杰1 , 贺跃辉2

(1. 北京航空航天大学 材料科学与工程学院, 北京 100083; 2. 中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘要: 用Ti3SiC2粉末作为焊料, 采用热压反应烧结连接法连接SiC, 通过正交实验, 研究了连接温度、 高温保温时间、 连接压力和连接层厚度对试样连接强度的影响, 优选出的最佳工艺参数分别为: 1500℃, 30min, 30MPa, 150μm。 所得到的接头最大剪切强度为39.49MPa。 微观结构研究和成分分析表明: 在界面处, 发生了元素的扩散, 促进了界面结合, 有明显的反应扩散层。 物相分析显示在高温、 高压、 氩气气氛以及使用石墨模具的条件下, Ti3SiC2与母材发生界面反应, 实现界面结合。

关键词: 陶瓷连接; 特种连接; Ti3SiC2 ; SiC陶瓷 中图分类号: TQ174.758

文献标识码: A

Joining of reaction bonded SiC ceramic using Ti3SiC2 powder as filler

DONG Hong-ying1, LI Shu-jie1, HE Yue-hui2

(1. School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics, Beijing 100083, China;

2. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The joining of RBSiC to RBSiC was successfully realized by hot pressing reaction joining process using Ti3SiC2 powder as filler. The optimized technological parameters were obtained by orthogonal experiments, which are the joining temperature of 1500℃, the dwelling time of 30min, the joining pressure of 30MPa and the interlayer thickness of 150μm. Under these conditions, the obtained shearing strength of the joint is 39.49MPa. The mechanism of bonding was investigated based on observation of the microstructure, determination of distribution of the elements and phase analysis at the welded area, which show that the mechanism of bonding at the interfaces is interdiffusion and interfacial reaction.

Key words: ceramic joining; special joining; Ti3SiC2; SiC ceramic

SiC陶瓷由于具有耐高温、 耐磨损、 耐腐蚀、 化学稳定性高等优良特性, 因而在航空航天、 汽车、 化工及核能等领域有着广阔的应用前景。 然而由于陶瓷本身固有的脆性较大, 难于加工成形等缺点, 在实际使用时, 经常需要把小型、 形状简单的SiC陶瓷连接成为一个大型、 形状复杂的整体。 但由于陶瓷材料本身特殊的物理化学性能, 因而, 陶瓷的连接存在着不少的难点与特殊性。 目前研究发展的各种连接技术有胶粘剂连接、 机械连接、 摩擦焊连接、 超声波连接、 活性金属钎焊、 SHS焊接、 局部瞬间液相连接、 固相扩散焊和热压反应烧结连接法等, 其中钎焊和扩散焊较为成熟[1, 2]。 由于SiC陶瓷主要以强的共价键接合, 不用中间层焊料较难实现SiC陶瓷的连接。 采用金属中间层获得的连接强度较低, 而且不适用于高温环境[3, 4]; 采用有机聚合物陶瓷先驱体作为中间层材料最大的缺点是有机聚合物在裂解过程中会在连接部位留下气孔, 从而严重影响连接强度[5]。 对于SiC陶瓷连接, 目前面临着选取合适的中间层焊料来提高接头的高温强度和高温稳定性的问题。 采用无机非金属材料作为中间层焊料的热压反应烧结连接法具有较好的发展前景。

三元化合物碳化硅钛(Ti3SiC2)是近年来比较受到关注的无机非金属材料。 它最初是由Jeitschko 和Novotny以TiH2, Si和石墨为原料, 通过固相反应合成并确定了其晶体结构[6]。 最近, 中国、 美国、 日本、 波兰、 奥地利等国家的科学家对其进行了包括合成、 材料性能预测在内的大量研究。 虽然碳化硅钛的研究目前还没有完全一致的结论, 但已经肯定碳化硅钛是一种综合了金属和陶瓷优点的新型材料。 它象金属具有良好的导热、 导电性能, 抗热震性好, 并且室温下具有较好的塑性, 更重要的是它可以用一般机械加工方法加工; 又象陶瓷, 耐高温氧化, 高温强度大。 Ti3SiC2的熔点高达3000℃以上, 具有高热稳定性, 在低于1800℃、 在真空或氩气中不分解[7-13]。 因此, 用它作为中间层连接SiC陶瓷不但可以满足SiC陶瓷的高温应用; 更重要的是有望通过其塑性变形缓解连接时从高温降到室温时产生的残余热应力从而进一步提高连接件的高温强度。 目前国内外对使用Ti3SiC2材料作为中间层焊料的研究比较少。

本研究选用合成好的Ti3SiC2粉末材料作为中间层焊料, 分别选取不同工艺条件, 采用热压反应烧结连接法进行SiC与SiC的连接。

1实验

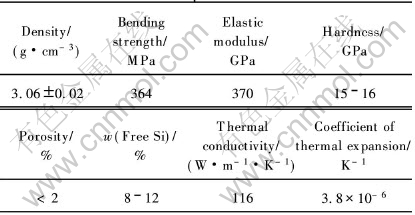

使用预先合成好的Ti3SiC2粉末(含有少量TiC)作为中间层焊料; 焊接母材为反应烧结SiC(RBSiC), 其基本性能如表1所列。

将陶瓷切成25mm×25mm×7mm的长方体, 对母材受焊表面进行研磨抛光。 然后将抛光好的母材放入酒精中, 在超声波仪器中清洗, 烘干后和中间层按照SiC/Ti3SiC2/SiC的顺序装入石墨模具[CM(22]中。 在热压炉中进行连接实验。 连接工艺为: 压力20~40MPa; 温度为1300~1500℃; 保温时间为30~90min, 并在连接过程中通入氩气作为保护气氛。

表1 反应烧结SiC的基本性能

Table 1 Properties of RBSiC

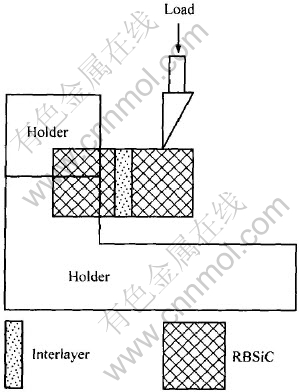

由于所加工的试样为非标准型, 采用非标准试样进行连接强度测试, 如图1所示。 连接件的强度根据方形截面梁强度计算公式计算[14]。

式中σ为剪切强度, Pa; Mb为弯矩, N·m; Wz为截面系数, m3; F为破坏载荷, N; x为受力点到破坏位置的距离, m; d为试样的宽度, m; h为试样的高度, m。

由图1可见, 用这种方法测定的强度值, 既不是单纯的抗剪强度, 也不是单纯的抗弯强度, 而是包含了两者, 以抗剪为主, 在本文中称为连接强度。 为了使数据具有可比性, 所有试样均采用同样的方法进行测定。

用扫描电镜(SEM)观察连接界面区域的微观组织形貌。 用能谱(EDX)分析界面两侧元素的分布。 对连接件的断口做X射线衍射(XRD)分析, 以研究中间层产物的相组成。

图1 剪切强度测试示意图

Fig.1 Diagrammatic sketch of instrument used to determine weld strength

2结果与讨论

2.1最佳工艺的确定

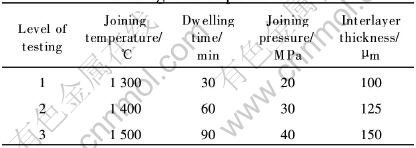

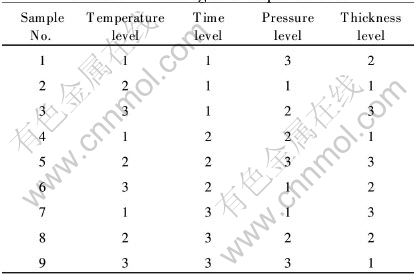

在陶瓷连接过程中, 影响连接强度的实验因素比较复杂, 本文用正交实验选取对连接强度影响较大的4个实验因素, 包括连接温度、 连接压力、 保温时间以及设计的理论中间层厚度(简称中间层厚度, 是指把中间层焊料充分致密化以后的理论厚度), 力求根据正交实验结果分析获得最佳的实验工艺参数。 表2列出了正交实验中选择的各因素及其各水平, 表3列出所选用的L9(34)正交实验表, 并对工艺参数进行优选。

2.2正交实验结果

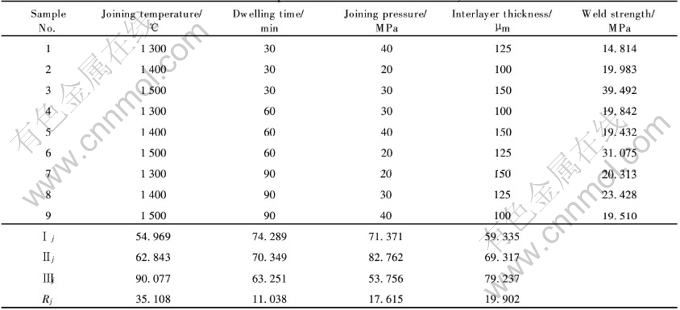

表4列出了4个因素在3个不同水平下的正交实验结果。 该表中Ⅰ、 Ⅱ、 Ⅲ分别表示水平1、 水平2、 水平3, j表示第j列; Ⅰj表示正交表中第j列的水平1所对应的指标之和; Ⅱj、 Ⅲj表示的意义依次类推。 极差Rj表示第j列中的Ⅰj、 Ⅱj以及Ⅲj中的最大值与最小值之差, 根据其大小, 可判断各因素影响的主次。

表2 正交实验中各水平的实验条件

Table 2 Processing parameters in orthogonal experiments

表3 L9(34)正交实验表

Table 3 Orthogonal experiments

利用正交实验的设计原理, 根据表中各列Ⅰj、 Ⅱj以及Ⅲj的值, 可得最佳工艺参数为: 1500℃, 30min, 30MPa, 150μm。 所得到的最大连接强度为39.49MPa, 在连接强度测试过程中, 试样在中间层焊料处断裂。 由表中Rj值可以看出设定的连接温度对测试指标影响最大, 设计的中间层厚度次之, 保温时间对测试指标的影响最小。

表4 正交实验结果与分析

Table 4 Experimental results and analyses

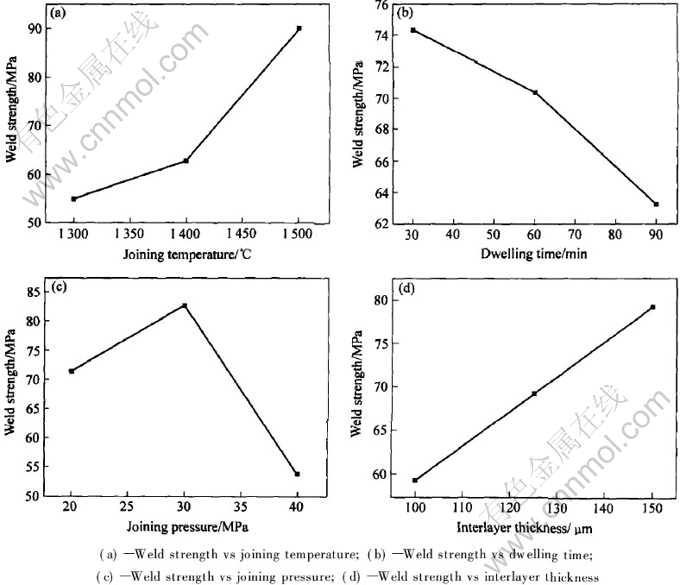

图2所示为各影响因素对测试指标的影响趋势。 温度是陶瓷热压反应烧结连接中的最重要的工艺因素, 它不仅决定界面反应能否发生, 还决定反应进行的速度。 图2显示在实验范围内, 随着连接温度的提高, 连接强度逐渐提高。 这表明在此温度范围之内, 较高的温度有利于中间层焊料与陶瓷母材反应, 有利于界面结合强度的提高, 而且连接强度随中间层厚度的增加而增加。 由于中间层焊料Ti3SiC2和母材RBSiC为两种不同的材料, 它们的热膨胀系数不同(Ti3SiC2陶瓷的热膨胀系数为9.2×10-6K-1[15]), 因此, 在焊接的降温过程中将产生热应力。 如前所述, 本研究拟利用Ti3SiC2室温塑性变形性能缓解焊接热应力。 显然, 中间层越厚, 其通过塑性变形缓解热应力的能力越强, 导致连接强度越高。 可见, 图2所示的实验结果与预期结果一致。 保温时间主要决定原子扩散和界面反应的程度。 设计所选用的保温时间的三个水平对连接强度的影响相对较小。 一定的连接压力可以使陶瓷/中间层焊料/陶瓷的界面紧密接触, 大大增加接触面积, 为发生界面反应以及界面扩散提供有利的条件。 从图2可以看出: 在20~30MPa范围内, 连接强度随着连接压力的增加而增加; 但在30~40MPa范围内, 随着连接压力的增加连接强度降低。 这是由于连接压力过高, 会增加连接时产生的残余应力, 而且有可能在SiC陶瓷中引起显微裂纹, 从而降低连接强度, 严重的会导致连接件变形或断裂。

2.3焊缝区微观结构及成分分析

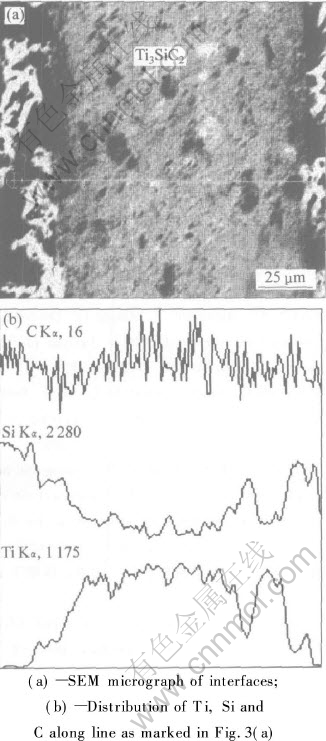

图3所示为连接试样SiC/Ti3SiC2/SiC的界面区域的SEM 显微照片和EDX线扫描成分分析所得各元素的分布, 其扫描路径如图3中横线条所示

图2 各因素对连接强度的影响趋势

Fig.2 Effects of technological parameters on weld strength referring to sum of weld strength as given in Table 4 at same level

图3 连接试样SiC/Ti3SiC2/SiC界面区域的SEM照片和EDX谱

Fig.3 SEM micrograph and EDX patterns of SiC/Ti3SiC2/SiC interfaces

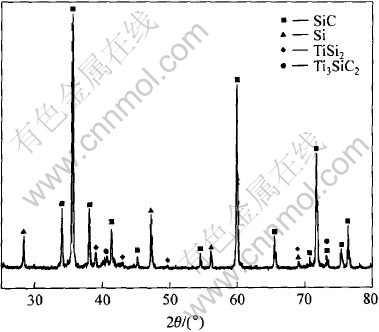

位置。 该试样是在1300℃保温60min, 同时施加30MPa的外加压力等条件下制取的。 从图中可以看出, 在SiC/Ti3SiC2的界面处, Si元素和Ti元素的分布曲线都出现一定程度的倾斜, 这说明在界面处, 发生了元素的扩散, 存在有明显的反应扩散层。 这些反应扩散层形成的原因是由于RBSiC母材中存在着一定量的游离硅, 游离硅和中间层粉料发生反应形成反应层。 据文献[16]报道, Ti3SiC2 可以在富Si或富C的条件下, 发生化学反应。 在富Si的条件下1200~1350℃时可以生成TiSi2和SiC。 图4所示为连接工艺参数分别为1500℃, 30min, 30MPa, 150μm时连接的试样在连接强度测试实验之后断口表面的X射线衍射谱。 从图中可以看出, 经过1500℃的高温连接后, 中间层中生成了TiSi2新相。 此结果证实在连接过程中, Ti3SiC2和母材发生了化学反应。 另外, RBSiC母材中存在一定量的空隙, 在高温和外加压力的作用下, 中间层粉料进入RBSiC的开孔, 增加了接触面积, 从而促进了界面反应和界面扩散的进行, 有利于连接强度的提高。 根据本实验的结果可以认为, 采用Ti3SiC2粉末中间层焊料通过热压反应烧结连接工艺连接RBSiC陶瓷的连接机制主要有两种: 一是中间层焊料在致密化的同时与母材之间发生元素的扩散实现连接; 二是在高温、 外加压力、 氩气气氛以及使用石墨模具的条件下, Ti3SiC2与母材发生界面化学反应实现界面结合。

图4 连接试样断口表面的X射线衍射谱

Fig.4 XRD pattern of fractural surface

3结论

1) 在正交实验的基础上, 使用Ti3SiC2粉末作为中间层焊料通过热压反应烧结连接工艺连接了RBSiC。 当连接温度为1500℃, 保温时间为30min, 连接压力为30MPa, 中间层厚度为150μm时获得了最大的连接强度(以抗剪强度为主)39.49MPa。 在正交实验所分析的4个因素中, 连接温度对连接强度的影响最大, 保温时间对连接强度的影响最小。

2) 连接机制主要有两种: 一是中间层焊料在致密化的同时与母材之间发生元素的扩散实现连接; 二是在本实验条件下Ti3SiC2与母材发生界面反应实现界面结合。

REFERENCES

[1]李荣久. 陶瓷-金属复合材料 [M]. 北京: 冶金工业出版社, 1995.

LI Rong-jiu. Ceramic-Metal Composites [M]. Beijing: Metallurgical Industry Press, 1995.

[2]张建军, 李树杰. 非氧化物陶瓷连接技术的进展[J]. 硅酸盐学报, 2002, 30(1): 102-107.

ZHANG Jian-jun, LI Shu-jie. Progresses of joining techniques of nonoxide ceramics[J]. Journal of the Chinese Ceramic Society, 2002, 30(1): 102-107.

[3]张利. 李树杰. 张建军, 等. SiC陶瓷连接工艺及焊料反应产物研究[J]. 稀有金属材料与工程, 2003, 32(3): 224-227.

ZHANG Li, LI Shu-jie, ZHANG Jian-jun, et al. Study on the joining process of SiC and the reaction products of filler[J]. Rare Metal Materials and Engineering, 2003, 32(3): 224-227.

[4]张建军, 李树杰, 张艳. 用Ti/Ag粉坯连接的SiC陶瓷界面[J]. 中国有色金属学报, 2004, 14(3): 455-459.

ZHANG Jian-jun, LI Shu-jie, ZHANG Yan. Interface of SiC joints welded by hot-pressing joining process with Ti and Ag[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 455-459.

[5]刘洪丽. 李树杰. 用有机聚合物连接碳化硅陶瓷及陶瓷基复合材料[J]. 硅酸盐学报, 2004, 32(10): 1246-1251.

LIU Hong-li, LI Shu-jie. Joining of SiC and SiC-based composites using preceramic polymers[J]. Journal of the Chinese Ceramic Society, 2004, 32(10): 1246-1251.

[6]Jeitschko W, Nowotny H. The crystal structure of Ti3SiC2—a new complex carbide[J]. Monatash Chem, 1967, 98(2): 329-337.

[7]TANG Ke, WANG Chang-an, HUANG Yong, et al. A study on reaction mechanism and growth of Ti3SiC2 synthesized by hot-pressing [J]. Mater Sci Eng A, 2002, A328: 206-212.

[8]Li J T, Miyamoto Y. Investigation on novel features during reactive synthesis of Ti3SiC2 ceramic[A]. Yan D S, Guan Z D, eds. Proceedings of the First China International Conference on High-Performance Ceramics[C]. Beijing: Tsinghua University Press, 1998. 594-597.

[9]Barsoum M W, El-Raghy T. Synthesis and characterization of a remarkable ceramic: Ti3SiC2[J]. Journal of Am Ceram Soc, 1996, 79(7): 1953-1956.

[10]Sun Z M, Zhou Y C. Synthesis of Ti3SiC2 powders by a solid-liquid method[J]. Scripta Mater, 1999, 41(1): 61-66.

[11]Gao N F, Miyamoto Y, Zhang D. Dense Ti3SiC2: prepared by reactive HIP[J]. Journal of Materials Science, 1999, 34(10): 4385-4391.

[12]Pampuch R, Lis J, Stobierski L, et al. Solid combustion synthesis of Ti3SiC2[J]. Journal of Europe Ceramic Society, 1989, 5(5): 283-288.

[13]El-Raghy T, Barsoum M W. Processing and mechanical properties of Ti3SiC2 (Ⅰ): reaction path and microstructure evolution[J]. Journal of the American Ceramic Society, 1999, 82(10): 2849-2854.

[14]单辉祖. 材料力学教材[M]. 北京: 国防工业出版社,1989. 134.

SHAN Hui-zu. Textbook of Material Mechanics [M]. Beijing: National Defence Industry Press, 1989. 134.

[15]陈艳林, 梅炳初, 朱教群. 可加工陶瓷Ti3SiC2的合成和性能[J]. 硅酸盐通报, 2003(3): 74-77.

CHEN Yan-lin, MEI Bing-chu, ZHU Jiao-qun. Synthesis and properties of the machinable ceramic Ti3SiC2[J]. Bulletin of the Chinese Ceramic Society, 2003(3): 74-77.

[16]El-Raghy T, Barsoum M W. Diffusion kinetics of the carbarization and silicidation of Ti3SiC2[J]. Journal of Application Physics, 1998, 83(1): 112-119.

基金项目: 国家自然科学基金资助项目(50271003); 中国航空基础科学基金资助项目(03H51024)

收稿日期: 2004-08-31; 修订日期: 2005-04-11

作者简介: 董红英(1974-), 女, 博士研究生.

通讯作者: 李树杰, 教授, 博士; 电话: 010-82317121; 传真: 010-82316100; E-mail: shujieli@publica.bj.cninfo.net

(编辑陈爱华)